SSANGYONG KORANDO 2012 Service Manual

KORANDO 2012

SSANGYONG

SSANGYONG

https://www.carmanualsonline.info/img/67/57504/w960_57504-0.png

SSANGYONG KORANDO 2012 Service Manual

Trending: inflation pressure, sunroof, hood open, catalytic converter, coolant capacity, ad blue, Gasoline

Page 891 of 1082

03-6

3. MAJOR CHANGES IN MANUAL TRANSAXLE

1) Gear Shift Lever and Cable

Gear shift lever assembly

Old New

The gear shift lever bracket has been changed to adopt the premium console.

Gear shift cable assembly

Old New

The connection and socket to lever has been changed.

Gear shift lever

bracket

Page 892 of 1082

03-73190-01

Front view Rear view

1. OVERVIEW

This vehicle is equipped with WM6F1 M/T (Manual Transmission). This transmission is integrated with an

axle and designed to maximize the driving performance by optimizing the gear ratio according to the

engine torque.

WM6F1 M/T assembly

Page 893 of 1082

03-8

1) Characteristics of WM6F1 M/T

Both Forward and Reverse gears use the helical gear and are made of high-strength material.

Drives the clutch with a concentric slave cylinder mounting bolt.

Shifting the transmission gears is performed through the remote control cable.

A pull type clutch is used for Reverse gear shifting.

Features triple/double/single synchronization. -

-

-

-

-

Clutch housing

Transmission case

Input shaft

Concentric slave cylinder

Shift lever

Selector lever

Wiring bracket

Neutral switch

Backup lamp switch

Reverse idle shaft mounting bolt 1.

2.

3.

4.

5.

6.

7.

8.

9.

10.Control guide bolt

Oil filler plug (for servicing)

Oil drain plug

Oil filler plug (for manufacturing)

Air breather

Detent pin (for securing shift fork)

Oil seal (RH)

Oil seal (LH)

Control housing 11.

12.

13.

14.

15.

16.

17.

18.

19.

Page 894 of 1082

03-93190-01

2) Internal Configuration

Page 895 of 1082

03-10

3) Schematic Diagram

4) Gear Ratio

ItemSpeed gear Final gear

Total gear

ratio Number of

teethGear ratioNumber of

teethGear ratio

Input Output Input Output

1st 13 46 3.538

13 59 4.53816.059

2nd 22 42 1.909 8.664

3rd 28 33 1.179 5.349

4th 43 35 0.814 3.694

5th 38 28 0.737

15 59 3.9332.898

6th 43 27 0.628 2.47

Reverse13 17

3.91 15.377

24 36

One input gear is used for 1st forward driving and back-up driving.

One input gear is used for 4th and 6th forward driving. -

-

Page 896 of 1082

03-113190-01

2. POWER FLOWS

1st speed gear

2nd speed gear3rd speed gear

Sectional view of WM6F1 M/T

Page 897 of 1082

03-12

Reverse gear

4th speed gear5th speed gear

6th speed gear

Page 898 of 1082

03-133190-01

3. SHIFTING MECHANISM

Control shaft Shift lever

Selector lever

5th/6th speed gear shift lug

Reverse gear shift fork

5th/6th speed gear shift fork

5th/6th speed gear & Reverse

shift rail

1st/2nd speed gear shift fork

3rd/4th speed gear shift fork

1st/2nd, 3rd/4th speed gear shift rail 3rd/4th speed

gear shift lug

Page 899 of 1082

04-30000-00

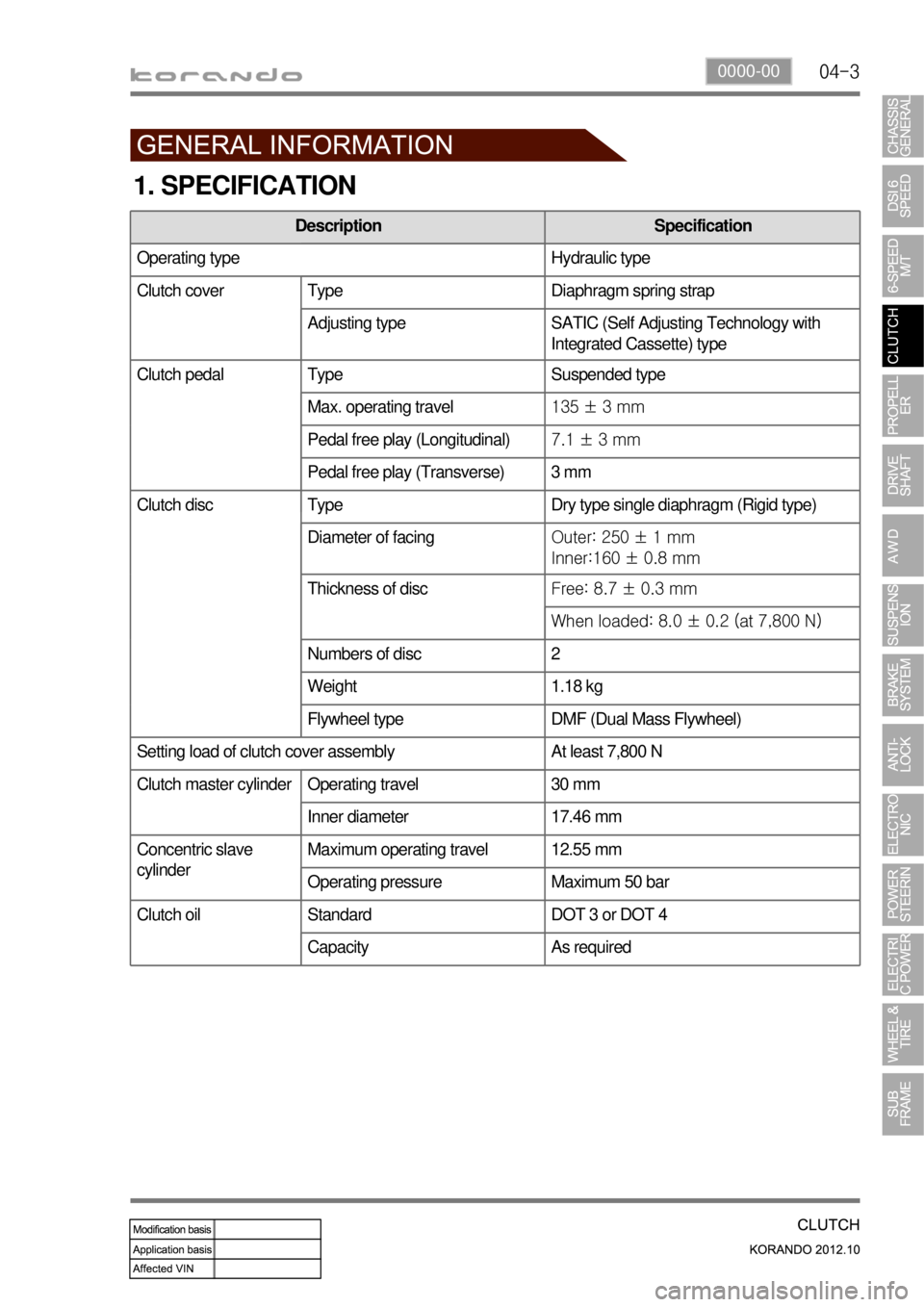

1. SPECIFICATION

Description Specification

Operating type Hydraulic type

Clutch cover Type Diaphragm spring strap

Adjusting type SATIC (Self Adjusting Technology with

Integrated Cassette) type

Clutch pedal Type Suspended type

Max. operating travel135 ± 3 mm

Pedal free play (Longitudinal)7.1 ± 3 mm

Pedal free play (Transverse) 3 mm

Clutch disc Type Dry type single diaphragm (Rigid type)

Diameter of facingOuter: 250 ± 1 mm

Inner:160 ± 0.8 mm

Thickness of discFree: 8.7 ± 0.3 mm

When loaded: 8.0 ± 0.2 (at 7,800 N)

Numbers of disc 2

Weight 1.18 kg

Flywheel type DMF (Dual Mass Flywheel)

Setting load of clutch cover assembly At least 7,800 N

Clutch master cylinder Operating travel 30 mm

Inner diameter 17.46 mm

Concentric slave

cylinderMaximum operating travel 12.55 mm

Operating pressure Maximum 50 bar

Standard DOT 3 or DOT 4

Capacity As required

Clutch oil

Page 900 of 1082

04-4

2. TIGHTENING TORQUE

DescriptionTightening torque

Amount

Clutch housing boltUpper (17 mm) 85.0 to 100 Nm 2

Front (14 mm)54.0 Nm + 20°1

Rear (14 mm) 51.3 to 56.7 Nm 2

Lower (14 mm) 56.0 to 62.0 Nm 4

Pressure plate assembly bolt (Hexagon 6 mm) 21.0 to 27.0 Nm 6

Concentric slave cylinder bolt (Hexagon 5 mm) 10 to 16 Nm 3

Concentric slave cylinder oil pipe nut 24.5 to 28.4 Nm Remove the nut if it is

necessary. (Once

removed, apply the

Loctite on the thread

before installation.)

Master cylinder nut (12 mm) 7.8 to 17.6 Nm

Master cylinder oil pipe nut (10 mm) 14.7 to 17.6 Nm

Master cylinder push rod lock nut 8.8 to 13.7 Nm

Clutch oil chamber screw and bolt (10 mm) 3.9 to 7.8 Nm

Oil pipe nut (10 mm) 14.7 to 17.6 Nm

Clutch pedal mounting nut (12 mm) 7.8 to 17.6 Nm

Stopper bolt 16 to 22 Nm

Trending: fuse box, fuel pressure, oil filter, wheel bolts, maintenance, automatic trans, clock