air condition SSANGYONG KORANDO 2013 Workshop Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2013, Model line: KORANDO, Model: SSANGYONG KORANDO 2013Pages: 1336, PDF Size: 92.18 MB

Page 1217 of 1336

6810-00

(4) Air source control

When pressing the air source selection switch, the air source mode is changed via the intake actuator's

operation. The air source mode is switched between the fresh air and recirculation alternatively each

time the switch is pressed. You can see the air source mode through the switch's indicator. (the indicator

comes on at recirculation mode)

Control by vehicle speed

The air source selection is controlled in accordance with the vehicle speed while driving. Operating

conditions and control process are as follows:

When the PTC heater operates at fresh air mode in winter

When the vehicle speed is 45 km/h or lower in fresh air mode, the air source door is open 30% of its

maximum opening. If the vehicle speed is 65 km/h or more, then the air source door is completely

open. -

-

However, the electronic fan should be more than 7.5 V.

Air source selection switch

Page 1219 of 1336

6810-00

Defroster & foot mode

If the defroster & foot mode switch is pressed, the indicator comes on while the air

flows to the footwell and the windshield.

Defroster mode

This is used to remove the condensation from the windshield. When you press the

switch, the indicator comes on and the air distribution is changed to the windshield

at the same time, then the air conditioner starts to operate.

Page 1220 of 1336

(6) A/C control

The air conditioner is operated at the defroster mode and MAX air conditioner mode and when the A/C

switch is turned to "ON" position. It is controlled by the A/C compressor of the engine ECU according to

the signal from the heater and A/C control assembly. The driver can see that the A/C has been activated

when an indicator lamps at the A/C switch and MAX A/C switch comes on. If the intake sensor detects

the freezing of the evaporator core, it stops the air conditioner by turning off the compressor.

MAX A/C control

This is designed for increasing driver comfort. When the switch is pressed, the air conditioner is

operated and vent and recirculation modes are selected automatically. The discharge temperature and

fan speed are regulated depending on the driver's choice.

A/C switch

MAX A/C control switch

Page 1221 of 1336

6810-00

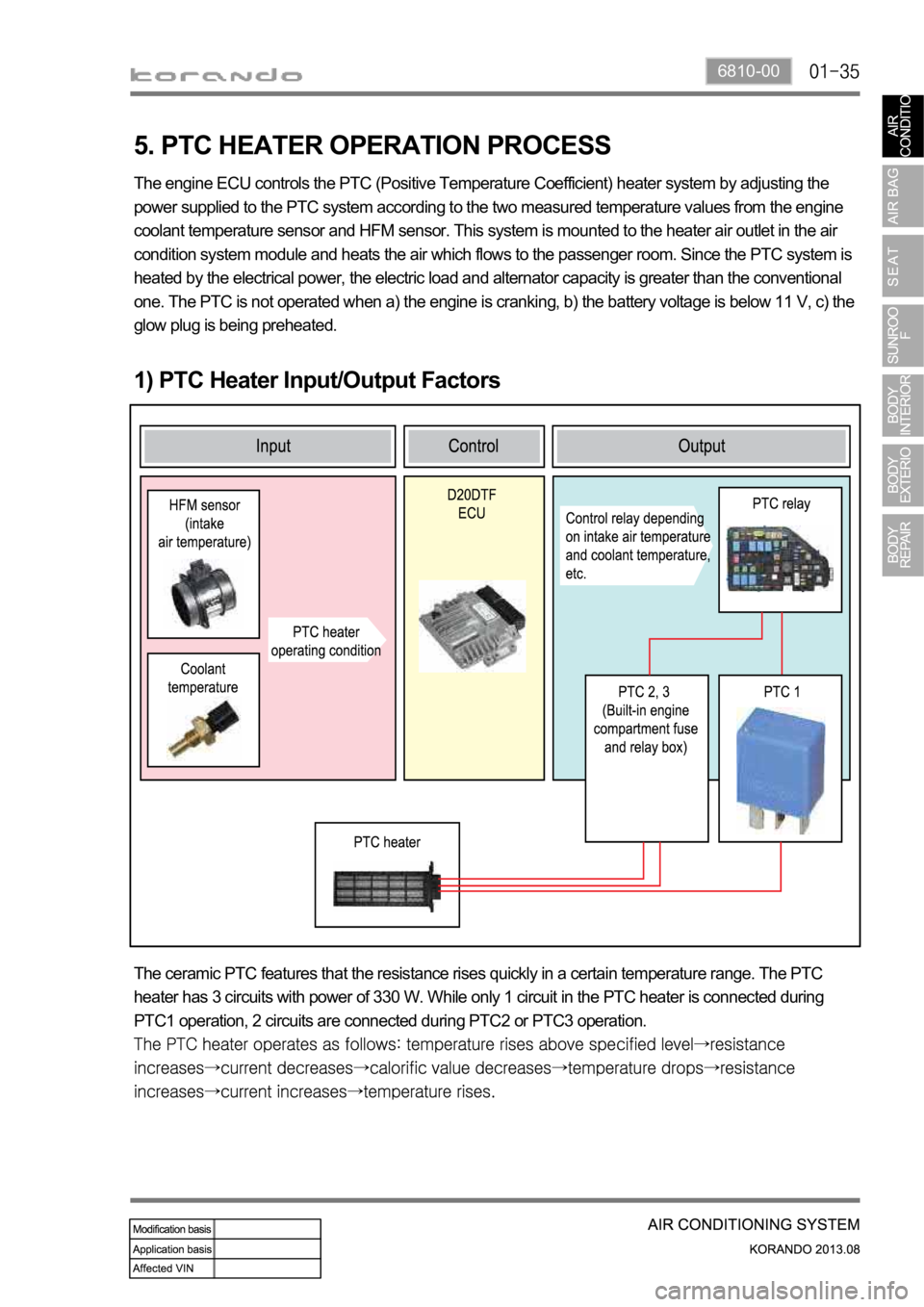

5. PTC HEATER OPERATION PROCESS

1) PTC Heater Input/Output Factors

The engine ECU controls the PTC (Positive Temperature Coefficient) heater system by adjusting the

power supplied to the PTC system according to the two measured temperature values from the engine

coolant temperature sensor and HFM sensor. This system is mounted to the heater air outlet in the air

condition system module and heats the air which flows to the passenger room. Since the PTC system is

heated by the electrical power, the electric load and alternator capacity is greater than the conventional

one. The PTC is not operated when a) the engine is cranking, b) the battery voltage is below 11 V, c) the

glow plug is being preheated.

The ceramic PTC features that the resistance rises quickly in a certain temperature range. The PTC

heater has 3 circuits with power of 330 W. While only 1 circuit in the PTC heater is connected during

PTC1 operation, 2 circuits are connected during PTC2 or PTC3 operation.

Page 1222 of 1336

2) Control Condition For PTC Heater

Operation Operating condition PTC heater status

HI mode operation

(PTC2, 3)PTC heater operates in

"HIGH" mode if operating

conditions are met

LO mode operation

(PTC1)PTC heater operates in

"LOW" mode if operating

conditions are met

Conditions for

deactivating

Air conditioner blower switch OFF

When the ambient temperature sensor is

faulty (short or open circuit in the wiring)

Engine is cranking

Battery voltage is 11 V or less

Glow plug is being preheated (Glow indicator

comes on) -

-

-

-

-

-

-

-

-

Conditions for PTC heater "LOW" operation mode (2nd step)

Page 1230 of 1336

8810-00

A large quantity of non-toxic gas (nitrogen gas) is generated with a loud noise when the air bag or

seat belt pretensioner deploys. If these airborne particles irritate your skin, eyes, nose, or throat, rinse

the area with cool water. If the irritation continues, see your doctor.

The windshield glass may be broken when the passenger air bag deploys.

The air bag is a unit to save an occupant's life from a sudden accident and it inflates at a very fast

speed by gas with high temperature, which might cause injury, such as an abrasion, bruise and burn

depending on the accident conditions.

The air bag components will be very hot after deployment. Do not touch them.

The deployed air bag/seat belt pretensioner cannot deploy again. It will work when an additional

impact is applied. Once the air bag system is triggered, the triggered air bag assembly should be

removed from the vehicle and replaced with a new one.

The air bag warning lamp is illuminated for 3 to 7 seconds after the engine is started to check

the system. If this warning lamp remains ON, then the system may be defective. Have the air

bag system checked immediately by Ssangyong Dealer or Ssangyong Authorized Service

Operation.

Incorrect inspection can result in serious injuries or malfunctions in the air bag and seat belt

pretensioner system. 12.

13.

14.

15.

16.

17.

18.

Page 1237 of 1336

The air bag will be deployed when:

The air bag can be deployed when:

the impact or type of a frontal collision is too much for the seat belt to protect the occupant. -

a collision to diagonal direction (not a frontal collision) occurs or the vehicle tips over.

a minor collision which the air bag sensor cannot detect occurs (impact is lower than that of

operating condition).

a collision against narrow objects, such as a telegraph pole or a tree, occurs.

the vehicle goes into a drainage or a puddle.

the vehicle wedges under a truck or a trailer or collides with the underbody of a heavy-duty

vehicle.

the hood is hit by falling stones.

the air bag warning lamp is on. -

-

-

-

-

-

-the vehicle rolls over or tips over sideward, or a side/rear collision occurs.

the impact of the collision is low enough for the seat belt to protect the occupant properly. -

-

The air bag will be hardly deployed when:

2) Front Air Bag System Operating Process

(1) Front air bag system deployment conditions

there is underbody impact from the road surface, impact against the curb at a very high speed, or

dropping impact onto the road surface with a large angle. -

The air bag will not be deployed when:

(2) Front air bag system deployment

When a collision occurs the air bag unit receives the signal from the front impact sensor and ignites the

front air bag to deploy the driver and passenger air bags and seat belt pretensioner.

Item Impact to (front)

Driver air bag Ignite

Passenger air bag Ignite

Seat belt pretensioner - Driver side Ignite

Seat belt pretensioner - Passenger side Ignite

(3) Component change after deployment

Air bag unit and its wirings (including connectors), seat belt pretensioner and its wirings (including

connectors), all front air bags, instrument panel, front impact sensor and other damaged components

Page 1238 of 1336

8810-00

The air bag will be deployed when:

The air bag can be deployed when:

a severe oblique collision occurs with a specific severity, angle, speed, and position. -

a collision with oblique impact to the front seat direction or a frontal collision to the diagonal direction

occurs.

a frontal or rear collision occurs.

the vehicle rolls over or tips over sideward with a minor impact.

the air bag warning lamp is on. -

-

-

-the vehicle is stationary or a frontal collision occurs at low speed.

a rear collision occurs.

the impact of the collision is low enough for the seat belt to protect the occupant properly. -

-

-

The air bag will be hardly deployed when:

3) Side Air bag System Operating Process

(1) Side air bag system deployment conditions

the vehicle rolls over or tips over sideward with a severe impact.

the vehicle is stationary or a frontal collision occurs at low speed.

a rear collision occurs.

the impact of the collision is low enough for the seat belt to protect the occupant properly. -

-

-

-

The air bag will not be deployed when:

Page 1245 of 1336

4. AIR BAG SYSTEM SELF DIAGNOSIS

1) Air Bag Unit (SDM) Self Diagnosis

The air bag unit monitors the internal/external devices of the air bag system including battery voltage,

limits certain functions of the air bag, and turns on the air bag warning lamp on the instrument cluster

according to the conditions.

Conditions for detecting and clearing faults

The time for detecting errors and clearing the errors is as follows:

Monitoring system Diagnosis

cycleTime for

detectingTime for

clearingClearing fault

Inflator circuit 400 ms 4 seconds 8 seconds with a diagnostic device

warning lamp circuit 100 ms 4 seconds 8 seconds with a diagnostic device

Battery voltage 10 ms 4 seconds 4 seconds with a diagnostic device

Impact sensor IGN ON 1 seconds2 to 4

seconds

(next Ign)with a diagnostic device

Impact record

(air bag deployed)-

Immediately-

by replacing SDM

(cannot be cleared with a

diagnostic device)

SDM internal fault--

by replacing SDM

(cannot be cleared with a

diagnostic device)

Page 1250 of 1336

8810-00

5) External monitoring

The air bag unit supplies a certain level of test current and monitors the resistance of the inflator circuit

within a specified range to deploy the air bag. It limits certain functions of the air bag, sets a DTC and

turns on the air bag warning lamp according to the conditions.

Inflator circuit resistance monitoring