ECU SSANGYONG KORANDO 2013 Owner's Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2013, Model line: KORANDO, Model: SSANGYONG KORANDO 2013Pages: 1336, PDF Size: 92.18 MB

Page 361 of 1336

1114-00

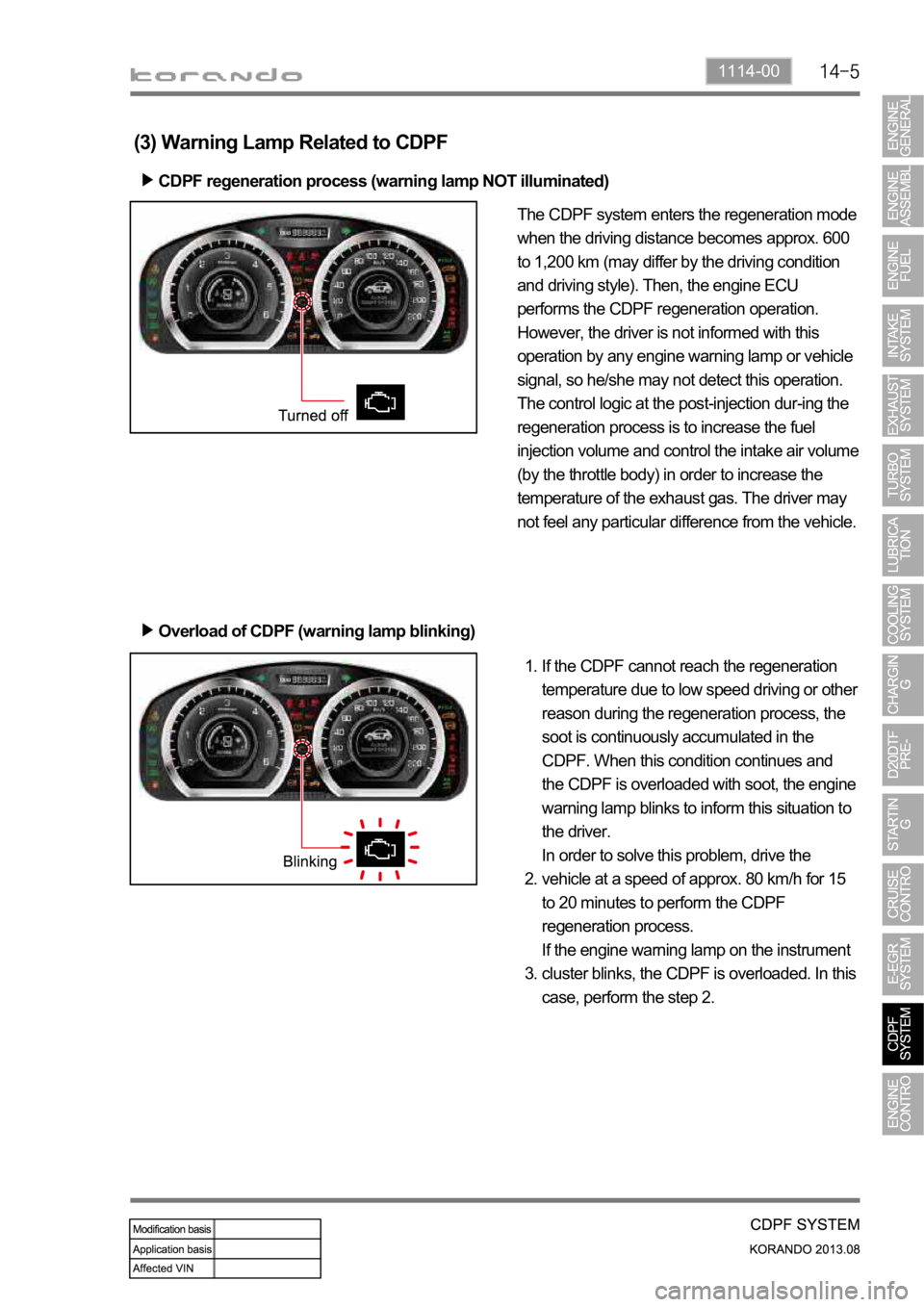

(3) Warning Lamp Related to CDPF

CDPF regeneration process (warning lamp NOT illuminated)

Overload of CDPF (warning lamp blinking)

The CDPF system enters the regeneration mode

when the driving distance becomes approx. 600

to 1,200 km (may differ by the driving condition

and driving style). Then, the engine ECU

performs the CDPF regeneration operation.

However, the driver is not informed with this

operation by any engine warning lamp or vehicle

signal, so he/she may not detect this operation.

The control logic at the post-injection dur-ing the

regeneration process is to increase the fuel

injection volume and control the intake air volume

(by the throttle body) in order to increase the

temperature of the exhaust gas. The driver may

not feel any particular difference from the vehicle.

If the CDPF cannot reach the regeneration

temperature due to low speed driving or other

reason during the regeneration process, the

soot is continuously accumulated in the

CDPF. When this condition continues and

the CDPF is overloaded with soot, the engine

warning lamp blinks to inform this situation to

the driver.

In order to solve this problem, drive the

vehicle at a speed of approx. 80 km/h for 15

to 20 minutes to perform the CDPF

regeneration process.

If the engine warning lamp on the instrument

cluster blinks, the CDPF is overloaded. In this

case, perform the step 2. 1.

2.

3.

Page 364 of 1336

Engine ECU (D20DTF)

Post-injectionDifferential pressure sensor

Calculates the amount of PM

collected by reading the pressure

difference between before and

after the CDPF.Electric throttle body

Regulates the rate of air

intake.

CDPF

(DOC + DPF)Front temperature

sensor

Protects the

turbocharger.Rear temperature

sensor

Measures the

temperature of fuel

combustion.

2. COMPONENT

Oxygen

sensor

Page 367 of 1336

1114-00

ECU (DCM 3.7)

T-MAP sensorIntake air

volume

Detecting

excess of PM

amount limit

Boos

t

pressure

/

temperature

Front EGT sensor

Measures the temperature of

DOC.

The DOC performs the redox

reaction at between 300 and

sensor monitors the

temperature of DOC.

Differential pressure sensor

Measures the pressure values

of before and after the CDPF.

The pressure difference

between before and after the

CDPF is measured by the

differential pressure sensor (If

PM is collected in the CDPF,

the pressure difference

between before and after the

CDPF exceeds the specified

value).

Rear EGT sensor

Measures the temperature of

DPF.

The DPF burns the soot with

hot exhaust gases

(regeneration) at around

sensor monitors the

temperature of DPF.

Injector (C3I)

Controls the post-injection.

Electric throttle body

Controls the intake air

volume.

HFM sensor

Page 368 of 1336

Collecting PM

The engine ECU detects the

amount of PM collected by the

information from the

temperature sensors and

differential pressure sensor.

When the soot is accumulated,

the engine ECU performs post-

injection to increase the

exhaust gas temperature and

burns the collected PM at

Oxidation (DOC)

When the exhaust gas enters

into the CDPF assembly, its

CO, HC and PM are reduced

by the redox reaction of the

DOC. The remaining PM is

filtered and collected in CDPF,

and the temperature of the

exhaust gas is increased to

5. OPERATING PROCESS

[Configuration and principle of operation]

The exhaust gas

passed through the

exhaust manifold

enters into the CDPF

assembly (at approx

Page 373 of 1336

1114-00

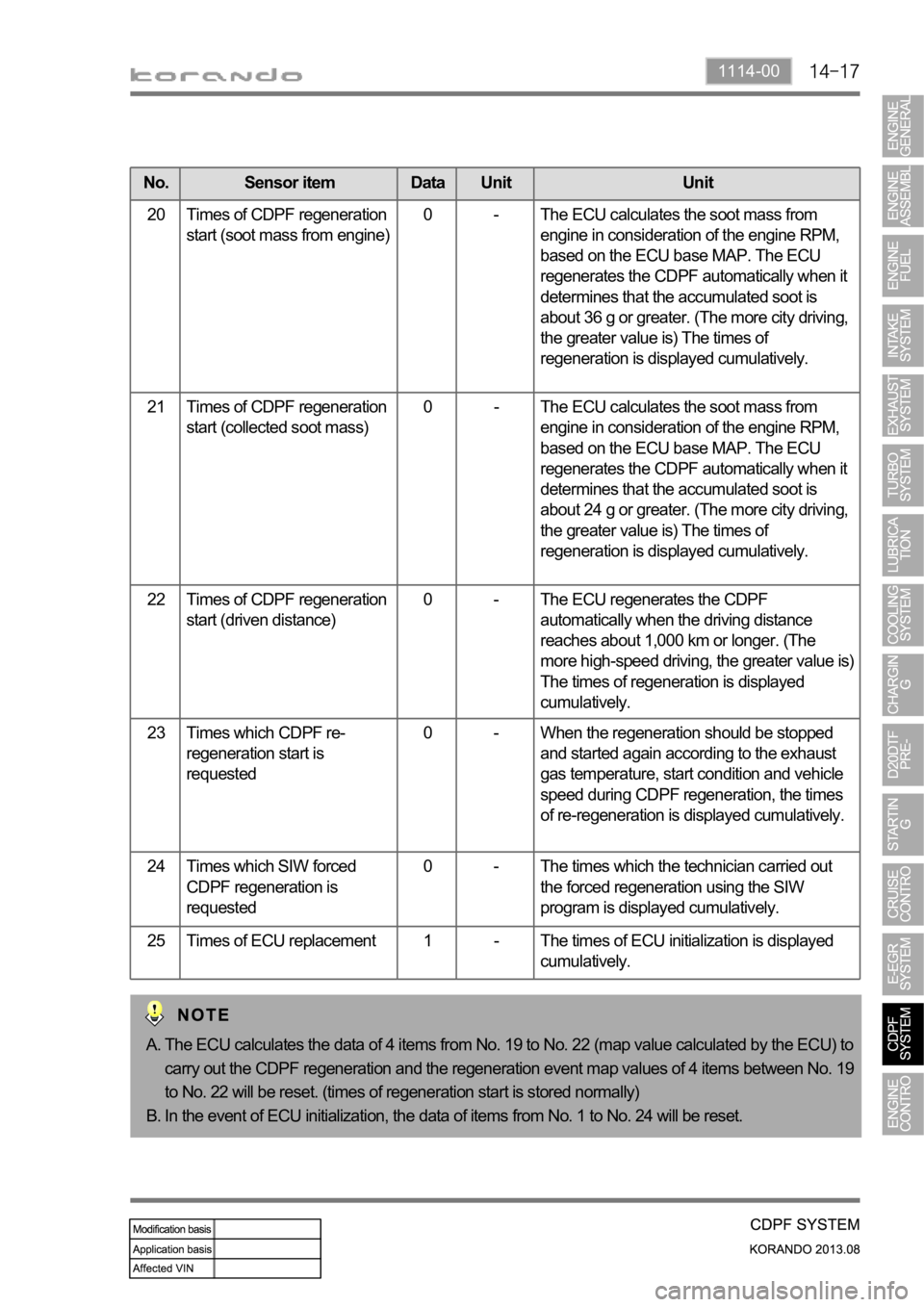

No. Sensor item Data Unit Unit

20 Times of CDPF regeneration

start (soot mass from engine)0 - The ECU calculates the soot mass from

engine in consideration of the engine RPM,

based on the ECU base MAP. The ECU

regenerates the CDPF automatically when it

determines that the accumulated soot is

about 36 g or greater. (The more city driving,

the greater value is) The times of

regeneration is displayed cumulatively.

21 Times of CDPF regeneration

start (collected soot mass)0 - The ECU calculates the soot mass from

engine in consideration of the engine RPM,

based on the ECU base MAP. The ECU

regenerates the CDPF automatically when it

determines that the accumulated soot is

about 24 g or greater. (The more city driving,

the greater value is) The times of

regeneration is displayed cumulatively.

22 Times of CDPF regeneration

start (driven distance)0 - The ECU regenerates the CDPF

automatically when the driving distance

reaches about 1,000 km or longer. (The

more high-speed driving, the greater value is)

The times of regeneration is displayed

cumulatively.

23 Times which CDPF re-

regeneration start is

requested0 - When the regeneration should be stopped

and started again according to the exhaust

gas temperature, start condition and vehicle

speed during CDPF regeneration, the times

of re-regeneration is displayed cumulatively.

24 Times which SIW forced

CDPF regeneration is

requested0 - The times which the technician carried out

the forced regeneration using the SIW

program is displayed cumulatively.

25 Times of ECU replacement 1 - The times of ECU initialization is displayed

cumulatively.

The ECU calculates the data of 4 items from No. 19 to No. 22 (map value calculated by the ECU) to

carry out the CDPF regeneration and the regeneration event map values of 4 items between No. 19

to No. 22 will be reset. (times of regeneration start is stored normally)

In the event of ECU initialization, the data of items from No. 1 to No. 24 will be reset. A.

B.

Page 376 of 1336

0000-00

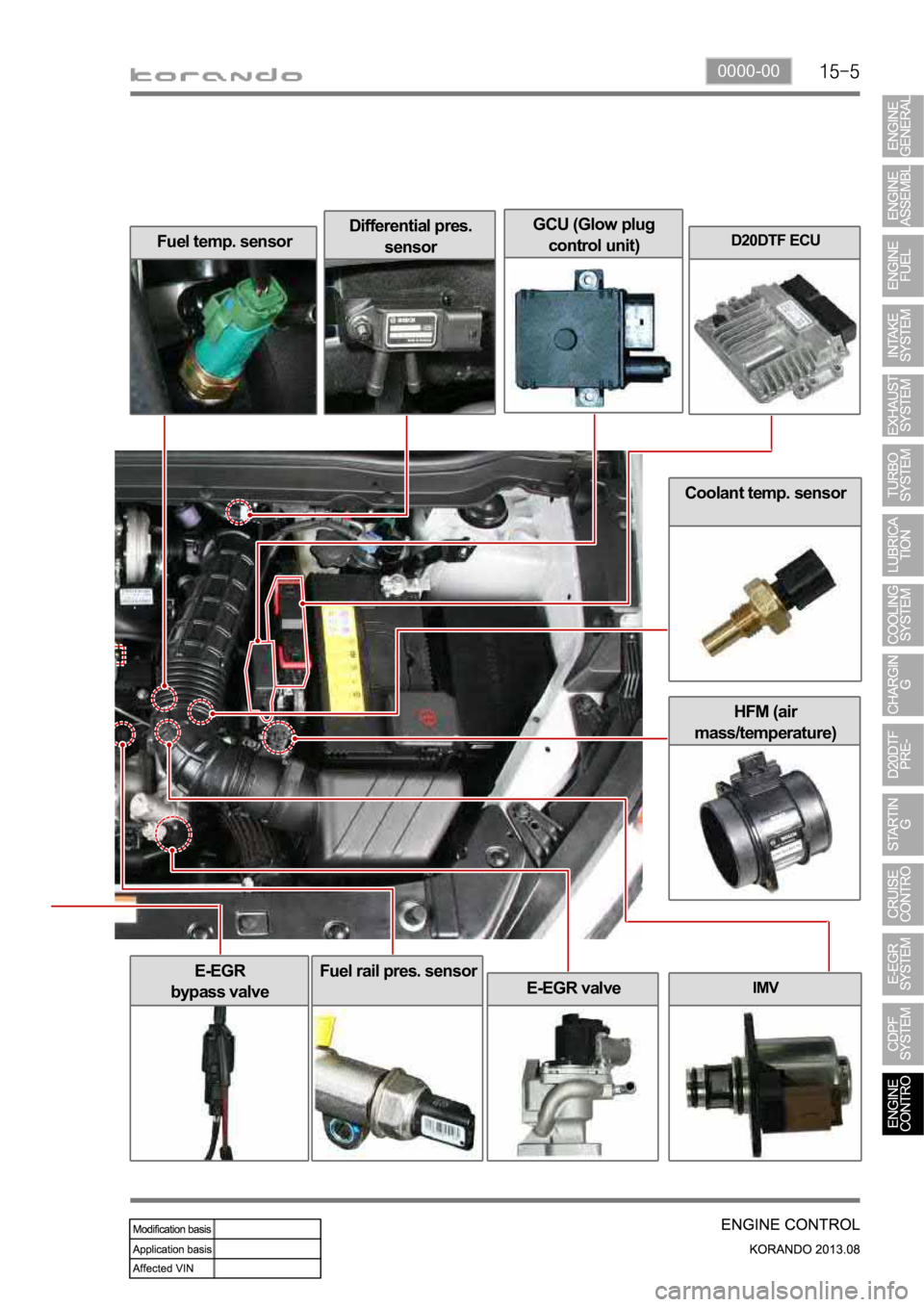

Coolant temp. sensor

HFM (air

mass/temperature)

Fuel temp. sensorDifferential pres.

sensorD20DTF ECU

IMV

E-EGR

bypass valve

E-EGR valve

Fuel rail pres. sensor

GCU (Glow plug

control unit)

Page 377 of 1336

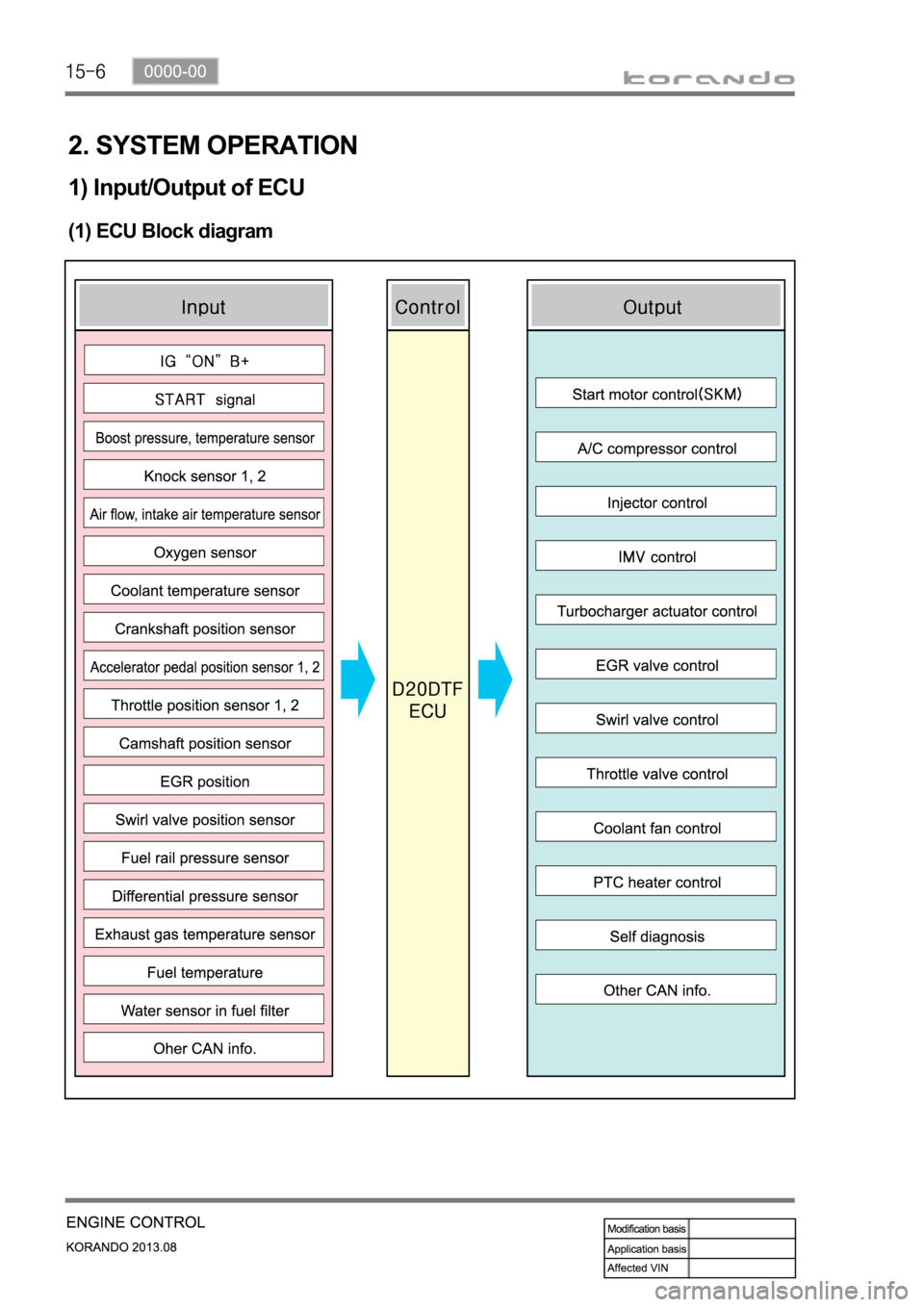

2. SYSTEM OPERATION

1) Input/Output of ECU

(1) ECU Block diagram

Page 378 of 1336

0000-00

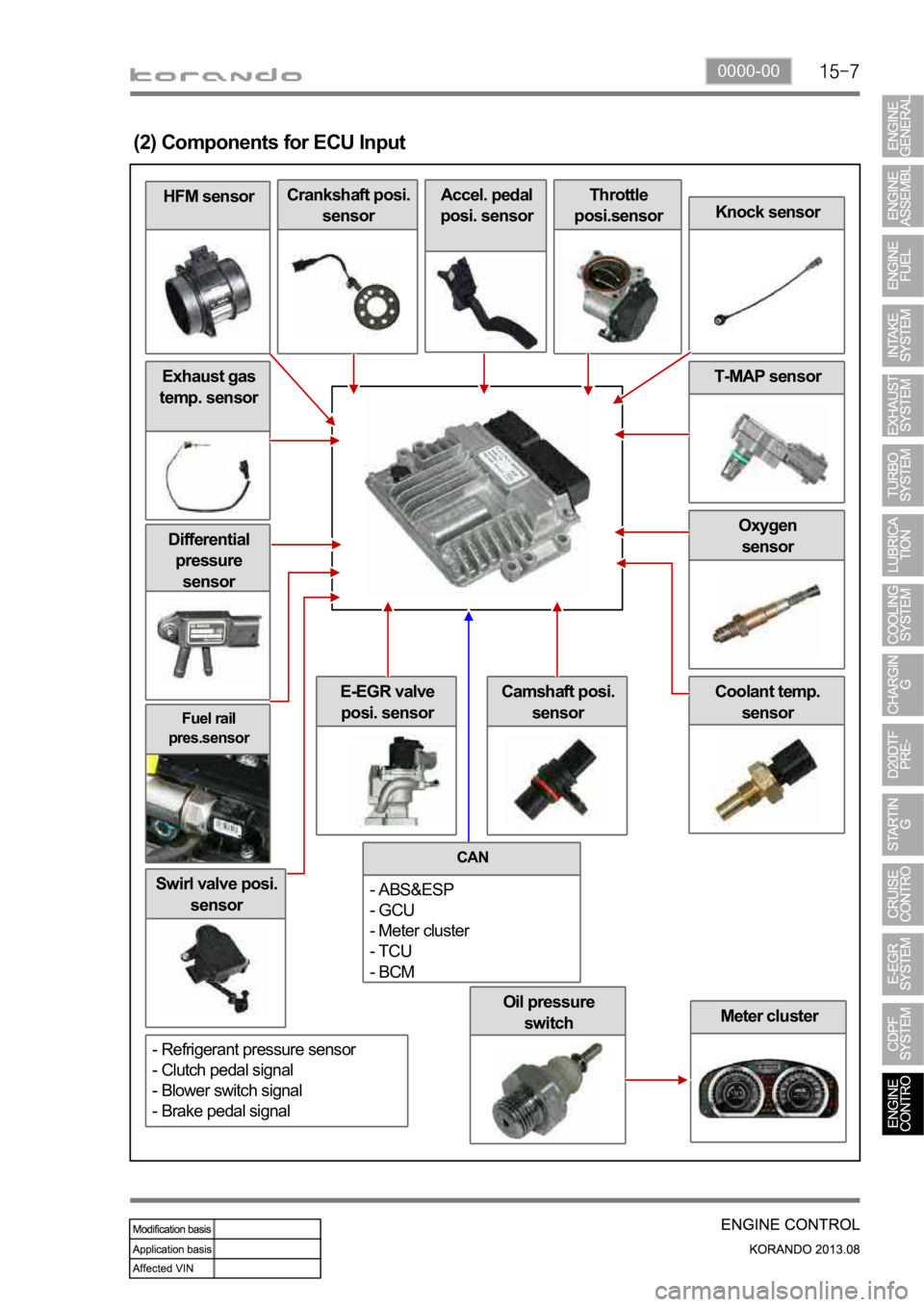

Oil pressure

switch

Fuel rail

pres.sensor

Differential

pressure

sensor

Swirl valve posi.

sensor

Meter cluster

Coolant temp.

sensorE-EGR valve

posi. sensor

Oxygen

sensor

Exhaust gas

temp. sensor

HFM sensor

(2) Components for ECU Input

Crankshaft posi.

sensorAccel. pedal

posi. sensorThrottle

posi.sensor

Knock sensor

T-MAP sensor

Camshaft posi.

sensor

CAN

- ABS&ESP

- GCU

- Meter cluster

- TCU

- BCM

- Refrigerant pressure sensor

- Clutch pedal signal

- Blower switch signal

- Brake pedal signal

Page 379 of 1336

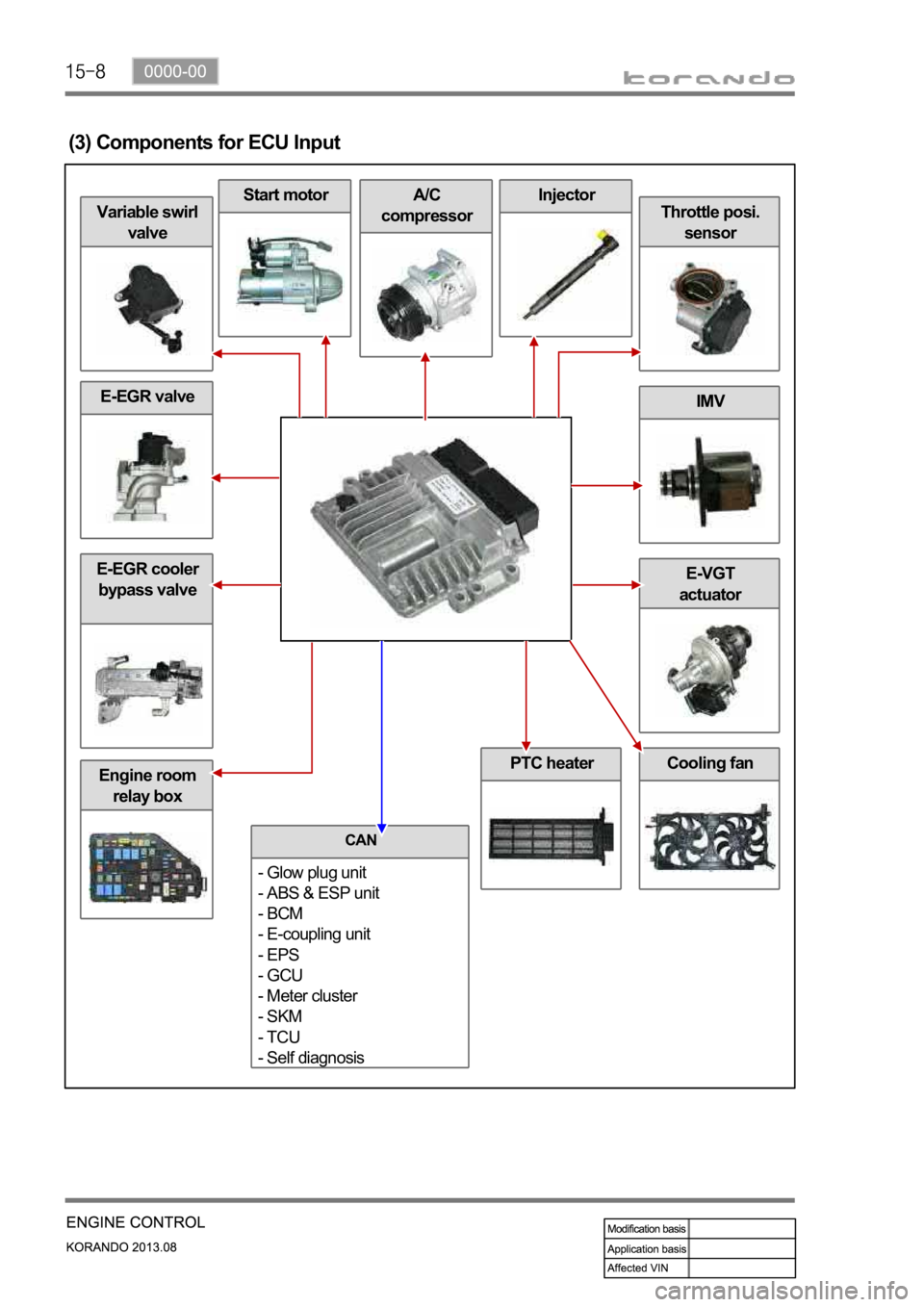

Engine room

relay box

E-EGR valve

Cooling fan

E-EGR cooler

bypass valveE-VGT

actuator

IMV

Throttle posi.

sensor

InjectorA/C

compressorStart motor

Variable swirl

valve

(3) Components for ECU Input

PTC heater

CAN

- Glow plug unit

- ABS & ESP unit

- BCM

- E-coupling unit

- EPS

- GCU

- Meter cluster

- SKM

- TCU

- Self diagnosis

Page 380 of 1336

0000-00

2) ECU Control

(1) Function

a. ECU Function

ECU receives and analyzes signals from various sensors and then modifies those signals into

permissible voltage levels and analyzes to control respective actuators.

ECU microprocessor calculates injection period and injection timing proper for engine piston speed and

crankshaft angle based on input data and stored specific map to control the engine power and emission

gas.

Output signal of the ECU microprocessor drives pressure control valve to control the rail pressure and

activates injector solenoid valve to control the fuel injection period and injection timing; so controls

various actuators in response to engine changes. Auxiliary function of ECU has adopted to reduce

emission gas, improve fuel economy and enhance safety, comforts and conveniences. For example,

there are EGR, booster pressure control, autocruise (export only) and immobilizer and adopted CAN

communication to exchange data among electrical systems (automatic T/M and brake system) in the

vehicle fluently. And Scanner can be used to diagnose vehicle status and defectives.

water and electromagnetism and there should be no mechanical shocks.

To control the fuel volume precisely under repeated injections, high current should be applied instantly

so there is injector drive circuit in the ECU to generate necessary current during injector drive stages.

Current control circuit divides current applying time (injection time) into full-in-current-phase and hold-

current-phase and then the injectors should work very correctly under every working condition.

b. Control Function

Controls by operating stages

To make optimum combustion under every operating stage, ECU should calculate proper injection

volume in each stage by considering various factors.

Starting injection volume control

During initial starting, injecting fuel volume will be calculated by function of temperature and engine

cranking speed. Starting injection continues from when the ignition switch is turned to ignition

position to till the engine reaches to allowable minimum speed.

Driving mode control

If the vehicle runs normally, fuel injection volume will be calculated by accelerator pedal travel and

engine rpm and the drive map will be used to match the drivers inputs with optimum engine power. -

-

-