Crankshaft SSANGYONG KORANDO 2013 Owner's Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2013, Model line: KORANDO, Model: SSANGYONG KORANDO 2013Pages: 1336, PDF Size: 92.18 MB

Page 454 of 1336

1311-01

The drive chain is single chain drive system with simple design and variable performance, and it utilizes

the hydraulic tensioner to reduce the wave impact generated by the chain. The silent chain provides the

silence during the operation. To improve NVH, the shoulder bolt has been introduced. Overview

Layout and Components

Hydraulic tensioner

Consists of tensioner housing

plug, spring, check valve, and

operated by hydraulic

pressure and spring in

tensioner

Timing chain

Chain type: Silent chain type

Links: 146 ea

Tensioner rail

Installed between exjaust

camshaft sprocket and

crankshaft sprocket

Crankshaft sprocket

Teeth: 21 ea

Oil pump sprocket

Teeth: 28 ea

Exhaust camshaft

sprocket

Teeth:42 eaIntake camshaft

sprocket

CVVT

Teeth: 42 ea

OCV

Controls the hydraulic circuit

to control the intake cam

sprocket variably

Clamping rail

Installed between intake

camshaft sprocket and

crankshaft sprocket

Mechanical tensioner

Operated by spring in

tensioner

Oil pump chain

Chain type: Silent chain type

Links: 58 ea

Page 455 of 1336

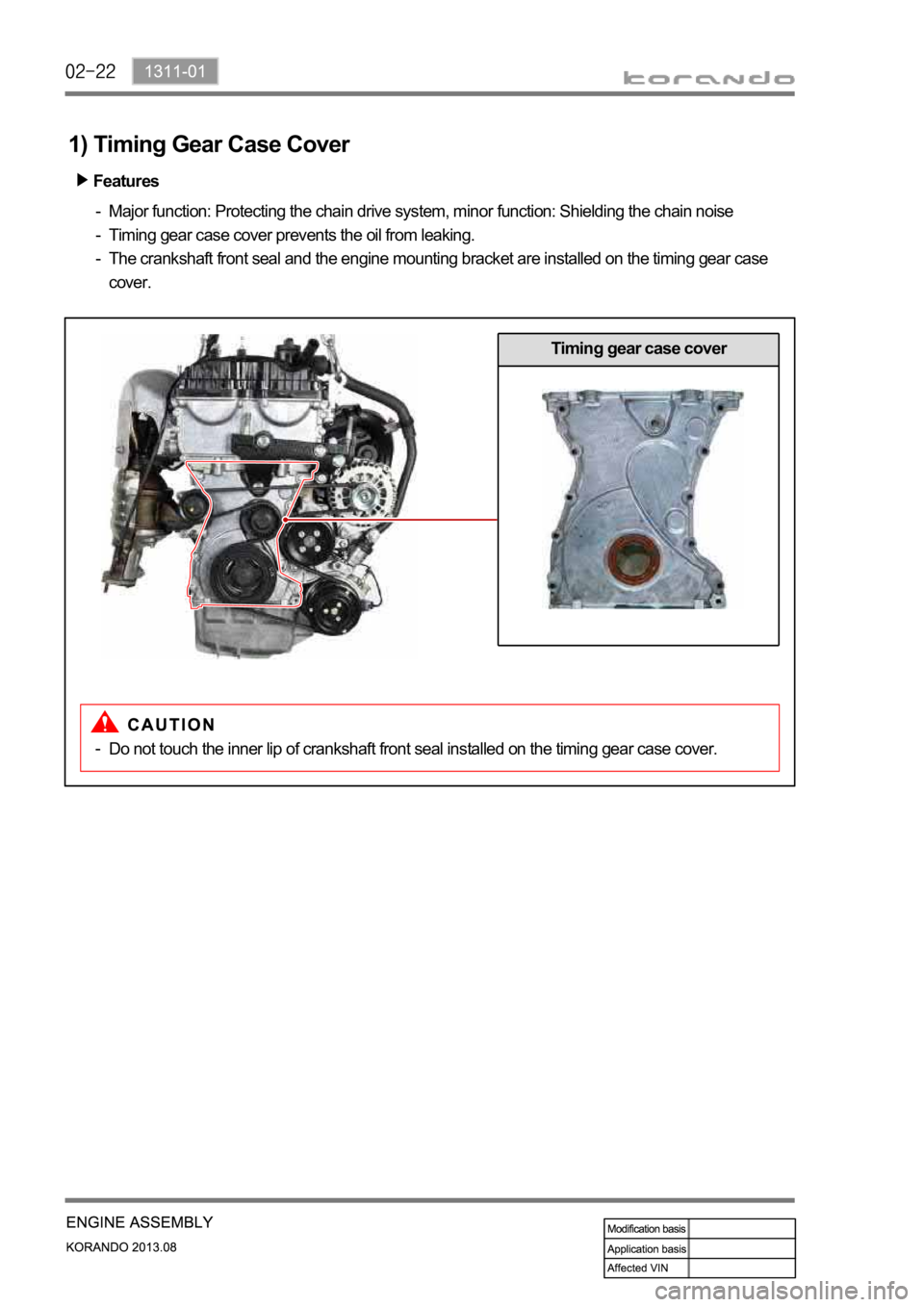

1) Timing Gear Case Cover

Features

Major function: Protecting the chain drive system, minor function: Shielding the chain noise

Timing gear case cover prevents the oil from leaking.

The crankshaft front seal and the engine mounting bracket are installed on the timing gear case

cover. -

-

-

Timing gear case cover

Do not touch the inner lip of crankshaft front seal installed on the timing gear case cover. -

Page 459 of 1336

Clamping rail

Installed between intake

camshaft sprocket and

crankshaft sprocket

5) Chain Rails

The chain rails are used for optimizing the movement of chain drive system. And they also prevent the

chain from contacting each other when the chain is loose, and reduces the chain wear. The chain rail is

normally made of PA (Polyamide nylon), and PA66 and PA46 are used for the chain rails in G20DF

engine. For the tensioner rail, PA46 is used to provide high anti-wear function and high strength since

the load to the rail is huge. Ther is an open area for shoulder bolt hole in the clamping rail. The chain

rails are installed by shoulder bolts.

Tensioner rail

Installed between

exhaust camshaft

sprocket and crankshaft

sprocket

Page 460 of 1336

1130-13

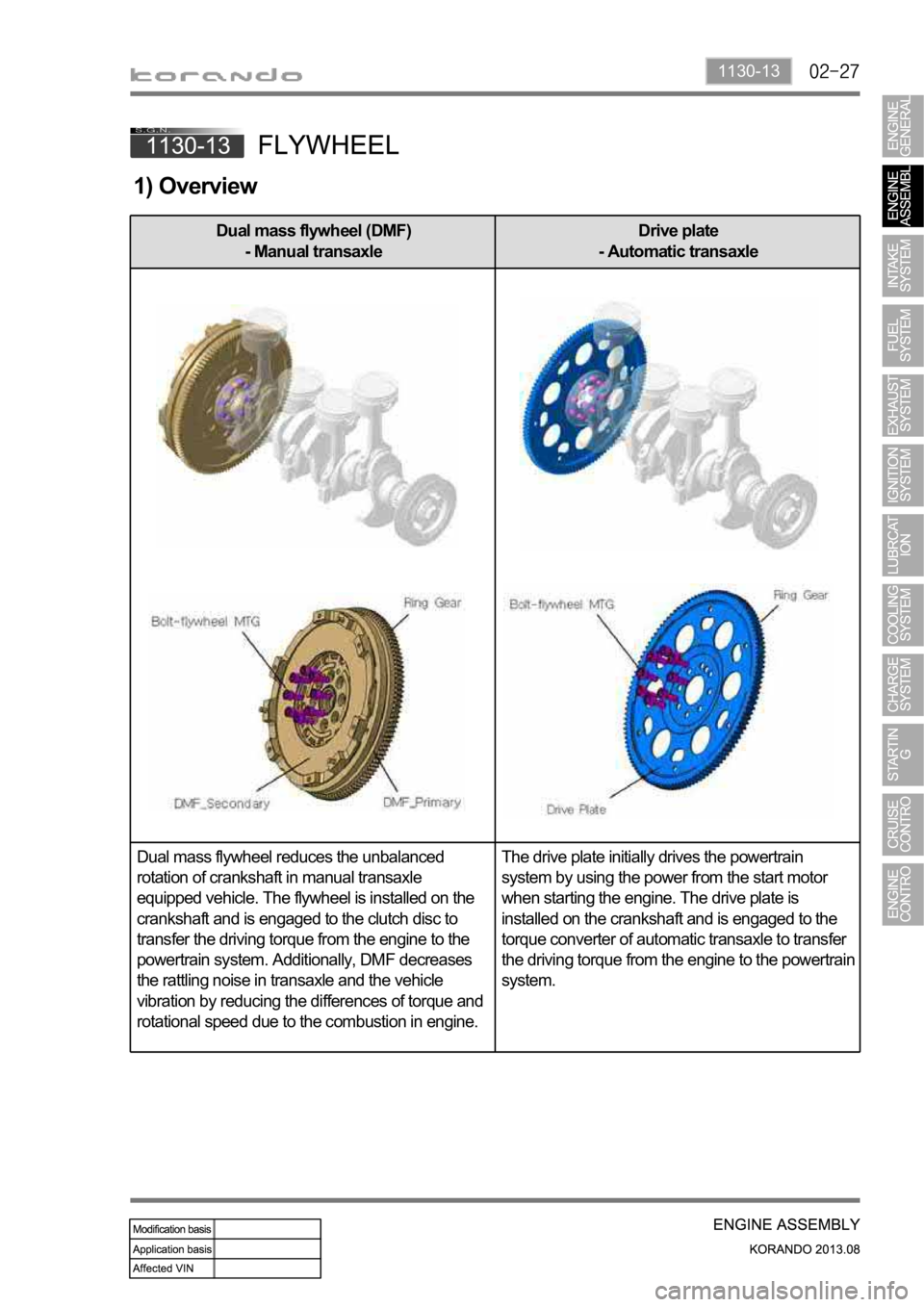

1) Overview

Dual mass flywheel (DMF)

- Manual transaxleDrive plate

- Automatic transaxle

Dual mass flywheel reduces the unbalanced

rotation of crankshaft in manual transaxle

equipped vehicle. The flywheel is installed on the

crankshaft and is engaged to the clutch disc to

transfer the driving torque from the engine to the

powertrain system. Additionally, DMF decreases

the rattling noise in transaxle and the vehicle

vibration by reducing the differences of torque and

rotational speed due to the combustion in engine.The drive plate initially drives the powertrain

system by using the power from the start motor

when starting the engine. The drive plate is

installed on the crankshaft and is engaged to the

torque converter of automatic transaxle to transfer

the driving torque from the engine to the powertrain

system.

Page 463 of 1336

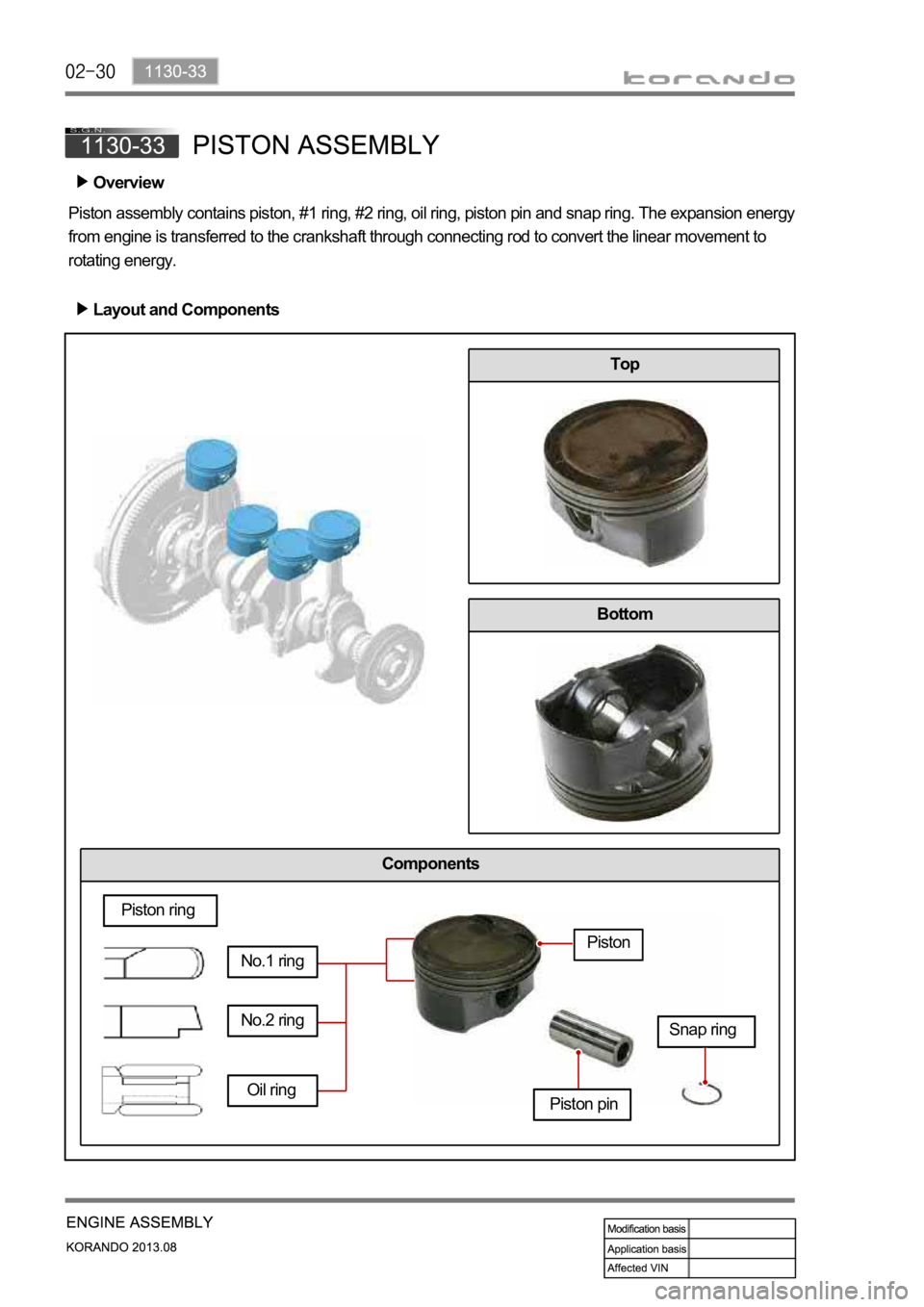

Components

Piston assembly contains piston, #1 ring, #2 ring, oil ring, piston pin and snap ring. The expansion energy

from engine is transferred to the crankshaft through connecting rod to convert the linear movement to

rotating energy.Overview

Layout and Components

Top

Bottom

Oil ring

Piston ring

No.1 ring

Piston pin

No.2 ringSnap ring

Piston

Page 466 of 1336

1130-25

Components

Overview

Connecting rod converts the reciprocating movement of piston to the rotating movement of crankshaft.

The big end is connected to connecting rod bearing and the crank pin journal, and the small end is

connected to the piston pin.

Components

Connecting rod

Piston pin bush

Connecting rod

Connecting rod upper bearing

Connecting rod lower bearing

Connecting rod cap

Connecting rod cap bolt A.

B.

C.

D.

E.

F.

Page 468 of 1336

1130-01

Overview

Crankshaft is installed on the cylinder block. The crankshaft converts the reciprocative movement of

piston to the rotatinal movement.

Layout and Components

Crankshaft

Page 469 of 1336

Bottom of cylinder block Crankshaft sprocket installing surface

Crankshaft lower bearing Crankshaft lower bearing

Selection of crankshaft main bearing

Pin

punch

markColorDiameter of crankshaft

main journal in cylinder

block (mm)

* Blue 62.500 ~ 62.506

** Yellow 62.506 ~ 62.513

*** Red 62.513 ~ 62.519Mark ColorDiameter of

crankshaft main

journal (mm)

B Blue 57.960 ~ 57.965

Y Yellow 57.955 ~ 57.960

R Red 57.950 ~ 57.955

W White 57.945 ~ 57.950

V Violet 57.940 ~ 57.945

Engine

name

Main

journal

bearing

#1 #2 #3 #4 #5

G2 0DF

RRWWR

Page 470 of 1336

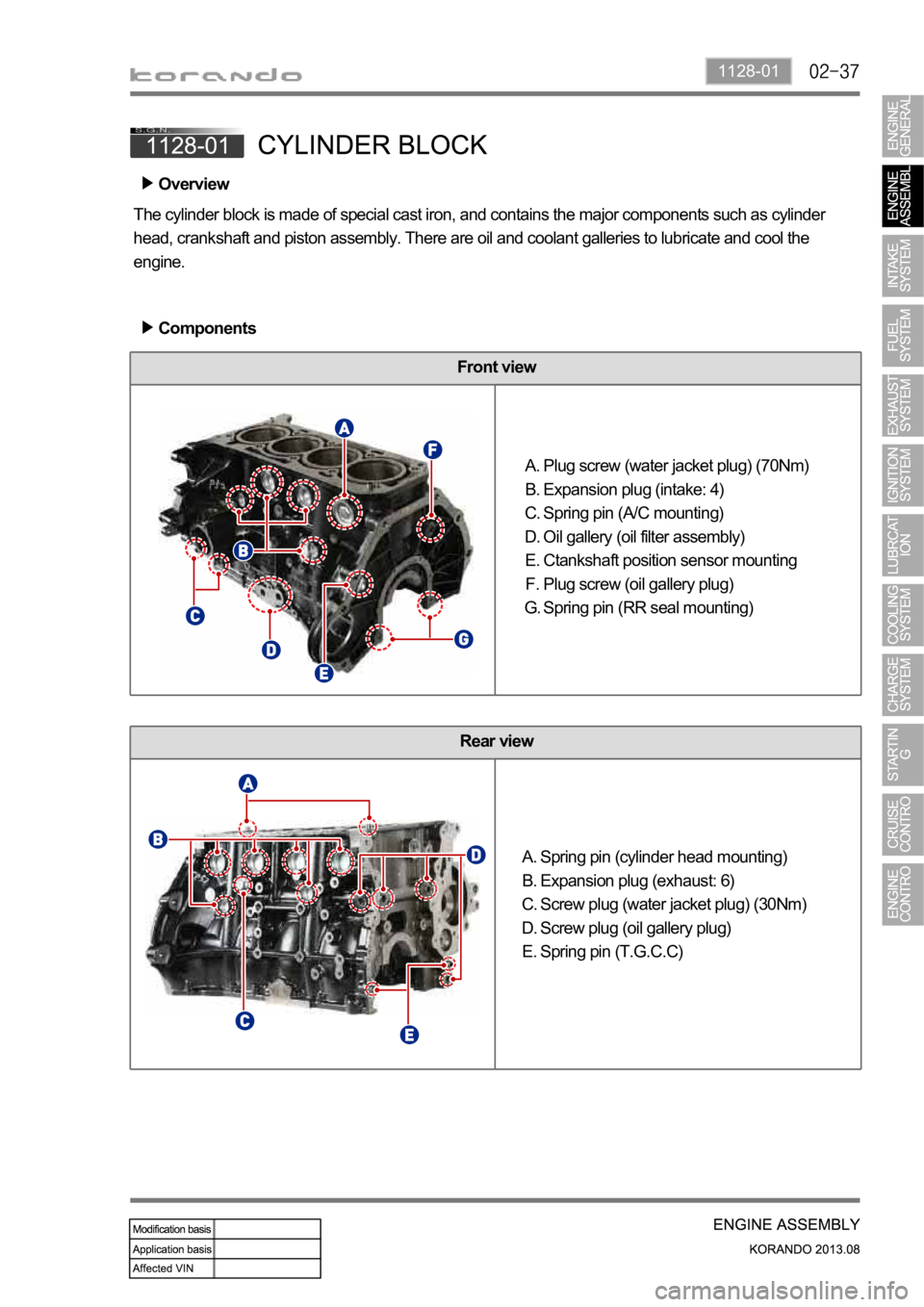

1128-01

Front view

Rear view

Spring pin (cylinder head mounting)

Expansion plug (exhaust: 6)

Screw plug (water jacket plug) (30Nm)

Screw plug (oil gallery plug)

Spring pin (T.G.C.C) A.

B.

C.

D.

E.

Overview

The cylinder block is made of special cast iron, and contains the major components such as cylinder

head, crankshaft and piston assembly. There are oil and coolant galleries to lubricate and cool the

engine.

Components

Plug screw (water jacket plug) (70Nm)

Expansion plug (intake: 4)

Spring pin (A/C mounting)

Oil gallery (oil filter assembly)

Ctankshaft position sensor mounting

Plug screw (oil gallery plug)

Spring pin (RR seal mounting) A.

B.

C.

D.

E.

F.

G.

Page 500 of 1336

1443-01

1. OVERVIEW

The ignition system is to supply high voltage generated from the ignition coil to the spark plug. The

G20DF engine is equipped with the independent type direct ignition system that the ignition coil is

installed in each cylinder.

The basic ignition timing in each cylinder is determined by the signals from camshaft position sensor and

crankshaft position sensor.

This ignition system controls the electronic ignition timing received from the engine ECU. To control the

ignition timing precisely, the ECU use the information below:

Engine load

Coolant temperature

Intake air temperature

Engine rpm

Camshaft position sensor (CPS)

Crankshaft position sensor (CKS) -

-

-

-

-

-

If the signal from the camshaft position sensor is not delivered to the engine ECU, the ignition coil and

fuel system cannot be operated.