fuel system SSANGYONG KORANDO 2012 Workshop Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2012, Model line: KORANDO, Model: SSANGYONG KORANDO 2012Pages: 1082, PDF Size: 96.1 MB

Page 523 of 1082

14-170000-00

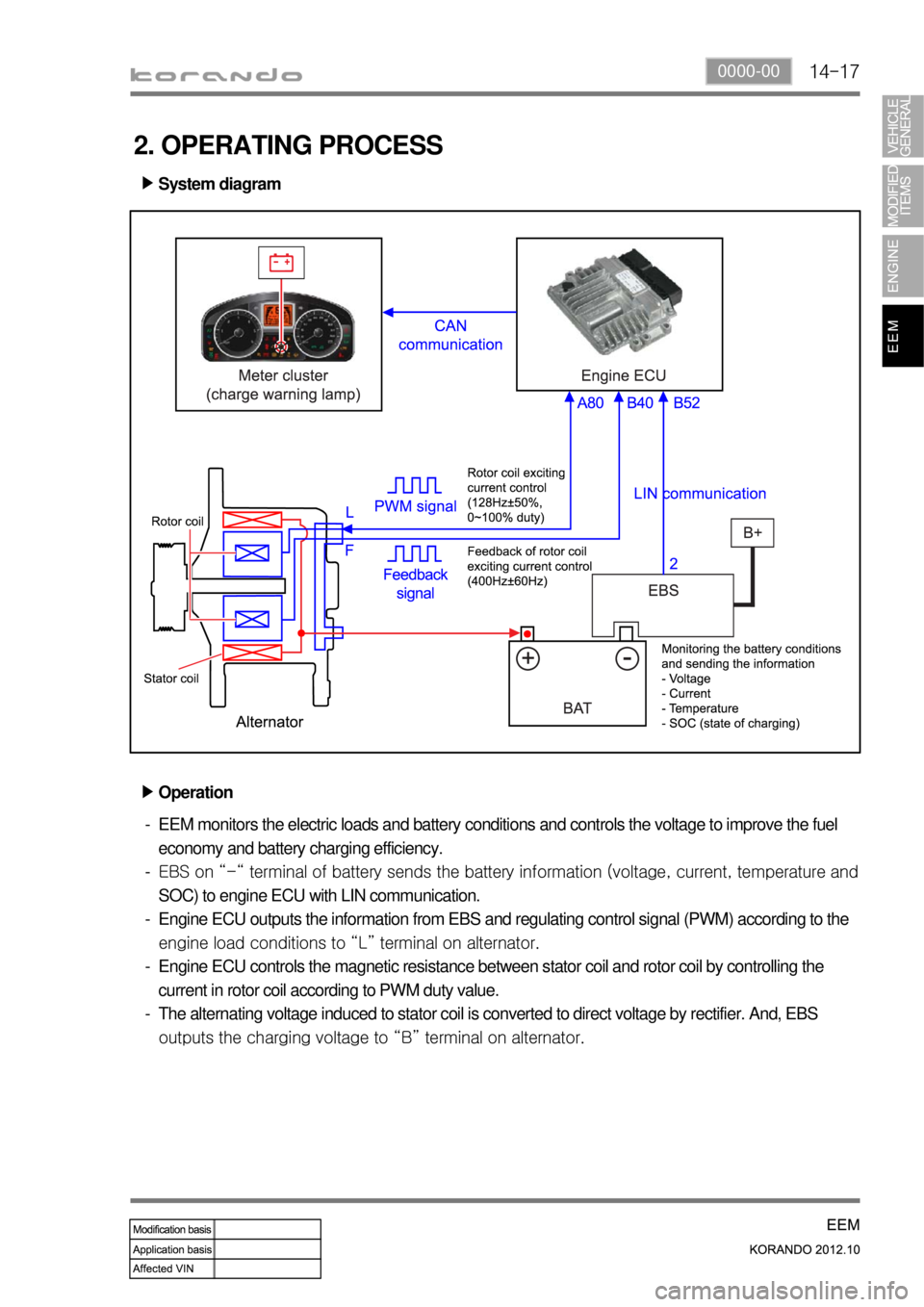

2. OPERATING PROCESS

System diagram ▶

Operation ▶

EEM monitors the electric loads and battery conditions and controls the voltage to improve the fuel

economy and battery charging efficiency.

EBS on “-“ terminal of battery sends the battery information (voltage, current, tem

perature and

SOC) to engine ECU with LIN communication.

Engine ECU outputs the information from EBS and regulating control signal (PWM) according to the

<008c0095008e00900095008c0047009300960088008b0047008a00960095008b0090009b009000960095009a0047009b0096004702c8007302c90047009b008c009900940090009500880093004700960095004700880093009b008c009900950088009b00

9600990055>

Engine ECU controls the magnetic resistance between stator coil and rotor coil by controlling the

current in rotor coil according to PWM duty value.

The alternating voltage induced to stator coil is converted to direct voltage by rectifier. And, EBS

<0096009c009b0097009c009b009a0047009b008f008c0047008a008f00880099008e00900095008e0047009d00960093009b0088008e008c0047009b0096004702c8006902c90047009b008c00990094009000950088009300470096009500470088009300

9b008c009900950088009b009600990055> -

-

-

-

-

Page 669 of 1082

05-6

SVC class

Previous Current

Changed from figure type to bar graph type.

6) Average fuel economy reset and calibrated automatically when

refilling

7) Instant fuel consumption display changed

8) Pre-warning indicator for engine overheat removed

Both SVC and STD class

Previous Current

Reset by user Reset by user and automatic reset when refilling

9) TDMS logic changed

SVC class

Current

TDMS (Tier Direction Management System) is not displayed when EPS warning lamp comes on.

SVC class STD class

Pre-warning indicator for engine overheat is removed.

EPS warning lampTDMS displayLCD not displayed

EPS warning lamp

comes onLCD screen is not

displayed.

Page 675 of 1082

05-12

Low fuel level warning lamp ▶

Warning lamp

(amber)

Engine overheat warning lamp ▶

Warning lamp

(red)

Door ajar ▶

Warning lamp

(red)

Seat belt reminder ▶

Warning lamp

(red)

Air bag ▶

Warning lamp

(red)

This lamp comes on if the fuel level is approx. 10 ℓ or below.

However, the fuel level may change slight depending on vehicle

condition, inclination of the road, etc. Also, it blinks if there is a short or

open circuit between the fuel level sensor and cluster.

<007e008f008c00950047009b008f008c0047008a00960096009300880095009b0047009b008c00940097008c00990088009b009c0099008c00470090009a0047005800590057020b006a0047009600990047008f0090008e008f008c009900530047009b00

8f0090009a0047009300880094009700470089009300900095>ks at an

interval of 1 second, a message is displayed, the warning sounds once

through the speaker and the buzzer sounds at an interval of 0.5 seconds.

This lamp comes on when any door is open or not closed completely.

(both STD and SVC class)

This lamp comes on when the ignition switch is pressed ON.

It keeps coming on if the driver's seat belt is not fastened.

This lamp comes on when the ignition switch is pressed to the ON mode.

Then, it goes off if the system is normal.

If this lamp stays on while driving, it means that the air bag system is faulty.

Page 711 of 1082

05-48

Pin No.Message

Operating condition

Domestic Export

Cruise control This message comes on when the ECO cruise mode

is deactivated.

EMSThis message comes on when the engine is faulty.

LampThis message comes on when the tail lamps are ON

with the ignition in the "OFF" or "ACC" position.

SUNROOF

SYSTEMFor the vehicle with SKM, this message comes on

when the sunroof is open with the ignition in the "OFF"

or "ACC" position. For the vehicle without SKM, this

comes on when the sunroof is open with the ignition in

the "OFF" position and the key removed.

Low fuel level This message comes on when the remaining fuel is

insufficient.

ESP checkThis message comes on when the ESP system is

faulty.

ABS check This message comes on when the ABS system is

faulty.

Engine oil level

checkThis message comes on when the engine oil level is

low. Pin No. Message Operating condition

Page 843 of 1082

02-93680-01

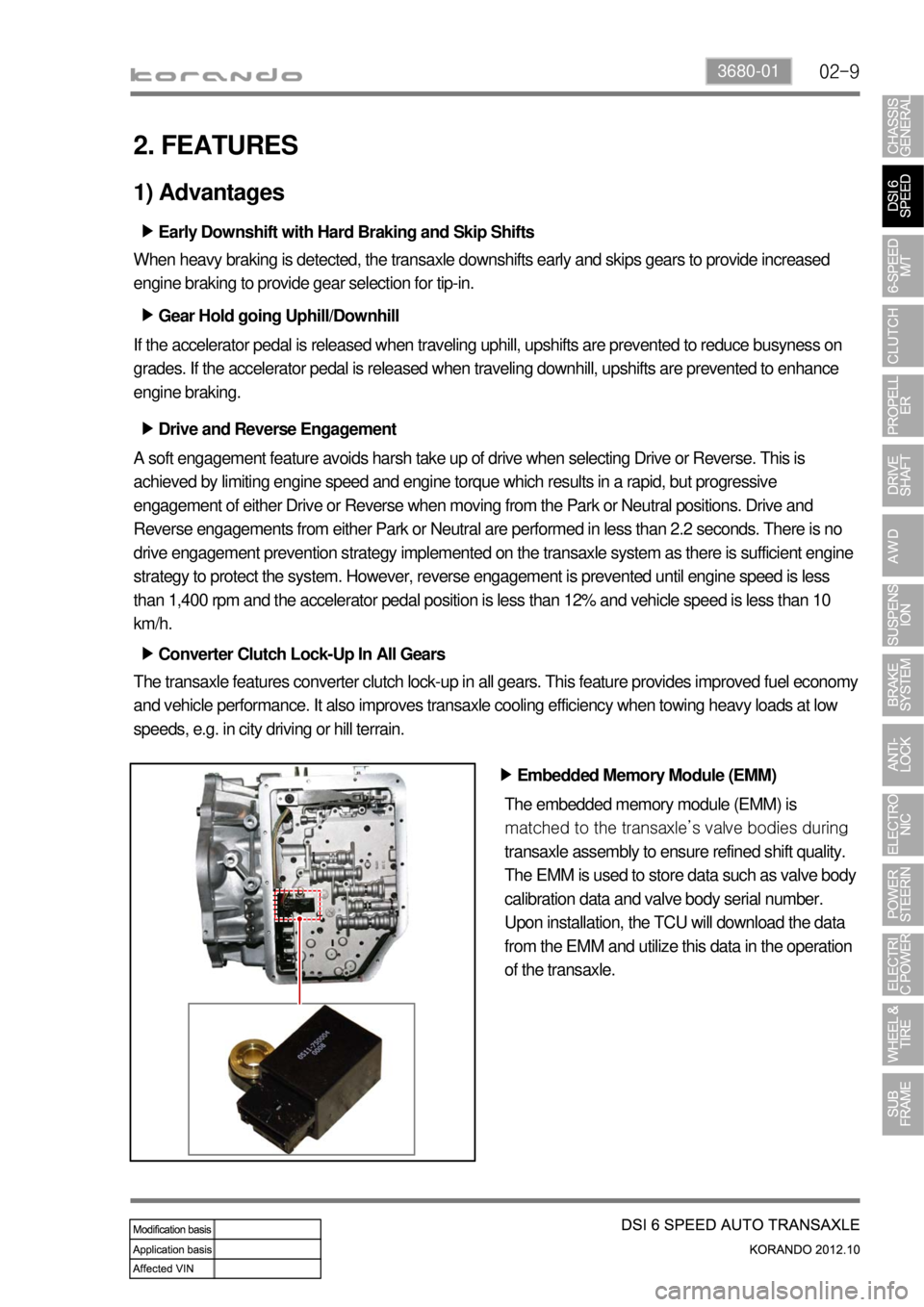

2. FEATURES

1) Advantages

Early Downshift with Hard Braking and Skip Shifts ▶

When heavy braking is detected, the transaxle downshifts early and skips gears to provide increased

engine braking to provide gear selection for tip-in.

Gear Hold going Uphill/Downhill ▶

If the accelerator pedal is released when traveling uphill, upshifts are prevented to reduce busyness on

grades. If the accelerator pedal is released when traveling downhill, upshifts are prevented to enhance

engine braking.

Drive and Reverse Engagement ▶

A soft engagement feature avoids harsh take up of drive when selecting Drive or Reverse. This is

achieved by limiting engine speed and engine torque which results in a rapid, but progressive

engagement of either Drive or Reverse when moving from the Park or Neutral positions. Drive and

Reverse engagements from either Park or Neutral are performed in less than 2.2 seconds. There is no

drive engagement prevention strategy implemented on the transaxle system as there is sufficient engine

strategy to protect the system. However, reverse engagement is prevented until engine speed is less

than 1,400 rpm and the accelerator pedal position is less than 12% and vehicle speed is less than 10

km/h.

Converter Clutch Lock-Up In All Gears ▶

The transaxle features converter clutch lock-up in all gears. This feature provides improved fuel economy

and vehicle performance. It also improves transaxle cooling efficiency when towing heavy loads at low

speeds, e.g. in city driving or hill terrain.

Embedded Memory Module (EMM) ▶

The embedded memory module (EMM) is

matched to the transaxle’s valve bodies during

transaxle assembly to ensure refined shift quality.

The EMM is used to store data such as valve body

calibration data and valve body serial number.

Upon installation, the TCU will download the data

from the EMM and utilize this data in the operation

of the transaxle.

Page 844 of 1082

02-10

2) Transaxle Cooling

The transaxle cooling system ensures rapid warm-up and constant operating temperature resulting in

reduced fuel consumption and refined shift quality.

It also includes a cooler by-pass within the hydraulic system to allow sufficient lubrication to the transaxle

drivetrain in the event of a blockage in the transaxle cooler.

3) Shift Strategy

Gear Change ▶

Transaxle gear change is controlled by the

TCU. The TCU receives inputs from various

engine and vehicle sensors to select shift

schedules and to control the shift feel and

torque converter clutch (TCC) operation at each

gear change.

Coast down ▶

Coast down down shifts occur at 0% pedal

when the vehicle is coasting down to a stop.

Torque Demand ▶

Torque demand down shifts occur

(automatically) when the driver demand for

torque is greater than the engine can provide at

that gear ratio. If applied, the transaxle will

disengage the TCC to provide added

acceleration.

Page 873 of 1082

03-133660-01

2) Transaxle Cooling

The transaxle cooling system ensures rapid warm-up and constant operating temperature resulting in

reduced fuel consumption and refined shift quality.

It also includes a cooler by-pass within the hydraulic system to allow sufficient lubrication to the transaxle

drivetrain in the event of a blockage in the transaxle cooler.

3) Shift Strategy

Gear Change ▶

Transaxle gear change is controlled by the

TCU. The TCU receives inputs from various

engine and vehicle sensors to select shift

schedules and to control the shift feel and

torque converter clutch (TCC) operation at each

gear change.

Coast down ▶

Coast down down shifts occur at 0% pedal

when the vehicle is coasting down to a stop.

Torque Demand ▶

Torque demand down shifts occur

(automatically) when the driver demand for

torque is greater than the engine can provide at

that gear ratio. If applied, the transaxle will

disengage the TCC to provide added

acceleration.

Page 905 of 1082

04-90000-00

3. DUAL MASS FLYWHEEL (DMF)

The dual mass flywheel (DMF) is of having a mass divided into two halves.

While one mass is connected to the engine crankshaft, which is affected by the mass moment of inertia

of the engine, the other mass is affected by one of the transmission.

The divided dual masses are connected to the coil spring and damping system internally.

The DMF has the following benefits: ▶

Reducing fuel consumption by lowering engine speed

Reducing rattling noise and vehicle vibration in all driving ranges

Reducing synchronization wear

Facilitating gear change

Protecting power train parts by preventing excessive load from being delivered -

-

-

-

-

Primary flywheel

Secondary flywheel

Arc damper spring

Torque limiter

Ring gear 1.

2.

3.

4.

5.

Page 989 of 1082

13-6

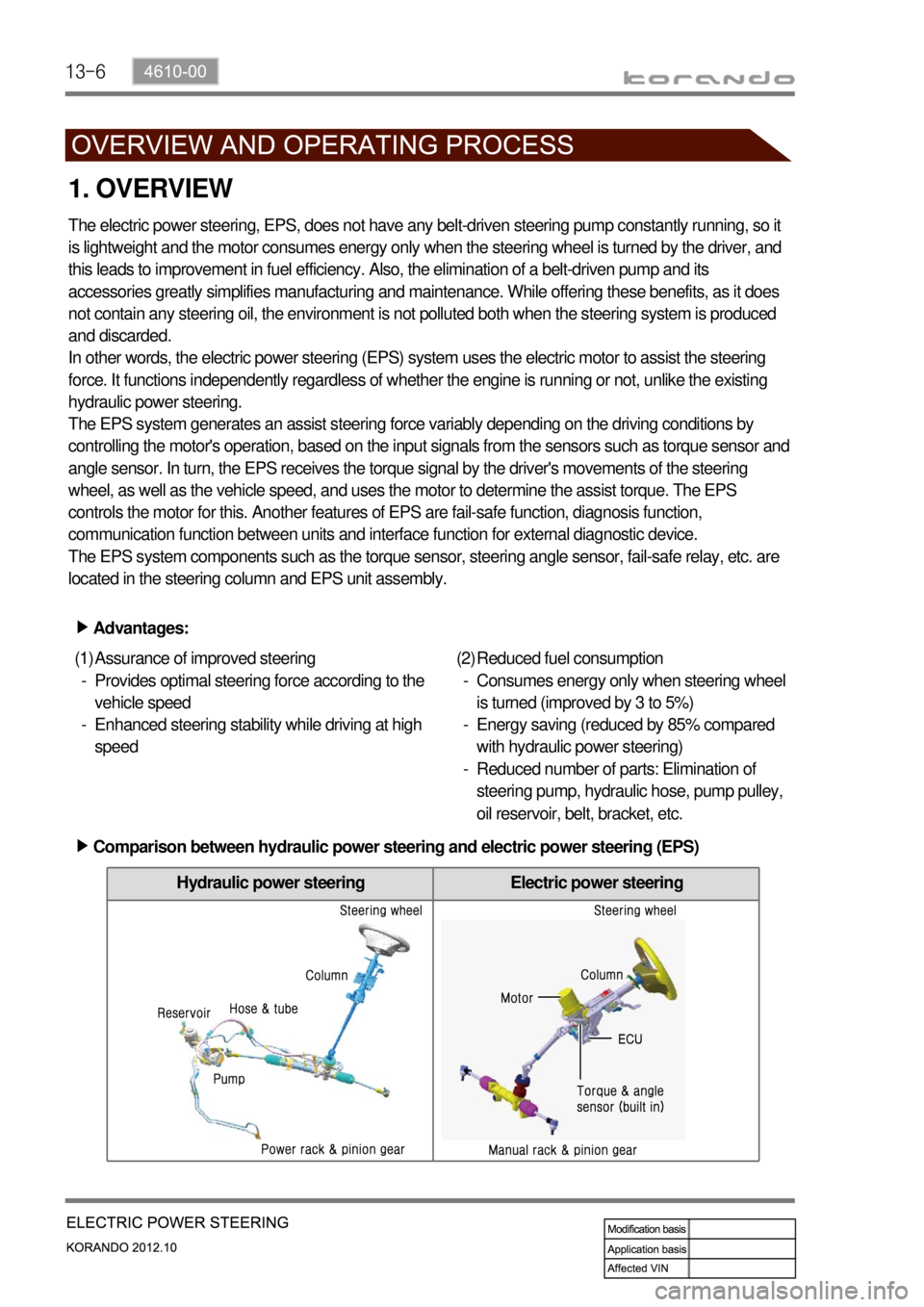

Hydraulic power steering Electric power steering

1. OVERVIEW

The electric power steering, EPS, does not have any belt-driven steering pump constantly running, so it

is lightweight and the motor consumes energy only when the steering wheel is turned by the driver, and

this leads to improvement in fuel efficiency. Also, the elimination of a belt-driven pump and its

accessories greatly simplifies manufacturing and maintenance. While offering these benefits, as it does

not contain any steering oil, the environment is not polluted both when the steering system is produced

and discarded.

In other words, the electric power steering (EPS) system uses the electric motor to assist the steering

force. It functions independently regardless of whether the engine is running or not, unlike the existing

hydraulic power steering.

The EPS system generates an assist steering force variably depending on the driving conditions by

controlling the motor's operation, based on the input signals from the sensors such as torque sensor and

angle sensor. In turn, the EPS receives the torque signal by the driver's movements of the steering

wheel, as well as the vehicle speed, and uses the motor to determine the assist torque. The EPS

controls the motor for this. Another features of EPS are fail-safe function, diagnosis function,

communication function between units and interface function for external diagnostic device.

The EPS system components such as the torque sensor, steering angle sensor, fail-safe relay, etc. are

located in the steering column and EPS unit assembly.

Advantages: ▶

Assurance of improved steering

Provides optimal steering force according to the

vehicle speed

Enhanced steering stability while driving at high

speed (1)

-

-Reduced fuel consumption

Consumes energy only when steering wheel

is turned (improved by 3 to 5%)

Energy saving (reduced by 85% compared

with hydraulic power steering)

Reduced number of parts: Elimination of

steering pump, hydraulic hose, pump pulley,

oil reservoir, belt, bracket, etc. (2)

-

-

-

Comparison between hydraulic power steering and electric power steering (EPS) ▶