differential SSANGYONG KORANDO 2013 Service Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2013, Model line: KORANDO, Model: SSANGYONG KORANDO 2013Pages: 1336, PDF Size: 92.18 MB

Page 207 of 1336

0000-00

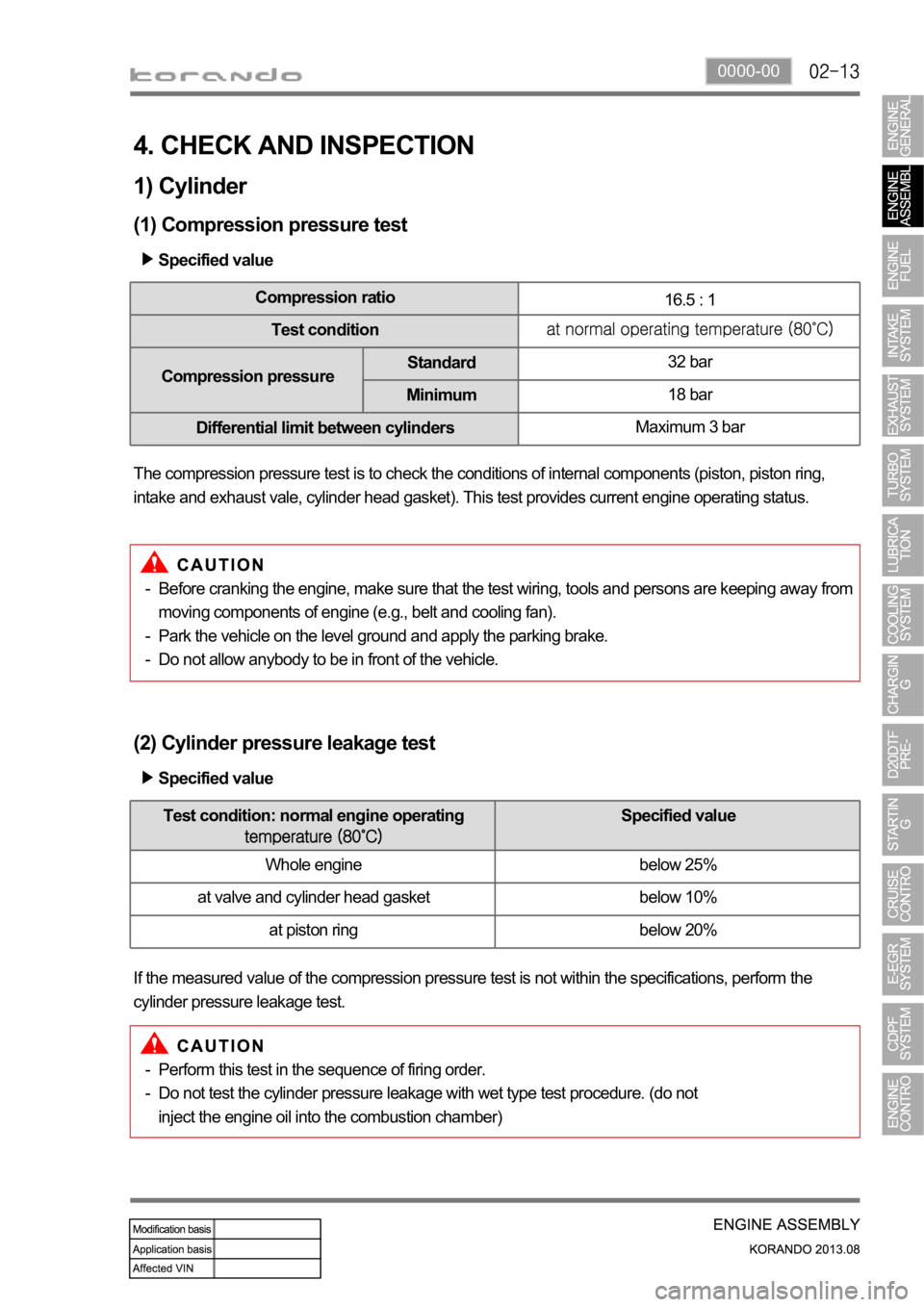

4. CHECK AND INSPECTION

1) Cylinder

(1) Compression pressure test

Specified value

Compression ratio

16.5 : 1

Test condition

Compression pressureStandard32 bar

Minimum18 bar

Differential limit between cylindersMaximum 3 bar

The compression pressure test is to check the conditions of internal components (piston, piston ring,

intake and exhaust vale, cylinder head gasket). This test provides current engine operating status.

Before cranking the engine, make sure that the test wiring, tools and persons are keeping away from

moving components of engine (e.g., belt and cooling fan).

Park the vehicle on the level ground and apply the parking brake.

Do not allow anybody to be in front of the vehicle. -

-

-

(2) Cylinder pressure leakage test

If the measured value of the compression pressure test is not within the specifications, perform the

cylinder pressure leakage test.Specified value

Perform this test in the sequence of firing order.

Do not test the cylinder pressure leakage with wet type test procedure. (do not

inject the engine oil into the combustion chamber) -

-

Test condition: normal engine operating Specified value

Whole engine below 25%

at valve and cylinder head gasket below 10%

at piston ring below 20%

Page 362 of 1336

Excessive overload of CDPF (warning lamp illuminated)

If the vehicle is driven at a speed of 5 to 10

km/h for an extended period of time, the soot

accumulated in the CDPF cannot be burned

as the CDPF cannot reach the regeneration

temperature. Then, an excessive amount of

soot can be accumulated in the CDPF.

This case is much worse than the simple over-

load of the CDPF. To inform this to the driver,

the engine warning lamp comes on and the

engine power is decreased to protect the

system.

To solve this problem, blow soot between the

engine and exhaust system several times and

erase the related DTC. Then, check if the

same DTC is regenerated again. If so, check

the DTC related to the differential pressure

sensor. 1.

2.

3.

Page 364 of 1336

Engine ECU (D20DTF)

Post-injectionDifferential pressure sensor

Calculates the amount of PM

collected by reading the pressure

difference between before and

after the CDPF.Electric throttle body

Regulates the rate of air

intake.

CDPF

(DOC + DPF)Front temperature

sensor

Protects the

turbocharger.Rear temperature

sensor

Measures the

temperature of fuel

combustion.

2. COMPONENT

Oxygen

sensor

Page 365 of 1336

1114-00

3. INPUT/OUTPUT DEVICES

Front temperature sensor: This sensor is installed at the inlet of DOC and detects whether the DOC

can burn (oxidize) the post-injected fuel or not.

Rear temperature sensor: This sensor is installed at the inlet of DPF and monitors that the 1.

2.

post-injection is decreased.

amount of fuel post-injection is increased. -

-

Differential pressure sensor: This sensor checks the amount of PM collected by calculating the

pressure difference between before and after the CDPF.

Electric throttle valve: This valve reduces the intake air flow to raise the temperature of the exhaust

gas when the CDPF is operating during idling. 3.

4.

Page 366 of 1336

A DPS (Differential Pressure Sensor) measures the pressure difference between before and after the

CDPF and detects whether the soot is collected in the CDPF or not. If PM is collected in the CDPF (In

this case the pressure difference between before and after the CDPF exceeds the specified value.

Normally, the system sends the signal when the driving distance becomes approx. 600 to 1,200 km), the

temperature of exhaust gas is increased and the post-injection is started for regeneration. The amount of

fuel post-injection is controlled by the exhaust gas temperature measured by the rear temperature

increase the regeneration temperature. Otherwise, the fuel injection amount is decreased or the fuel is

not injected.

When the engine is running with low load, the intake air amount is also controlled as well as fuel injection

amount. This function is used to increaser the combustion temperature by increasing the amount of fuel

post-injection with the lowest air amount within the specified control logic.

4. POST-INJECTION AND AIR MASS CONTROL

Page 367 of 1336

1114-00

ECU (DCM 3.7)

T-MAP sensorIntake air

volume

Detecting

excess of PM

amount limit

Boos

t

pressure

/

temperature

Front EGT sensor

Measures the temperature of

DOC.

The DOC performs the redox

reaction at between 300 and

sensor monitors the

temperature of DOC.

Differential pressure sensor

Measures the pressure values

of before and after the CDPF.

The pressure difference

between before and after the

CDPF is measured by the

differential pressure sensor (If

PM is collected in the CDPF,

the pressure difference

between before and after the

CDPF exceeds the specified

value).

Rear EGT sensor

Measures the temperature of

DPF.

The DPF burns the soot with

hot exhaust gases

(regeneration) at around

sensor monitors the

temperature of DPF.

Injector (C3I)

Controls the post-injection.

Electric throttle body

Controls the intake air

volume.

HFM sensor

Page 368 of 1336

Collecting PM

The engine ECU detects the

amount of PM collected by the

information from the

temperature sensors and

differential pressure sensor.

When the soot is accumulated,

the engine ECU performs post-

injection to increase the

exhaust gas temperature and

burns the collected PM at

Oxidation (DOC)

When the exhaust gas enters

into the CDPF assembly, its

CO, HC and PM are reduced

by the redox reaction of the

DOC. The remaining PM is

filtered and collected in CDPF,

and the temperature of the

exhaust gas is increased to

5. OPERATING PROCESS

[Configuration and principle of operation]

The exhaust gas

passed through the

exhaust manifold

enters into the CDPF

assembly (at approx

Page 372 of 1336

![SSANGYONG KORANDO 2013 Service Manual No. Sensor item Data Unit Description

1 Driven distance from last

CDPF regeneration0 km

2 CDPF regeneration history

(distance/time) Index0 -

3 Driven distance between

CDPF regenerations[0]0 SSANGYONG KORANDO 2013 Service Manual No. Sensor item Data Unit Description

1 Driven distance from last

CDPF regeneration0 km

2 CDPF regeneration history

(distance/time) Index0 -

3 Driven distance between

CDPF regenerations[0]0](/img/67/57503/w960_57503-371.png)

No. Sensor item Data Unit Description

1 Driven distance from last

CDPF regeneration0 km

2 CDPF regeneration history

(distance/time) Index0 -

3 Driven distance between

CDPF regenerations[0]0 km

4 Driven distance between

CDPF regenerations[1]0 km

5 Driven distance between

CDPF regenerations[2]0 km

6 Driven distance between

CDPF regenerations[3]0 km

7 Driven distance between

CDPF regenerations[4]0 km

8 CDPF regeneration time[0] 0.0 S

9 CDPF regeneration time[2] 0.0 S

10 CDPF regeneration time[2] 0.0 S

11 CDPF regeneration time[3] 0.0 S

12 CDPF regeneration time[4] 0.0 S

13 CDPF regeneration history

(OK/Fail) Index0 -

14 CDPF regeneration history[0] OK OK/Fail

15 CDPF regeneration history[1] OK OK/Fail

16 CDPF regeneration history[2] OK OK/Fail

17 CDPF regeneration history[3] OK OK/Fail

18 CDPF regeneration history[4] OK OK/Fail

19 Times of CDPF regeneration

start (differential pressure)0 -

Driven distance from last generation up to

now

Display regeneration history (distance/time)

stored until now in figure, Index ([0] ~ [4])

The regeneration distance/time is stored up

to the last 5 events in sequence and the

oldest one will be deleted if the number of

events is exceeded 5 times.

The currently displayed index value indicates

where the regeneration information will be

stored in the future and the just previous

value shows the last regeneration

information.

Ex) Index value: 3 (last regeneration

information stored at 2)

Display regeneration history (OK/Fail) stored

until now in figure, Index ([0]~[4])

The regeneration distance/time is stored up

to the last 5 events in sequence and the

oldest one will be deleted if the number of

events is exceeded 5 times.

The currently displayed index value indicates

where the regeneration information will be

stored in the future and the just previous

value shows the last regeneration

information.

Ex) Index value: 3 (last regeneration

information stored at 2)

Times which regeneration is requested using

differential pressure sensor signal

9. DESCRIPTION ON CDPF REGENERATION

Page 376 of 1336

0000-00

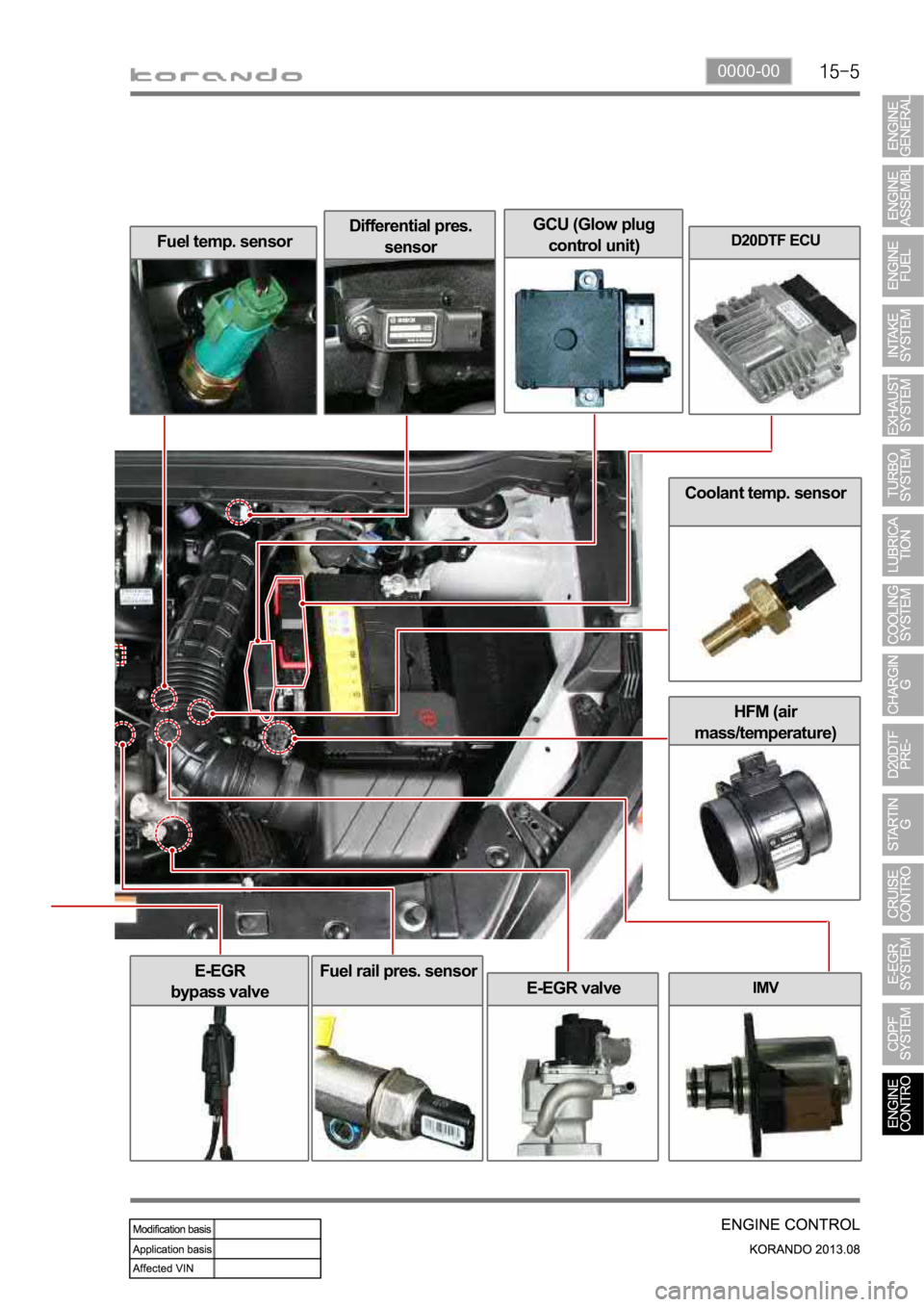

Coolant temp. sensor

HFM (air

mass/temperature)

Fuel temp. sensorDifferential pres.

sensorD20DTF ECU

IMV

E-EGR

bypass valve

E-EGR valve

Fuel rail pres. sensor

GCU (Glow plug

control unit)

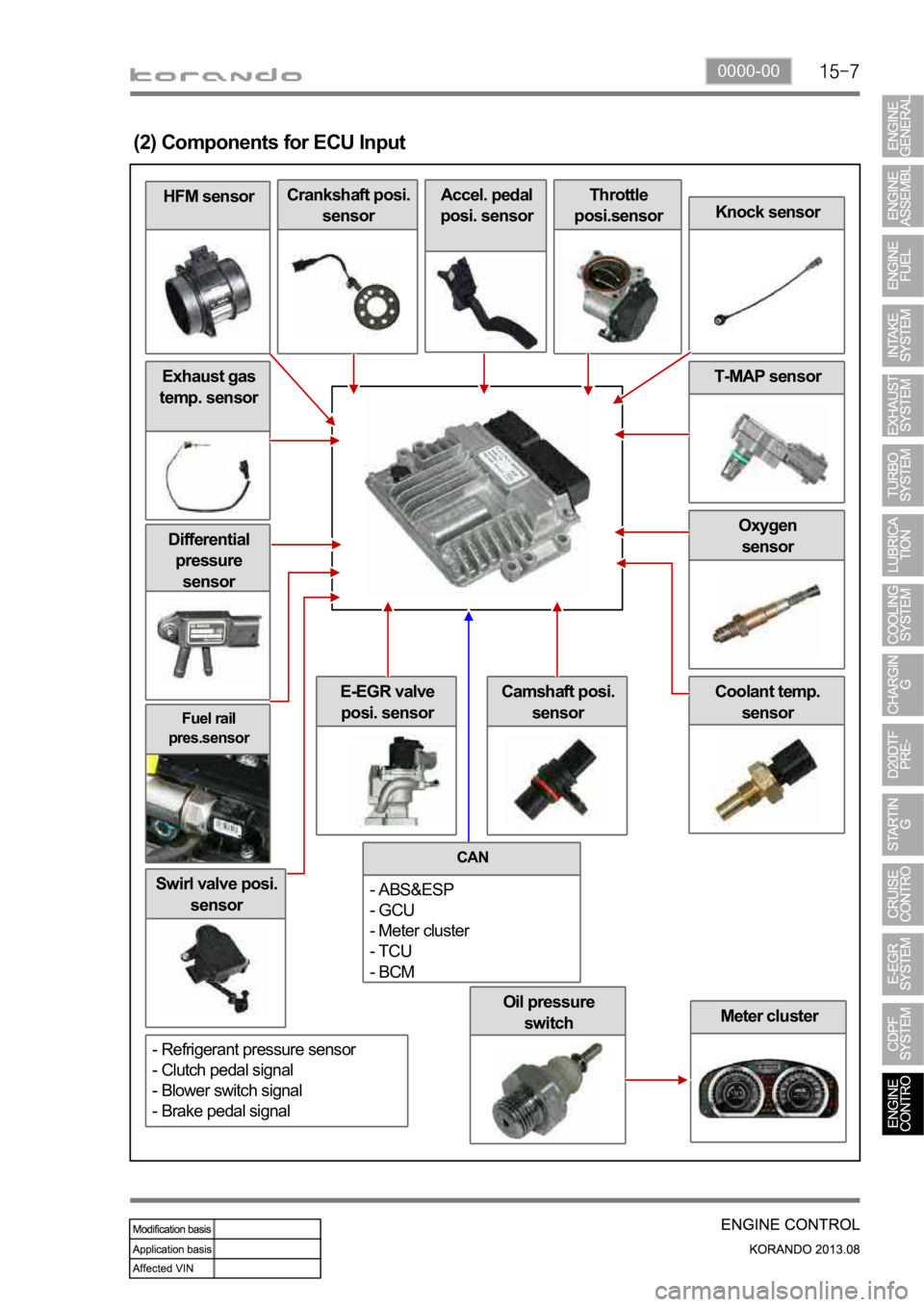

Page 378 of 1336

0000-00

Oil pressure

switch

Fuel rail

pres.sensor

Differential

pressure

sensor

Swirl valve posi.

sensor

Meter cluster

Coolant temp.

sensorE-EGR valve

posi. sensor

Oxygen

sensor

Exhaust gas

temp. sensor

HFM sensor

(2) Components for ECU Input

Crankshaft posi.

sensorAccel. pedal

posi. sensorThrottle

posi.sensor

Knock sensor

T-MAP sensor

Camshaft posi.

sensor

CAN

- ABS&ESP

- GCU

- Meter cluster

- TCU

- BCM

- Refrigerant pressure sensor

- Clutch pedal signal

- Blower switch signal

- Brake pedal signal