engine SSANGYONG KORANDO 2013 Service Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2013, Model line: KORANDO, Model: SSANGYONG KORANDO 2013Pages: 1336, PDF Size: 92.18 MB

Page 1132 of 1336

0000-00

5) ARP (Active Roll-Over Protection)

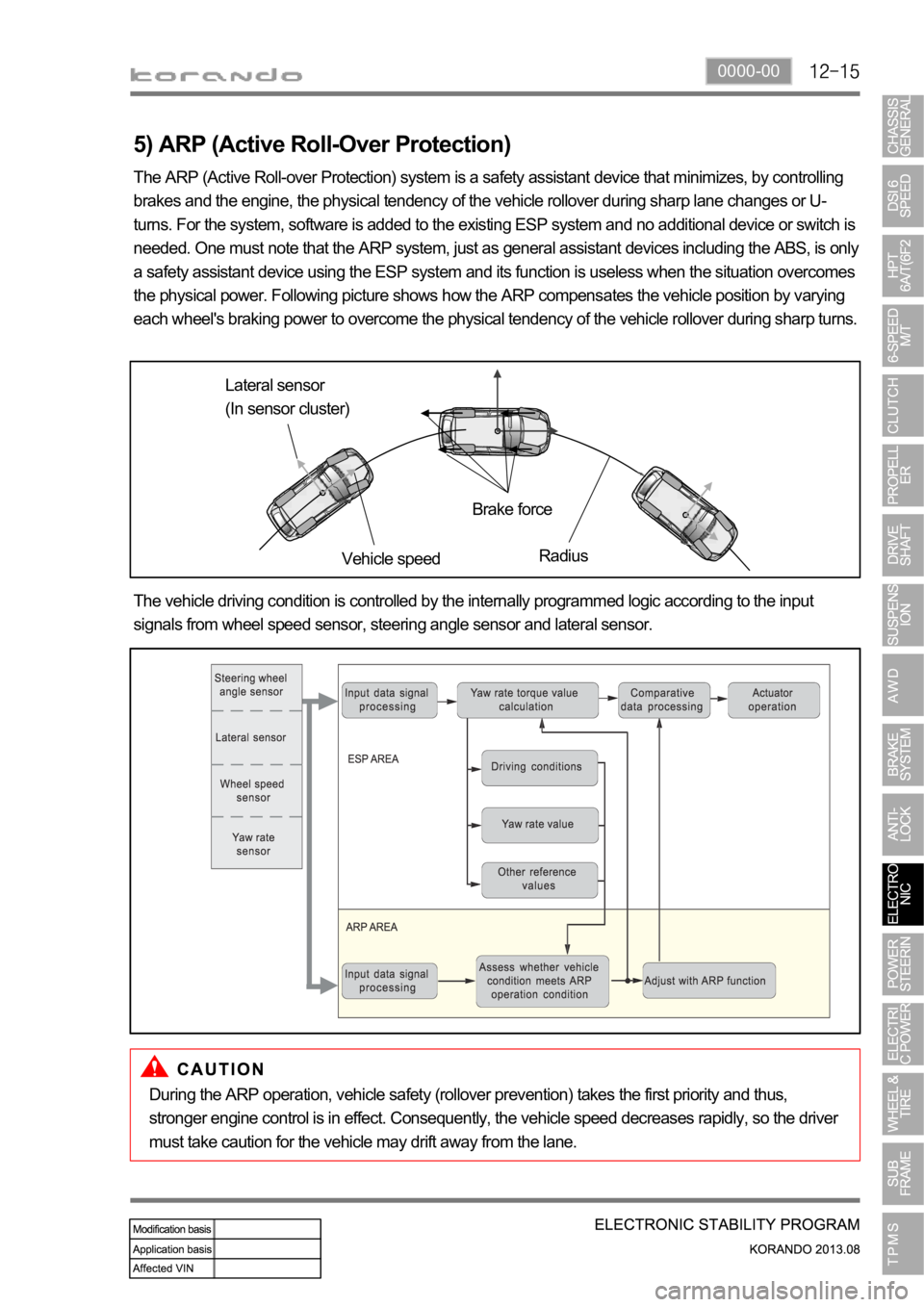

The ARP (Active Roll-over Protection) system is a safety assistant device that minimizes, by controlling

brakes and the engine, the physical tendency of the vehicle rollover during sharp lane changes or U-

turns. For the system, software is added to the existing ESP system and no additional device or switch is

needed. One must note that the ARP system, just as general assistant devices including the ABS, is only

a safety assistant device using the ESP system and its function is useless when the situation overcomes

the physical power. Following picture shows how the ARP compensates the vehicle position by varying

each wheel's braking power to overcome the physical tendency of the vehicle rollover during sharp turns.

Lateral sensor

(In sensor cluster)

Vehicle speedBrake force

Radius

The vehicle driving condition is controlled by the internally programmed logic according to the input

signals from wheel speed sensor, steering angle sensor and lateral sensor.

During the ARP operation, vehicle safety (rollover prevention) takes the first priority and thus,

stronger engine control is in effect. Consequently, the vehicle speed decreases rapidly, so the driver

must take caution for the vehicle may drift away from the lane.

Page 1137 of 1336

Circuit description

When compared to the vehicle equipped with ABS/EBD only, the internal hydraulic circuit has a

normally-open separation valve and a shuttle valve in primary circuit and in secondary circuit.

When the vehicle brakes are not applied during engine running or when applying the non-ABS operating

brakes, the normally-open separation valve and the inlet valve are open, whereas the normally-closed

shuttle valve and the outlet valve are closed.

When the ESP system is operating, the normally-open separation valve will be closed by the solenoid

valve operation and the hydraulic circuit will be established by the shuttle valve. Then, the inlet and outlet

valves will be closed or open depending on the braking pressure RISE, HOLD or DUMP conditions.

Flashing warning lamp and warning sound during ESP operation

When the ESP operates while the vehicle is moving, the ESP warning lamp on the instrument panel

flickers and the buzzer sounds at every 0.1 second. The ESP lamp operation is to inform a driver that the

vehicle is extremely unstable.

The ESP system is just a supplementary system for the vehicle and it cannot control the vehicle over the

physical limit. Do not solely rely on the system but be advised to drive the vehicle safely.

Drive feeling during ESP operation

When the ESP system activates, the driving feeling can be different depending on vehicle driving

conditions. For example, it will feel different when the ESP system is activated while the ABS is operated

by depressing the brake pedal and when the ESP system is in control without the brake pedal

depressed on the same curve.

If the ESP system operates with the brake applied, the brake pressure will be increased on the

corresponding wheel which already has braking pressure for the ESP controls. In other words, the ESP

system would make the driver feel more abruptly braked compared to the situation that the braking

pressure is applied to wheel which had no braking force.

Noise and vibration that driver senses during ESP operation

The ESP system may transfer noise and vibration to a driver due to the pressure changes caused by the

motor and valve operations in a very short period of time.

Extreme cornering will trigger the ESP operation and this will make the driver sense noise and vibration

due to sudden brake application.

Also, the ESP system controls the engine power. Therefore, the driver may notice the engine power

decreases even when the accelerator pedal is depressed.

Page 1149 of 1336

0000-00

Installation of steering

gear box and pipe

Installation of reservoir and hoseInstallation of power steering pump

and pipe

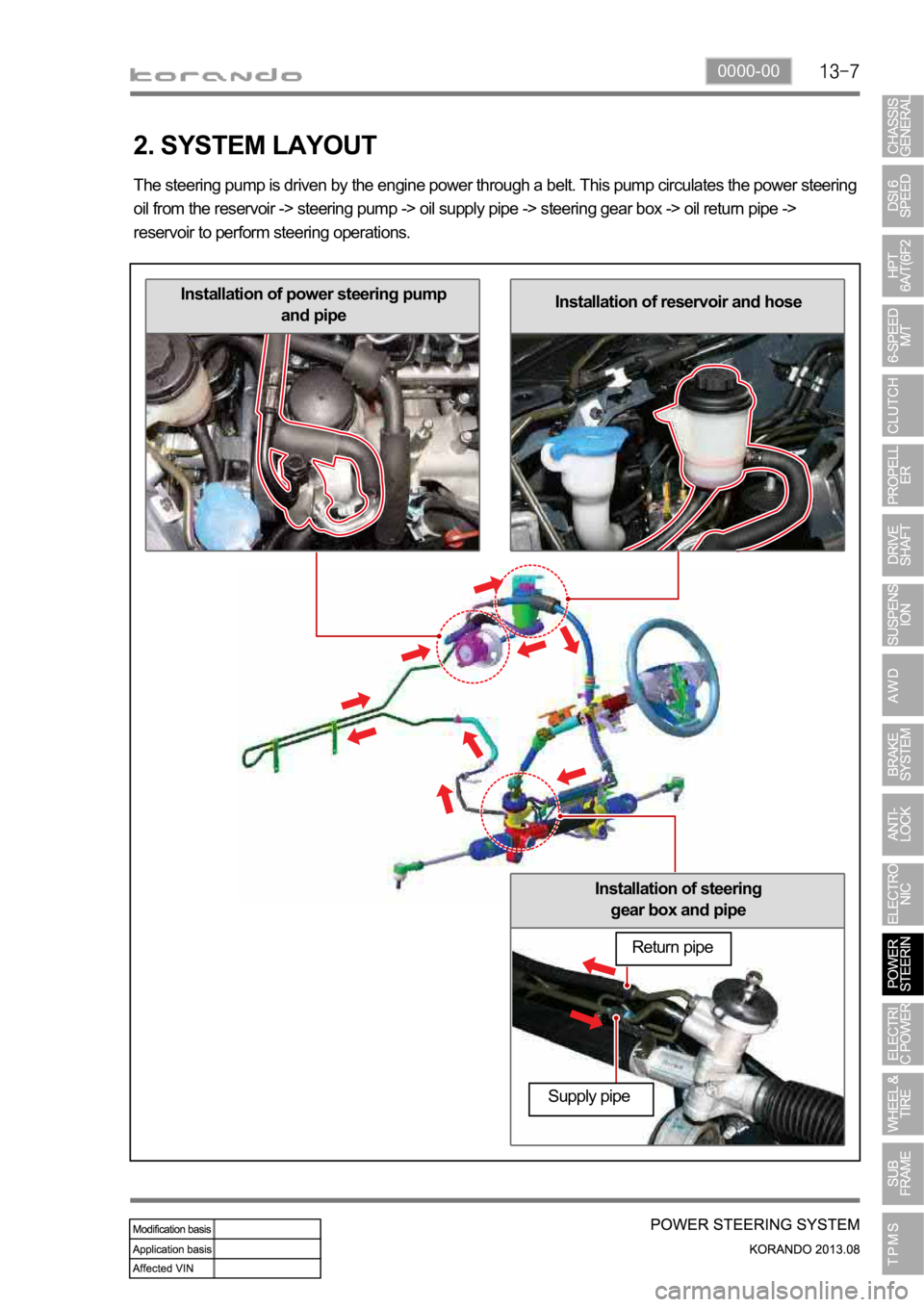

2. SYSTEM LAYOUT

The steering pump is driven by the engine power through a belt. This pump circulates the power steering

oil from the reservoir -> steering pump -> oil supply pipe -> steering gear box -> oil return pipe ->

reservoir to perform steering operations.

Return pipe

Supply pipe

Page 1153 of 1336

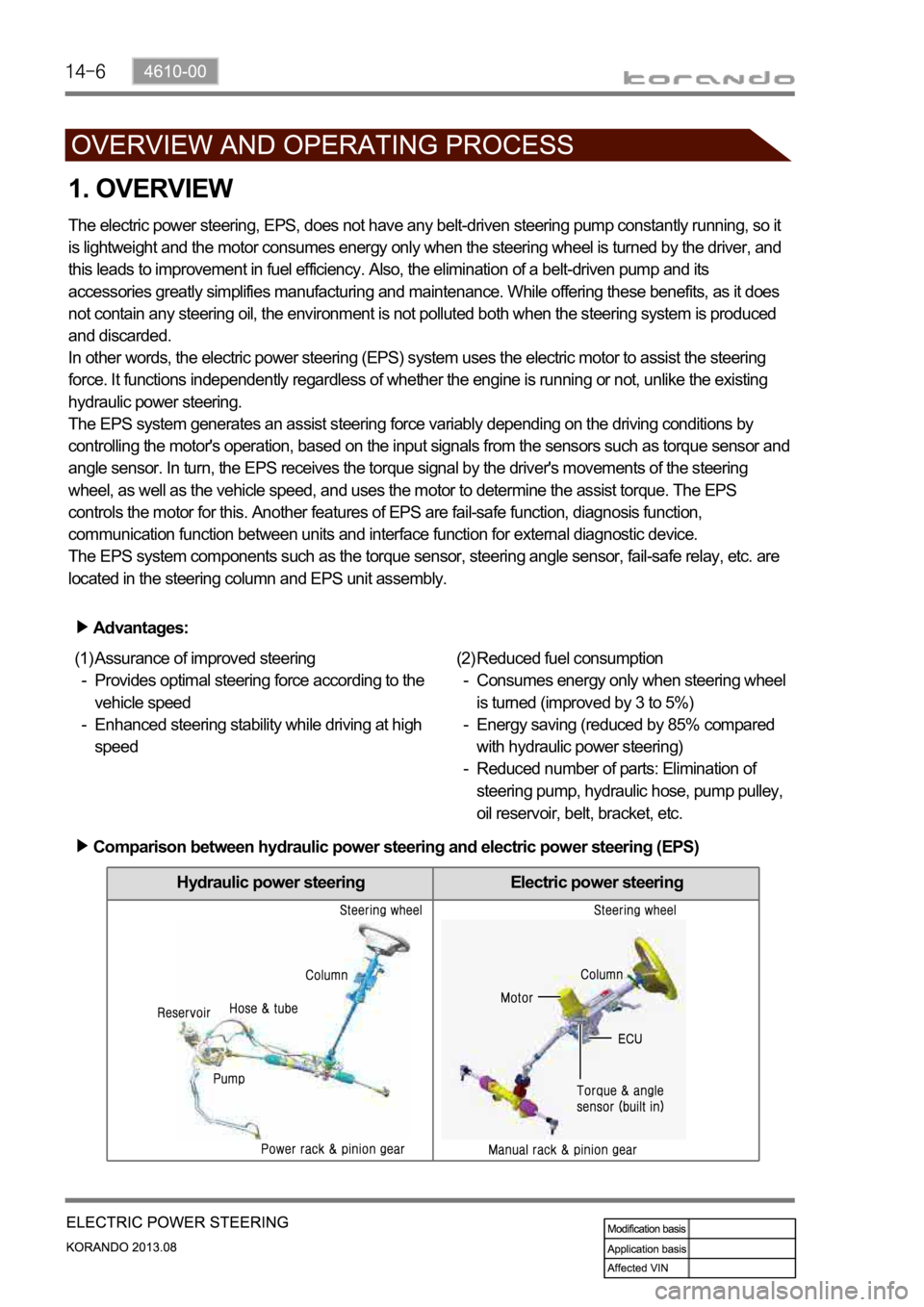

Hydraulic power steering Electric power steering

1. OVERVIEW

The electric power steering, EPS, does not have any belt-driven steering pump constantly running, so it

is lightweight and the motor consumes energy only when the steering wheel is turned by the driver, and

this leads to improvement in fuel efficiency. Also, the elimination of a belt-driven pump and its

accessories greatly simplifies manufacturing and maintenance. While offering these benefits, as it does

not contain any steering oil, the environment is not polluted both when the steering system is produced

and discarded.

In other words, the electric power steering (EPS) system uses the electric motor to assist the steering

force. It functions independently regardless of whether the engine is running or not, unlike the existing

hydraulic power steering.

The EPS system generates an assist steering force variably depending on the driving conditions by

controlling the motor's operation, based on the input signals from the sensors such as torque sensor and

angle sensor. In turn, the EPS receives the torque signal by the driver's movements of the steering

wheel, as well as the vehicle speed, and uses the motor to determine the assist torque. The EPS

controls the motor for this. Another features of EPS are fail-safe function, diagnosis function,

communication function between units and interface function for external diagnostic device.

The EPS system components such as the torque sensor, steering angle sensor, fail-safe relay, etc. are

located in the steering column and EPS unit assembly.

Advantages:

Assurance of improved steering

Provides optimal steering force according to the

vehicle speed

Enhanced steering stability while driving at high

speed (1)

-

-Reduced fuel consumption

Consumes energy only when steering wheel

is turned (improved by 3 to 5%)

Energy saving (reduced by 85% compared

with hydraulic power steering)

Reduced number of parts: Elimination of

steering pump, hydraulic hose, pump pulley,

oil reservoir, belt, bracket, etc. (2)

-

-

-

Comparison between hydraulic power steering and electric power steering (EPS)

Page 1168 of 1336

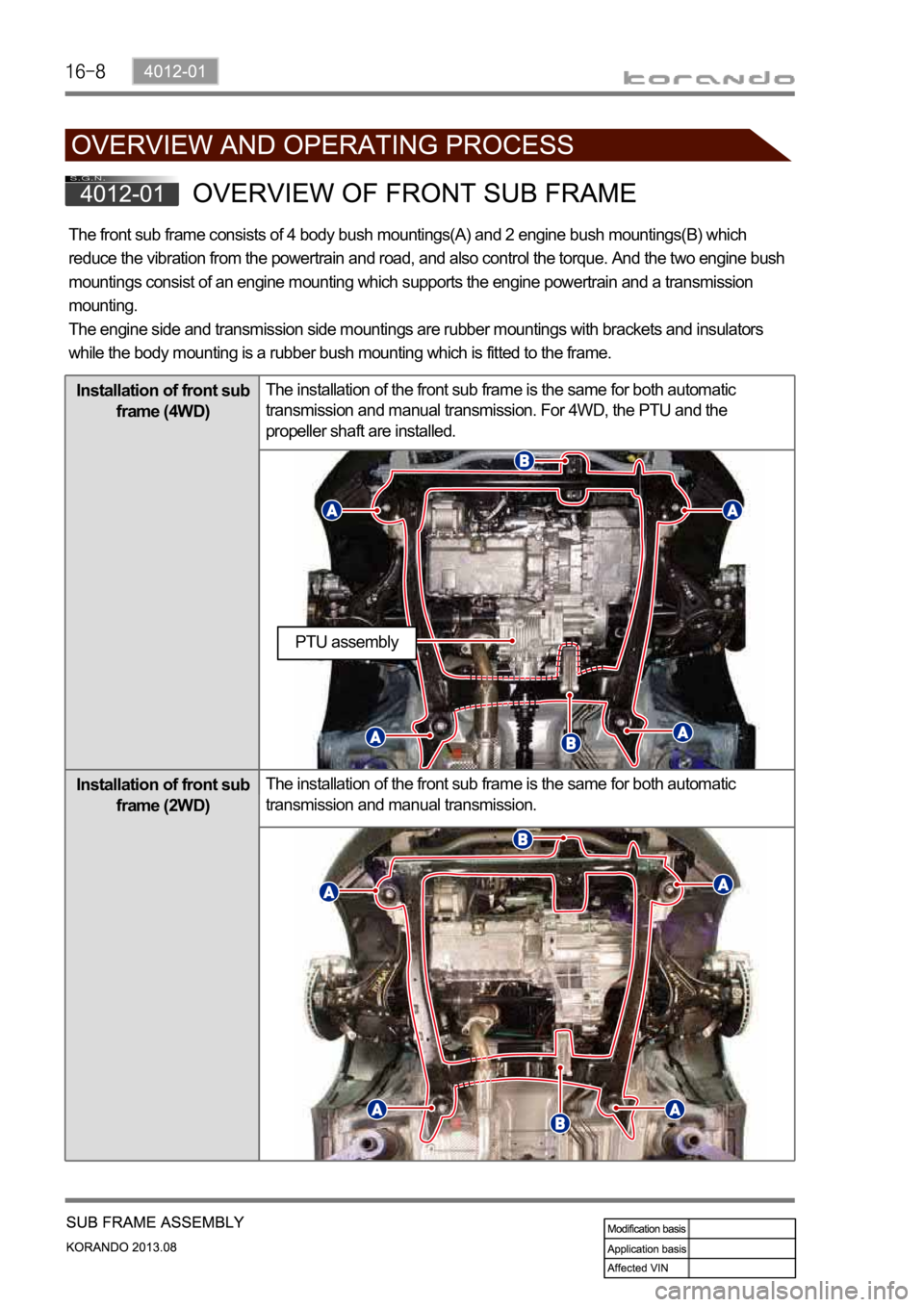

The front sub frame consists of 4 body bush mountings(A) and 2 engine bush mountings(B) which

reduce the vibration from the powertrain and road, and also control the torque. And the two engine bush

mountings consist of an engine mounting which supports the engine powertrain and a transmission

mounting.

The engine side and transmission side mountings are rubber mountings with brackets and insulators

while the body mounting is a rubber bush mounting which is fitted to the frame.

Installation of front sub

frame (4WD)The installation of the front sub frame is the same for both automatic

transmission and manual transmission. For 4WD, the PTU and the

propeller shaft are installed.

Installation of front sub

frame (2WD)The installation of the front sub frame is the same for both automatic

transmission and manual transmission.

PTU assembly

Page 1181 of 1336

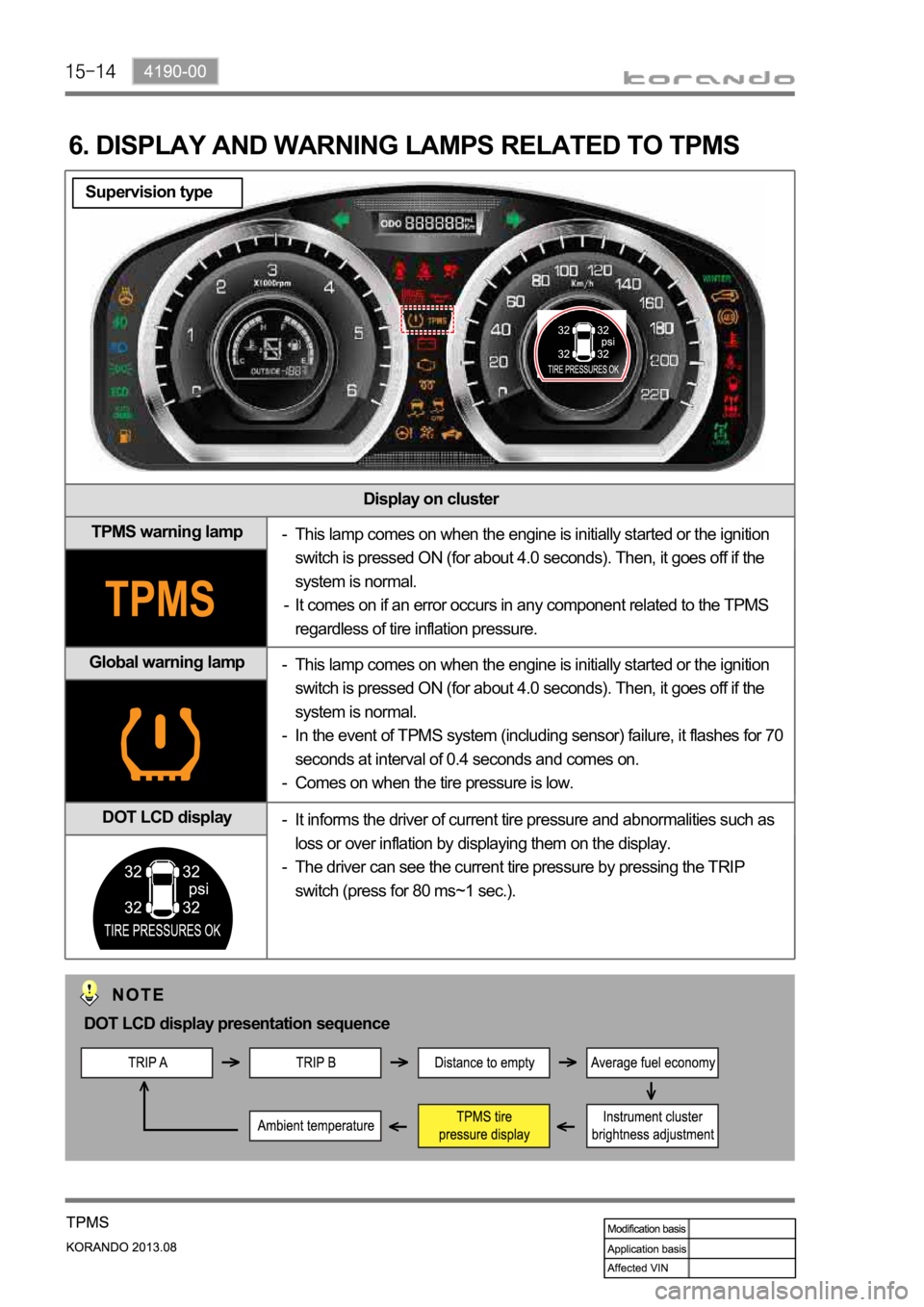

Display on cluster

TPMS warning lamp

Global warning lamp

DOT LCD display

6. DISPLAY AND WARNING LAMPS RELATED TO TPMS

This lamp comes on when the engine is initially started or the ignition

switch is pressed ON (for about 4.0 seconds). Then, it goes off if the

system is normal.

It comes on if an error occurs in any component related to the TPMS

regardless of tire inflation pressure. -

-

This lamp comes on when the engine is initially started or the ignition

switch is pressed ON (for about 4.0 seconds). Then, it goes off if the

system is normal.

In the event of TPMS system (including sensor) failure, it flashes for 70

seconds at interval of 0.4 seconds and comes on.

Comes on when the tire pressure is low. -

-

-

It informs the driver of current tire pressure and abnormalities such as

loss or over inflation by displaying them on the display.

The driver can see the current tire pressure by pressing the TRIP

switch (press for 80 ms~1 sec.). -

-

DOT LCD display presentation sequence

Supervision type

Page 1182 of 1336

4190-00

Display on cluster

TPMS warning lamp

Global warning lamp

DOT display

This lamp comes on when the engine is initially started or the ignition

switch is pressed ON (for about 4.0 seconds). Then, it goes off if the

system is normal.

It comes on if an error occurs in any component related to the TPMS

regardless of tire inflation pressure. -

-

This lamp comes on when the engine is initially started or the ignition

switch is pressed ON (for about 4.0 seconds). Then, it goes off if the

system is normal.

In the event of TPMS system (including sensor) failure, it flashes for 70

seconds at interval of 0.4 seconds and comes on.

Comes on when the tire pressure is low. -

-

-

The tire pressure for front wheels is displayed on the LCD display. The

tire pressure for rear wheels is displayed when pressing the Trip switch. -

Standard type

DOT display presentation sequence

Page 1194 of 1336

2. LAYOUT

1) Exterior Layout

Liquid and suction pipe

The high/low-pressure A/C refrigerant flows

through this pipe. It is fitted with the refrigerant

pressure sensor.

Electric fan

It cools down the A/C condenser to speed up the

compression for the refrigerant in the condenser.

Refrigerant pressure sensor

It is mounted to the latter part of the right

headlamp. It converts the A/C refrigerant pressure

to voltage value and sends it to the engine ECU.

A/C compressor

It is installed to the left side of the engine

assembly, compresses the low-temperature and

low-pressure coolant and converts it to the high-

temperature and high-pressure coolant. Then, it

sends the coolant to the A/C condenser.

Page 1195 of 1336

6810-00

A/C condenser & receiver drier

It is installed in front of vehicle and condenses vapor

refrigerant into low temperature and high pressure liquid

refrigerant. The receiver drier is built in it.Ambient temperature sensor

It is mounted to the front section of the

vehicle and detects the ambient

temperature to send the voltage value

according to the resistance change to

the heater and A/C control assembly.

Engine ECU

It controls the A/C compressor, electric fan

and PTC heater according to the signal from

the A/C control panel.

Expansion valve

It is mounted to the inlet of the evaporator

core and supplies the appropriate quantity

of refrigerant to the evaporator.

Integrated receiver drier

Page 1197 of 1336

6810-00

Intake sensor

It is mounted to the side of

evaporator core and detects the

temperature of the evaporator

core.Water temperature

sensor

It is mounted to the heater pipe

part and detects the coolant

temperature.

3) Air Conditioner Module Layout

Temp actuator

It changes the air mix door

opening according to the

control command from the

heater and A/C control

assembly.Evaporator core

It cools the surrounding air by

passing through the low-

temperature and low-pressure

refrigerant sprayed from the

expansion valve.

Heater core

It is mounted to the left-hand of

the air conditioner module and

heats the indoor using the heat

of the engine coolant.

Mode actuator

It controls the air outlet damper

to the five directions according

to the control command from

the heater and A/C control

assembly.