Crankshaft SSANGYONG KORANDO 2013 Owner's Guide

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2013, Model line: KORANDO, Model: SSANGYONG KORANDO 2013Pages: 1336, PDF Size: 92.18 MB

Page 502 of 1336

1443-01

Electric throttle valveT-MAP sensorAccelerator pedal position

sensor

Coolant temperature

sensor

Engine ECU

Crankshaft position

sensor

Page 526 of 1336

1452-01

1. SPECIFICATION

Unit Description Specification

AlternatorType HPS EPS

Crankshaft pulley : Alternator pulley 1 : 2.66

Normal output

(idle/2200rpm)70/140A

Regulator voltage 12V

BrushLength 12.5mm

Wear limit 7.0mm

BatteryType MF

Capacity 90AH

Page 559 of 1336

0000-00

Purge control

solenoid valve

G20DF engine

ECUCoolant Temp

sensorCamshaft position

sensor

Crankshaft position

sensor

T-MAP sensorVIS solenoid valveElectronic throttle

bodyMagnetic trigger

ring

Front oxygen

sensor

Page 561 of 1336

0000-00

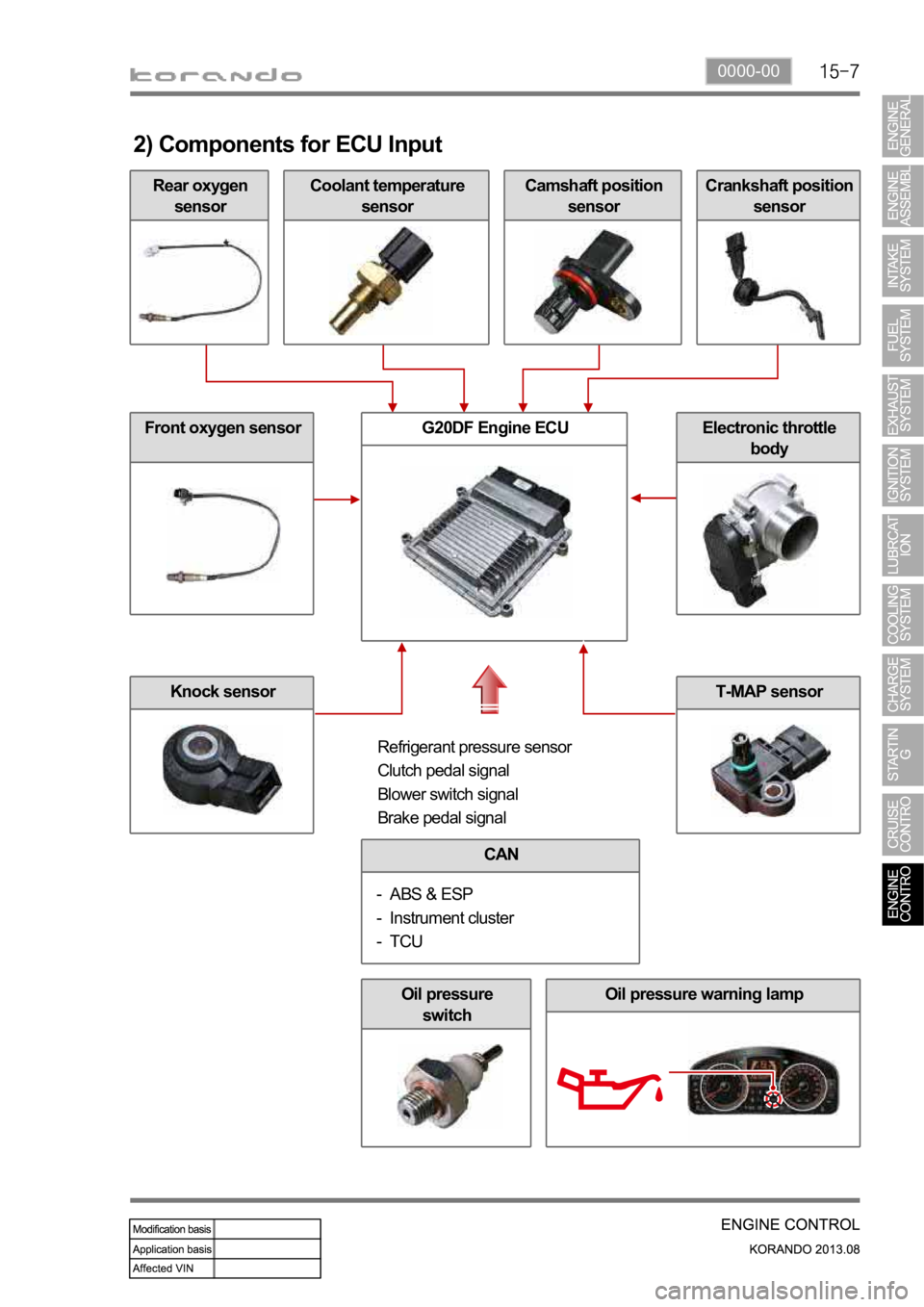

Rear oxygen

sensor

2) Components for ECU Input

Coolant temperature

sensorCamshaft position

sensorCrankshaft position

sensor

Front oxygen sensor

Knock sensor

G20DF Engine ECUElectronic throttle

body

Refrigerant pressure sensor

Clutch pedal signal

Blower switch signal

Brake pedal signal

CAN

ABS & ESP

Instrument cluster

TCU -

-

-

Oil pressure

switchOil pressure warning lamp

T-MAP sensor

Page 563 of 1336

1490-00

3. ECU CONTROL

1) Functions

ECU receives and analyzes signals from various sensors and then modifies those signals into

permissible voltage levels and analyzes to control respective actuators.

ECU microprocessor calculates injection period and injection timing proper for engine piston speed and

crankshaft angle based on input data and stored specific map to control the engine power and emission

gas.

Output signal of the ECU microprocessor activates the injector solenoid valve to control the fuel injection

period and injection timing; so controls various actuators in response to engine changes.

Auxiliary function of ECU has adopted to reduce emission gas, improve fuel economy and enhance

safety, comforts and conveniences. For example, there are autocruise and immobilizer and adopted

CAN communication to exchange data among electrical systems (automatic T/M and brake system) in

the vehicle fluently. And the diagnostic tool can be used to diagnose vehicle status and defectives.

water and electromagnetism and there should be no mechanical shocks.

2) Control Functions

Controls by operating stages:

To make optimum combustion under every operating stage, ECU should calculate proper injection

volume in each stage by considering various factors.

Starting injection volume control:

During initial starting, injecting fuel volume will be calculated by function of temperature and engine

cranking speed. Starting injection continues from when the ignition switch is turned to ignition

position to till the engine reaches to allowable minimum speed.

Driving mode control:

If the vehicle runs normally, fuel injection volume will be calculated by accelerator pedal travel and

engine rpm and the drive map will be used to match the drivers inputs with optimum engine power. -

-

-

Page 564 of 1336

3) Injection Volume Control

(1) Overview

To keep the best engine conditions and to reduce the emission gas, ECU determines the injection

volume and timing.

(2) Components

Input Components

Accelerator pedal

position sensorFront oxygen

sensorCoolant temperature

sensorCrankshaft position

sensor

Camshaft position

sensorKnock sensorT-MAP sensorElectronic throttle

body

Output Components

Page 567 of 1336

0000-00

Coolant temperature

sensor

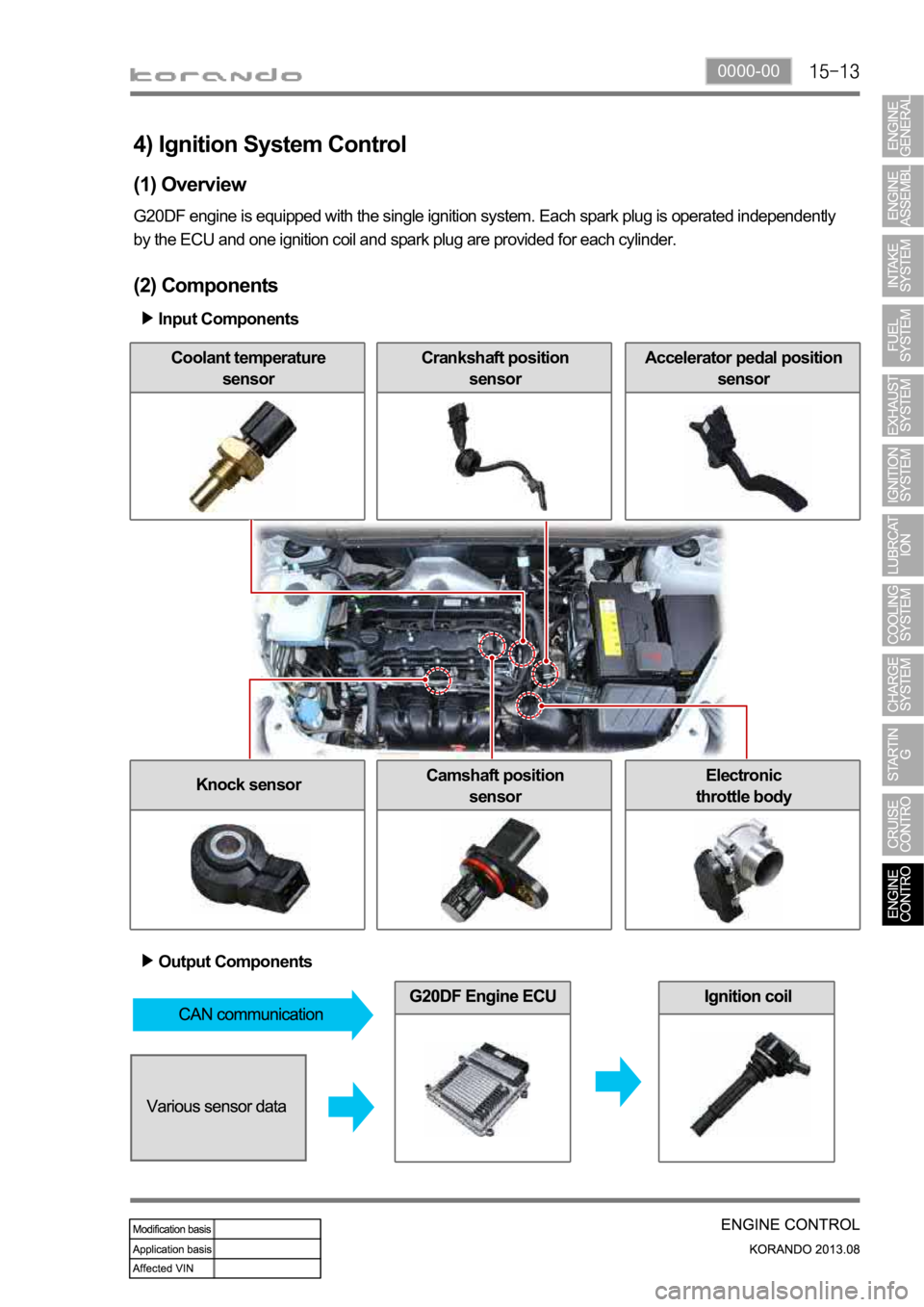

4) Ignition System Control

(1) Overview

G20DF engine is equipped with the single ignition system. Each spark plug is operated independently

by the ECU and one ignition coil and spark plug are provided for each cylinder.

(2) Components

Input Components

Crankshaft position

sensorAccelerator pedal position

sensor

Knock sensorCamshaft position

sensorElectronic

throttle body

Output Components

Page 569 of 1336

0000-00

(4) Features

Determines the ignition timing according to input signal

The ECU always analyzes the following elements when determining the ignition timing. 1.

Crankshaft position sensor

Camshaft position sensor

Coolant temperature sensor

Intake air temperature/air mass -

-

-

-

Warm-up of catalytic converter

The ignition timing is retarded for about 20 seconds to operate the catalytic converter according to the

operating temperature under the following conditions: 2.

The idle speed is increased by the idle speed control to help warming up of the catalytic converter -

-

Idle speed control

The ignition timing control can be performed faster than the control through the throttle valve.

Fuel cut-off in deceleration

The ignition timing is retarded temporarily to prevent abrupt increase of the torque when the

combustion is restarted.

Intake air temperature/coolant temperature

The ignition timing is retarded to prevent knocking if the intake air temperature or coolant temperature

is high. The ignition timing is retarded in the following cases. 3.

4.

5.

-

-

The ignition timing retard for intake air temperature and for coolant temperature is added up for

correction.

ESP/ASR control mode

The ignition timing is retarded to reduce engine torque as fast as possible under the ESP/ASR

control mode.

Knocking control

If knocking occurs in the cylinder, the ignition angle of the corresponding cylinder is retarded. The

6.

7.

Page 570 of 1336

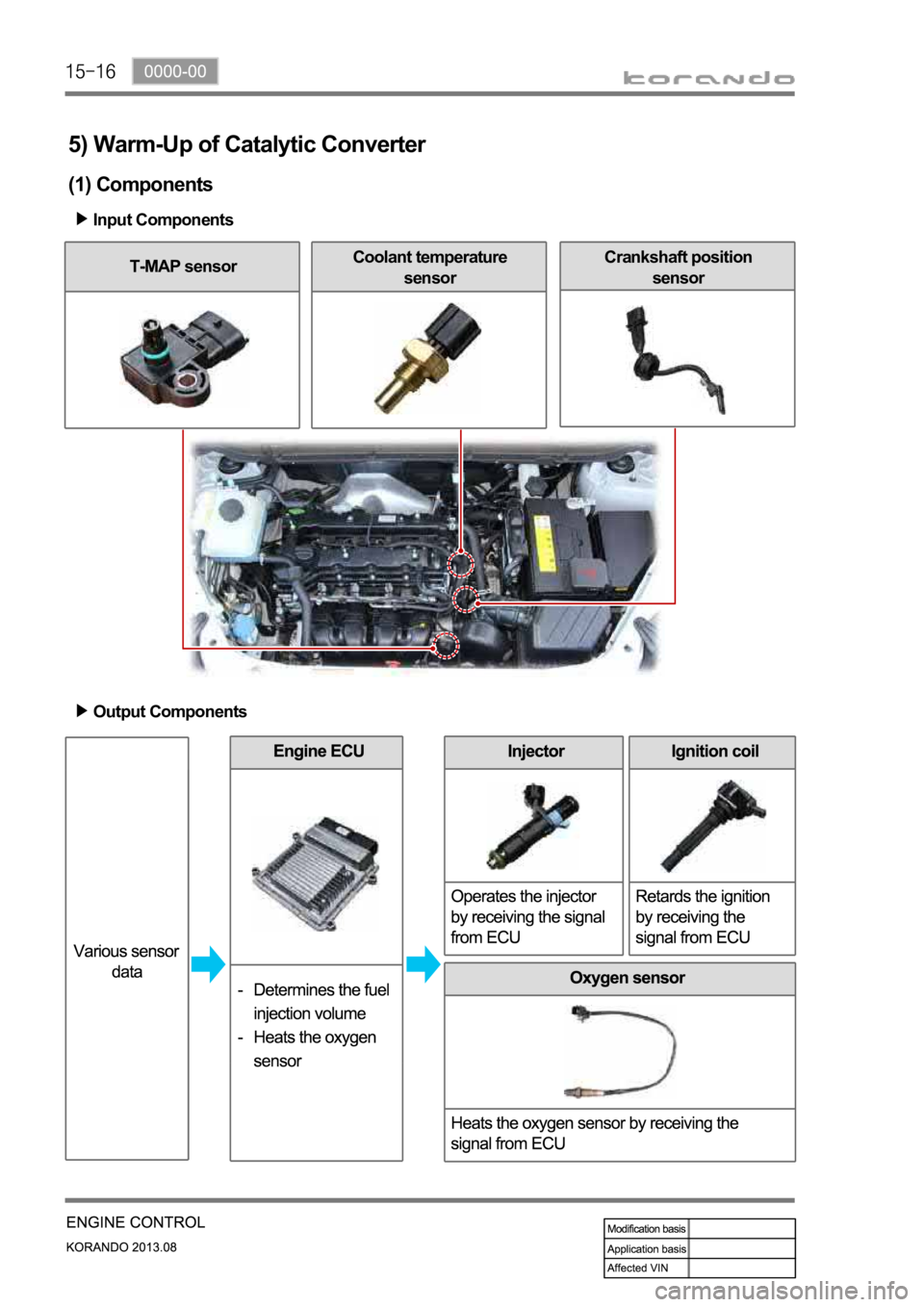

5) Warm-Up of Catalytic Converter

(1) Components

Input Components

T-MAP sensorCoolant temperature

sensorCrankshaft position

sensor

Output Components

Page 1070 of 1336

0000-00

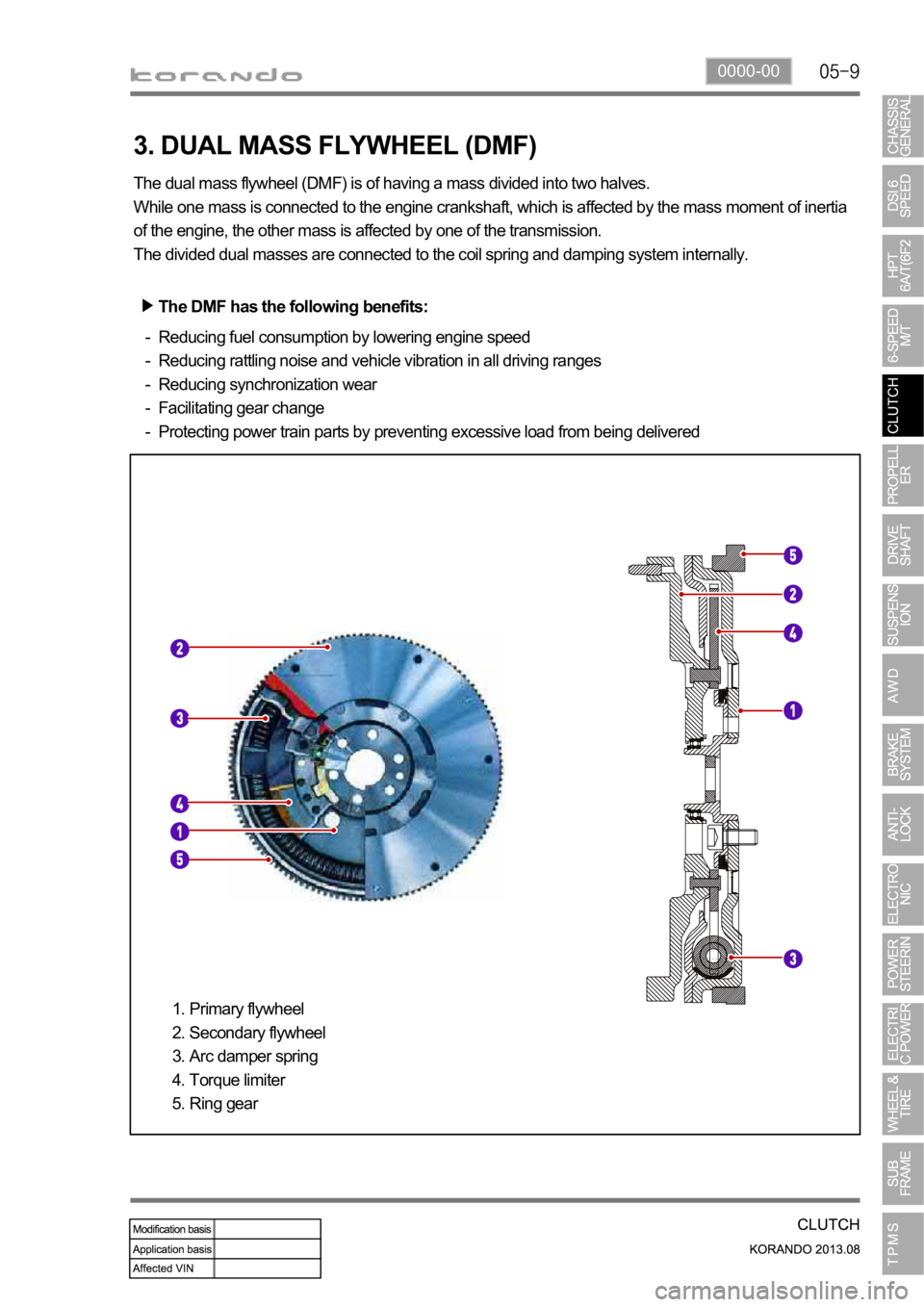

3. DUAL MASS FLYWHEEL (DMF)

The dual mass flywheel (DMF) is of having a mass divided into two halves.

While one mass is connected to the engine crankshaft, which is affected by the mass moment of inertia

of the engine, the other mass is affected by one of the transmission.

The divided dual masses are connected to the coil spring and damping system internally.

The DMF has the following benefits:

Reducing fuel consumption by lowering engine speed

Reducing rattling noise and vehicle vibration in all driving ranges

Reducing synchronization wear

Facilitating gear change

Protecting power train parts by preventing excessive load from being delivered -

-

-

-

-

Primary flywheel

Secondary flywheel

Arc damper spring

Torque limiter

Ring gear 1.

2.

3.

4.

5.