service SSANGYONG KORANDO 2012 Owner's Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2012, Model line: KORANDO, Model: SSANGYONG KORANDO 2012Pages: 1082, PDF Size: 96.1 MB

Page 497 of 1082

01-90000-00

4. SCHEDULED MAINTENANCE SERVICES

Page 502 of 1082

02-30000-00

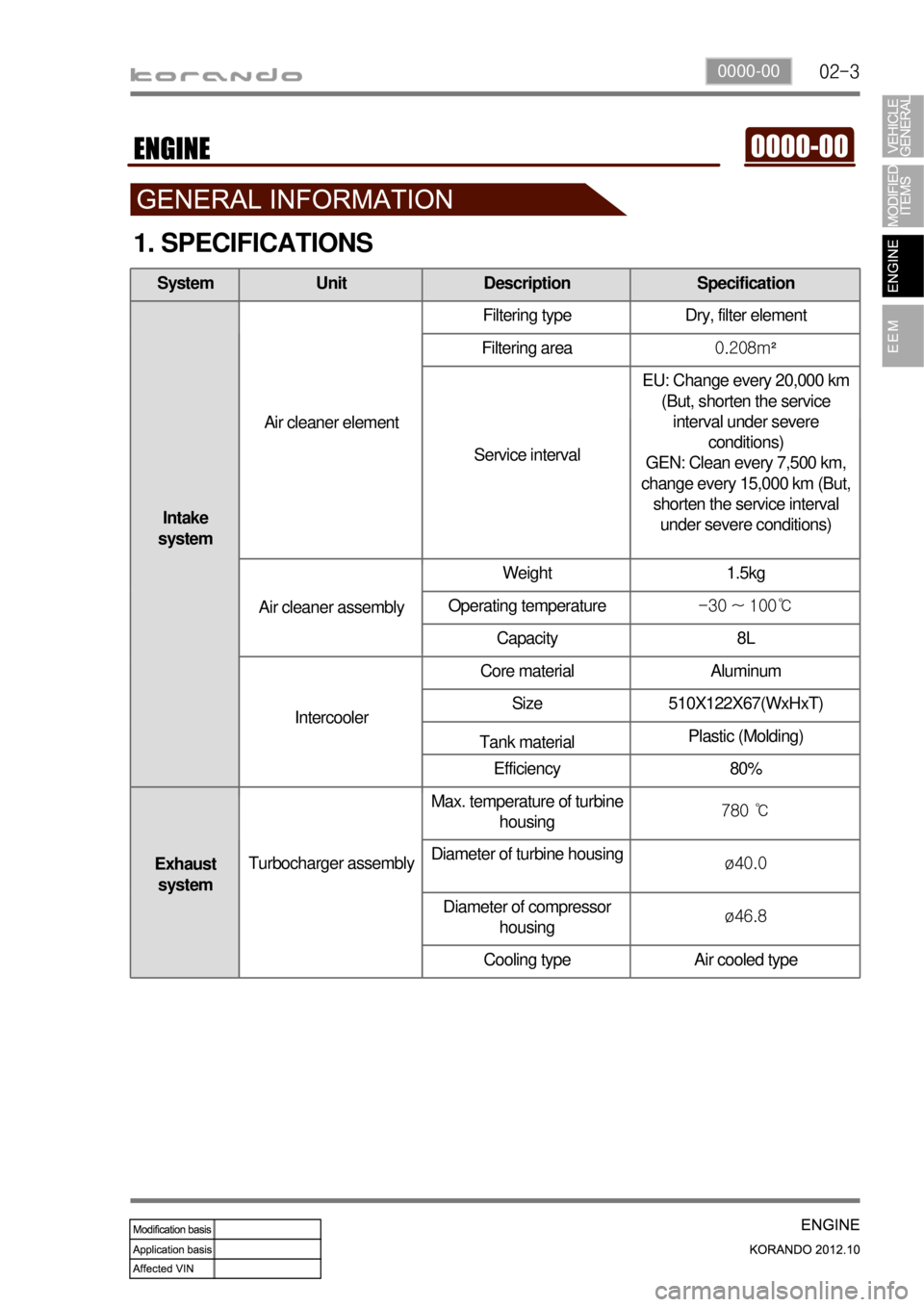

1. SPECIFICATIONS

System Unit Description Specification

Intake

systemAir cleaner elementFiltering type Dry, filter element

Filtering area0.208m²

Service intervalEU: Change every 20,000 km

(But, shorten the service

interval under severe

conditions)

GEN: Clean every 7,500 km,

change every 15,000 km (But,

shorten the service interval

under severe conditions)

Air cleaner assemblyWeight 1.5kg

Operating temperature-30 ~ 100℃

Capacity 8L

IntercoolerCore material Aluminum

Size 510X122X67(WxHxT)

Tank materialPlastic (Molding)

Efficiency 80%

Exhaust

systemTurbocharger assemblyMax. temperature of turbine

housing780 ℃

Diameter of turbine housing

ø40.0

Diameter of compressor

housingø46.8

Cooling type Air cooled type

Page 807 of 1082

10-58910-05

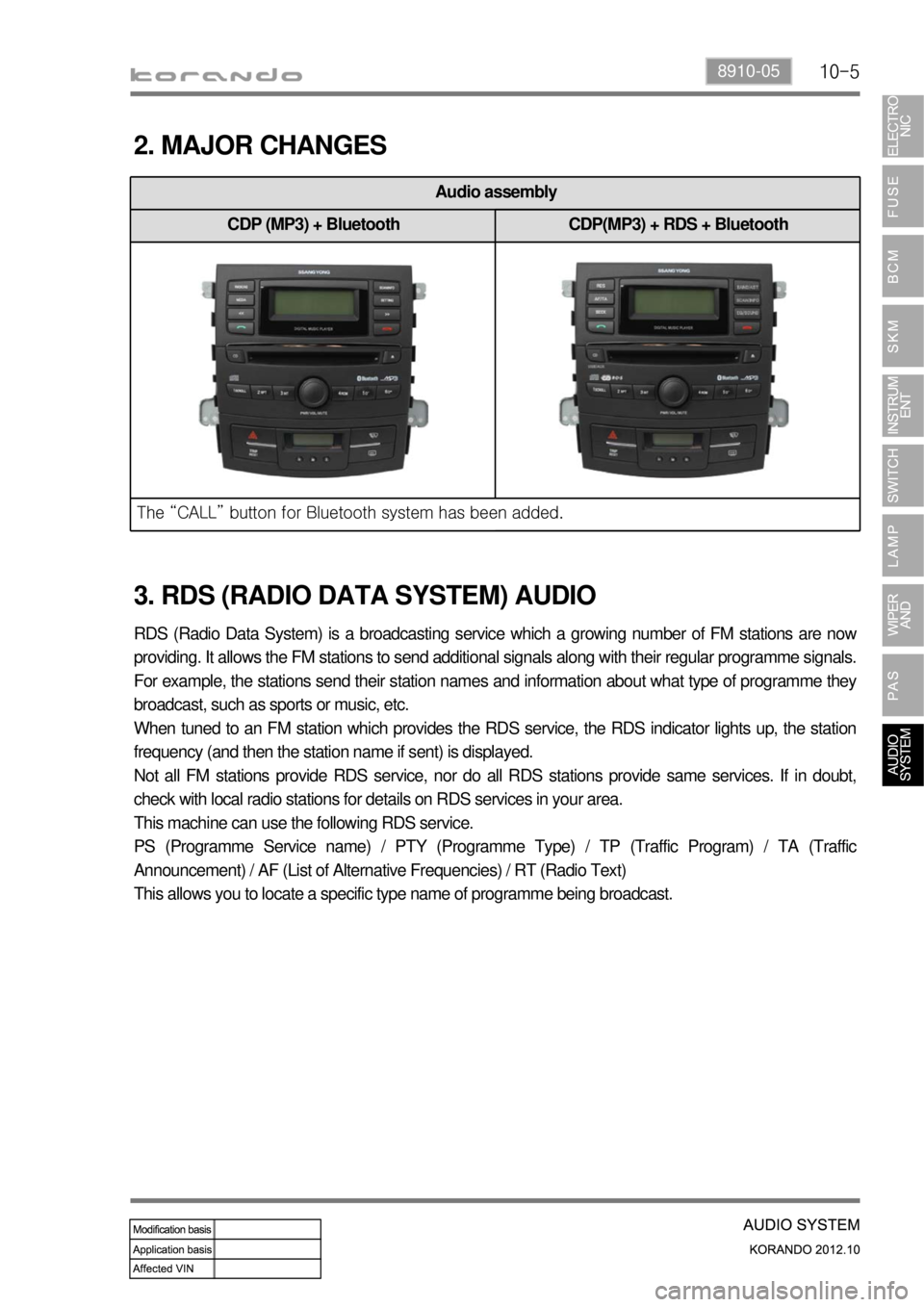

Audio assembly

CDP (MP3) + Bluetooth CDP(MP3) + RDS + Bluetooth

<007b008f008c004702c8006a00680073007302c900470089009c009b009b009600950047008d00960099004700690093009c008c009b00960096009b008f0047009a00a0009a009b008c00940047008f0088009a00470089008c008c009500470088008b00

8b008c008b0055>

2. MAJOR CHANGES

RDS (Radio Data System) is a broadcasting service which a growing number of FM stations are now

providing. It allows the FM stations to send additional signals along with their regular programme signals.

For example, the stations send their station names and information about what type of programme they

broadcast, such as sports or music, etc.

When tuned to an FM station which provides the RDS service, the RDS indicator lights up, the station

frequency (and then the station name if sent) is displayed.

Not all FM stations provide RDS service, nor do all RDS stations provide same services. If in doubt,

check with local radio stations for details on RDS services in your area.

This machine can use the following RDS service.

PS (Programme Service name) / PTY (Programme Type) / TP (Traffic Program) / TA (Traffic

Announcement) / AF (List of Alternative Frequencies) / RT (Radio Text)

This allows you to locate a specific type name of programme being broadcast.

3. RDS (RADIO DATA SYSTEM) AUDIO

Page 832 of 1082

01-22

1. GUIDELINES FOR SERVICE WORKS

1) For Safety

To perform the service works easily ans safely, the service technicians must keep the proper working

procedures and rules.

This manual provides the useful instructions to the service technicians so that they can perform the

servive works with standard working process, skills, tips in time.

Please read this manual and follow the instructions carefully.

Signal words such as “WARNING”, “CAUTION” and “NOTE” have special meanings.

indicates information to assist maintenance and instructions.

However, above references and cautions cannot be inclusive measures, so should have habits of

paying attentions and cautions based on common senses.

indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate

injury or property damage.

indicates a potentially hazardous situation which, if not avoided, could result in death or serious

injury.

Page 833 of 1082

01-230000-00

3) General Instructions

Before lifting up the vehicle with a lift, correctly support the lifting points.

When using a jack, park the vehicle on a level ground and place the wheel chocks under the tires.

Position the jack under the frame and lift up the vehicle and then support with chassis stand before

service work.

Make sure to disconnect the negative (-) cable from the battery to prevent any damage to electric

systems.

If you have to work on vehicle, cover the seats and floor with protection covers to avoid any

damage and contamination.

Brake fluid and anti-freeze can damage the painted surface of body. So carefully handle them

during service work.

To improve the efficiency of service work, use only recommended and specified tools.

Use only Ssangyong genuine spare parts.

Never reuse the cotter pin, gasket, O-ring, oil seal, lock washer and self-locking nut. Replace them

with new ones. If reused, normal functions cannot be maintained.

Store the disassembled parts as a set based on disassembly order and unit.

Pay particular attention not to miss or mix the fasteners.

If necessary, especially for inspection, clean the removed parts completely.

Apply the oil or grease on the running and sliding surfeces before installation. Use the specified

sealant and gasket to prevent leakage if necessary.

Tighten the fasteners to the specified tightening torque.

As a final stage of service work, check if the serviced system is working properly and the problem

has been eliminated clearly. (1)

(2)

(3)

(4)

(5)

(6)

(7)

(8)

(9)

(10)

(11)

(12)

(13)

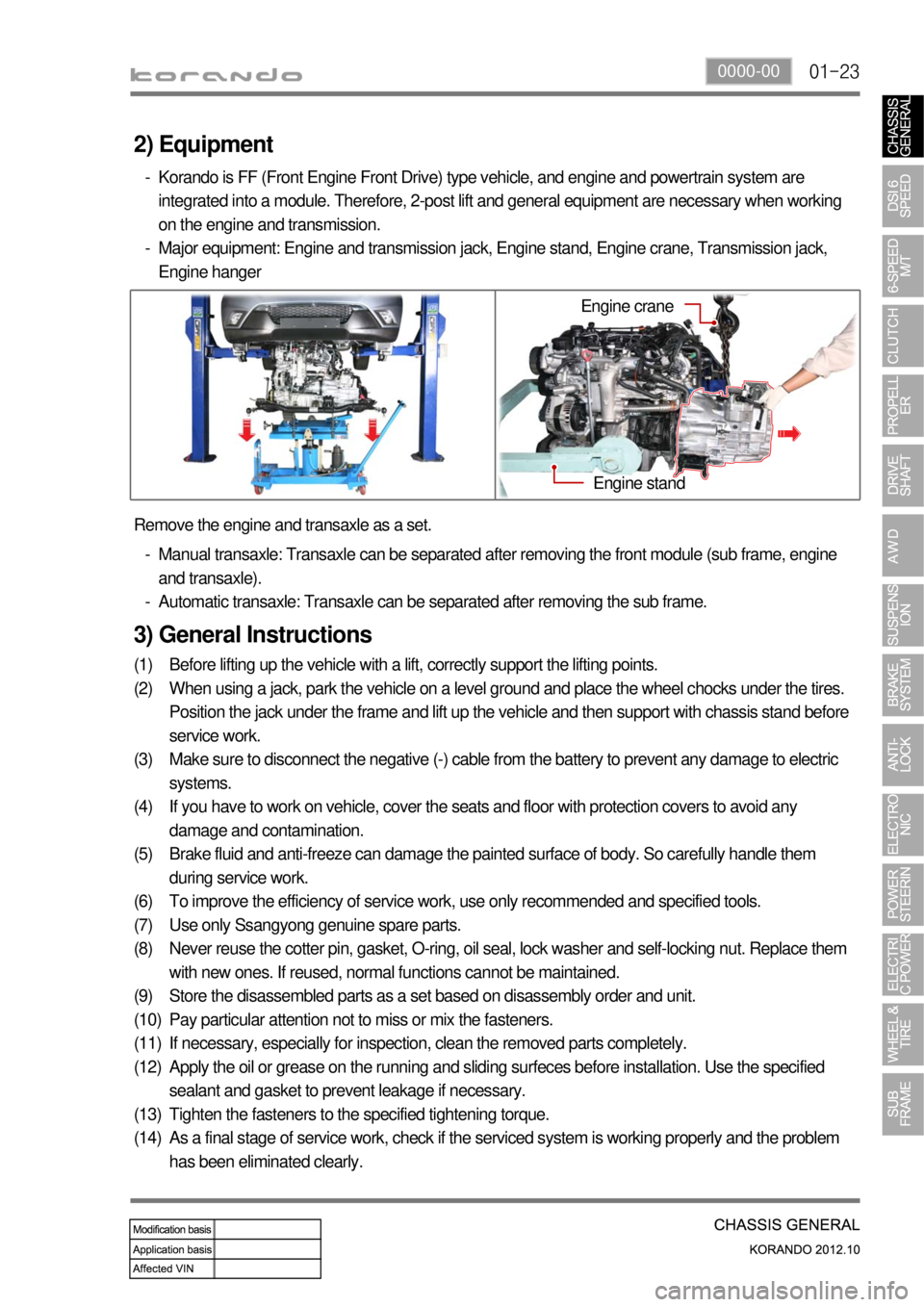

(14) Remove the engine and transaxle as a set.

Manual transaxle: Transaxle can be separated after removing the front module (sub frame, engine

and transaxle).

Automatic transaxle: Transaxle can be separated after removing the sub frame. -

-

2) Equipment

Korando is FF (Front Engine Front Drive) type vehicle, and engine and powertrain system are

integrated into a module. Therefore, 2-post lift and general equipment are necessary when working

on the engine and transmission.

Major equipment: Engine and transmission jack, Engine stand, Engine crane, Transmission jack,

Engine hanger -

-

Engine stand

Engine crane

Page 849 of 1082

02-153680-01

This information is used by the TCU to decide which shift pattern to select and for shift energy

management. Electro-hydraulic solenoid valves and variable bleed solenoids control the transaxle gear

changes.

Six variable bleed solenoids and four on/off solenoids are used to direct transaxle fluid flow to control the

fluid pressure within the three clutches and two bands. Separate pressure regulators are used

exclusively for torque converter clutch control and main transaxle line pressure.

The TCU monitors all TCU inputs and outputs to confirm correct system operation. If a fault occurs the

TCU is able to perform default action and inform the driver of the problem through the instrument cluster

warning lights. Detailed information is available via trouble codes which can be read with the service tool.

Page 870 of 1082

03-10

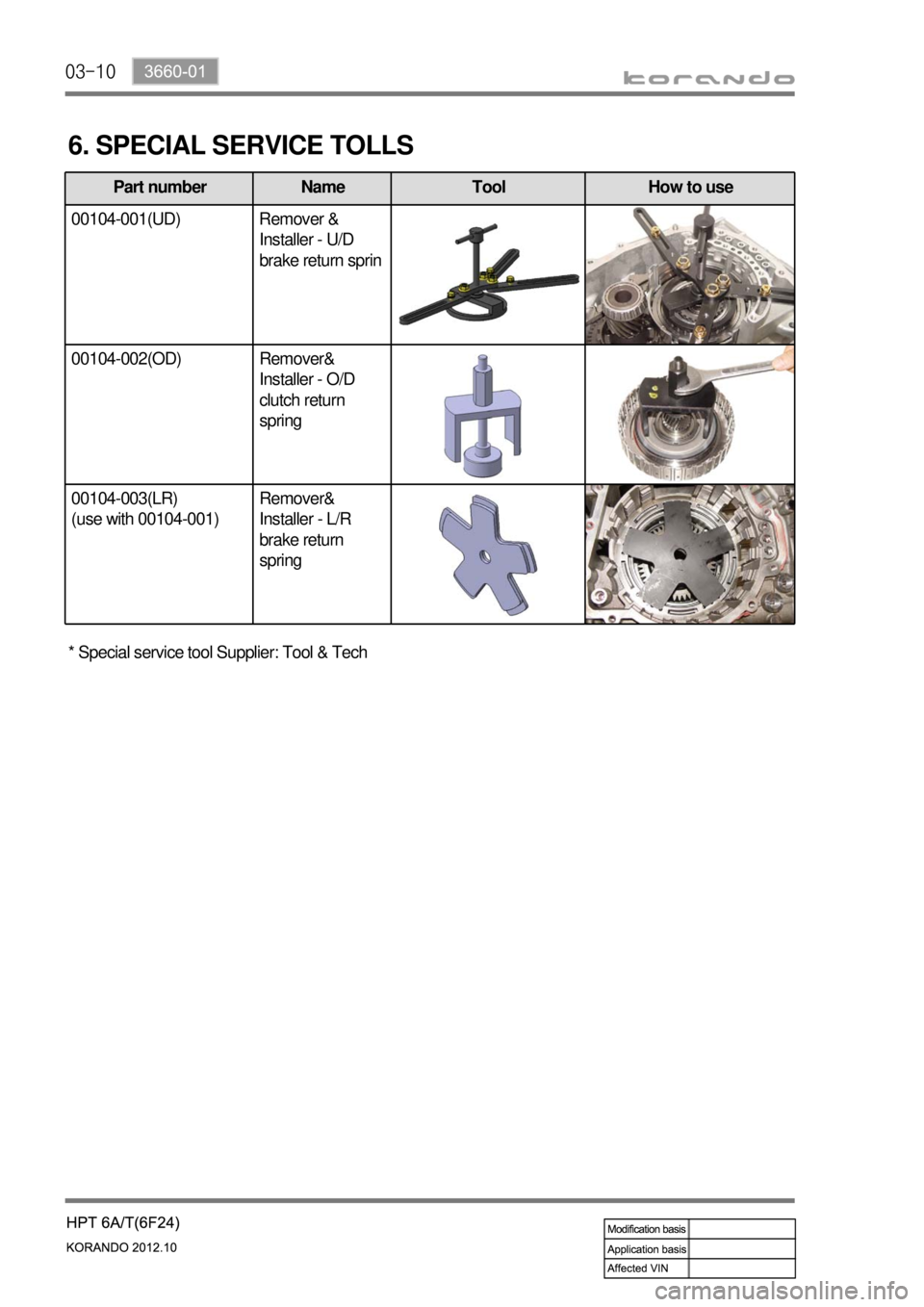

6. SPECIAL SERVICE TOLLS

Part number Name Tool How to use

00104-001(UD) Remover &

Installer - U/D

brake return sprin

00104-002(OD) Remover&

Installer - O/D

clutch return

spring

00104-003(LR)

(use with 00104-001)Remover&

Installer - L/R

brake return

spring

* Special service tool Supplier: Tool & Tech

Page 877 of 1082

03-173660-01

5. TRANSAXLE ELECTRONIC CONTROL SYSTEM

1) General Information

The transmission control unit (TCU) and its input/output network control the following transmission

operations:

Shift timing

Line pressure

Clutch pressure (shift feel)

Torque converter clutch -

-

-

-

also uses these signals when determining transaxle operating strategy. Using all of these input signals,

the TCU can determine when the time and conditions are right for a shift, or when to apply or release the

torque converter clutch. It will also determine the pressure needed to optimise shift feel.

2) TCU (Transmission Control Unit)

The transaxle control unit (TCU) is mounted

under the driver's seat and controls the operation

of the transaxle.

Internal sensors and signals received across the

CAN bus in analogue and digital forms such as:

Transaxle input speed

Transaxle output speed

Accelerator pedal position

Gear selector position

Engine torque

Engine speed

Transaxle fluid temperature

Brake pedal status

Engine oil temperature

Engine coolant temperature

Ambient air temperature

Barometric pressure -

-

-

-

-

-

-

-

-

-

-

-

The TCU monitors all TCU inputs and outputs to confirm correct system operation. If a fault occurs the

TCU is able to perform default action and inform the driver of the problem through the instrument cluster

warning lights. Detailed information is available via trouble codes which can be read with the service tool.

Page 926 of 1082

09-6

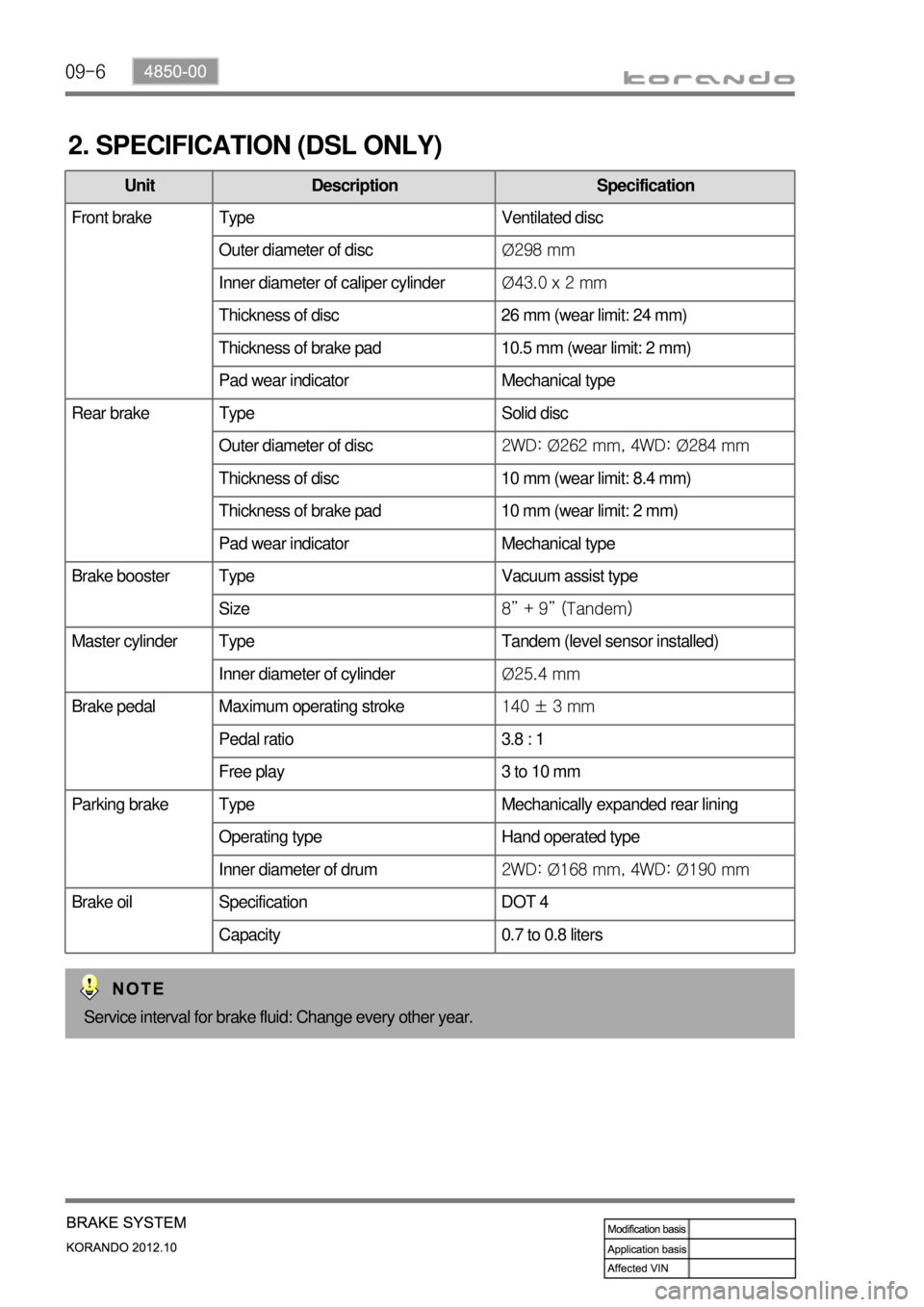

2. SPECIFICATION (DSL ONLY)

Unit Description Specification

Front brake Type Ventilated disc

Outer diameter of discØ298 mm

Inner diameter of caliper cylinderØ43.0 x 2 mm

Thickness of disc 26 mm (wear limit: 24 mm)

Thickness of brake pad 10.5 mm (wear limit: 2 mm)

Pad wear indicator Mechanical type

Rear brake Type Solid disc

Outer diameter of disc2WD: Ø262 mm, 4WD: Ø284 mm

Thickness of disc 10 mm (wear limit: 8.4 mm)

Thickness of brake pad 10 mm (wear limit: 2 mm)

Pad wear indicator Mechanical type

Brake booster Type Vacuum assist type

Size8” + 9” (Tandem)

Master cylinder Type Tandem (level sensor installed)

Inner diameter of cylinderØ25.4 mm

Brake pedal Maximum operating stroke140 ± 3 mm

Pedal ratio 3.8 : 1

Free play 3 to 10 mm

Parking brake Type Mechanically expanded rear lining

Operating type Hand operated type

Inner diameter of drum2WD: Ø168 mm, 4WD: Ø190 mm

Brake oil Specification DOT 4

Capacity 0.7 to 0.8 liters

Service interval for brake fluid: Change every other year.

Page 1022 of 1082

02-6

Seldom oeprate ▶The air bag deploys when: ▶

The air bag can deploy when: ▶a severe oblique collision occurs with a specific severity, angle, speed, and position. -

A collision with oblique impact to the front seat direction or a front collision to the diagonal

direction occurs.

a frontal or rear collision occurs.

The vehicle rolls over or tips over sideward with minor impact.

The air bag warning lamp is on. -

-

-

-the vehicle rolls over or tips over sideward with a severe impact.

The vehicle is stationary or a front collision occurs with low speed.

A rear collision occurs.

The impact of the collision is low enough for the seat belt to protect the occupant properly. -

-

-

-

Seldom oeprate ▶The air bag deploys when: ▶

The air bag can deploy when: ▶

The air bag does not deploy when: ▶

The vehicle is stationary or a front collision occurs with low speed.

A rear collision occurs.

The impact of the collision is low enough for the seat belt to protect the occupant properly. -

-

-

C. General Warnings for Air Bag

Do not check the circuits with a circuit tester. Do not attempt to modify any air bag component

including the steering wheel, air bag mountings and related wirings.

Do not subject any air bag component, such as the steering wheel, air bag mountings, wirings, to

impacts. You might get severely injured by sudden deployment of the air bag.

As the air bag/seat belt pretensioner parts are very hot after being deployed. Allow them to cool

down sufficiently before touching them.

The deployed air bag/seat belt pretensioner cannot deploy again. It will work when an additional

impact is applied. The components of the deployed air bag/seat belt pretensioner are non-reusable

parts. Therefore, remove or replace them as a unit.

The air bag and seat belt pretensioner systems contain explosive charges, so handle carefully when

disposing or replacing them.

Incorrect inspection can result in serious injuries or malfunctions in the air bag and seat belt

pretensioner system.

The air bag warning lamp is illuminated for 3 to 7 sec. after the engine is started to check the system.

Drive the vehicle after this warning lamp is turned off. If this warning lamp stays ON, the system may

be defective. Have the air bag system checked immediately by Ssangyong Dealer or Ssangyong

Authorized Service Center. -

-

-

-

-

-

-