tire pressure SSANGYONG KORANDO 2013 User Guide

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2013, Model line: KORANDO, Model: SSANGYONG KORANDO 2013Pages: 1336, PDF Size: 92.18 MB

Page 858 of 1336

8510-00

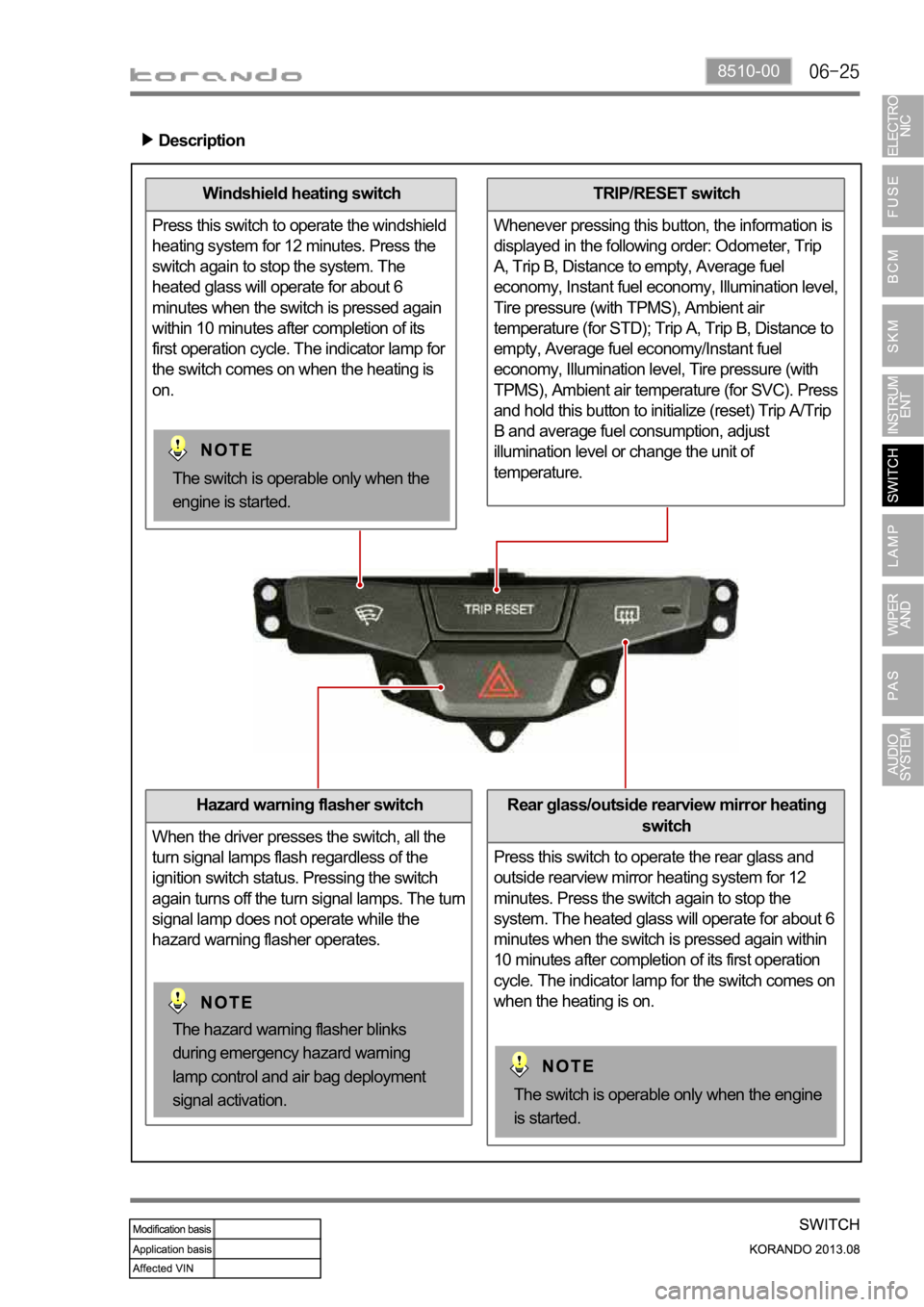

Windshield heating switch

Press this switch to operate the windshield

heating system for 12 minutes. Press the

switch again to stop the system. The

heated glass will operate for about 6

minutes when the switch is pressed again

within 10 minutes after completion of its

first operation cycle. The indicator lamp for

the switch comes on when the heating is

on.

Hazard warning flasher switch

When the driver presses the switch, all the

turn signal lamps flash regardless of the

ignition switch status. Pressing the switch

again turns off the turn signal lamps. The turn

signal lamp does not operate while the

hazard warning flasher operates.

TRIP/RESET switch

Whenever pressing this button, the information is

displayed in the following order: Odometer, Trip

A, Trip B, Distance to empty, Average fuel

economy, Instant fuel economy, Illumination level,

Tire pressure (with TPMS), Ambient air

temperature (for STD); Trip A, Trip B, Distance to

empty, Average fuel economy/Instant fuel

economy, Illumination level, Tire pressure (with

TPMS), Ambient air temperature (for SVC). Press

and hold this button to initialize (reset) Trip A/Trip

B and average fuel consumption, adjust

illumination level or change the unit of

temperature.

Description

Rear glass/outside rearview mirror heating

switch

Press this switch to operate the rear glass and

outside rearview mirror heating system for 12

minutes. Press the switch again to stop the

system. The heated glass will operate for about 6

minutes when the switch is pressed again within

10 minutes after completion of its first operation

cycle. The indicator lamp for the switch comes on

when the heating is on.

The switch is operable only when the engine

is started.

The hazard warning flasher blinks

during emergency hazard warning

lamp control and air bag deployment

signal activation.

The switch is operable only when the

engine is started.

Page 982 of 1336

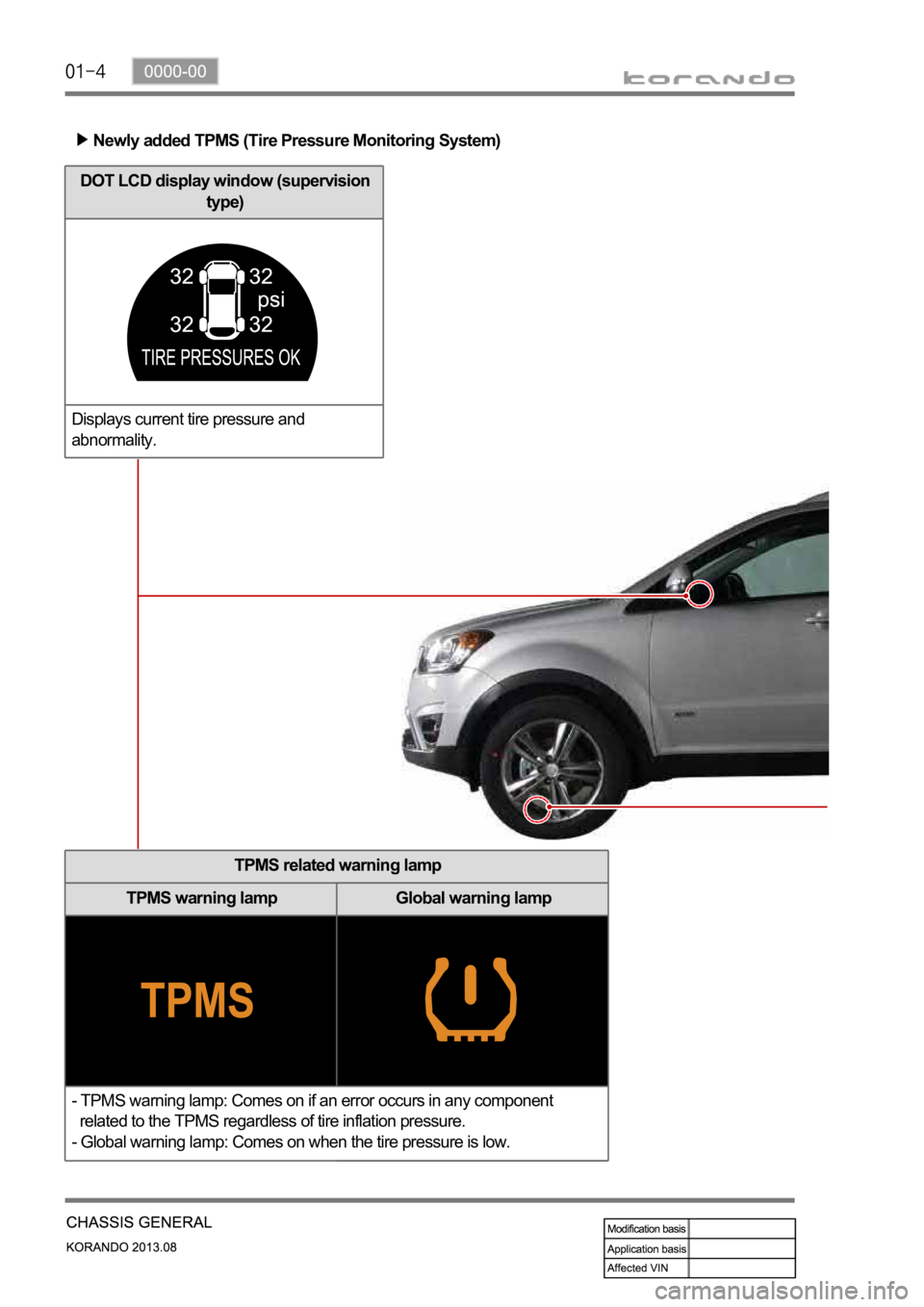

Newly added TPMS (Tire Pressure Monitoring System)

TPMS related warning lamp

TPMS warning lamp Global warning lamp

- TPMS warning lamp: Comes on if an error occurs in any component

related to the TPMS regardless of tire inflation pressure.

- Global warning lamp: Comes on when the tire pressure is low.

DOT LCD display window (supervision

type)

Displays current tire pressure and

abnormality.

Page 983 of 1336

0000-00

Wheel module

The wheel modules are mounted to each wheel rim and hole. They transmit

the signal of the pressure and temperature in tire, rotating direction and

wheel module ID code, etc. using the radio frequency to the TPMS ECU.

TPMS ECU

The TPMS ECU is located to the rear bumper rail under the vehicle. It outputs the tire pressure

information and CAN data.

Page 985 of 1336

0000-00

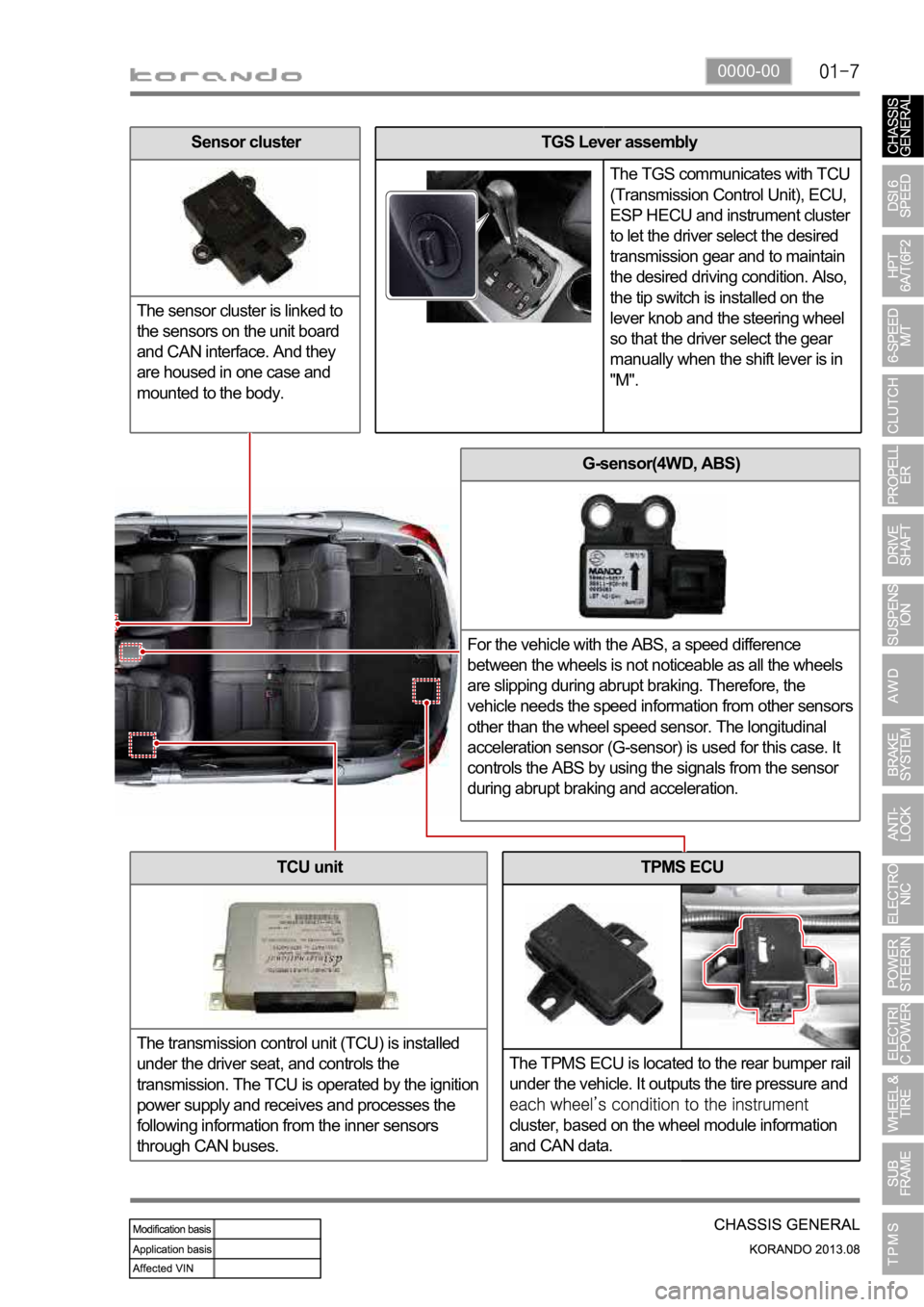

TPMS ECU

The TPMS ECU is located to the rear bumper rail

under the vehicle. It outputs the tire pressure and

cluster, based on the wheel module information

and CAN data.

G-sensor(4WD, ABS)

For the vehicle with the ABS, a speed difference

between the wheels is not noticeable as all the wheels

are slipping during abrupt braking. Therefore, the

vehicle needs the speed information from other sensors

other than the wheel speed sensor. The longitudinal

acceleration sensor (G-sensor) is used for this case. It

controls the ABS by using the signals from the sensor

during abrupt braking and acceleration.

TCU unit

The transmission control unit (TCU) is installed

under the driver seat, and controls the

transmission. The TCU is operated by the ignition

power supply and receives and processes the

following information from the inner sensors

through CAN buses.

TGS Lever assembly

The TGS communicates with TCU

(Transmission Control Unit), ECU,

ESP HECU and instrument cluster

to let the driver select the desired

transmission gear and to maintain

the desired driving condition. Also,

the tip switch is installed on the

lever knob and the steering wheel

so that the driver select the gear

manually when the shift lever is in

"M".Sensor cluster

The sensor cluster is linked to

the sensors on the unit board

and CAN interface. And they

are housed in one case and

mounted to the body.

Page 1000 of 1336

4) Basic Inspection

(1) Horn operation

Listen for the horn sound when pressing the horn pad on the steering wheel. -

(2) Brake operation

Check if there is any abnormal noise, unusually long braking distance, or uneven braking force. If the

brake warning lamp does not go out even after starting the engien or are flashing during driving,

have the brake system checked immediately.

Check the brake pipes and hoses for connection, oil leak, crack or interference after changing the

position of tires. When replacing the tires, check the brake disc for surface condition and wear.

Check the parking brake cable and brake operation. Shorten the checking interval if the parking

brake is used frequently. -

-

-

(3) Exhaust system

Be aware to any changes in sound or smell from the exhaust system. These may be caused by leak or

overheat. Have the exhaust system checked and repaired immediately.

Inspect the exhaust system including catalytic converter. Inspect all the components and body frame

near the exhaust system. -

-

(4) Tires

Unusual vibration of the steering wheel and seats or pulling to one side on the straight and level roads

may indicates the uneven tire inflation pressure or poor wheel balance. -

(5) Steering and suspension system

Inspect the front and rear suspension and the steering system for damage, looseness or missing

parts, signs of wear or lack of lubrication. Inspect the power steering line and the hoses for

connection, leak, crack and chafing. Inspect the drive axle boot and seals for damage, tear or leak.

Replace or repair the system if necessary. -

(6) Engine oil

Check the oil level when the engine is still warm and add the specified engine oil if necessary. -

(7) Coolant

Check the coolant level in the coolant reservoir, coolant conditions (contamination, foreign material),

and hoses for damage and leak. Replace or add the Ssangyong genuine coolant, if needed. -

(8) Engine drive belt

Check all drive belts on the engine for wear, crack and looseness. Retighten or replace the belt, if

needed. -

Page 1111 of 1336

4890-00

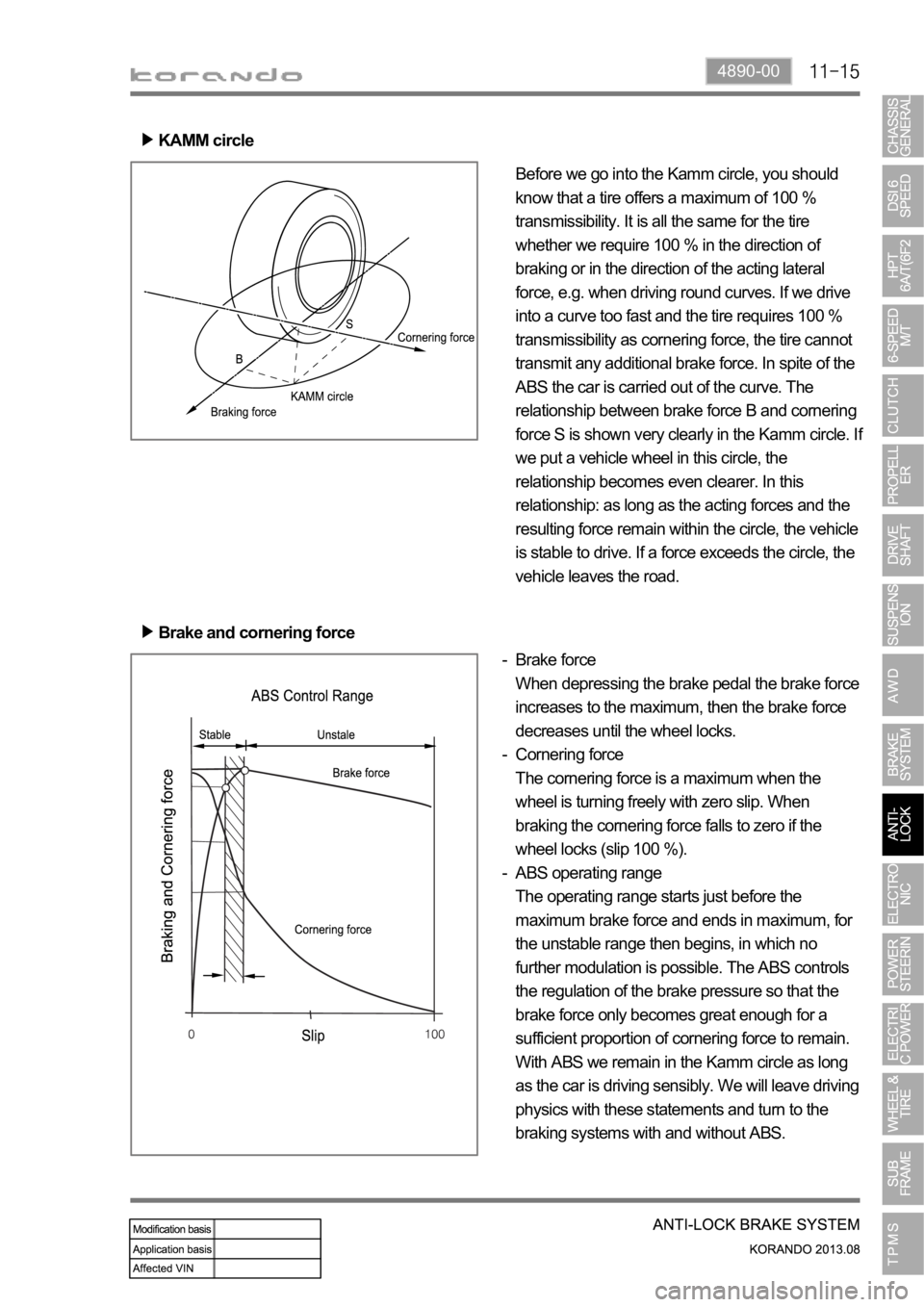

KAMM circle

Before we go into the Kamm circle, you should

know that a tire offers a maximum of 100 %

transmissibility. It is all the same for the tire

whether we require 100 % in the direction of

braking or in the direction of the acting lateral

force, e.g. when driving round curves. If we drive

into a curve too fast and the tire requires 100 %

transmissibility as cornering force, the tire cannot

transmit any additional brake force. In spite of the

ABS the car is carried out of the curve. The

relationship between brake force B and cornering

force S is shown very clearly in the Kamm circle. I

f

we put a vehicle wheel in this circle, the

relationship becomes even clearer. In this

relationship: as long as the acting forces and the

resulting force remain within the circle, the vehicle

is stable to drive. If a force exceeds the circle, the

vehicle leaves the road.

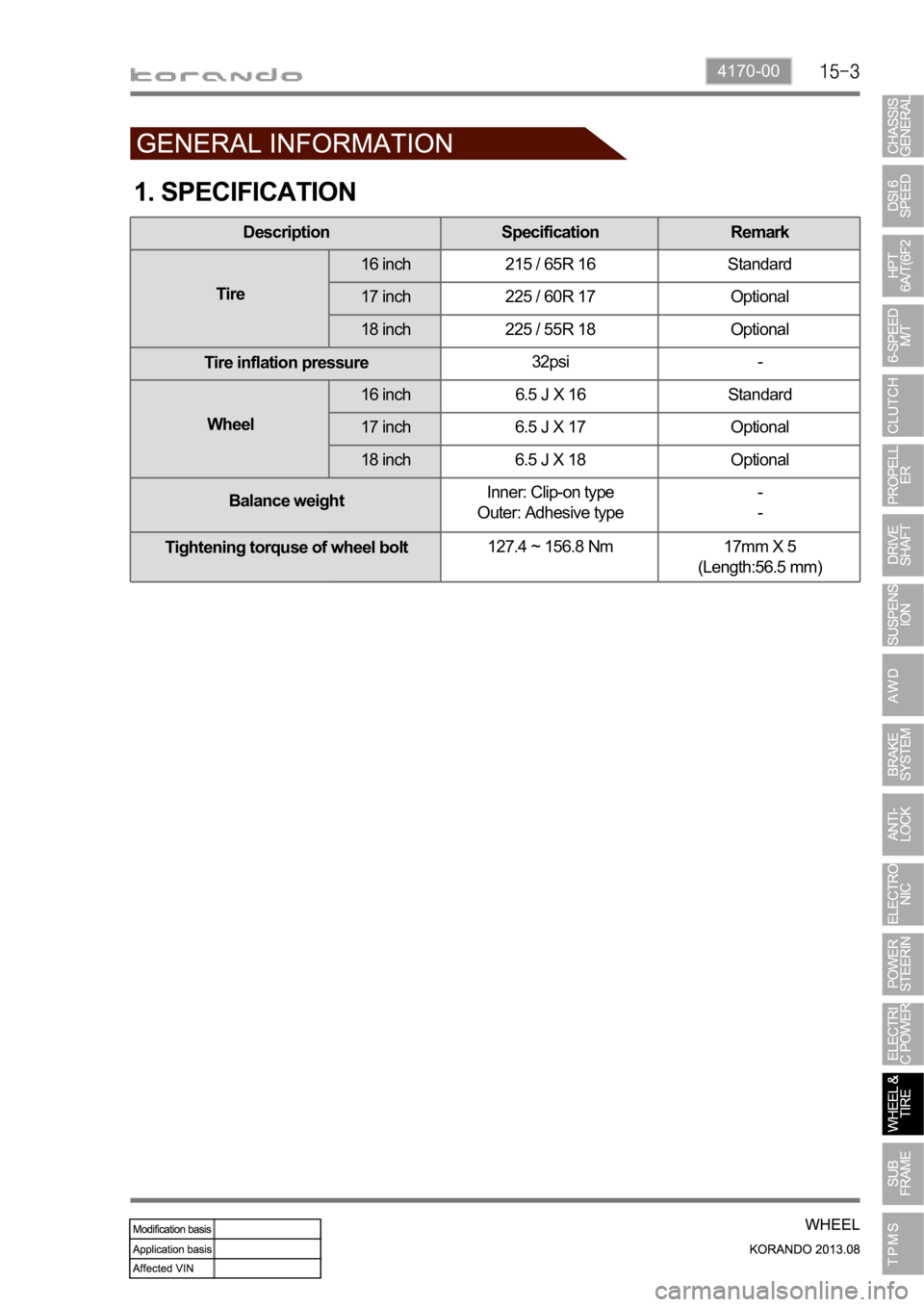

Brake force

When depressing the brake pedal the brake force

increases to the maximum, then the brake force

decreases until the wheel locks.

Cornering force

The cornering force is a maximum when the

wheel is turning freely with zero slip. When

braking the cornering force falls to zero if the

wheel locks (slip 100 %).

ABS operating range

The operating range starts just before the

maximum brake force and ends in maximum, for

the unstable range then begins, in which no

further modulation is possible. The ABS controls

the regulation of the brake pressure so that the

brake force only becomes great enough for a

sufficient proportion of cornering force to remain.

With ABS we remain in the Kamm circle as long

as the car is driving sensibly. We will leave driving

physics with these statements and turn to the

braking systems with and without ABS. -

-

- Brake and cornering force

Page 1155 of 1336

4170-00

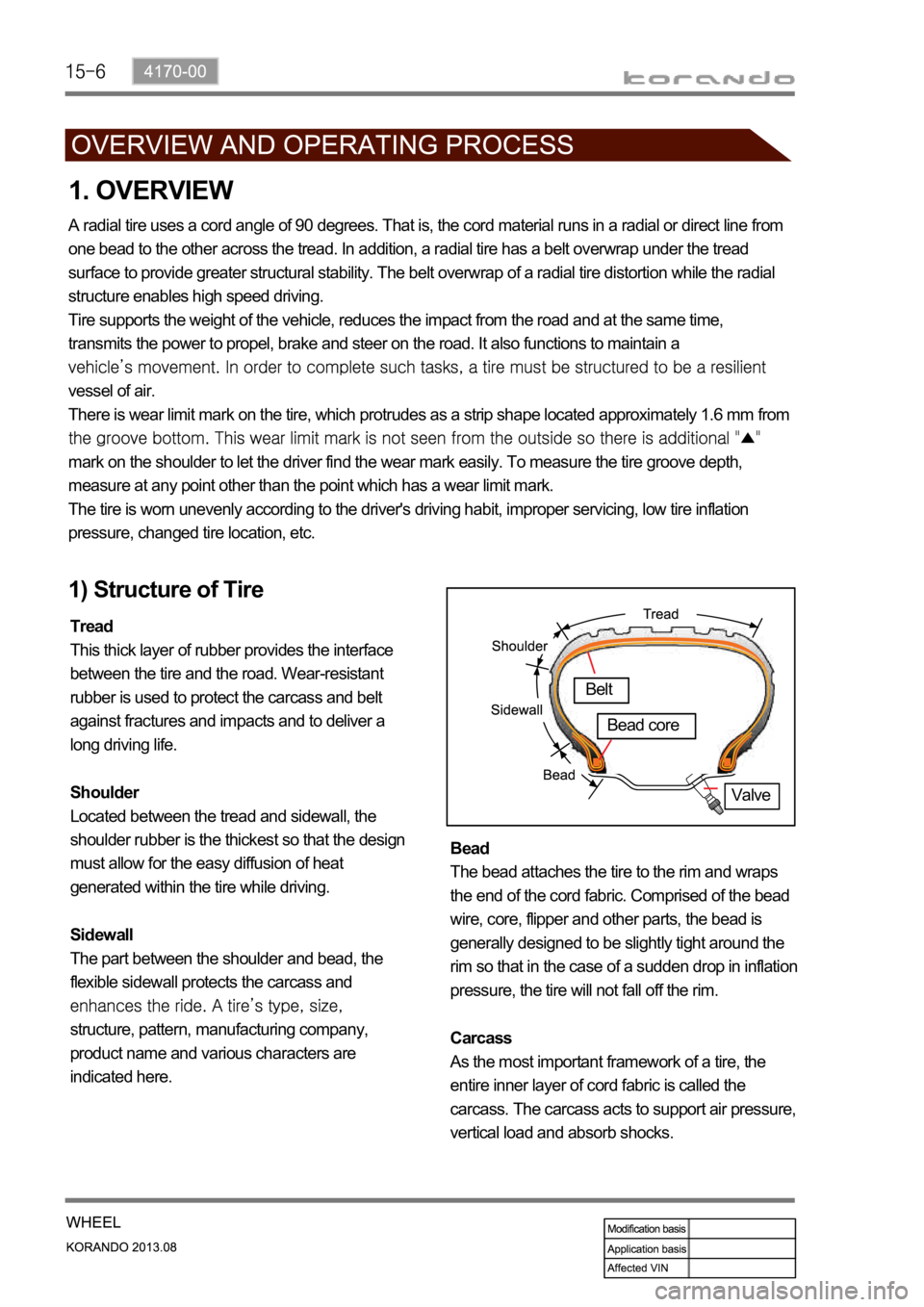

1. SPECIFICATION

Description Specification Remark

Tire16 inch 215 / 65R 16 Standard

17 inch 225 / 60R 17 Optional

18 inch 225 / 55R 18 Optional

Tire inflation pressure32psi -

Wheel16 inch 6.5 J X 16 Standard

17 inch 6.5 J X 17 Optional

18 inch 6.5 J X 18 Optional

Balance weightInner: Clip-on type

Outer: Adhesive type-

-

Tightening torquse of wheel bolt127.4 ~ 156.8 Nm 17mm X 5

(Length:56.5 mm)

Page 1157 of 1336

4170-00

Wheel module

The wheel modules are mounted to each wheel rim and hole. They transmit the signal of the pressure

and temperature in tire, rotating direction and wheel module ID code, etc. using the radio frequency to

the TPMS ECU.

Repair kit

Repair kit changed

Newly added TPMS (Tire Pressure Monitoring System)

Page 1158 of 1336

1. OVERVIEW

A radial tire uses a cord angle of 90 degrees. That is, the cord material runs in a radial or direct line from

one bead to the other across the tread. In addition, a radial tire has a belt overwrap under the tread

surface to provide greater structural stability. The belt overwrap of a radial tire distortion while the radial

structure enables high speed driving.

Tire supports the weight of the vehicle, reduces the impact from the road and at the same time,

transmits the power to propel, brake and steer on the road. It also functions to maintain a

vessel of air.

There is wear limit mark on the tire, which protrudes as a strip shape located approximately 1.6 mm from

mark on the shoulder to let the driver find the wear mark easily. To measure the tire groove depth,

measure at any point other than the point which has a wear limit mark.

The tire is worn unevenly according to the driver's driving habit, improper servicing, low tire inflation

pressure, changed tire location, etc.

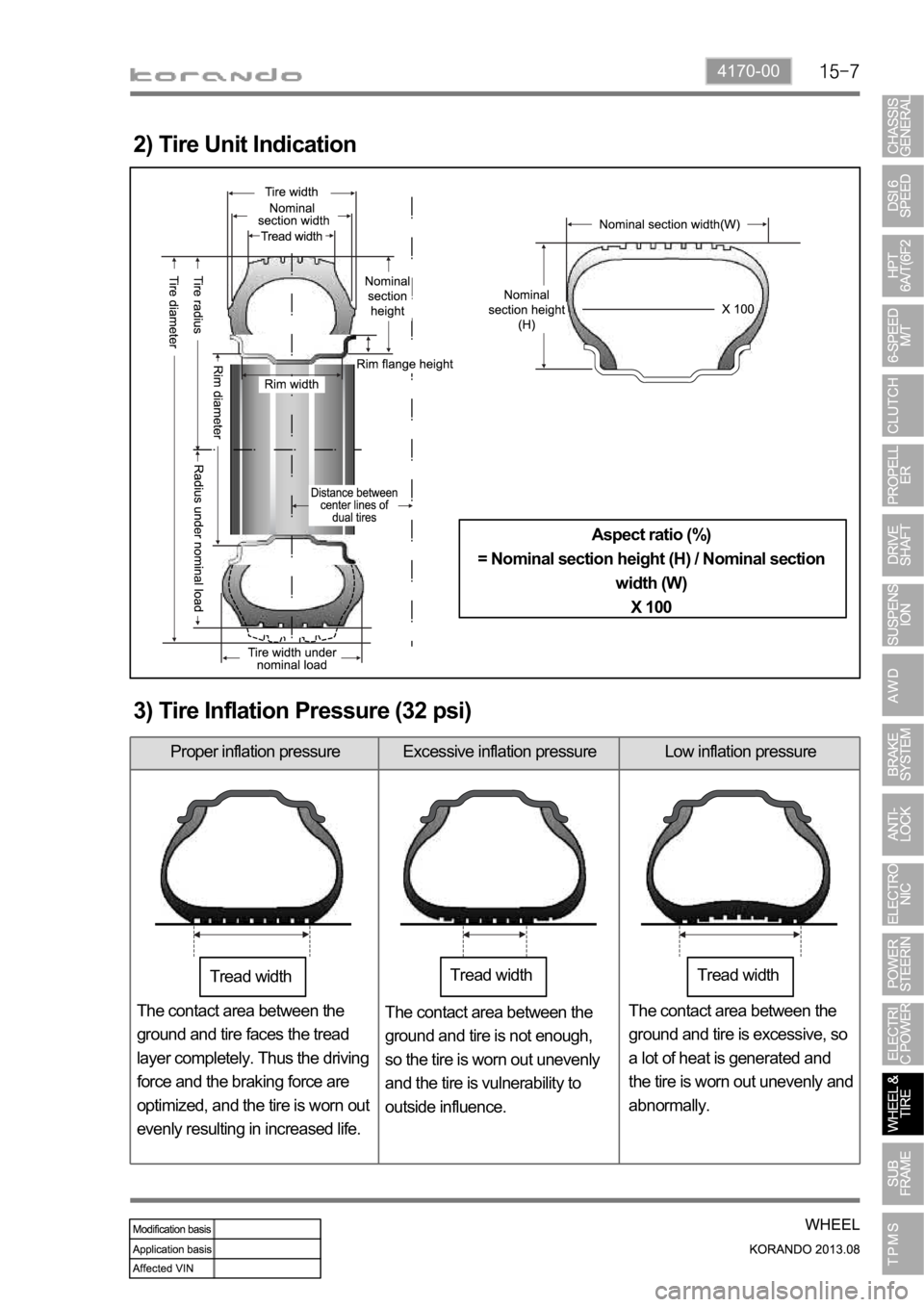

1) Structure of Tire

Tread

This thick layer of rubber provides the interface

between the tire and the road. Wear-resistant

rubber is used to protect the carcass and belt

against fractures and impacts and to deliver a

long driving life.

Shoulder

Located between the tread and sidewall, the

shoulder rubber is the thickest so that the design

must allow for the easy diffusion of heat

generated within the tire while driving.

Sidewall

The part between the shoulder and bead, the

flexible sidewall protects the carcass and

structure, pattern, manufacturing company,

product name and various characters are

indicated here. Bead

The bead attaches the tire to the rim and wraps

the end of the cord fabric. Comprised of the bead

wire, core, flipper and other parts, the bead is

generally designed to be slightly tight around the

rim so that in the case of a sudden drop in inflation

pressure, the tire will not fall off the rim.

Carcass

As the most important framework of a tire, the

entire inner layer of cord fabric is called the

carcass. The carcass acts to support air pressure,

vertical load and absorb shocks.

Valve

Belt

Bead core

Page 1159 of 1336

4170-00

2) Tire Unit Indication

Aspect ratio (%)

= Nominal section height (H) / Nominal section

width (W)

X 100

3) Tire Inflation Pressure (32 psi)

Proper inflation pressure Excessive inflation pressure Low inflation pressure

The contact area between the

ground and tire faces the tread

layer completely. Thus the driving

force and the braking force are

optimized, and the tire is worn out

evenly resulting in increased life.The contact area between the

ground and tire is not enough,

so the tire is worn out unevenly

and the tire is vulnerability to

outside influence.The contact area between the

ground and tire is excessive, so

a lot of heat is generated and

the tire is worn out unevenly and

abnormally.

Tread widthTread widthTread width