warning lights SSANGYONG KORANDO 2012 Service Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2012, Model line: KORANDO, Model: SSANGYONG KORANDO 2012Pages: 1082, PDF Size: 96.1 MB

Page 155 of 1082

03-20

3. CAUTIONS FOR DI ENGINE

1) Cautions for DI Engine

This chapter describes the cautions for DI engine equipped vehicle. This includes the water separation

from engine, warning lights, symptoms when engine malfunctioning, causes and actions.

DI Engine 1.

Comparatively conventional diesel engines, DI engine controls the fuel injection and timing electrically,

delivers high power and reduces less emission.

System Safety Mode 2.

When a severe failure has been occurred in a vehicle, the system safety mode is activated to protect the

system. It reduces the driving force, restricts the engine speed (rpm) and stops engine operation. Refer

to "Diagnosis" section in this manual.

Engine CHECK Warning Lamp 3.

The Engine CHECK warning lamp on the instrument cluster comes on when the fuel or

major electronic systems of the engine are not working properly. As a result, the

<008c0095008e00900095008c02c5009a004700970096009e008c009900470096009c009b0097009c009b00470094008800a00047008b008c008a0099008c0088009a008c0047009600990047009b008f008c0047008c0095008e00900095008c0047009400

8800a00047009a009b0088009300930055>

Water Separator Warning Lamp 4.

When the water level inside water separator in fuel filter exceeds a certain level (approx.

45 cc), this warning light comes on and buzzer sounds.

Also, the driving force of the vehicle decreases (torque reduction). If these conditions

occur, immediately drain the water from fuel filter.

Page 601 of 1082

03-358710-01

10) Keyless Entry

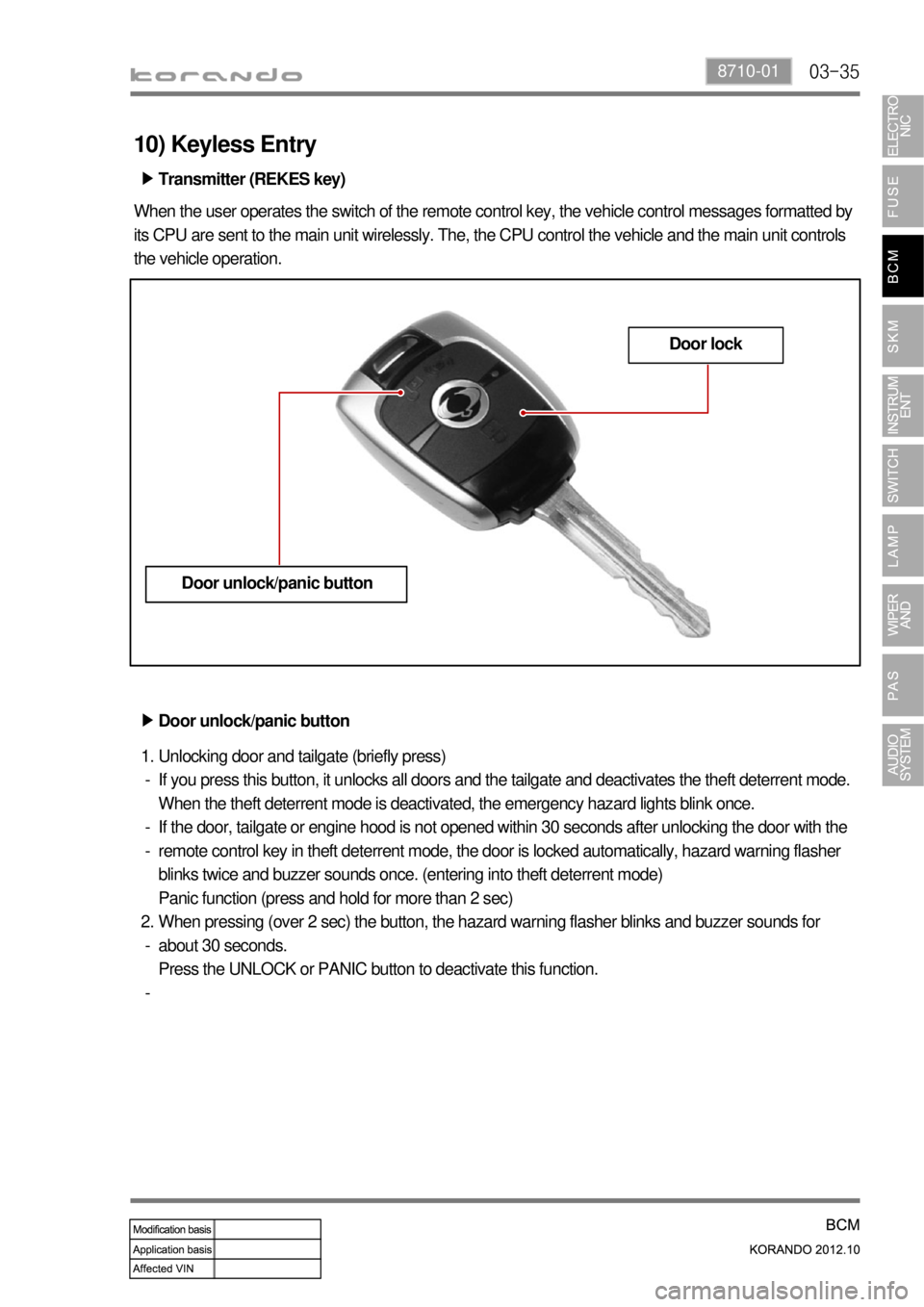

Transmitter (REKES key) ▶

When the user operates the switch of the remote control key, the vehicle control messages formatted by

its CPU are sent to the main unit wirelessly. The, the CPU control the vehicle and the main unit controls

the vehicle operation.

Door unlock/panic buttonDoor lock

Door unlock/panic button ▶

Unlocking door and tailgate (briefly press)

If you press this button, it unlocks all doors and the tailgate and deactivates the theft deterrent mode.

When the theft deterrent mode is deactivated, the emergency hazard lights blink once.

If the door, tailgate or engine hood is not opened within 30 seconds after unlocking the door with the

remote control key in theft deterrent mode, the door is locked automatically, hazard warning flasher

blinks twice and buzzer sounds once. (entering into theft deterrent mode)

Panic function (press and hold for more than 2 sec)

When pressing (over 2 sec) the button, the hazard warning flasher blinks and buzzer sounds for

about 30 seconds.

Press the UNLOCK or PANIC button to deactivate this function. 1.

-

-

-

2.

-

-

Page 688 of 1082

05-258010-01

Operations for power supply in SVC ▶

When the ignition switch is turned to ON position, the message "WELCOME" is displayed for 2

seconds on the DOT LCD and the seat belt reminder comes on for 4 seconds. However, if a signal

with higher priority is received, the seat belt reminder comes on only for 2 seconds to display it.

The pre-warning (system check) indicator comes on for 4 seconds and goes off 0.4 seconds after

that the ignition is switched on.

All input signals can be input 4 seconds after the pre-warning (system check) indicator starts

illuminating.

Only the symbol and DOT LCD are illuminated initially, if the SKM (Smart Key Module) or door (B-

CAN) signal is received

while B+ power is supplied.

If the ignition is switched on with the LCD illuminated, the DOT LCD and the symbol follow

the side fascia panel.

When the step 1, 2 and 3 are performed after 4 seconds, the seat belt warning lamp is deactivated in

advance.

Dial light ON condition: Lights up gradually for 2 seconds when the ignition is switched on. 1.

2.

3.

4.

5.

6.

5) Illumination & Brightness

(1) Operations for Power Supply

Page 849 of 1082

02-153680-01

This information is used by the TCU to decide which shift pattern to select and for shift energy

management. Electro-hydraulic solenoid valves and variable bleed solenoids control the transaxle gear

changes.

Six variable bleed solenoids and four on/off solenoids are used to direct transaxle fluid flow to control the

fluid pressure within the three clutches and two bands. Separate pressure regulators are used

exclusively for torque converter clutch control and main transaxle line pressure.

The TCU monitors all TCU inputs and outputs to confirm correct system operation. If a fault occurs the

TCU is able to perform default action and inform the driver of the problem through the instrument cluster

warning lights. Detailed information is available via trouble codes which can be read with the service tool.

Page 877 of 1082

03-173660-01

5. TRANSAXLE ELECTRONIC CONTROL SYSTEM

1) General Information

The transmission control unit (TCU) and its input/output network control the following transmission

operations:

Shift timing

Line pressure

Clutch pressure (shift feel)

Torque converter clutch -

-

-

-

also uses these signals when determining transaxle operating strategy. Using all of these input signals,

the TCU can determine when the time and conditions are right for a shift, or when to apply or release the

torque converter clutch. It will also determine the pressure needed to optimise shift feel.

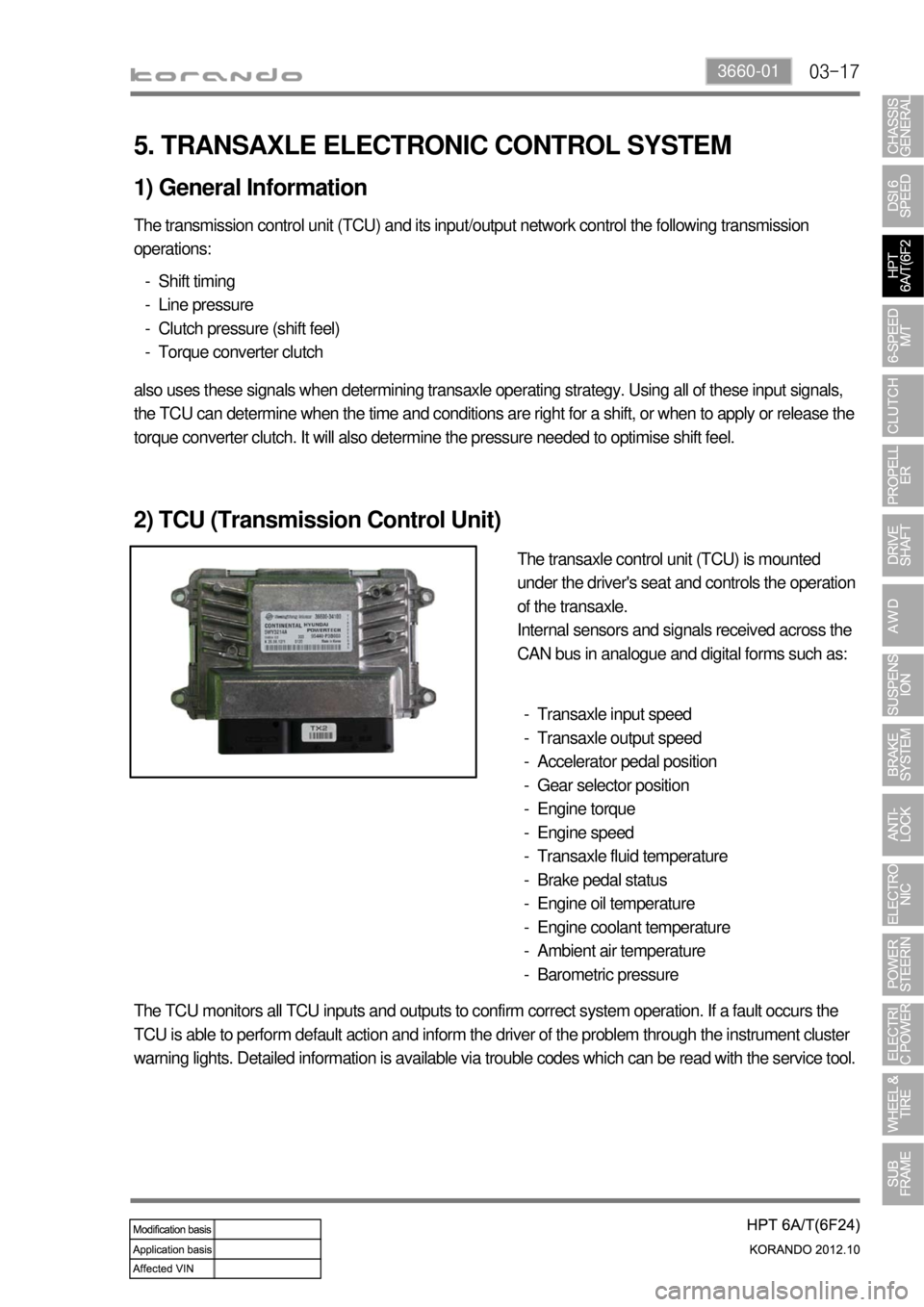

2) TCU (Transmission Control Unit)

The transaxle control unit (TCU) is mounted

under the driver's seat and controls the operation

of the transaxle.

Internal sensors and signals received across the

CAN bus in analogue and digital forms such as:

Transaxle input speed

Transaxle output speed

Accelerator pedal position

Gear selector position

Engine torque

Engine speed

Transaxle fluid temperature

Brake pedal status

Engine oil temperature

Engine coolant temperature

Ambient air temperature

Barometric pressure -

-

-

-

-

-

-

-

-

-

-

-

The TCU monitors all TCU inputs and outputs to confirm correct system operation. If a fault occurs the

TCU is able to perform default action and inform the driver of the problem through the instrument cluster

warning lights. Detailed information is available via trouble codes which can be read with the service tool.