clutch SSANGYONG KORANDO 2012 Owner's Guide

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2012, Model line: KORANDO, Model: SSANGYONG KORANDO 2012Pages: 1082, PDF Size: 96.1 MB

Page 873 of 1082

03-133660-01

2) Transaxle Cooling

The transaxle cooling system ensures rapid warm-up and constant operating temperature resulting in

reduced fuel consumption and refined shift quality.

It also includes a cooler by-pass within the hydraulic system to allow sufficient lubrication to the transaxle

drivetrain in the event of a blockage in the transaxle cooler.

3) Shift Strategy

Gear Change ▶

Transaxle gear change is controlled by the

TCU. The TCU receives inputs from various

engine and vehicle sensors to select shift

schedules and to control the shift feel and

torque converter clutch (TCC) operation at each

gear change.

Coast down ▶

Coast down down shifts occur at 0% pedal

when the vehicle is coasting down to a stop.

Torque Demand ▶

Torque demand down shifts occur

(automatically) when the driver demand for

torque is greater than the engine can provide at

that gear ratio. If applied, the transaxle will

disengage the TCC to provide added

acceleration.

Page 876 of 1082

03-16

4. LIMP HOME MODE

When the transaxle is defective ▶

In the event of a system fault, the TCU also provides for failure mode effect control (FMEC) to maintain

maximum functional operation of the transaxle. (There are 3 FMEC modes, mechanical limp-home

mode, electrical limp-home mode, limp-home mode C.)

In the event of a total loss of control or electrical power, the basic transaxle functions (Park, Reverse,

Neutral and Drive) are retained. The 4th and reverse gear ratios with the torque converter clutch in the

unlocked state are the retained gear states the hydraulic system supports without any electrical

assistance. (Mechanical limp-home)

If the speed sensor circuit is failed, the gear is fixed to 4th gear, but manual shifting

<004f00590095008b02e9005a0099008b02e9005b009b008f005000470090009a00470088009d008800900093008800890093008c0055004f006c0093008c008a009b00990090008a00880093004700930090009400970047008f00960094008c0047009400

96008b008c0050>

If the inhibitor switch signals are invalid, shifting to1st and 2nd gear is forbidden. (Limp-home C)

The TCU communicates with other vehicle electronic control modules by the controller area network

(CAN). If a major fault is developed, the transaxle may not accomplish the intelligent shift control. The

TCU controls the transaxle with preset values.

The TCU also provides for transaxle diagnostics, which meet the requirements of OBD II regulation,

monitoring all components which may effect vehicle emissions. 1.

2.

3.

4.

5.

6.

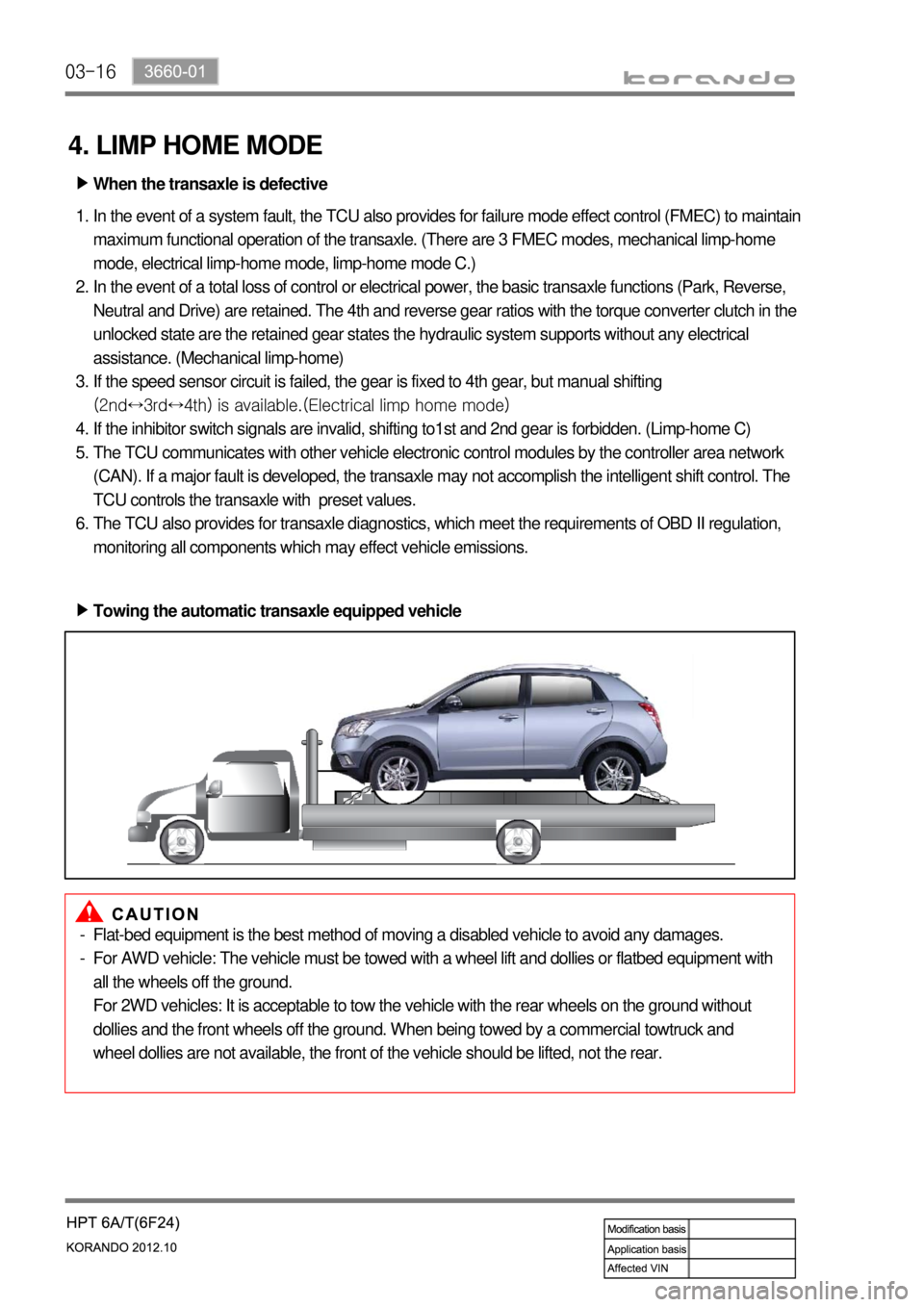

Towing the automatic transaxle equipped vehicle ▶

Flat-bed equipment is the best method of moving a disabled vehicle to avoid any damages.

For AWD vehicle: The vehicle must be towed with a wheel lift and dollies or flatbed equipment with

all the wheels off the ground.

For 2WD vehicles: It is acceptable to tow the vehicle with the rear wheels on the ground without

dollies and the front wheels off the ground. When being towed by a commercial towtruck and

wheel dollies are not available, the front of the vehicle should be lifted, not the rear. -

-

Page 877 of 1082

03-173660-01

5. TRANSAXLE ELECTRONIC CONTROL SYSTEM

1) General Information

The transmission control unit (TCU) and its input/output network control the following transmission

operations:

Shift timing

Line pressure

Clutch pressure (shift feel)

Torque converter clutch -

-

-

-

also uses these signals when determining transaxle operating strategy. Using all of these input signals,

the TCU can determine when the time and conditions are right for a shift, or when to apply or release the

torque converter clutch. It will also determine the pressure needed to optimise shift feel.

2) TCU (Transmission Control Unit)

The transaxle control unit (TCU) is mounted

under the driver's seat and controls the operation

of the transaxle.

Internal sensors and signals received across the

CAN bus in analogue and digital forms such as:

Transaxle input speed

Transaxle output speed

Accelerator pedal position

Gear selector position

Engine torque

Engine speed

Transaxle fluid temperature

Brake pedal status

Engine oil temperature

Engine coolant temperature

Ambient air temperature

Barometric pressure -

-

-

-

-

-

-

-

-

-

-

-

The TCU monitors all TCU inputs and outputs to confirm correct system operation. If a fault occurs the

TCU is able to perform default action and inform the driver of the problem through the instrument cluster

warning lights. Detailed information is available via trouble codes which can be read with the service tool.

Page 879 of 1082

03-193660-01

7. POWER TRANSFER

Power transfer modes are as follow:

Manual: 1st gear (position M)

Drive: 1st gear

Drive: 2nd gear

Drive: 3rd gear

Drive: 4th gear - limp home mode

Drive: 5th gear

Drive: 6th gear -

-

-

-

-

-

-

1) Overview

Name Component

C1 OVER DRIVE CLUTCH

C2 35R CLUTCH

B1 LOW & REVERSE BRAKE

B2 2/6 BRAKE

B3 UNDER DRIVE BRAKE

1F 1-2 ONE WAY CLUTCH

GEARCLUTCH BRAKE

OWC Gear Ratio

OD 35R 26 LR UD

1ST△*O O 4.212

2ND O O 2.637

3RD O O 1.800

4TH O O 1.386

5TH O O 1.000

6TH O O 0.772

REV O O 3.385

N.P O

(1) Gear Selection and Engagement Element

Operation when vehicle speed under 5kph *

Page 880 of 1082

03-20

2) Operation in Each Gear Position

(1) Neutral/Park

Lower & reverse brake (LR/B) op<008c00990088009b008c008b004702e700470076009d008c0099008b00990090009d008c0047004f00760056006b00500047008f009c0089004700930096008a0092008c008b004702e7004700740090008b008b0093008c0047004d00470099008c008800

9900470047004f00740070006b0047004d0047>

REAR) P/C locked

<007000950097009c009b0047009a008f0088008d009b004700990096009b0088009b008c008b004702e700470079008c008800990047009a009c00950047008e008c00880099004700990096009b0088009b008c008b004702e700470079008c0088009900

47009000950095008c00990047009700900095009000960095> reverse rotated → Rear outer

<009700900095009000960095004700990096009b0088009b008c008b004702e700470079008c008800990047008800950095009c0093009c009a0047008e008c00880099004700990096009b0088009b008c008b004702e70047006d009900960095009b00

47008800950095009c0093009c009a0047008e008c00880099> rotated → Front pinion

<00990096009b0088009b008c008b004702e70047006d009900960095009b0047009a009c00950047008e008c0088009900470099008c009d008c0099009a008c004700990096009b0088009b008c008b004702e70047007c0095008b008c0099008b009900

90009d008c0047004f007c0056006b00500047008f009c0089> reverse rotated

Input shaft rotated → Overdrive clutch (OD/C) retainer rotated

Input shaft rotated → 35R clutch rotated -

-

-

-

Power flow ▶

Description 35R C OD C 26 B UD B LR B O.W.C

P.N●

Page 885 of 1082

03-253660-01

(6) 4th Drive Gear (1.386)

Front sun gear locked, rear planetary gear and rear sun gear rotated

When the overdrive clutch (OD/C) operates, the carrier is engaged with sun gear in rear planetary

gear set and the power with 1:1 ratio flows to the front planetary gear locked with sun gear after

passing through the rear & front annulus gears.

At this moment, by operation of speed-reduced annulus gears and carrier in 1:1 ratio, the middle sun

gear in middle planetary gear set increases its speed without load (idling). -

-

-

Power flow ▶

Description 35R C OD C 26 B UD B LR B O.W.C

4th●●

Page 893 of 1082

03-8

1) Characteristics of WM6F1 M/T

Both Forward and Reverse gears use the helical gear and are made of high-strength material.

Drives the clutch with a concentric slave cylinder mounting bolt.

Shifting the transmission gears is performed through the remote control cable.

A pull type clutch is used for Reverse gear shifting.

Features triple/double/single synchronization. -

-

-

-

-

Clutch housing

Transmission case

Input shaft

Concentric slave cylinder

Shift lever

Selector lever

Wiring bracket

Neutral switch

Backup lamp switch

Reverse idle shaft mounting bolt 1.

2.

3.

4.

5.

6.

7.

8.

9.

10.Control guide bolt

Oil filler plug (for servicing)

Oil drain plug

Oil filler plug (for manufacturing)

Air breather

Detent pin (for securing shift fork)

Oil seal (RH)

Oil seal (LH)

Control housing 11.

12.

13.

14.

15.

16.

17.

18.

19.

Page 899 of 1082

04-30000-00

1. SPECIFICATION

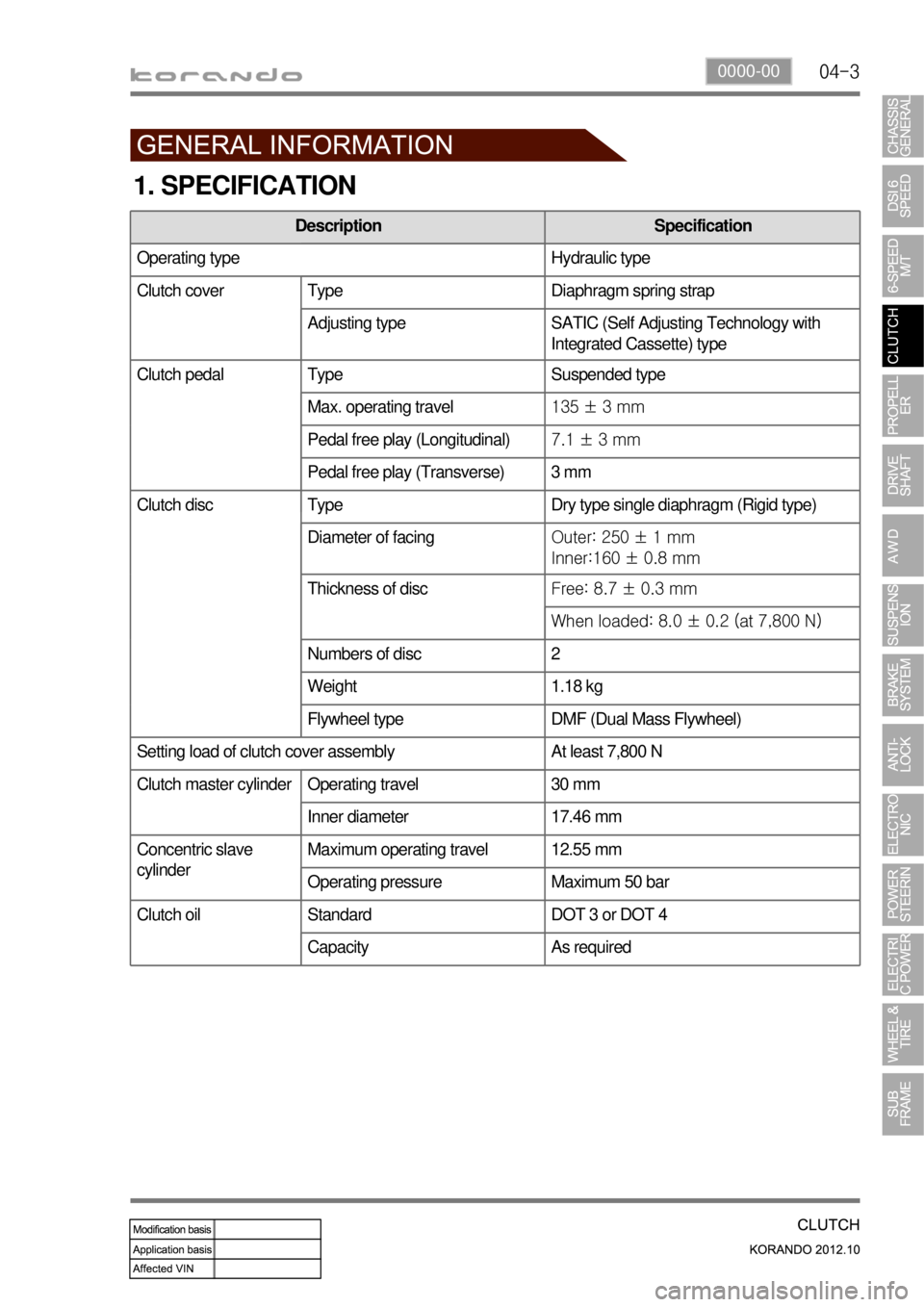

Description Specification

Operating type Hydraulic type

Clutch cover Type Diaphragm spring strap

Adjusting type SATIC (Self Adjusting Technology with

Integrated Cassette) type

Clutch pedal Type Suspended type

Max. operating travel135 ± 3 mm

Pedal free play (Longitudinal)7.1 ± 3 mm

Pedal free play (Transverse) 3 mm

Clutch disc Type Dry type single diaphragm (Rigid type)

Diameter of facingOuter: 250 ± 1 mm

Inner:160 ± 0.8 mm

Thickness of discFree: 8.7 ± 0.3 mm

When loaded: 8.0 ± 0.2 (at 7,800 N)

Numbers of disc 2

Weight 1.18 kg

Flywheel type DMF (Dual Mass Flywheel)

Setting load of clutch cover assembly At least 7,800 N

Clutch master cylinder Operating travel 30 mm

Inner diameter 17.46 mm

Concentric slave

cylinderMaximum operating travel 12.55 mm

Operating pressure Maximum 50 bar

Standard DOT 3 or DOT 4

Capacity As required

Clutch oil

Page 900 of 1082

04-4

2. TIGHTENING TORQUE

DescriptionTightening torque

Amount

Clutch housing boltUpper (17 mm) 85.0 to 100 Nm 2

Front (14 mm)54.0 Nm + 20°1

Rear (14 mm) 51.3 to 56.7 Nm 2

Lower (14 mm) 56.0 to 62.0 Nm 4

Pressure plate assembly bolt (Hexagon 6 mm) 21.0 to 27.0 Nm 6

Concentric slave cylinder bolt (Hexagon 5 mm) 10 to 16 Nm 3

Concentric slave cylinder oil pipe nut 24.5 to 28.4 Nm Remove the nut if it is

necessary. (Once

removed, apply the

Loctite on the thread

before installation.)

Master cylinder nut (12 mm) 7.8 to 17.6 Nm

Master cylinder oil pipe nut (10 mm) 14.7 to 17.6 Nm

Master cylinder push rod lock nut 8.8 to 13.7 Nm

Clutch oil chamber screw and bolt (10 mm) 3.9 to 7.8 Nm

Oil pipe nut (10 mm) 14.7 to 17.6 Nm

Clutch pedal mounting nut (12 mm) 7.8 to 17.6 Nm

Stopper bolt 16 to 22 Nm

Page 901 of 1082

04-50000-00

1. OVERVIEW

The hydraulic clutch transmits the force required to operate the clutch pedal to the concentric slave

cylinder fitted to the clutch housing as a hydraulic pressure.

(The hydraulic pressure is transmitted in the following order: Clutch pedal - Clutch master cylinder -

Clutch pipe - Clutch damper - Clutch pipe and hose - Concentric slave cylinder - Pressure plate -

Flywheel.)

If a driver depress the clutch pedal, the hydraulic pressure is generated in the master cylinder. It is

transmitted to the concentric slave cylinder through the pipe, resulting in the cylinder being forced out. At

this time, the clutch disc is forced against the cylinder by pushing the cover. This, in turn, remove the

flywheel from the pressure plate. As a consequence, the power from the engine will be cut off and the

gear change can be carried out.