wheel torque SSANGYONG KORANDO 2012 Owner's Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2012, Model line: KORANDO, Model: SSANGYONG KORANDO 2012Pages: 1082, PDF Size: 96.1 MB

Page 850 of 1082

02-16

3) Shift Map Selection

The driver can manually select between normal (S) and winter modes (W) via the mode switch.

Depending on the transaxle temperature, uphill and downhill grades and altitude, shift maps will be

selected by the TCU to suit the driving conditions. The following maps are available.

Standard (Normal) Mode ▶

Normal Mode is selected when the lever is in the D position with the mode switch in the normal (S)

position and the transaxle is within normal temperature ranges. Shift schedule points are optimised for

fuel efficiency and general driving conditions.

Uphill and Downhill Mode ▶

In this mode, depending on the load of the vehicle, adaptive shift maps are selected to progressively

adjust the shift points and torque converter lock points.

Altitude Mode ▶

Shift points are automatically adjusted at higher altitudes to compensate for changes in engine torque

where the torque produced by the engine is greatly reduced by the effects of reduced barometric

pressure and temperature.

Winter (W) Mode ▶

When winter mode is selected, starting in second gear is facilitated and the WINTER mode indicator

light is switched ON. To prevent wheel spin on slippery surfaces, the transmission will not allow first gear

unless manually overridden.

Warm up Schedule ▶

<007c009a008c008b0047009b00a000970090008a00880093009300a00047009e008f008c00950047009b009900880095009a0088009f0093008c0047008d0093009c0090008b0047009b008c00940097008c00990088009b009c0099008c00470090009a00

470089008c00930096009e00470059005700b6006a0055>

The torque converter will not lock-up below 20°C to assist in transaxle warm-up.

Hot Mode ▶

<007b008f008c0047008f0096009b004700940096008b008c00470090009a0047009700990096008e0099008c009a009a0090009d008c009300a0004700880097009700930090008c008b00470089008c009b009e008c008c00950047009b008c0094009700

8c00990088009b009c0099008c009a00470096008d00470058>10° ~ 200°C. The torque

converter lock-up is increased to prevent heat generation by the torque converter.

Activation of the hot mode inhibits other transmission performance features including uphill and downhill

compensation and altitude compensation. Some degradation in shift feel may be experienced as the

torque converter is not unlocked during shifting.

Cruise Control Mode ▶

When cruise control is activated the engine ECU may request the transaxle to downshift under trailing

throttle conditions to increase engine braking.

Above 110℃the electrical radiator fans are switch ON

Above 130℃the engine torque will be reduced and the W light on the instrument cluster will flash

Above 200℃the transaxle will neutralise until the fluid tem

perature falls below 200°C as a final

protection.

Page 864 of 1082

03-4

2. GENERAL INFORMATION

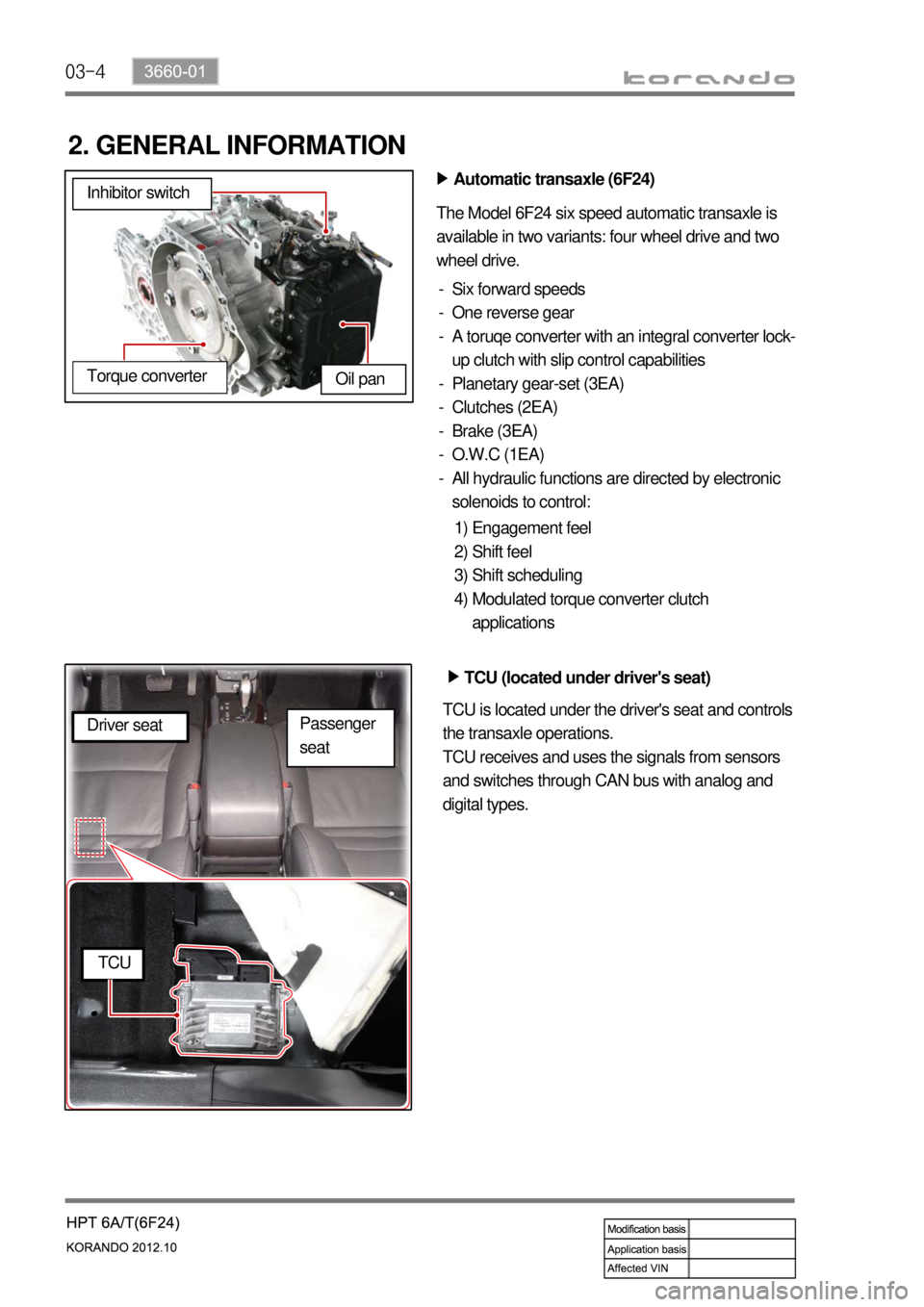

Automatic transaxle (6F24) ▶

The Model 6F24 six speed automatic transaxle is

available in two variants: four wheel drive and two

wheel drive.

Six forward speeds

One reverse gear

A toruqe converter with an integral converter lock-

up clutch with slip control capabilities

Planetary gear-set (3EA)

Clutches (2EA)

Brake (3EA)

O.W.C (1EA)

All hydraulic functions are directed by electronic

solenoids to control: -

-

-

-

-

-

-

-

Engagement feel

Shift feel

Shift scheduling

Modulated torque converter clutch

applications 1)

2)

3)

4) Inhibitor switch

Oil pan

Torque converter

TCU (located under driver's seat) ▶

TCU is located under the driver's seat and controls

the transaxle operations.

TCU receives and uses the signals from sensors

and switches through CAN bus with analog and

digital types. Driver seat

TCU

Passenger

seat

Page 876 of 1082

03-16

4. LIMP HOME MODE

When the transaxle is defective ▶

In the event of a system fault, the TCU also provides for failure mode effect control (FMEC) to maintain

maximum functional operation of the transaxle. (There are 3 FMEC modes, mechanical limp-home

mode, electrical limp-home mode, limp-home mode C.)

In the event of a total loss of control or electrical power, the basic transaxle functions (Park, Reverse,

Neutral and Drive) are retained. The 4th and reverse gear ratios with the torque converter clutch in the

unlocked state are the retained gear states the hydraulic system supports without any electrical

assistance. (Mechanical limp-home)

If the speed sensor circuit is failed, the gear is fixed to 4th gear, but manual shifting

<004f00590095008b02e9005a0099008b02e9005b009b008f005000470090009a00470088009d008800900093008800890093008c0055004f006c0093008c008a009b00990090008a00880093004700930090009400970047008f00960094008c0047009400

96008b008c0050>

If the inhibitor switch signals are invalid, shifting to1st and 2nd gear is forbidden. (Limp-home C)

The TCU communicates with other vehicle electronic control modules by the controller area network

(CAN). If a major fault is developed, the transaxle may not accomplish the intelligent shift control. The

TCU controls the transaxle with preset values.

The TCU also provides for transaxle diagnostics, which meet the requirements of OBD II regulation,

monitoring all components which may effect vehicle emissions. 1.

2.

3.

4.

5.

6.

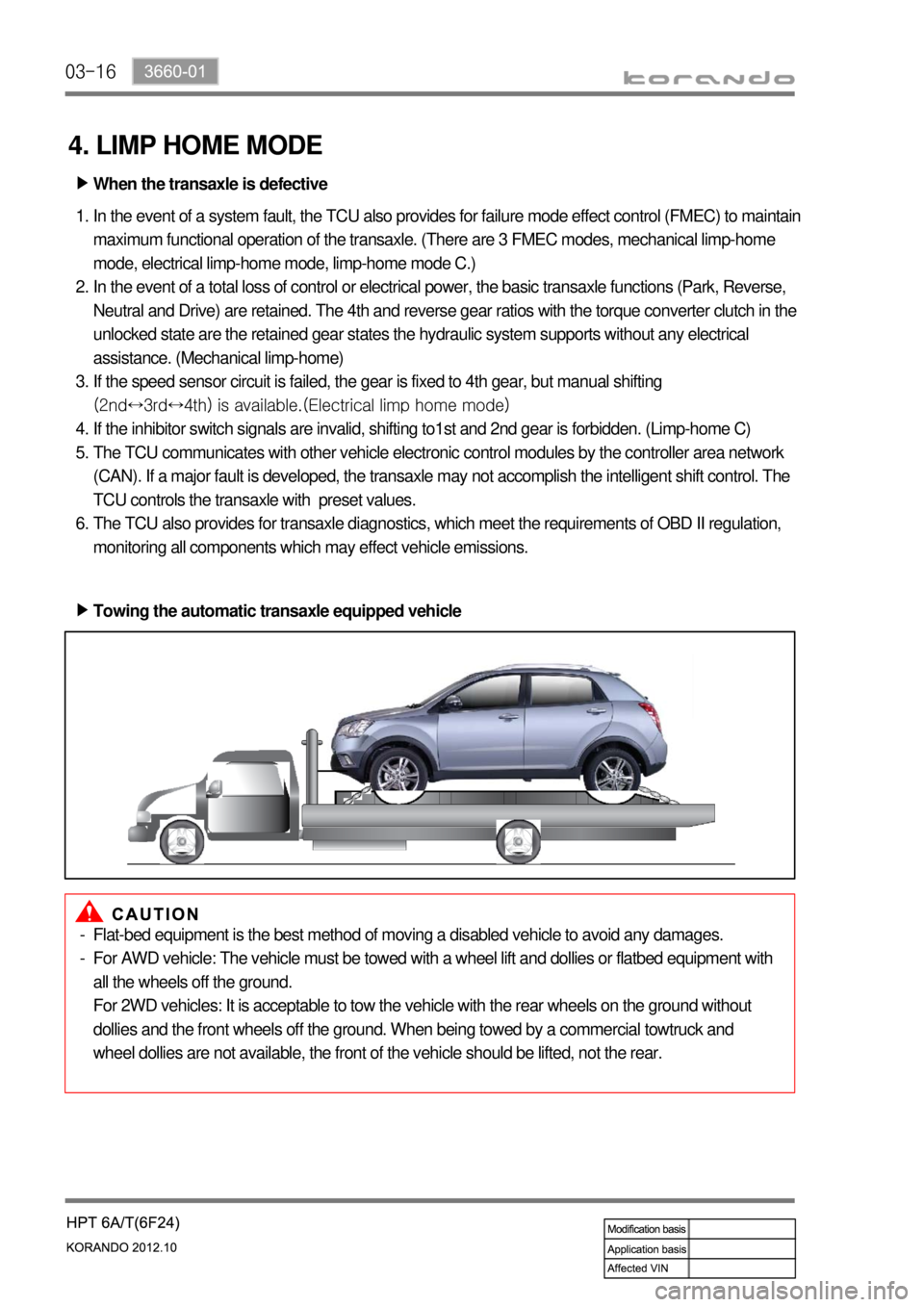

Towing the automatic transaxle equipped vehicle ▶

Flat-bed equipment is the best method of moving a disabled vehicle to avoid any damages.

For AWD vehicle: The vehicle must be towed with a wheel lift and dollies or flatbed equipment with

all the wheels off the ground.

For 2WD vehicles: It is acceptable to tow the vehicle with the rear wheels on the ground without

dollies and the front wheels off the ground. When being towed by a commercial towtruck and

wheel dollies are not available, the front of the vehicle should be lifted, not the rear. -

-

Page 905 of 1082

04-90000-00

3. DUAL MASS FLYWHEEL (DMF)

The dual mass flywheel (DMF) is of having a mass divided into two halves.

While one mass is connected to the engine crankshaft, which is affected by the mass moment of inertia

of the engine, the other mass is affected by one of the transmission.

The divided dual masses are connected to the coil spring and damping system internally.

The DMF has the following benefits: ▶

Reducing fuel consumption by lowering engine speed

Reducing rattling noise and vehicle vibration in all driving ranges

Reducing synchronization wear

Facilitating gear change

Protecting power train parts by preventing excessive load from being delivered -

-

-

-

-

Primary flywheel

Secondary flywheel

Arc damper spring

Torque limiter

Ring gear 1.

2.

3.

4.

5.

Page 911 of 1082

06-54110-01

2. TORQUE STEER

Torque steer is a condition in which a vehicle pulls to either side because of an inequality of traction

between the left and right driving wheels when a large torque is applied to the front wheel of a FWD or

4WD.

Especially for a FWD vehicle, this mechanical condition can cause the steering effect because of the

output torque (rotational force) produced by the gyroscope.

This rotational force is due to the difference in distance between the left/right front wheels and the

transaxle which leads to the change of the shaft bending angle.

To prevent this, the intermediate shaft, called Intermediate shaft, is employed on each side so that the

bending angle and the length are kept constant.

A gyroscope is a device for measuring or maintaining orientation, based on the principles of angular

momentum. In essence, a mechanical gyroscope is a spinning wheel or disk whose axle is free to

take any orientation. Although this orientation does not remain fixed, it changes in response to an

external torque much less and in a different direction than it would without the large angular

momentum associated with the disk's high rate of spin and moment of inertia. Since external torque

is minimized by mounting the device in gimbals, its orientation remains nearly fixed, regardless of

any motion of the platform on which it is mounted.

Page 915 of 1082

07-50000-00

2. SYSTEM LAYOUT

1) Components

(1) PTU (Power Transfer Unit)

<007b008f008c004700970096009e008c00990047009b009900880095009a008d008c00990047009c00950090009b0047009000950047009b008f008c0047008d009900960095009b0047009e008f008c008c00930047008b00990090009d008c0047009400

96008b008c00930047008a008f00880095008e008c009a0047>the angle of engine torque to 90°

and transfer it to E-coupling to distribute the torque to rear wheels.

(2) E-Coupling (Electronic Coupling)

E-Coupling transfer the engine torque from PTU to rear axle and controls to distribute it between front

wheels and rear wheels.

(3) E-Coupling Control Unit (ECU)

E-Coupling controls the current (clutch engagement force) of EMCD in E-Coupling according to CAN

signals (wheel speed, engine torque, pedal position, ABS/ESP signals).

* EMCD: Electro-Magnetic Control Device PTU assemblyE-coupling control unit

(located on the floor under driver seat)E-coupling

Page 929 of 1082

09-94850-00

Rear disc brake ▶

Caliper

Brake hose

Brake disc

KnuckleWheel disc

Brake hub

Brake disc

Fastener Tightening torque Remark

Brake pad guide bolt 25.5 ~ 30.4Nm 14 mm x 2EA

Brake caliper mounting bolt 52.9 ~ 63.7Nm 17 mm x 2EA

Brake hose bolt 19.6 ~ 29.4Nm 12mm

Brake hose bracket mounting bolt 9.8 ~ 12.8Nm 12mm

Air breather screw 8.8 ~ 10.8Nm -

1) Tightening torque

Page 955 of 1082

11-30000-00

1. SPECIFICATION

1) Specification of Active Wheel Sensor

Description Specification

Supplying voltage DC 12 V

Output current (at 2.75 km/h of vehicle speed) 7 mA (Lo) ~ 14 mA (Hi) +20%/-16%

Tightening torque Front: 7.8 to 11.8 Nm

Rear: 7.8 to 11.8 Nm

Operating temperature-40 ~ 150 ℃

Operating frequency 1 ~ 2,500 Hz

UnitDescription

ABS ESP

HECU Clock frequency: 32 MHz Clock frequency: 50 MHz

Memory: 128 KB Memory: 512 KB

Switch orifice Switch orifice

Wheel speed sensor Active type Active type

Steering wheel angle

sensorNone Max. detection angle speed:

1500 °/Sec

Operating voltage: 9 to 12 V

Sensor cluster None Yaw rate sensor + lateral G sensor +

longitudinal G sensor (4WD)

Longitudinal G sensor 4WD only None

Pressure sensor None HECU integrated

Page 981 of 1082

12-4

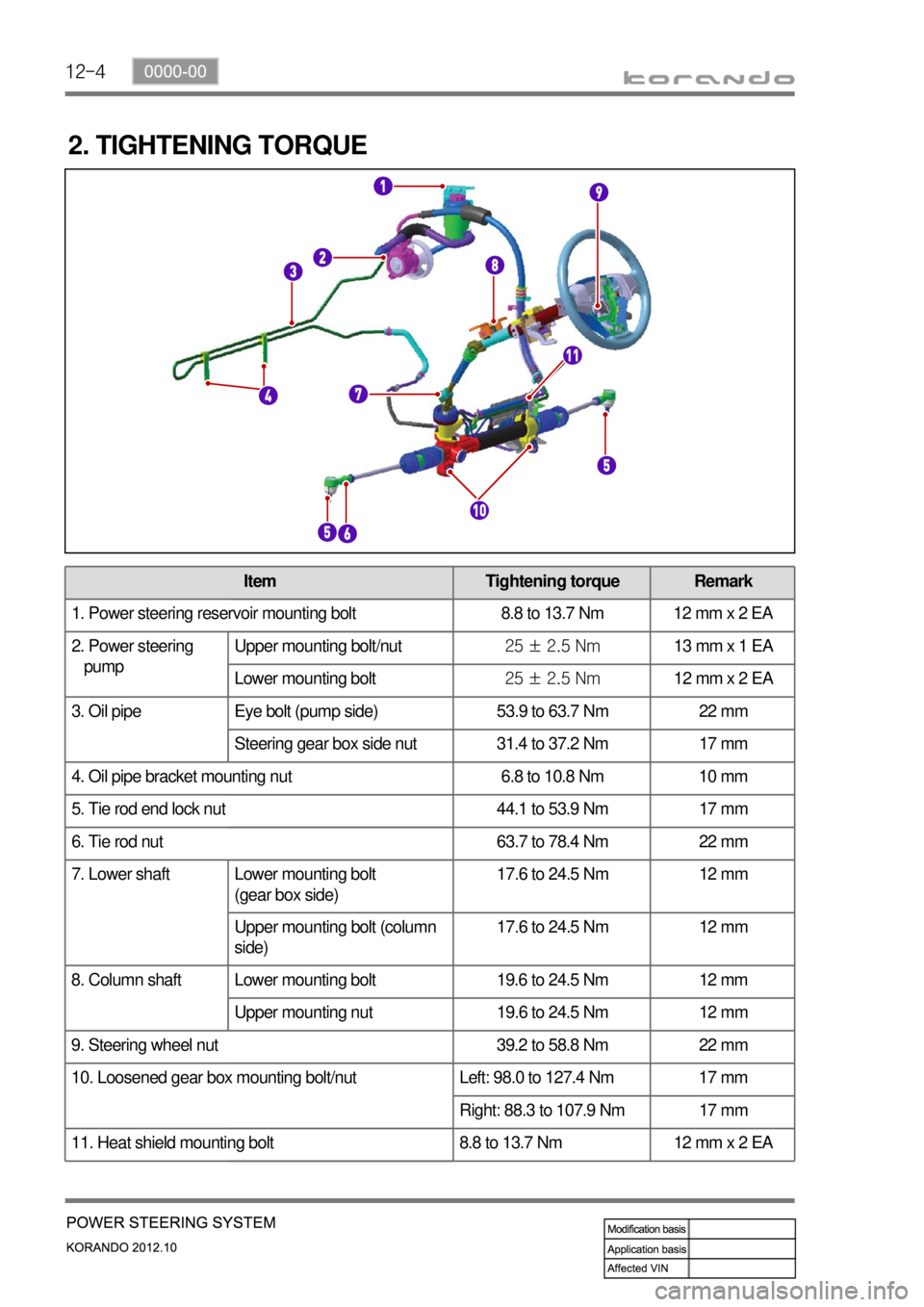

2. TIGHTENING TORQUE

Item Tightening torque Remark

1. Power steering reservoir mounting bolt 8.8 to 13.7 Nm 12 mm x 2 EA

2. Power steering

pumpUpper mounting bolt/nut25 ± 2.5 Nm13 mm x 1 EA

Lower mounting bolt25 ± 2.5 Nm12 mm x 2 EA

3. Oil pipe Eye bolt (pump side) 53.9 to 63.7 Nm 22 mm

Steering gear box side nut 31.4 to 37.2 Nm 17 mm

4. Oil pipe bracket mounting nut 6.8 to 10.8 Nm 10 mm

5. Tie rod end lock nut 44.1 to 53.9 Nm 17 mm

6. Tie rod nut 63.7 to 78.4 Nm 22 mm

7. Lower shaft Lower mounting bolt

(gear box side)17.6 to 24.5 Nm 12 mm

Upper mounting bolt (column

side)17.6 to 24.5 Nm 12 mm

8. Column shaft Lower mounting bolt 19.6 to 24.5 Nm 12 mm

Upper mounting nut 19.6 to 24.5 Nm 12 mm

9. Steering wheel nut 39.2 to 58.8 Nm 22 mm

10. Loosened gear box mounting bolt/nut Left: 98.0 to 127.4 Nm 17 mm

Right: 88.3 to 107.9 Nm 17 mm

11. Heat shield mounting bolt 8.8 to 13.7 Nm 12 mm x 2 EA

Page 986 of 1082

13-34610-00

1. SPECIFICATION

Unit Description Specification

System operationOperating type Motor driven power steering system

Operating temperature- 40°C to 80°C

Rated voltage 12 V

Rated current 85 A

Operating voltageNetwork 8 to 16 V

C-EPS ECU 8 to 16 V

Full Performance 10 to 16 V

MotorType 3-Phase BLAC (Brushless AC)

Rated current/voltage 85 A / 12 V (at idle 0.5 A)

Position sensor type Hall sensor type

Torque & angle sensorType Non-contact type

Steering columnOperating type Manual tilting & telescoping

Lower shaftType Sliding (Ball slip) type

Steering gearGear ratio 46.94 mm/rev

Rack stroke 146 mm

Maximum steering angleInner wheel39°

Outer wheel31.24°