air condition SSANGYONG KORANDO 2012 Owner's Guide

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2012, Model line: KORANDO, Model: SSANGYONG KORANDO 2012Pages: 1082, PDF Size: 96.1 MB

Page 713 of 1082

05-50

5. SELF DIAGNOSIS

1. Self diagnosis for gauge

Speedometer: Check the whole speed range (minimum to maximum).

Tachometer: Check the whole rpm range (minimum to maximum). -

-

2. Self diagnosis for symbols

All symbols ON

(except the wired type symbols: air bag, passenger air bag, turn signal indicators, hazard warning

lamp, high beam, front fog lamp) -

3. ETC

When entering into the self diagnosis mode, the instrument cluster illumination output will be 100%.

All the remaining segments are ON.

The spanner symbol goes off if CAN messages to the instrument cluster are OK. If not, it blinks.

The mode and illumination switch inputs are overridden. -

-

-

-

6. VARIANT CODING

The instrument cluster enables all functions by receiving the vehicle's variant codes through CAN

communication when turning the ignition switch to ON position.

The systems verified by variant code performs the pre-warning and time-out operation. If not

confirmed, all data for the systems, even exiting in CAN network, are overridden. -

- 4. Diagnosis mode deactivation condition

The diagnosis mode is deactivated when the ignition switch is turned to "OFF" position or the

engine is running. -

Page 714 of 1082

06-38510-01

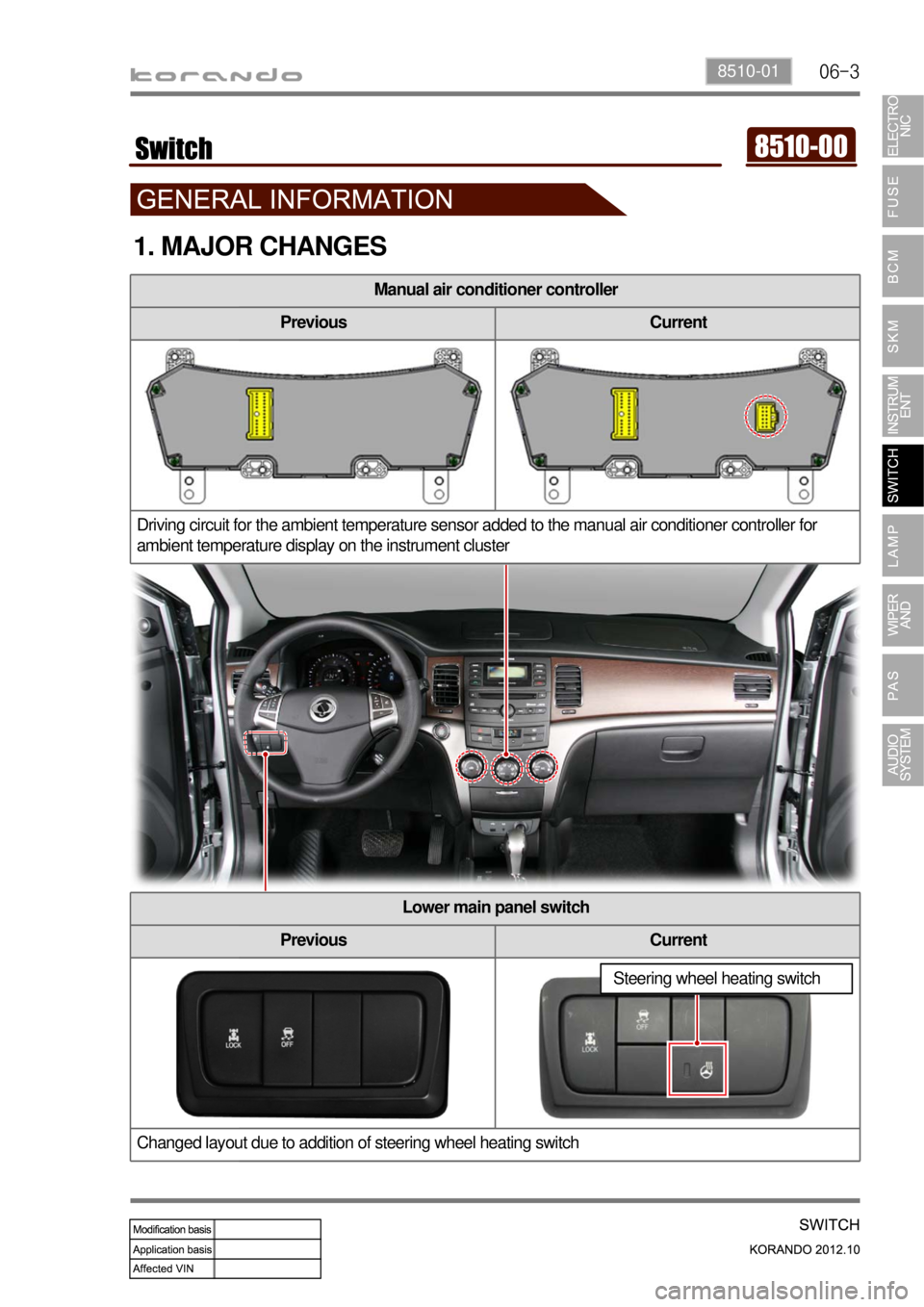

1. MAJOR CHANGES

Manual air conditioner controller

Previous Current

Driving circuit for the ambient temperature sensor added to the manual air conditioner controller for

ambient temperature display on the instrument cluster

Lower main panel switch

Previous Current

Changed layout due to addition of steering wheel heating switch

Steering wheel heating switch

Page 731 of 1082

06-20

Temperature dial

In full AUTO mode, the FATC receives various signals

such as the indoor temperature, ambient temperature,

engine coolant temperature, sunlight, from different

sensors to control the A/C compressor, mode door, intake

actuator assembly, air mix door, blower motors, etc. to

keep indoor environments fresh.

Fan speed dial

In full AUTO mode, the blower

motor is controlled

automatically according to the

set temperature. The blower

motor speed can also be

controlled manually.Mode dial

You can choose a desired

mode from the 5 modes by

turning the mode as required.

The dial indicator for the

selected mode comes on to

inform the operator.

Air source mode switch

When you press this switch,

recirculation indicator comes on and

the system is changed into the

recirculation mode. (However, under

defroster

mode or defroster/floor mode, it stays

in the fresh air mode.)

A/C switch

When pressing this switch, the

air conditioner operates in

manual mode and A/C ON

indicator comes on.

The A/C starts automatically

when the defroster mode is

selected.

Page 834 of 1082

01-24

4) Basic Inspection

(1) Horn operation

Listen for the horn sound when pressing the horn pad on the steering wheel. -

(2) Brake operation

Check if there is any abnormal noise, unusually long braking distance, or uneven braking force. If the

brake warning lamp does not go out even after starting the engien or are flashing during driving,

have the brake system checked immediately.

Check the brake pipes and hoses for connection, oil leak, crack or interference after changing the

position of tires. When replacing the tires, check the brake disc for surface condition and wear.

Check the parking brake cable and brake operation. Shorten the checking interval if the parking

brake is used frequently. -

-

-

(3) Exhaust system

Be aware to any changes in sound or smell from the exhaust system. These may be caused by leak or

overheat. Have the exhaust system checked and repaired immediately.

Inspect the exhaust system including catalytic converter. Inspect all the components and body frame

near the exhaust system. -

-

(4) Tires

Unusual vibration of the steering wheel and seats or pulling to one side on the straight and level roads

may indicates the uneven tire inflation pressure or poor wheel balance. -

(5) Steering and suspension system

Inspect the front and rear suspension and the steering system for damage, looseness or missing

parts, signs of wear or lack of lubrication. Inspect the power steering line and the hoses for

connection, leak, crack and chafing. Inspect the drive axle boot and seals for damage, tear or leak.

Replace or repair the system if necessary. -

(6) Engine oil

Check the oil level when the engine is still warm and add the specified engine oil if necessary. -

(7) Coolant

Check the coolant level in the coolant reservoir, coolant conditions (contamination, foreign material),

and hoses for damage and leak. Replace or add the Ssangyong genuine coolant, if needed. -

(8) Engine drive belt

Check all drive belts on the engine for wear, crack and looseness. Retighten or replace the belt, if

needed. -

Page 848 of 1082

02-14

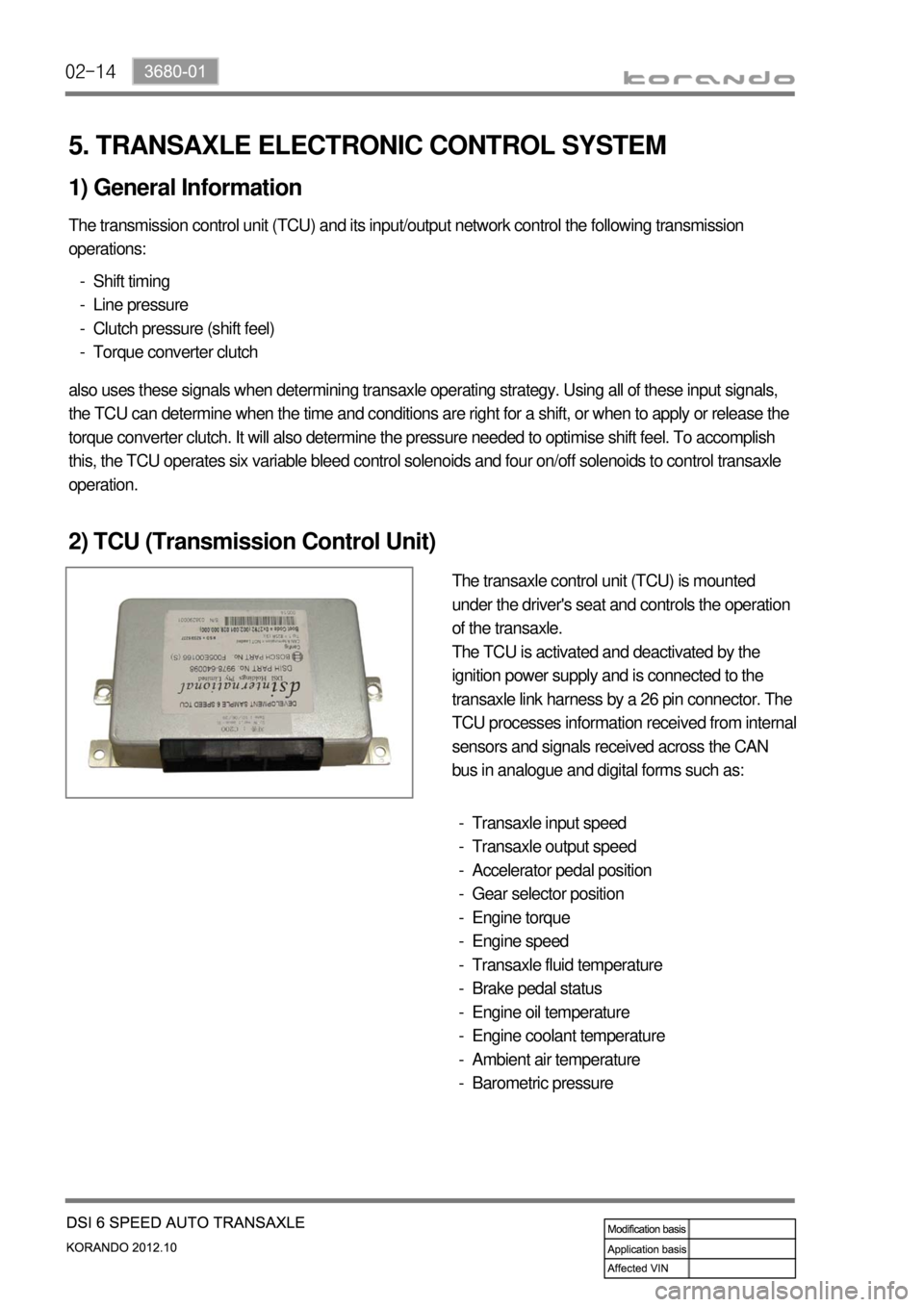

5. TRANSAXLE ELECTRONIC CONTROL SYSTEM

1) General Information

The transmission control unit (TCU) and its input/output network control the following transmission

operations:

Shift timing

Line pressure

Clutch pressure (shift feel)

Torque converter clutch -

-

-

-

also uses these signals when determining transaxle operating strategy. Using all of these input signals,

the TCU can determine when the time and conditions are right for a shift, or when to apply or release the

torque converter clutch. It will also determine the pressure needed to optimise shift feel. To accomplish

this, the TCU operates six variable bleed control solenoids and four on/off solenoids to control transaxle

operation.

2) TCU (Transmission Control Unit)

The transaxle control unit (TCU) is mounted

under the driver's seat and controls the operation

of the transaxle.

The TCU is activated and deactivated by the

ignition power supply and is connected to the

transaxle link harness by a 26 pin connector. The

TCU processes information received from internal

sensors and signals received across the CAN

bus in analogue and digital forms such as:

Transaxle input speed

Transaxle output speed

Accelerator pedal position

Gear selector position

Engine torque

Engine speed

Transaxle fluid temperature

Brake pedal status

Engine oil temperature

Engine coolant temperature

Ambient air temperature

Barometric pressure -

-

-

-

-

-

-

-

-

-

-

-

Page 877 of 1082

03-173660-01

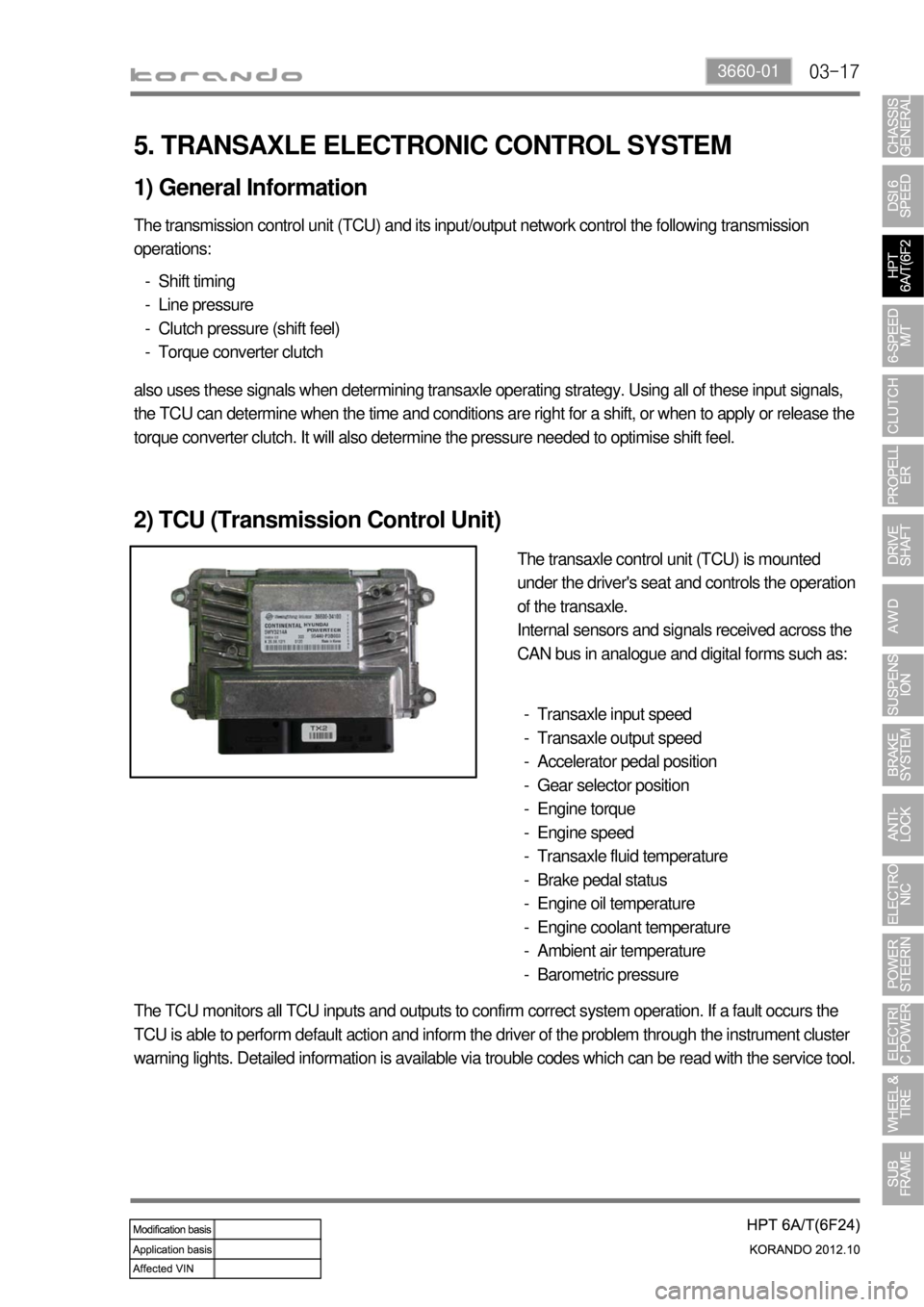

5. TRANSAXLE ELECTRONIC CONTROL SYSTEM

1) General Information

The transmission control unit (TCU) and its input/output network control the following transmission

operations:

Shift timing

Line pressure

Clutch pressure (shift feel)

Torque converter clutch -

-

-

-

also uses these signals when determining transaxle operating strategy. Using all of these input signals,

the TCU can determine when the time and conditions are right for a shift, or when to apply or release the

torque converter clutch. It will also determine the pressure needed to optimise shift feel.

2) TCU (Transmission Control Unit)

The transaxle control unit (TCU) is mounted

under the driver's seat and controls the operation

of the transaxle.

Internal sensors and signals received across the

CAN bus in analogue and digital forms such as:

Transaxle input speed

Transaxle output speed

Accelerator pedal position

Gear selector position

Engine torque

Engine speed

Transaxle fluid temperature

Brake pedal status

Engine oil temperature

Engine coolant temperature

Ambient air temperature

Barometric pressure -

-

-

-

-

-

-

-

-

-

-

-

The TCU monitors all TCU inputs and outputs to confirm correct system operation. If a fault occurs the

TCU is able to perform default action and inform the driver of the problem through the instrument cluster

warning lights. Detailed information is available via trouble codes which can be read with the service tool.

Page 1006 of 1082

01-56810-00

2) Manual A/C Controller

Manual air conditioner controller

Previous Current

The driving circuit for the ambient temperature sensor is added to the manual air conditioner controller

for ambient temperature display on the instrument cluster.

Connector added

Pin No. Function

B1 -

B2 -

B3 -

B4 Water temp. signal

B5 -

B6 -

B7 -

B8 -

B9 -

B10 Sun-load sensor signal

B11 Ambient temp. sensor signal

B12 -

Page 1010 of 1082

01-96810-00

Incar sensor

This sensor detects the inside temperature and

installed in PCB.Face-Level

(vent mode)Face/Foot-Level

(bi-level mode)Foot-Level

(foot mode)

Foot/Defrost-level

(foot/defrost mode)

Defroster switch

Use this switch to remove for or

ice from the windshield. When

choosing this mode, the airflow

direction will be changed to the

windshield and side glasses, the

air conditioner operates

automatically, and fresh air

comes in. The air flow direction can be controlled by turning the dial. -

Airflow is changed

automatically according to the

setting temperature.

Fan speed dial

Manual control

Fan speed is manually controlled b

y

this dial. The increment is 1℃.

Auto control

Fan speed is automatically

controlled by temperature setting.

The blower motor operates in a

stepless mode. -

-

A/C switch

When pressing this switch,

the air conditioner operates

in manual mode and A/C

ON indicator comes on.

Fan speed dial ▶Mode dial ▶

Page 1013 of 1082

01-12

3. A/C COOLING CYCLE

1) System flow

Condition: Gas/Liquid

Function: Keeps the refrigerant free from moisture by separating/collecting the moisture from it. -

-"Compression -> Condensation -> Expansion -> Evaporation" -

Condition: Liquefied gas/Gas

Function: Cools the air by absorbing the heat from the air around the evaporator. -

-Condition: Liquid/Liquefied gas

Function: Performs adiabatic expansion and flow control for easier evaporation. -

-Condition: Gas/Liquid

Function: Cools and condenses the refrigerant by using ambient air to liquefy it under high pressure. -

-Condition: Gas

Function: Circulates the refrigerant and increases the pressure and temperature for easier

evaporation. -

- 2) Functions

(2) Condenser

(3) Receiver drier

(4) Expansion valve

(5) Evaporator

(1) Compressor

Page 1014 of 1082

01-136810-00

The refrigerant is converted from liquid to gas in the evaporator.

(The refrigerant in the form of fog in the evaporator is vaporized actively)

At this time the refrigerant, in the form of liquid, absorbs the heat in the air which is need for

evaporation (latent heat) and is cooled down. Then the blower blows the cooled air inside the vehicle

to lower the temperature.

There are liquid refrigerant from the expansion valve and evaporated refrigerant in the evaporator.

The evaporation temperature can be predicted from the evaporation pressure (i.e. relationship

between saturation pressure and saturation temperature).

It is important to keep the pressure inside the evaporator low, so that the refrigerant is evaporated at

low temperature to make sure the completely evaporated refrigerant is entered into the compressor. -

-

-

-

- (4) Evaporator (3) Expansion (2) Condensation

The liquid refrigerant lowers the pressure making its evaporation easily accomplished.

This process (lowering the pressure to the level at which evaporation easily takes place before the

liquid refrigerant is sent to the evaporator) is called

"Adiabatic Expansion".

During adiabatic expansion, the expansion valve lowers the pressure of the refrigerant and

determines the correct amount of refrigerant going into the air conditioning evaporator.

That is, the amount of heat, which is needed to stop the evaporation, is determined according to the

cooling load.

The expansion valve detects this and regulates the amount of the refrigerant exactly. -

-

-

-

-The high pressure and high temperature gas (refrigerant) from the compressor is cooled down by

the fresh air entered into the condenser. Then, this gas is converted to liquid and collected in the

receiver drier.

The heat generated from the high pressure refrigerant is dissipated to the ambient air, and it is called

"heat of condensation".

The heat of condensation is the summation of the heat of vaporization (heat that the refrigerant

absorbs from the inside of the vehicle) and the calorific value converted from the amount of work

which is needed to compress. -

- 3) Description for Each Cycle

(1) Compression

The evaporated refrigerant in the evaporator enters to the compressor. And the refrigerant gas is

compressed until it can be liquefied at ambient temperature.

Thus, the low refrigerant pressure is maintained so that the liquid refrigerant can be evaporated

actively at low temperature (around 0℃). -

-