oil temperature SSANGYONG KORANDO 2012 User Guide

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2012, Model line: KORANDO, Model: SSANGYONG KORANDO 2012Pages: 1082, PDF Size: 96.1 MB

Page 202 of 1082

07-50000-00

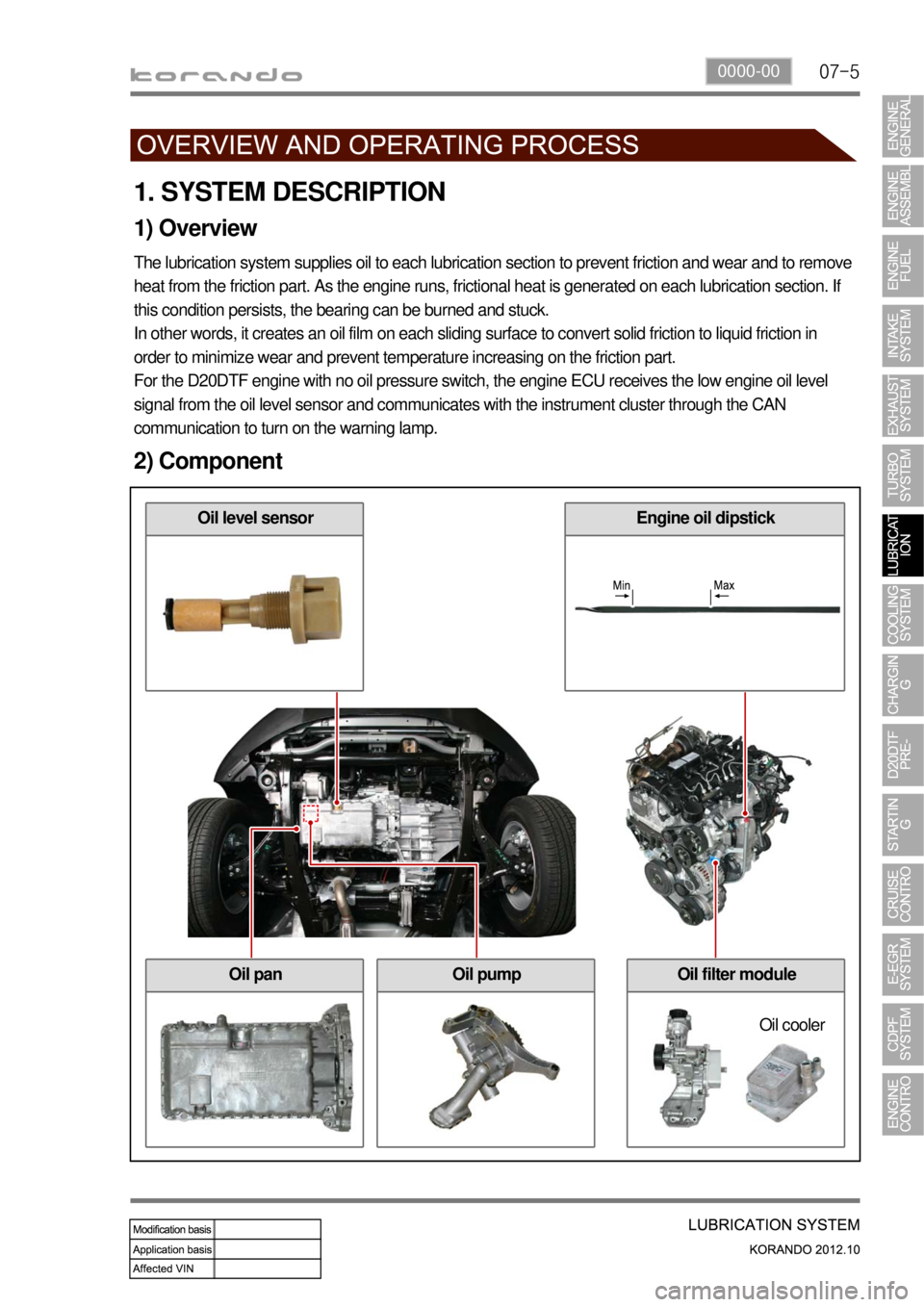

1. SYSTEM DESCRIPTION

1) Overview

The lubrication system supplies oil to each lubrication section to prevent friction and wear and to remove

heat from the friction part. As the engine runs, frictional heat is generated on each lubrication section. If

this condition persists, the bearing can be burned and stuck.

In other words, it creates an oil film on each sliding surface to convert solid friction to liquid friction in

order to minimize wear and prevent temperature increasing on the friction part.

For the D20DTF engine with no oil pressure switch, the engine ECU receives the low engine oil level

signal from the oil level sensor and communicates with the instrument cluster through the CAN

communication to turn on the warning lamp.

2) Component

Oil level sensorEngine oil dipstick

Oil panOil pumpOil filter module

Oil cooler

Page 211 of 1082

08-8

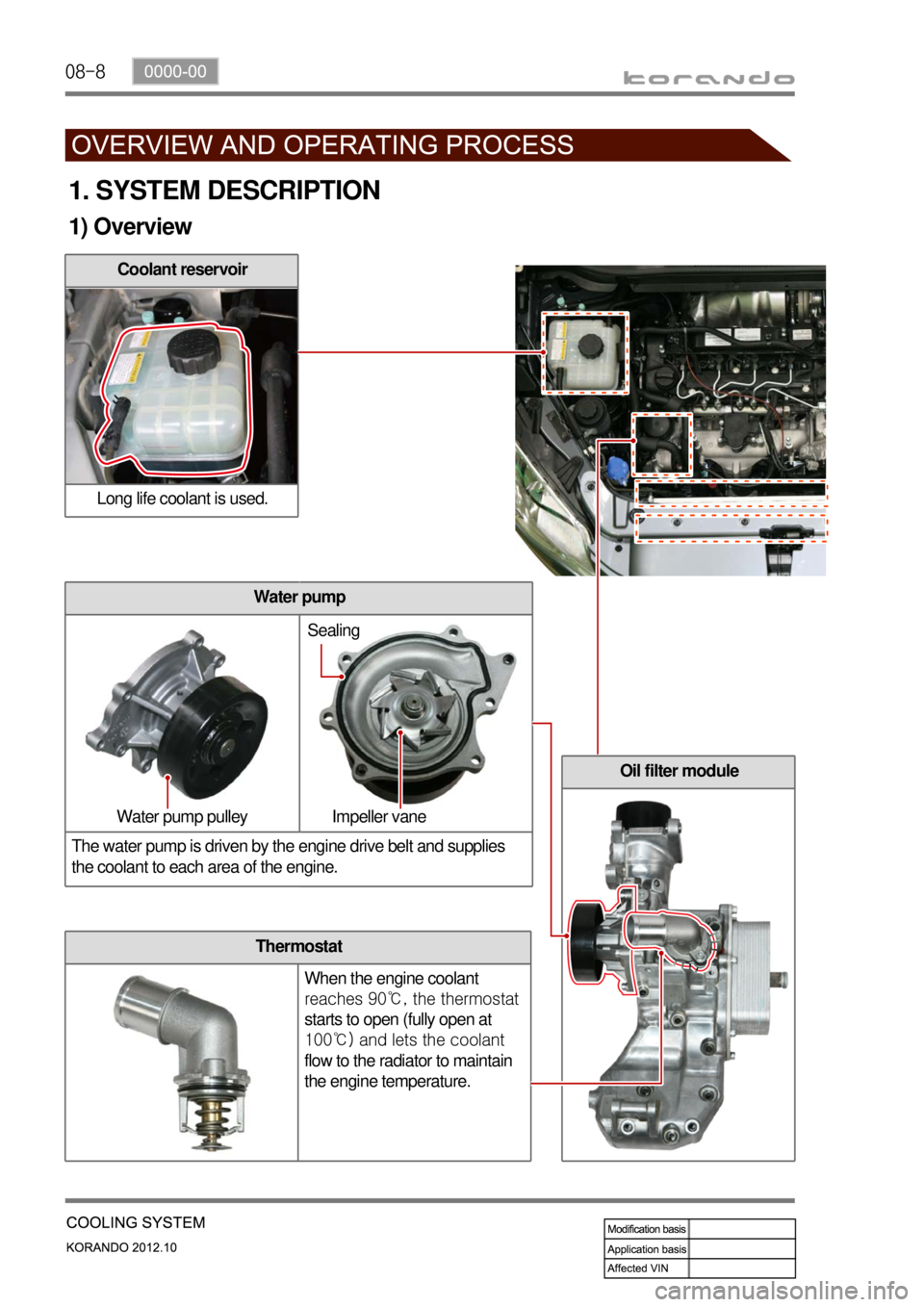

Thermostat

When the engine coolant

reaches 90℃, the thermostat

starts to open (fully open at

100℃) and lets the coolant

flow to the radiator to maintain

the engine temperature.

1. SYSTEM DESCRIPTION

1) Overview

Coolant reservoir

Long life coolant is used.

Water pump

The water pump is driven by the engine drive belt and supplies

the coolant to each area of the engine.

Oil filter module

Water pump pulley Impeller vaneSealing

Page 285 of 1082

15-90000-00

2) ECU Control

(1) Function

a. ECU Function

ECU receives and analyzes signals from various sensors and then modifies those signals into

permissible voltage levels and analyzes to control respective actuators.

ECU microprocessor calculates injection period and injection timing proper for engine piston speed and

crankshaft angle based on input data and stored specific map to control the engine power and emission

gas.

Output signal of the ECU microprocessor drives pressure control valve to control the rail pressure and

activates injector solenoid valve to control the fuel injection period and injection timing; so controls

various actuators in response to engine changes. Auxiliary function of ECU has adopted to reduce

emission gas, improve fuel economy and enhance safety, comforts and conveniences. For example,

there are EGR, booster pressure control, autocruise (export only) and immobilizer and adopted CAN

communication to exchange data among electrical systems (automatic T/M and brake system) in the

vehicle fluently. And Scanner can be used to diagnose vehicle status and defectives.

<00760097008c00990088009b00900095008e0047009b008c00940097008c00990088009b009c0099008c0047009900880095008e008c00470096008d0047006c006a007c00470090009a0047009500960099009400880093009300a000470054005b005700

47009b009600470052005f005c00b6006a004700880095008b> protected from factors like oil,

water and electromagnetism and there should be no mechanical shocks.

To control the fuel volume precisely under repeated injections, high current should be applied instantly

so there is injector drive circuit in the ECU to generate necessary current during injector drive stages.

Current control circuit divides current applying time (injection time) into full-in-current-phase and hold-

current-phase and then the injectors should work very correctly under every working condition.

b. Control Function

Controls by operating stages

To make optimum combustion under every operating stage, ECU should calculate proper injection

volume in each stage by considering various factors.

Starting injection volume control

During initial starting, injecting fuel volume will be calculated by function of temperature and engine

cranking speed. Starting injection continues from when the ignition switch is turned to ignition

position to till the engine reaches to allowable minimum speed.

Driving mode control

If the vehicle runs normally, fuel injection volume will be calculated by accelerator pedal travel and

engine rpm and the drive map will be used to match the drivers inputs with optimum engine power. -

-

-

Page 310 of 1082

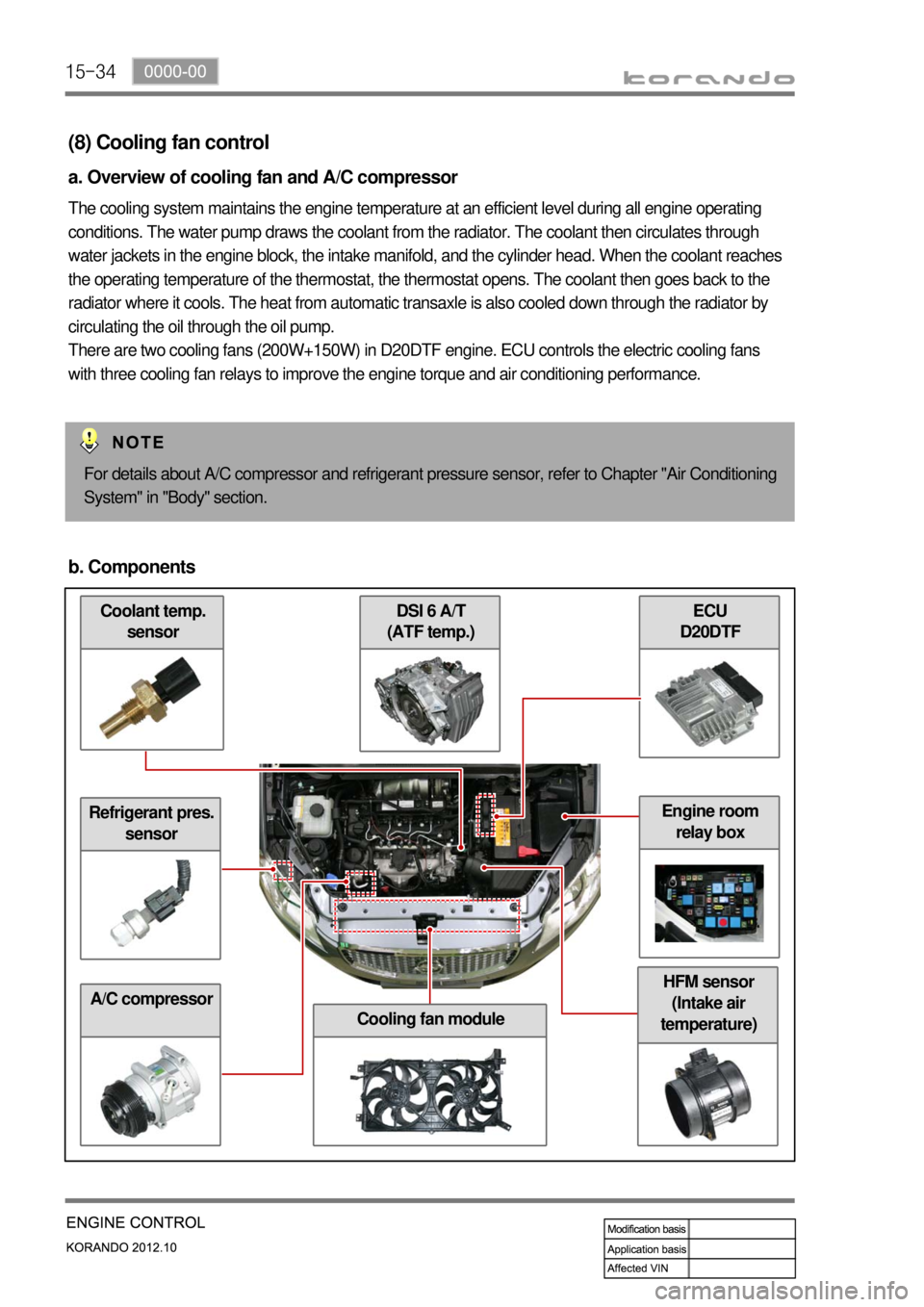

15-34

Coolant temp.

sensor

(8) Cooling fan control

a. Overview of cooling fan and A/C compressor

The cooling system maintains the engine temperature at an efficient level during all engine operating

conditions. The water pump draws the coolant from the radiator. The coolant then circulates through

water jackets in the engine block, the intake manifold, and the cylinder head. When the coolant reaches

the operating temperature of the thermostat, the thermostat opens. The coolant then goes back to the

radiator where it cools. The heat from automatic transaxle is also cooled down through the radiator by

circulating the oil through the oil pump.

There are two cooling fans (200W+150W) in D20DTF engine. ECU controls the electric cooling fans

with three cooling fan relays to improve the engine torque and air conditioning performance.

For details about A/C compressor and refrigerant pressure sensor, refer to Chapter "Air Conditioning

System" in "Body" section.

b. Components

Refrigerant pres.

sensor

A/C compressor

ECU

D20DTF DSI 6 A/T

(ATF temp.)

Cooling fan module

HFM sensor

(Intake air

temperature)

Engine room

relay box

Page 323 of 1082

15-470000-00

e. Cautions

Use only specified Engine Oil (approved by MB Sheet 229.51) for CDPF. -

1. Use only specified engine oil (Low Ash Oil)

The vehicle equipped with CDPF should use specific engine oil to improve the engine performance

and fuel economy, and ensure the service life of CDPF. -

2. Issue with normal engine oil

Sulfur, one of the contents of engine oil is burned and generates soot that is not regenerated by the

DPF. This remains on the filter as ashes and keeps accumulating. Eventually, this ashes will block the

filter. -

3. Benefit for specified engine oil

Minimized the sulfur content of engine oil which reduces the service life.

Improved fuel economy and emission level of CO2 with high performance and low viscosity.

Increased service life of engine oil with high resistance to temperature. -

-

-

4. Problems when using unspecified engine oil

The service life of filter may be reduced by 30% or more by the ashes accumulated on the filter.

The fuel economy may be reduced because of engine rolling resistance, frequent regeneration of

DPF. -

-

These problems are also caused by oil with high sulfur content, such as tax exemption oil and

heating oil, etc. *

Page 328 of 1082

01-4

Engine mounting bracket

2. MAJOR COMPONENTS

Front View ▶

Cylinder head front cover

Timing gear case cover

EPS idler pulley

Alternator

Water pump pulley

A/C compressor

Crankshaft pulley

Oil pan assembly

Rear View ▶

Camshaft position sensor

Breather nipple

Purge control solenoid valveCoolant temperature sensor

Electronic throttle body

T-MAP sensor

MCC complete

VIS solenoid valve Cylinder head cover

Dual mass flywheel

Crankshaft position sensor

Hydraulic tensioner assembly

Page 337 of 1082

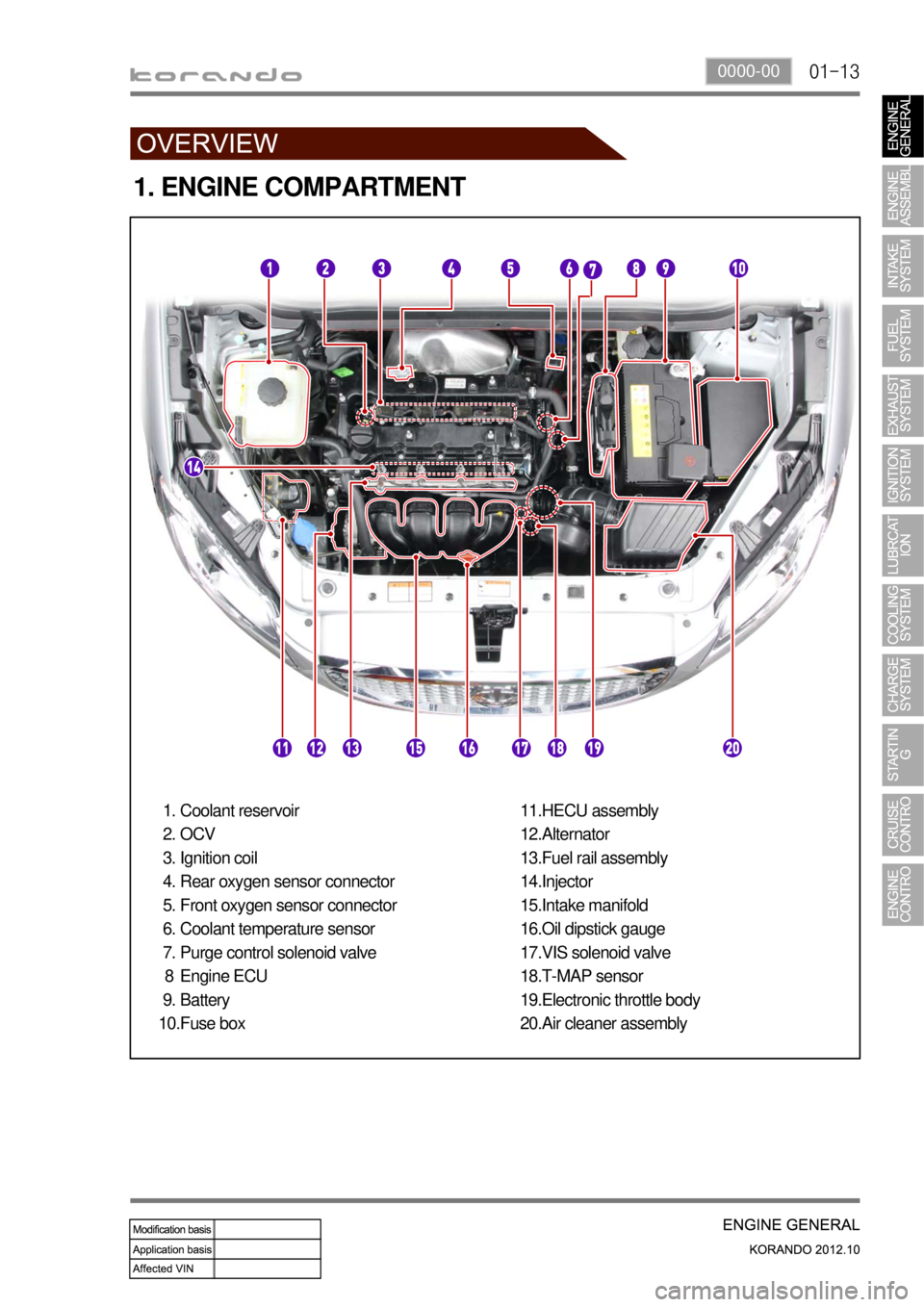

01-130000-00

1. ENGINE COMPARTMENT

Coolant reservoir

OCV

Ignition coil

Rear oxygen sensor connector

Front oxygen sensor connector

Coolant temperature sensor

Purge control solenoid valve

Engine ECU

Battery

Fuse box 1.

2.

3.

4.

5.

6.

7.

8

9.

10.HECU assembly

Alternator

Fuel rail assembly

Injector

Intake manifold

Oil dipstick gauge

VIS solenoid valve

T-MAP sensor

Electronic throttle body

Air cleaner assembly 11.

12.

13.

14.

15.

16.

17.

18.

19.

20.

Page 413 of 1082

06-51443-01

1. OVERVIEW

The ignition system is to supply high voltage generated from the ignition coil to the spark plug. The

G20DF engine is equipped with the independent type direct ignition system that the ignition coil is

installed in each cylinder.

The basic ignition timing in each cylinder is determined by the signals from camshaft position sensor and

crankshaft position sensor.

This ignition system controls the electronic ignition timing received from the engine ECU. To control the

ignition timing precisely, the ECU use the information below:

Engine load

Coolant temperature

Intake air temperature

Engine rpm

Camshaft position sensor (CPS)

Crankshaft position sensor (CKS) -

-

-

-

-

-

If the signal from the camshaft position sensor is not delivered to the engine ECU, the ignition coil and

fuel system cannot be operated.

Page 420 of 1082

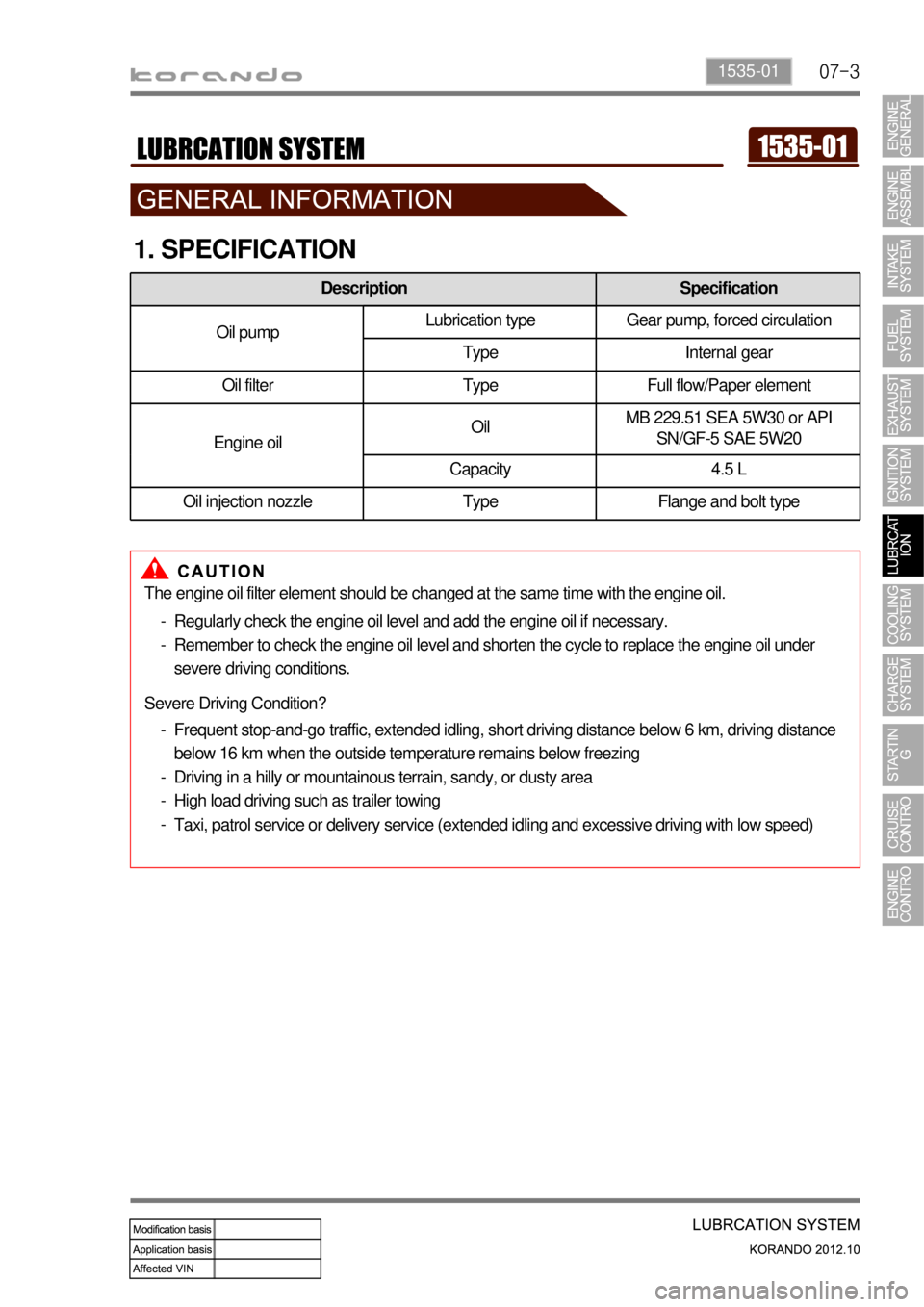

07-31535-01

1. SPECIFICATION

Description Specification

Oil pumpLubrication type Gear pump, forced circulation

Type Internal gear

Oil filter Type Full flow/Paper element

Engine oilOilMB 229.51 SEA 5W30 or API

SN/GF-5 SAE 5W20

Capacity 4.5 L

Oil injection nozzle Type Flange and bolt type

Regularly check the engine oil level and add the engine oil if necessary.

Remember to check the engine oil level and shorten the cycle to replace the engine oil under

severe driving conditions. -

- The engine oil filter element should be changed at the same time with the engine oil.

Frequent stop-and-go traffic, extended idling, short driving distance below 6 km, driving distance

below 16 km when the outside temperature remains below freezing

Driving in a hilly or mountainous terrain, sandy, or dusty area

High load driving such as trailer towing

Taxi, patrol service or delivery service (extended idling and excessive driving with low speed) -

-

-

- Severe Driving Condition?

Page 424 of 1082

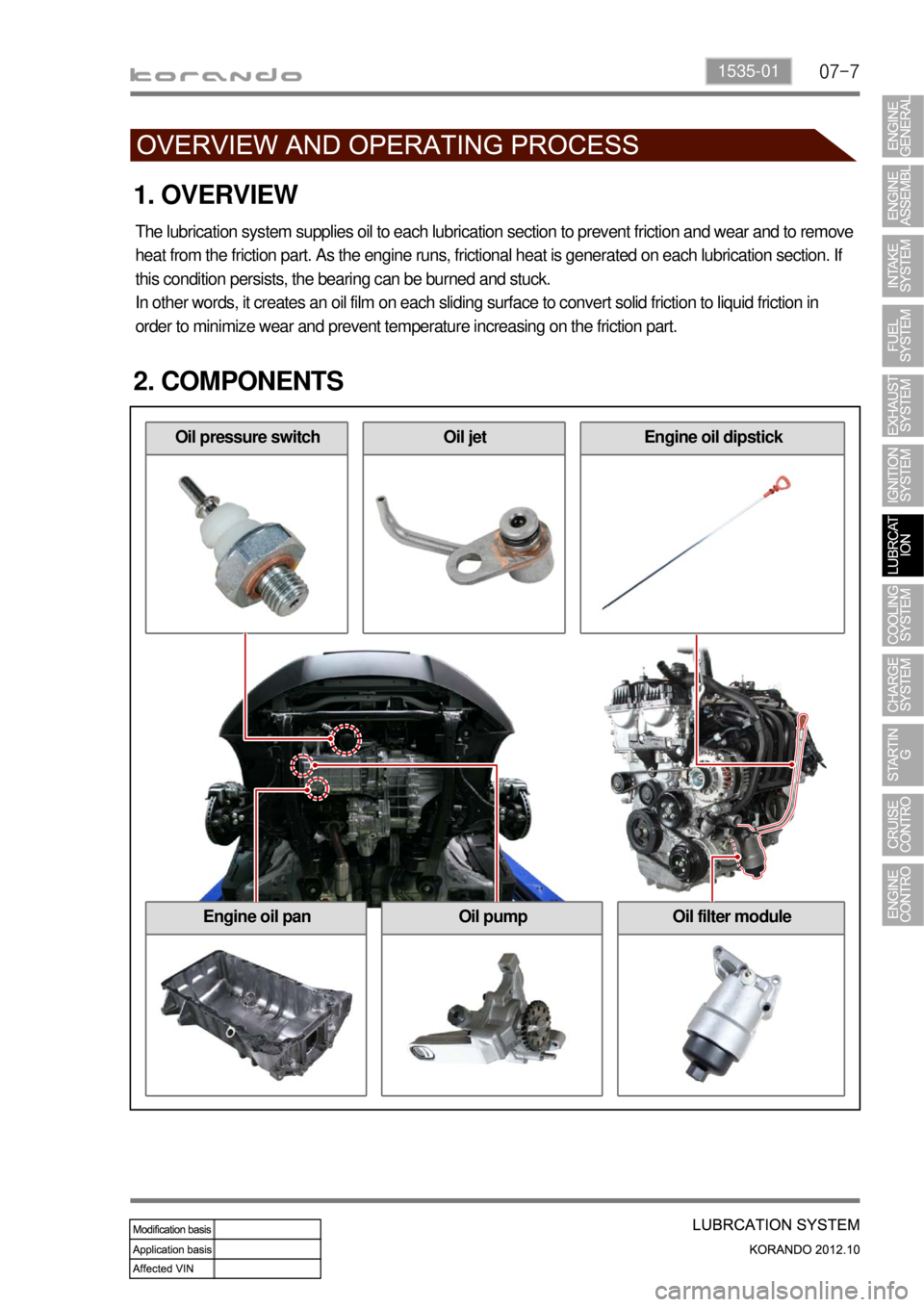

07-71535-01

Oil pressure switch

1. OVERVIEW

The lubrication system supplies oil to each lubrication section to prevent friction and wear and to remove

heat from the friction part. As the engine runs, frictional heat is generated on each lubrication section. If

this condition persists, the bearing can be burned and stuck.

In other words, it creates an oil film on each sliding surface to convert solid friction to liquid friction in

order to minimize wear and prevent temperature increasing on the friction part.

2. COMPONENTS

Engine oil dipstickOil jet

Engine oil panOil pumpOil filter module