wheel torque SSANGYONG KORANDO 2012 Owner's Guide

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2012, Model line: KORANDO, Model: SSANGYONG KORANDO 2012Pages: 1082, PDF Size: 96.1 MB

Page 989 of 1082

13-6

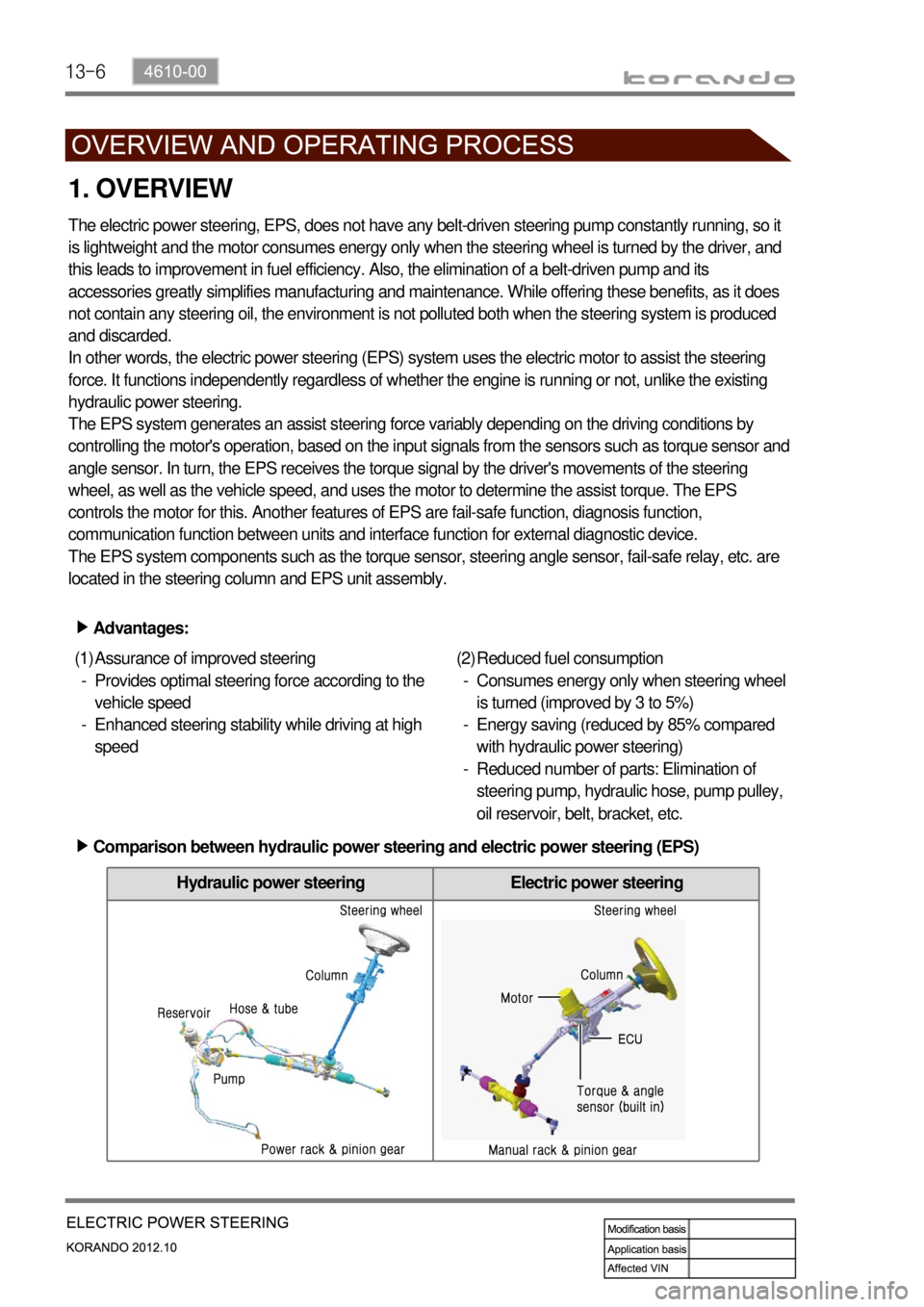

Hydraulic power steering Electric power steering

1. OVERVIEW

The electric power steering, EPS, does not have any belt-driven steering pump constantly running, so it

is lightweight and the motor consumes energy only when the steering wheel is turned by the driver, and

this leads to improvement in fuel efficiency. Also, the elimination of a belt-driven pump and its

accessories greatly simplifies manufacturing and maintenance. While offering these benefits, as it does

not contain any steering oil, the environment is not polluted both when the steering system is produced

and discarded.

In other words, the electric power steering (EPS) system uses the electric motor to assist the steering

force. It functions independently regardless of whether the engine is running or not, unlike the existing

hydraulic power steering.

The EPS system generates an assist steering force variably depending on the driving conditions by

controlling the motor's operation, based on the input signals from the sensors such as torque sensor and

angle sensor. In turn, the EPS receives the torque signal by the driver's movements of the steering

wheel, as well as the vehicle speed, and uses the motor to determine the assist torque. The EPS

controls the motor for this. Another features of EPS are fail-safe function, diagnosis function,

communication function between units and interface function for external diagnostic device.

The EPS system components such as the torque sensor, steering angle sensor, fail-safe relay, etc. are

located in the steering column and EPS unit assembly.

Advantages: ▶

Assurance of improved steering

Provides optimal steering force according to the

vehicle speed

Enhanced steering stability while driving at high

speed (1)

-

-Reduced fuel consumption

Consumes energy only when steering wheel

is turned (improved by 3 to 5%)

Energy saving (reduced by 85% compared

with hydraulic power steering)

Reduced number of parts: Elimination of

steering pump, hydraulic hose, pump pulley,

oil reservoir, belt, bracket, etc. (2)

-

-

-

Comparison between hydraulic power steering and electric power steering (EPS) ▶

Page 990 of 1082

13-74610-00

2. OPERATION

When the driver turns the steering wheel, a torque is generated and the torque sensor and the steering

angle sensor in the EPS system detect the rotation of the steering column to run the electric motor. At

this time, the worm gear connected to the motor drives the helical gear mounted to the steering column

to generate the assist torque for the steering column. This allows the driver to operate the steering wheel

easier.Output torque = 1) Steering force (manual torque) + 2) Assist torque

Page 996 of 1082

14-8

If weight is not equally distributed around the wheel, unbalance centrifugal force by the wheel rotation

produces vibration. As the centrifugal force is produced proportional to the square of the rotating speed,

the wheel weight should be balanced even at high speed. There are two types of the tire and wheel

balancing: static and dynamic. Abnormal vibration may also occur due to unbalanced rigidity or size of

tires.

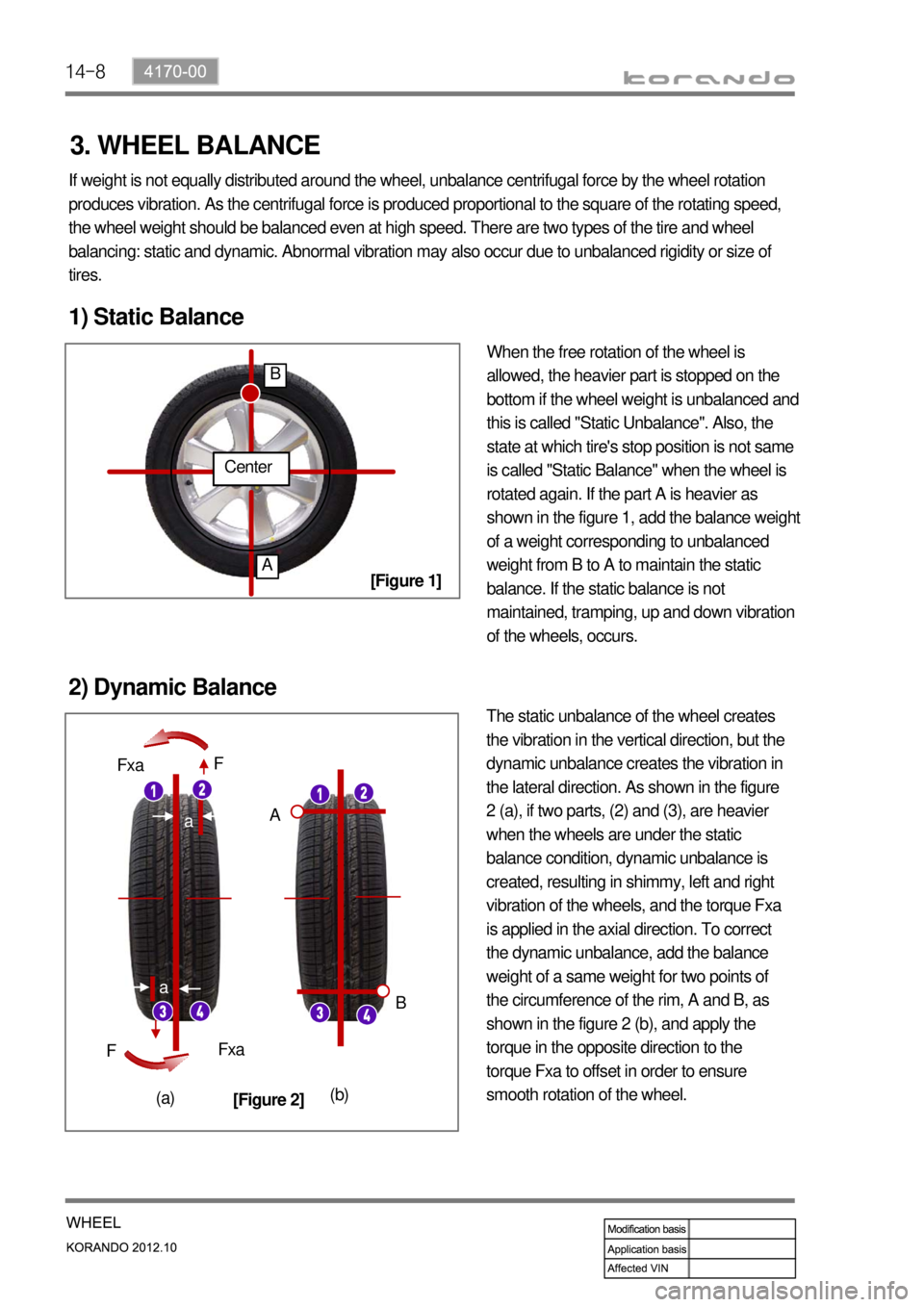

1) Static Balance

When the free rotation of the wheel is

allowed, the heavier part is stopped on the

bottom if the wheel weight is unbalanced and

this is called "Static Unbalance". Also, the

state at which tire's stop position is not same

is called "Static Balance" when the wheel is

rotated again. If the part A is heavier as

shown in the figure 1, add the balance weight

of a weight corresponding to unbalanced

weight from B to A to maintain the static

balance. If the static balance is not

maintained, tramping, up and down vibration

of the wheels, occurs.

2) Dynamic Balance

The static unbalance of the wheel creates

the vibration in the vertical direction, but the

dynamic unbalance creates the vibration in

the lateral direction. As shown in the figure

2 (a), if two parts, (2) and (3), are heavier

when the wheels are under the static

balance condition, dynamic unbalance is

created, resulting in shimmy, left and right

vibration of the wheels, and the torque Fxa

is applied in the axial direction. To correct

the dynamic unbalance, add the balance

weight of a same weight for two points of

the circumference of the rim, A and B, as

shown in the figure 2 (b), and apply the

torque in the opposite direction to the

torque Fxa to offset in order to ensure

smooth rotation of the wheel.

Center

A

B

a

a

Fxa

Fxa F

F

A

B

(a)(b)

[Figure 1]

[Figure 2]

3. WHEEL BALANCE