warning light SSANGYONG KORANDO 2013 User Guide

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2013, Model line: KORANDO, Model: SSANGYONG KORANDO 2013Pages: 1336, PDF Size: 92.18 MB

Page 836 of 1336

8510-00

1. SPECIFICATIONS

Unit Specification

Multifunction

switchRated voltage DC 12 V

Rated

loadMultifunction

turn light

switchLight switch ON: 1 A (relay load)

Dimmer & passing

switchHigh beam: 0.3 A (relay load)

Low beam: 0.3 A (relay load)

Passing: 0.3 A (relay load)

Turn signal lamp

switch0.1 A (relay load)

AUTO hazard

warning flasher

switch0.1 A (relay load)

Multifunction

wiper

switchWiper switchLO: 0.1 A (relay load)

HI: 0.1 A (relay load)

Fixed: Max. 0.1 A (relay load)

AUTO washer switch

0.1 A (relay load)

Washer switch 0.1 A (relay load)

Wiping speed control

switchMax. 25 mA

Mist switch 0.1 A (relay load)

Rear wiper & washer

switchRear wiper: 0.1 A (relay load)

Multifunction switch

Page 872 of 1336

8510-00

Multifunction wiper switches

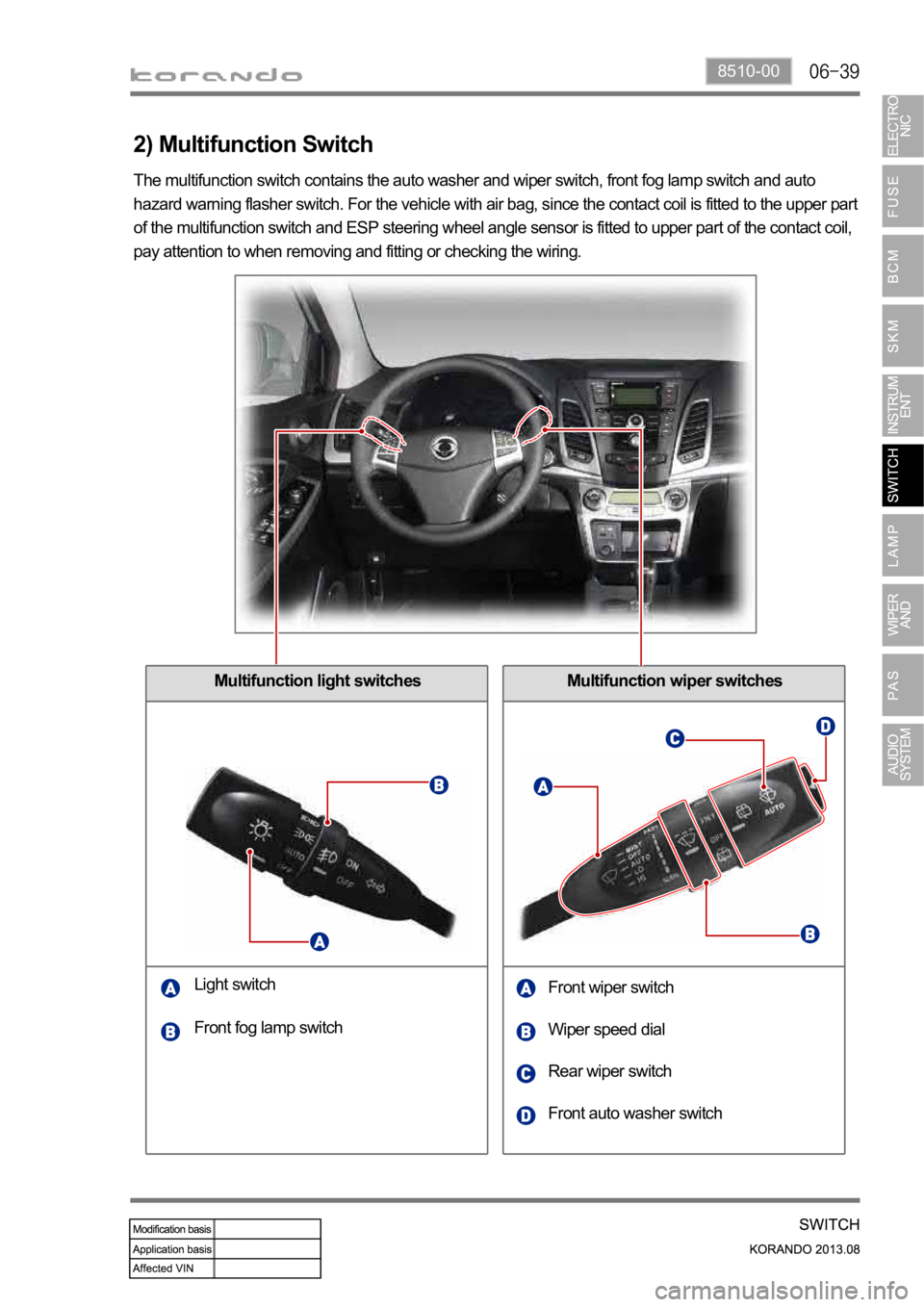

2) Multifunction Switch

Multifunction light switches

Light switch

Front wiper switch

Wiper speed dial

Rear wiper switch Front fog lamp switch

Front auto washer switch The multifunction switch contains the auto washer and wiper switch, front fog lamp switch and auto

hazard warning flasher switch. For the vehicle with air bag, since the contact coil is fitted to the upper part

of the multifunction switch and ESP steering wheel angle sensor is fitted to upper part of the contact coil,

pay attention to when removing and fitting or checking the wiring.

Page 994 of 1336

A. Indicators on instrument cluster

C. HECU assembly

The HECU assemblies for ABS and ESP have

similar appearance but they have different inner

structure and connector connections from each

other. D. Front brake assembly

The disc brake for 4WD vehicle is the same with

the one for 2WD vehicle.

7. BRAKE SYSTEM AND ESP SYSTEM LAYOUT

B. Master cylinder assembly

Description for master cylinder in this chapter is

based on ABS/ESP equipped vehicle. For CBS,

there is an extra pressure valve mounted to the

master cylinder.

CaliperDisc

Parking brake

warning light

ABS warning lamp

ESP indicator

Page 1015 of 1336

3680-01

This information is used by the TCU to decide which shift pattern to select and for shift energy

management. Electro-hydraulic solenoid valves and variable bleed solenoids control the transaxle gear

changes.

Six variable bleed solenoids and four on/off solenoids are used to direct transaxle fluid flow to control the

fluid pressure within the three clutches and two bands. Separate pressure regulators are used

exclusively for torque converter clutch control and main transaxle line pressure.

The TCU monitors all TCU inputs and outputs to confirm correct system operation. If a fault occurs the

TCU is able to perform default action and inform the driver of the problem through the instrument cluster

warning lights. Detailed information is available via trouble codes which can be read with the service tool.

Page 1043 of 1336

3660-01

5. TRANSAXLE ELECTRONIC CONTROL SYSTEM

1) General Information

The transmission control unit (TCU) and its input/output network control the following transmission

operations:

Shift timing

Line pressure

Clutch pressure (shift feel)

Torque converter clutch -

-

-

-

also uses these signals when determining transaxle operating strategy. Using all of these input signals,

the TCU can determine when the time and conditions are right for a shift, or when to apply or release the

torque converter clutch. It will also determine the pressure needed to optimise shift feel.

2) TCU (Transmission Control Unit)

The transaxle control unit (TCU) is mounted

under the driver's seat and controls the operation

of the transaxle.

Internal sensors and signals received across the

CAN bus in analogue and digital forms such as:

Transaxle input speed

Transaxle output speed

Accelerator pedal position

Gear selector position

Engine torque

Engine speed

Transaxle fluid temperature

Brake pedal status

Engine oil temperature

Engine coolant temperature

Ambient air temperature

Barometric pressure -

-

-

-

-

-

-

-

-

-

-

-

The TCU monitors all TCU inputs and outputs to confirm correct system operation. If a fault occurs the

TCU is able to perform default action and inform the driver of the problem through the instrument cluster

warning lights. Detailed information is available via trouble codes which can be read with the service tool.