differential SSANGYONG KORANDO 2013 User Guide

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2013, Model line: KORANDO, Model: SSANGYONG KORANDO 2013Pages: 1336, PDF Size: 92.18 MB

Page 415 of 1336

Rear temp.

sensor

Front temp.

sensorCDPF (DOC+DPF)

Throttle valveD20DTF ECUDifferential pres.

sensor

Oxygen sensor

(11) CDPF control

a. Overview

As the solution for environmental regulations and PM Particle Material) of diesel engine, the low emission

vehicle is getting popular. This vehicle is equipped with an extra filter to collect the soot and burn it again

so that the amount of PM in the exhaust gas passed through the DOC (Diesel Oxidation Catalyst) is

reduced. The CDPF (Catalyst & Diesel Particulate Filter) is an integrated filter including DOC (Diesel

Oxidation Catalyst) and DPF (Diesel Particulate Filter).

For details, refer to Chapter "CDPF".

b. Components

Page 417 of 1336

Rear temp. sensor:

Measure DPF

temp.DPF performs

recycling

(combustion)

process at 600C,

and rear

temperature sensor

monitors the

temperature of DPF.

Differential pressure

sensor measures the

pressure difference

between pre-CDPF

and post-CDPF (If

PM has been

accumulated, the

measured value is

over the specified

value).Diff. pres. sensor:

Measure

pressure between

front side and

rear side of CDPF

Injector: Control

post injection

Front temp.

sensor: Measure

DOC temp.DOC performs

oxidation and

reduction process at

front temperature

sensor monitors the

temperature of

DOC.

Electronic

throttle body:

Control intake ai

r

mass

ECU (DCM 3.7)

d. Operation process

When the differential pressure sensor detects the pressure difference between the front and the rear

side of CDPF, the sensor sends signal indicating the soot is accumulated and the post injection is

performed to raise the temperature of exhaust gas. The amount of fuel injected is determined according

to the temperature of exhaust gas detected by the rear temperature sensor. If the temperature is below

low load range, the amount of post injection and the amount of intake air are controlled. It is to raise the

temperature by increasing the amount of fuel while decreasing the amount of intake air.

T-MAP sensor

Intake air

mass

Exceed PM

limitBooster

pressure/

temperaturePost injection

Control intake air

mass

Page 986 of 1336

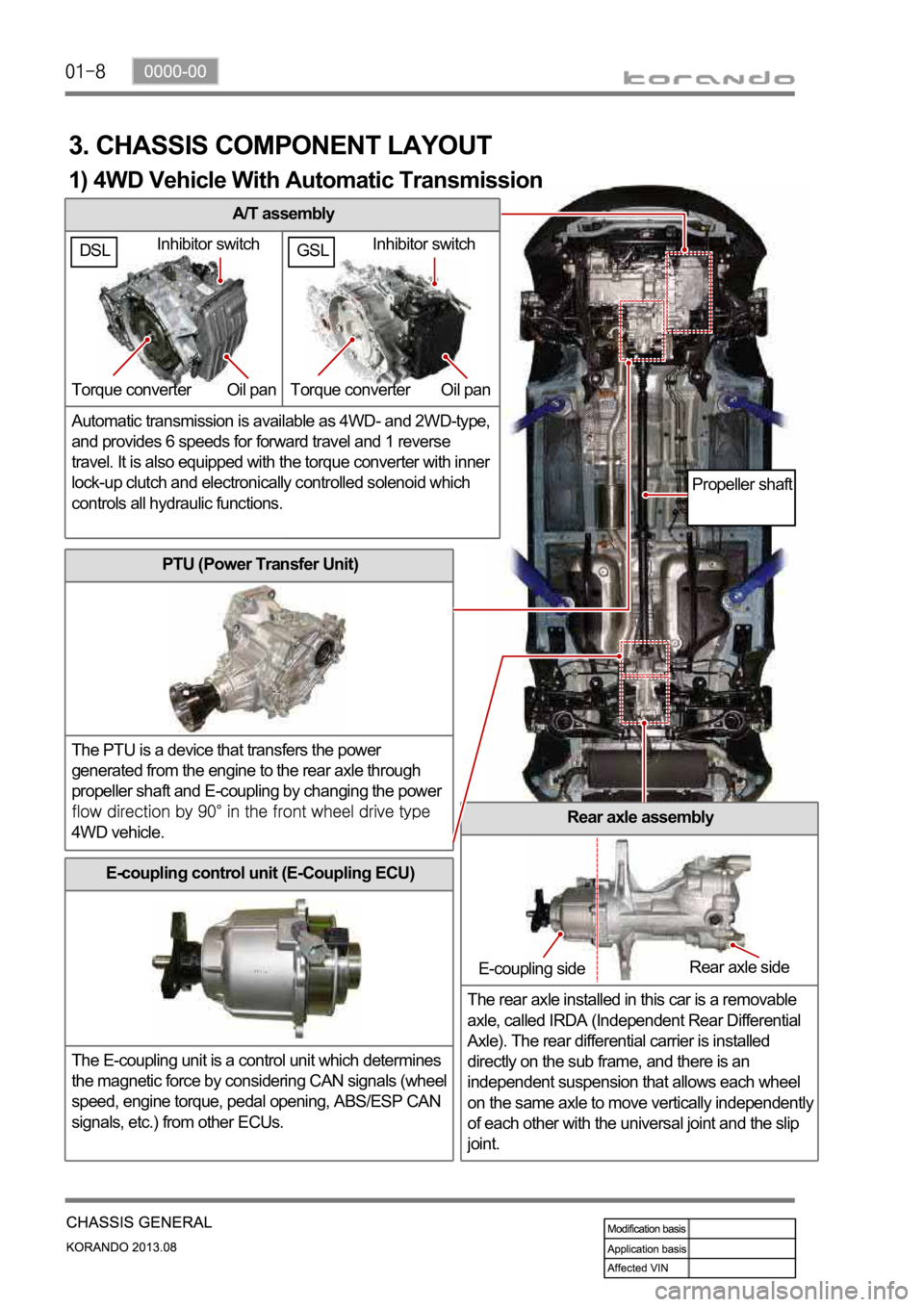

A/T assembly

Automatic transmission is available as 4WD- and 2WD-type,

and provides 6 speeds for forward travel and 1 reverse

travel. It is also equipped with the torque converter with inner

lock-up clutch and electronically controlled solenoid which

controls all hydraulic functions.

3. CHASSIS COMPONENT LAYOUT

PTU (Power Transfer Unit)

The PTU is a device that transfers the power

generated from the engine to the rear axle through

propeller shaft and E-coupling by changing the power

4WD vehicle.Rear axle assembly

The rear axle installed in this car is a removable

axle, called IRDA (Independent Rear Differential

Axle). The rear differential carrier is installed

directly on the sub frame, and there is an

independent suspension that allows each wheel

on the same axle to move vertically independentl

y

of each other with the universal joint and the slip

joint.

E-coupling control unit (E-Coupling ECU)

The E-coupling unit is a control unit which determines

the magnetic force by considering CAN signals (wheel

speed, engine torque, pedal opening, ABS/ESP CAN

signals, etc.) from other ECUs.

Inhibitor switch

Torque converter Oil pan

E-coupling sideRear axle side

Propeller shaft

1) 4WD Vehicle With Automatic Transmission

GSLDSLInhibitor switch

Torque converter Oil pan

Page 1006 of 1336

2) Sectional Diagram

Double planetary gear-set

Clutch packSingle planetary gear-set

Oil pump

Torque converter

Input shaft

Intermediate shaft

Differential assembly

Page 1019 of 1336

3680-01

2) Power Flowing Sequence

Torque converter Input shaft Front planetary gear

C2 clutch Forwarding sun gear Rear planetary gear

C1 clutch Center support Intermediate shaft

assembly

inal reduction and

differential gearThis is a fluid clutch.

Transfers the power from

engine to transaxle and

amplifies the torque.Transfers the power

from torque converter

to front planetary

gear.Generates the gear

ratio and transfers the

power.

Engaged by hydraulic

pressure and transfers the

power to C1 clutch.Transfers the power from

torque converter to rear

planetary gear.Generates the gear ratio

and transfers the power.

Engaged by hydraulic

pressure and transfers the

power to C1 clutch.Transfers the power from

input shaft to intermediate

shaft.Changes the rotating direction

and generates the final

reduction rear ratio.

Generates the final reduction gear ratio and performs

the differential function.

Transfers the power to constant velocity shaft.

Page 1020 of 1336

3) Power Flow

Front planetary gear

Front sun gear (FSG)

Planetary hear pinion (PP)

Ring gear (Internal) 1.

2.

3.

Rear planetary gear

Forward sun gear (FSG)

Reverse sun gear (RSG)

Short pinion (SPP)

Long oinion (LPP)

Ring gear (RG) 4.

5.

6.

7.

8.Intermediate gearDrive gear

Driven gear 9.

10.

Differential gear

Pinion

Differential 11.

12.

Page 1056 of 1336

3190-01

2. TIGHTENING TORQUE

Part name Tightening torque Remark

1. Drive gear mounting bolt of differential carrier 166.6 to 176.4 Nm 10 EA

2. Reverse shaft mounting bolt 74.5 to 89.2 Nm

3. Transmission case mounting bolt 19.6 to 26.5 Nm 22 EA

4. Concentric slave cylinder mounting bolt 11.8 to 14.7 Nm 3 EA

5. Backup lamp switch 29.4 to 34.3 Nm

6. Neutral switch 29.4 to 34.3 Nm

7. Oil filler plug 58.8 to 78.4 Nm

8. Oil drain plug 58.8 to 78.4 Nm

9. Oil plug 58.8 to 78.4 Nm

10. Shift lever mounting nut 42.2 to 53.9 Nm

11. Selector lever mounting nut 42.2 to 53.9 Nm

12. Control shaft assembly mounting bolt 9.8 to 11.8 Nm 7 EA

13. Guide bolt 42.2 to 53.9 Nm

Page 1074 of 1336

4110-01

1. SPECIFICATION

Component Item Specifications

2WD,

4WDFront drive

shaftJoint type Inside: Tripod joint

Outside: Ball joint

Max. allowed angle

To compensate the bending

angleInstallation of equivalent

length shaft

Rear drive

shaftJoint type Inside: Cross groove joint

Outside: Ball joint

Max. allowed angle

Rear differential

carrierType Independent Rear Drive Axle

(IRDA)

Reduction gear type Hypoid gear

Gear reduction ratio 2.93

Diameter of gear

Oil type Hypoid gear oil

(SAE 75W/90)

Final drive gear backlash 0.10 to 0.15 mm

Differential gear backlash 0 to 0.076 mm

Propeller shaft Joint type PTU side: CV joint

Rear axle side: Rubber coupling

Sliding distance

Unbalance 80 g.mm or less at 3,000 rpm

Total runout 0.3 mm or less

4WD

only

Page 1075 of 1336

1. COMPONENT

For AWD vehicle For 2WD vehicle

Front drive shaft (LH)

Front drive shaft (RH)

Intermediate shaft

Power transfer unit(PTU) - 4WD

Propeller shaft - 4WD 1.

2.

3.

4.

5.E-coupling - 4WD

Rear differential carrier - 4WD

Rear drive shaft (LH) - 4WD

Rear drive shaft (RH) - 4WD 6.

7.

8.

9.

Page 1077 of 1336

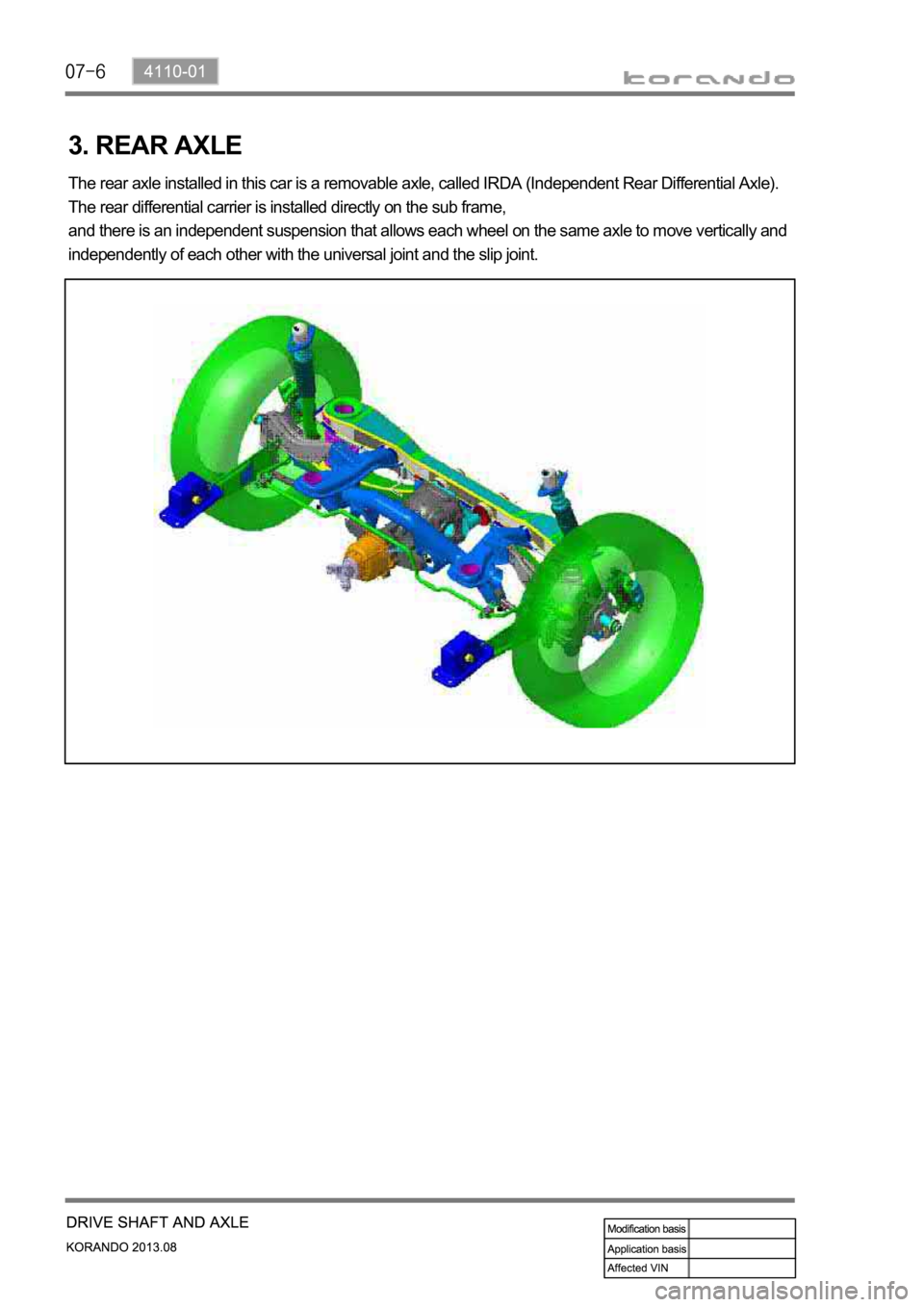

3. REAR AXLE

The rear axle installed in this car is a removable axle, called IRDA (Independent Rear Differential Axle).

The rear differential carrier is installed directly on the sub frame,

and there is an independent suspension that allows each wheel on the same axle to move vertically and

independently of each other with the universal joint and the slip joint.