wiring SSANGYONG KORANDO 2013 Owner's Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2013, Model line: KORANDO, Model: SSANGYONG KORANDO 2013Pages: 1336, PDF Size: 92.18 MB

Page 627 of 1336

0000-00

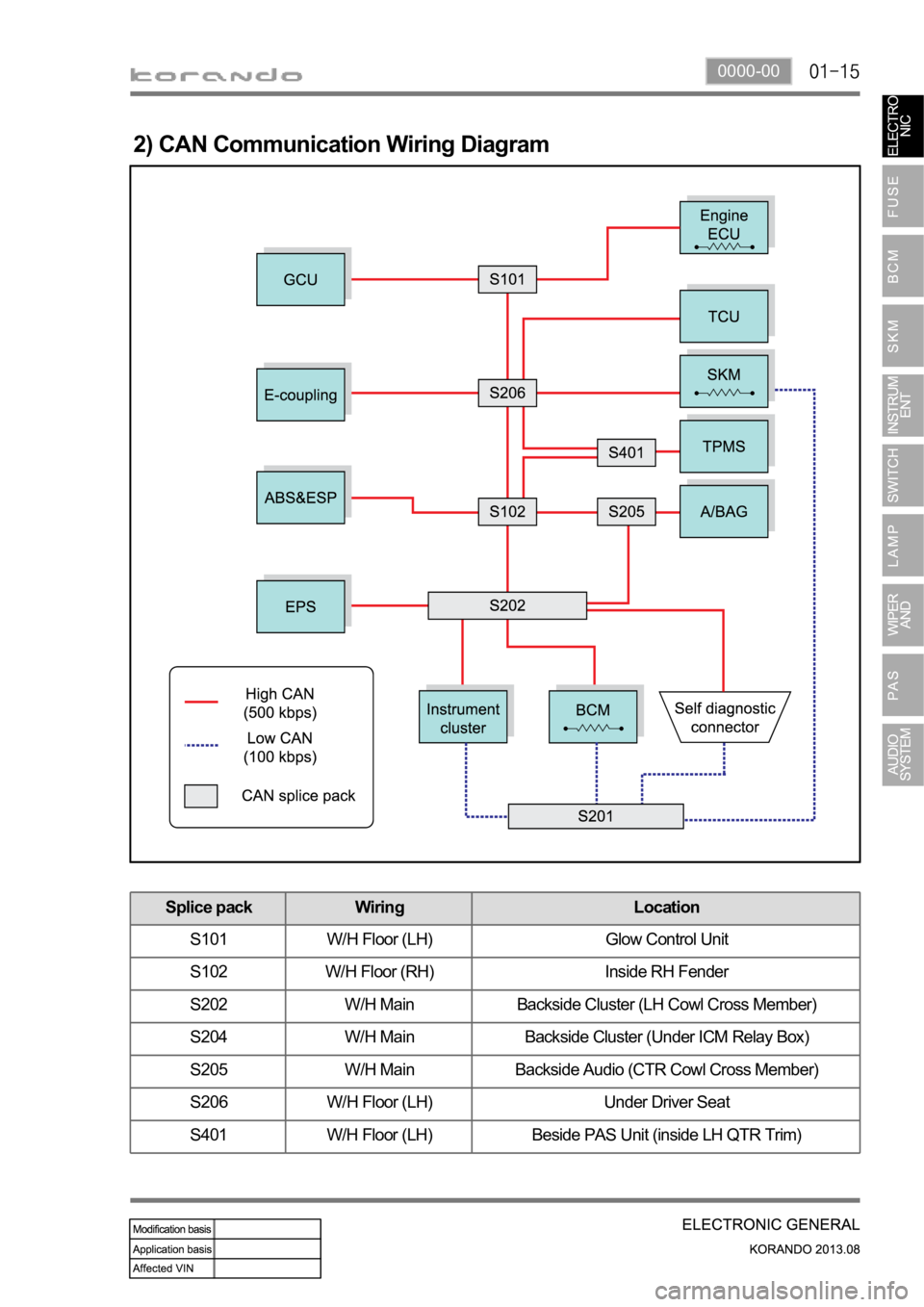

2) CAN Communication Wiring Diagram

Splice pack Wiring Location

S101 W/H Floor (LH) Glow Control Unit

S102 W/H Floor (RH) Inside RH Fender

S202 W/H Main Backside Cluster (LH Cowl Cross Member)

S204 W/H Main Backside Cluster (Under ICM Relay Box)

S205 W/H Main Backside Audio (CTR Cowl Cross Member)

S206 W/H Floor (LH) Under Driver Seat

S401 W/H Floor (LH) Beside PAS Unit (inside LH QTR Trim)

Page 630 of 1336

Make sure a connector is connected

securely. Loose connection results in

malfunction. -

When disconnecting a connector equipped with

a lock, press it down to the direction in the below

figure. -

When checking voltage or continuity of the

connector terminal with a circuit tester, connect

the tester probe to the terminal at the harness

side. For a sealed type connector, connect the

probe to the terminal through the hole in the

rubber cap of the wiring. Take care not to

damage the insulation of the wires. Insert the

probe until it contacts the terminal completely. -

When inspecting the airbag system, make sure to use a diagnostic device, not a circuit tester.

Page 631 of 1336

8410-00

2. CHECKING CABLES AND WIRES

Check for loose connection or rust.

Check terminals and wires for corrosion due to electrolyte leakage.

Check terminals and wires for open circuit.

Check the wire insulation and coat for damage, cracks or deterioration.

Check if the conductive parts of the terminals do not contact with vehicle body or other metal parts.

Check that the grounding part has continuity with mounting bolts and vehicle body.

Check that wires are properly routed.

Make sure that wires are securely fixed to avoid contact with sharp body parts and high-temperature

parts, such as the exhaust manifold and exhaust pipes.

The rotating parts, such as fan pulley and fan belt, perturbative parts and wiring should be secured

tightly at regular intervals.

Secure the wiring between the fixed parts, such as the vehicle body, and vibrating parts, such as the

engine, after slackening it slightly to prevent it from being damaged. -

-

-

-

-

-

-

-

-

-

Page 704 of 1336

Door LOCK/UNLOCK control by door knob switch

The driver and passenger door LOCK knob switches are in the LOCK position from UNLOCK

position.

The door LOCK relay is activated for 0.5 seconds (T1). A.

B. Operation 1.

The driver and passenger door LOCK knob switches are in the UNLOCK position from LOCK

position.

The door UNLOCK relay is activated for 0.5 seconds (T2). C.

D. Operation 2.

All open doors are closed.

The LOCK signal is input within 0.5 seconds (T3).

The UNLOCK signal for all doors is output once for 0.5 seconds (T4). E.

F.

G. Operation 3.

14. CENTRAL DOOR LOCKING SYSTEM CONTROL

For BCM with SKM, sleep mode is deactivated by receiving the status signals from the driver door

knob switch, passenger door knob switch, rear LH/RH door knob switch, and central door

LOCK/UNLOCK switch through the wiring.

If all doors are unlocked 5 times within 1 minute after door LOCK signal output, because of faulty

door knob switch and door open switch, the doors are forced to lock and not allowed to unlock.

However, the UNLOCK conditions are met, the UNKLOCK signal is input normally. -

-

The door lock/unlock system does not work regardless of the door LOCK/UNLOCK switch position,

when reconnecting the battery. (to reset, turn the ignition ON) -

The signal change from UNLOCK to LOCK is ignored during LOCK/UNLOCK output by the central

door LOCK switch, REKES key, and door handle switch.

If LOCK signal from the switch is input within 0.5 seconds after any door is closed, UNLOCK signal

is output. -

-

Page 872 of 1336

8510-00

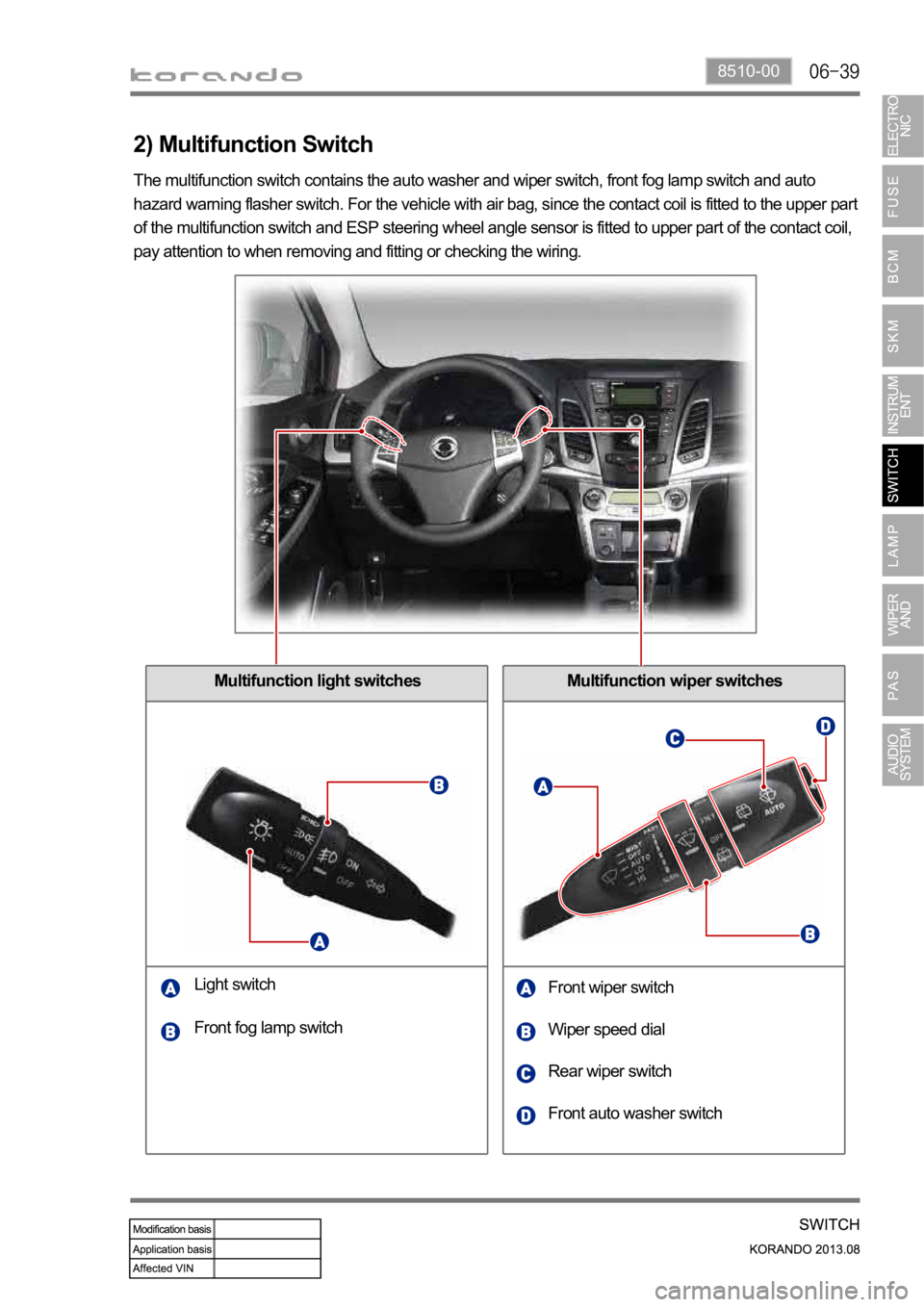

Multifunction wiper switches

2) Multifunction Switch

Multifunction light switches

Light switch

Front wiper switch

Wiper speed dial

Rear wiper switch Front fog lamp switch

Front auto washer switch The multifunction switch contains the auto washer and wiper switch, front fog lamp switch and auto

hazard warning flasher switch. For the vehicle with air bag, since the contact coil is fitted to the upper part

of the multifunction switch and ESP steering wheel angle sensor is fitted to upper part of the contact coil,

pay attention to when removing and fitting or checking the wiring.

Page 1058 of 1336

3190-01

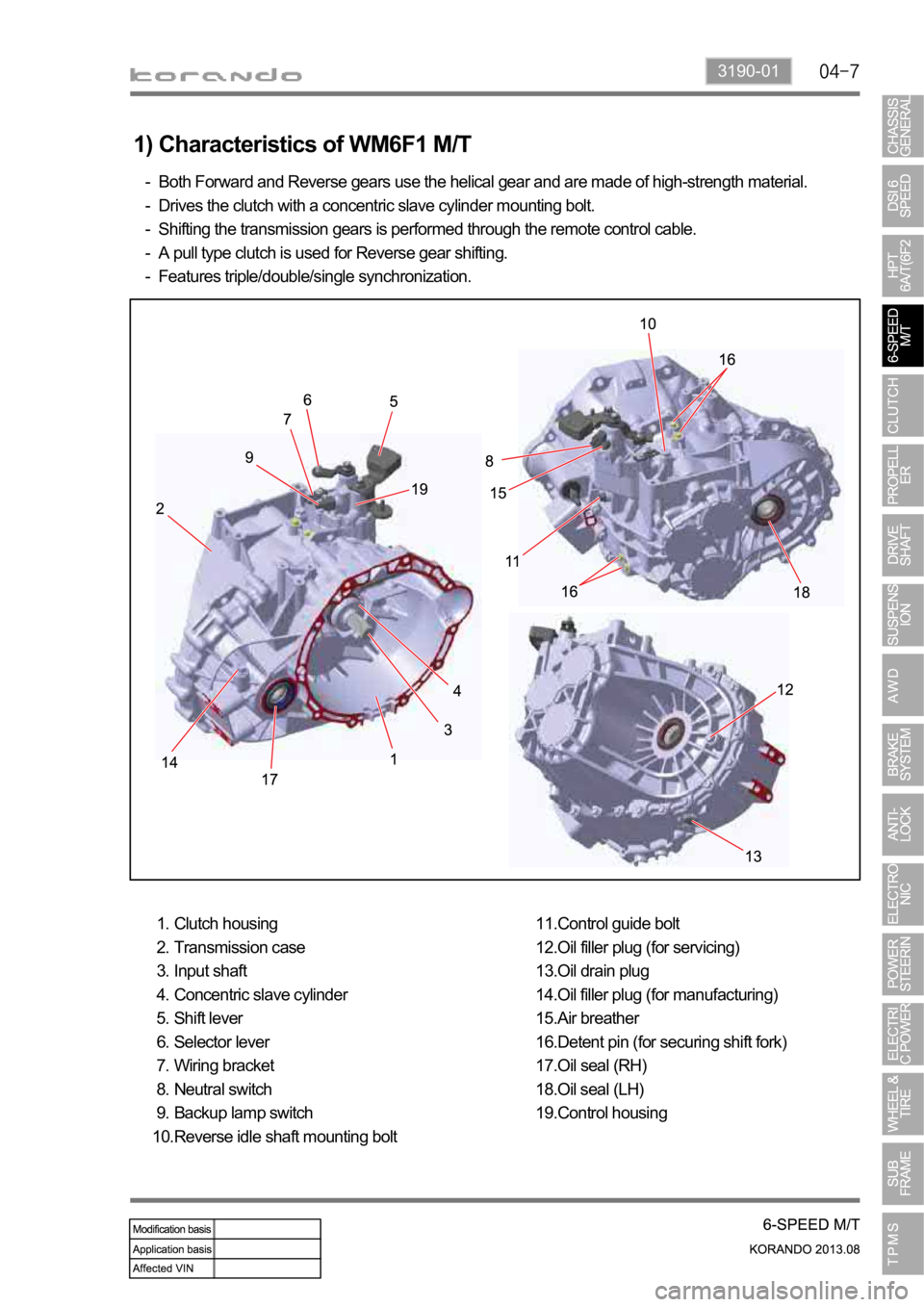

1) Characteristics of WM6F1 M/T

Both Forward and Reverse gears use the helical gear and are made of high-strength material.

Drives the clutch with a concentric slave cylinder mounting bolt.

Shifting the transmission gears is performed through the remote control cable.

A pull type clutch is used for Reverse gear shifting.

Features triple/double/single synchronization. -

-

-

-

-

Clutch housing

Transmission case

Input shaft

Concentric slave cylinder

Shift lever

Selector lever

Wiring bracket

Neutral switch

Backup lamp switch

Reverse idle shaft mounting bolt 1.

2.

3.

4.

5.

6.

7.

8.

9.

10.Control guide bolt

Oil filler plug (for servicing)

Oil drain plug

Oil filler plug (for manufacturing)

Air breather

Detent pin (for securing shift fork)

Oil seal (RH)

Oil seal (LH)

Control housing 11.

12.

13.

14.

15.

16.

17.

18.

19.

Page 1222 of 1336

2) Control Condition For PTC Heater

Operation Operating condition PTC heater status

HI mode operation

(PTC2, 3)PTC heater operates in

"HIGH" mode if operating

conditions are met

LO mode operation

(PTC1)PTC heater operates in

"LOW" mode if operating

conditions are met

Conditions for

deactivating

Air conditioner blower switch OFF

When the ambient temperature sensor is

faulty (short or open circuit in the wiring)

Engine is cranking

Battery voltage is 11 V or less

Glow plug is being preheated (Glow indicator

comes on) -

-

-

-

-

-

-

-

-

Conditions for PTC heater "LOW" operation mode (2nd step)

Page 1237 of 1336

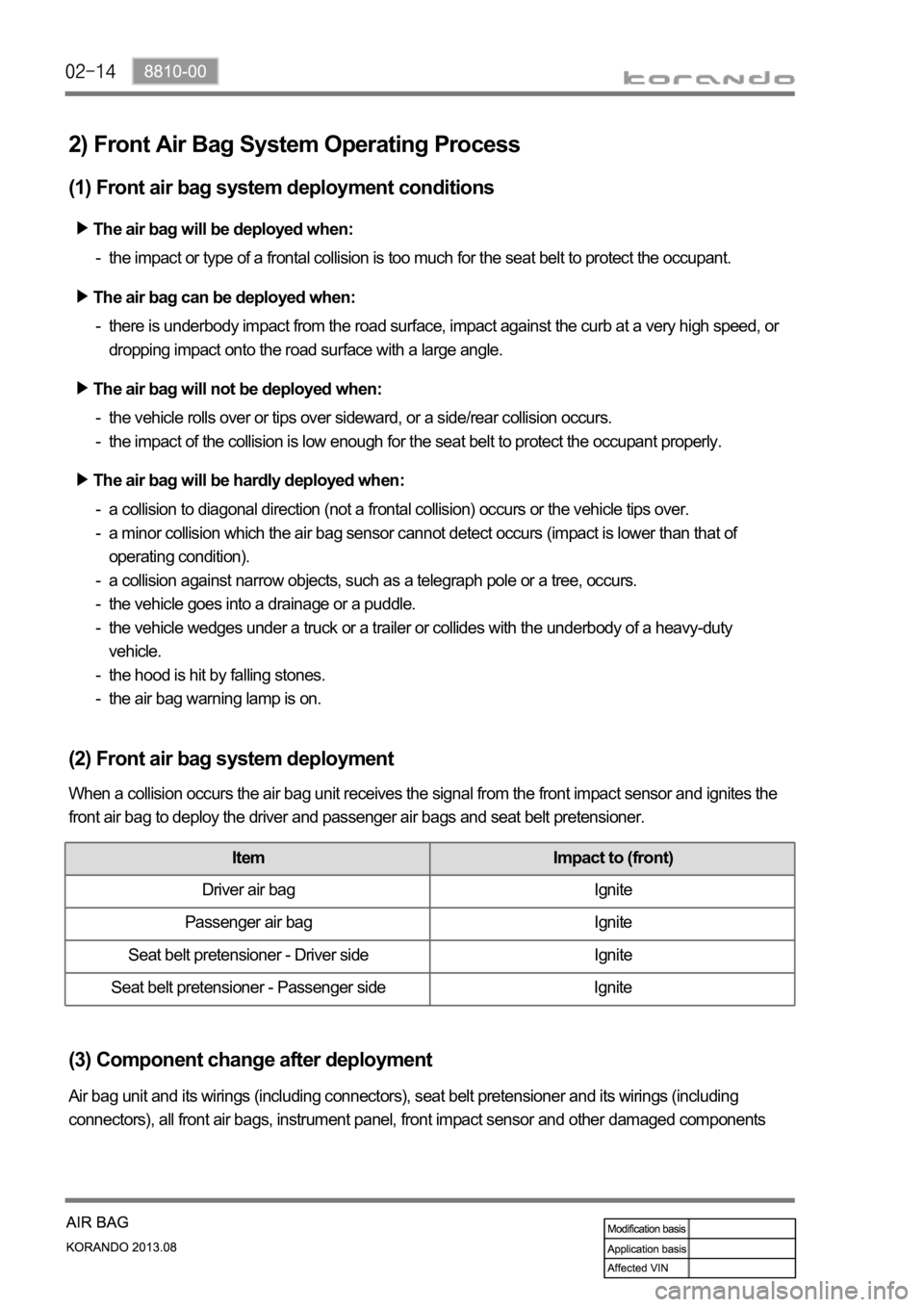

The air bag will be deployed when:

The air bag can be deployed when:

the impact or type of a frontal collision is too much for the seat belt to protect the occupant. -

a collision to diagonal direction (not a frontal collision) occurs or the vehicle tips over.

a minor collision which the air bag sensor cannot detect occurs (impact is lower than that of

operating condition).

a collision against narrow objects, such as a telegraph pole or a tree, occurs.

the vehicle goes into a drainage or a puddle.

the vehicle wedges under a truck or a trailer or collides with the underbody of a heavy-duty

vehicle.

the hood is hit by falling stones.

the air bag warning lamp is on. -

-

-

-

-

-

-the vehicle rolls over or tips over sideward, or a side/rear collision occurs.

the impact of the collision is low enough for the seat belt to protect the occupant properly. -

-

The air bag will be hardly deployed when:

2) Front Air Bag System Operating Process

(1) Front air bag system deployment conditions

there is underbody impact from the road surface, impact against the curb at a very high speed, or

dropping impact onto the road surface with a large angle. -

The air bag will not be deployed when:

(2) Front air bag system deployment

When a collision occurs the air bag unit receives the signal from the front impact sensor and ignites the

front air bag to deploy the driver and passenger air bags and seat belt pretensioner.

Item Impact to (front)

Driver air bag Ignite

Passenger air bag Ignite

Seat belt pretensioner - Driver side Ignite

Seat belt pretensioner - Passenger side Ignite

(3) Component change after deployment

Air bag unit and its wirings (including connectors), seat belt pretensioner and its wirings (including

connectors), all front air bags, instrument panel, front impact sensor and other damaged components

Page 1239 of 1336

(2) Side air bag system deployment

The side air bag system is activated in the event of a left side or right side collision. The seat side air bags

are installed to the driver and passenger seat (one on each seat) and the curtain air bags are installed in

the end of the roof located on the upper sides of both doors. The side air bags and the curtain air bags are

operated by the same signal. The air bags of the driver seat and passenger seat are operated separately

according to the impact position (left side, right side).

ItemImpact to (side)

LH RH

Side air bag - Driver side Ignite Not ignite

Side air bag - Passenger side Not ignite Ignite

Curtain air bag - Driver side Ignite Not ignite

Curtain air bag - Passenger side Not ignite Ignite

Seat belt pretensioner - Driver side Not ignite Not ignite

Seat belt pretensioner - Passenger side Not ignite Not ignite

(3) Component change after deployment

Side air bag deployed

Deployed side air bag, air bag unit and its wirings (including connectors), side impact sensor, other

damaged trim, seat components

Curtain air bag deployed

Deployed curtain air bag, air bag unit and its wirings (including connectors), side impact sensor,

damaged trim, seat and roof headlining

Page 1251 of 1336

Impact sensor monitoring

The air bag unit supplies a certain level of test current to monitor the front and side impact sensors. If the

wiring is open/short circuited or no signal is input, or communication is malfunctioning, it sets a DTC and

turns on the air bag warning lamp.

FaultsDetection

Time for clearing

Fault condition Time for detecting

Normal errorsIncorrect ID after IGN ON

Approx. 1 seconds.Approx. 2 seconds.

(next Ign) Faulty sensor after IGN ON

Communication error

Incorrect ID Inconsistent ID after IGN ON

Communication

errorCommunication data error

Approx. 2 seconds.

Open/Short circuit (B+)

Short Circuit to

GroundShort Circuit to Groundapprox. 2 to 4

seconds

6) DTC and Air Bag Deployment Data Storing

DTC storing

Airbag deployment data storing

The air bag deployment data due to a collision cannot be cleared. The air bag unit should be

replaced. -

- All DTCs of air bag system are stored in the air bag unit. Maximum number of DTCs that can be stored

is 16. If a new DTC is set after 16 DTCs are stored, the oldest stored code is erased first.

The air bag deployment data is stored in the air bat unit. Maximum number of data that can be stored is

7.