clutch system SSANGYONG KORANDO 2013 Service Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2013, Model line: KORANDO, Model: SSANGYONG KORANDO 2013Pages: 1336, PDF Size: 92.18 MB

Page 334 of 1336

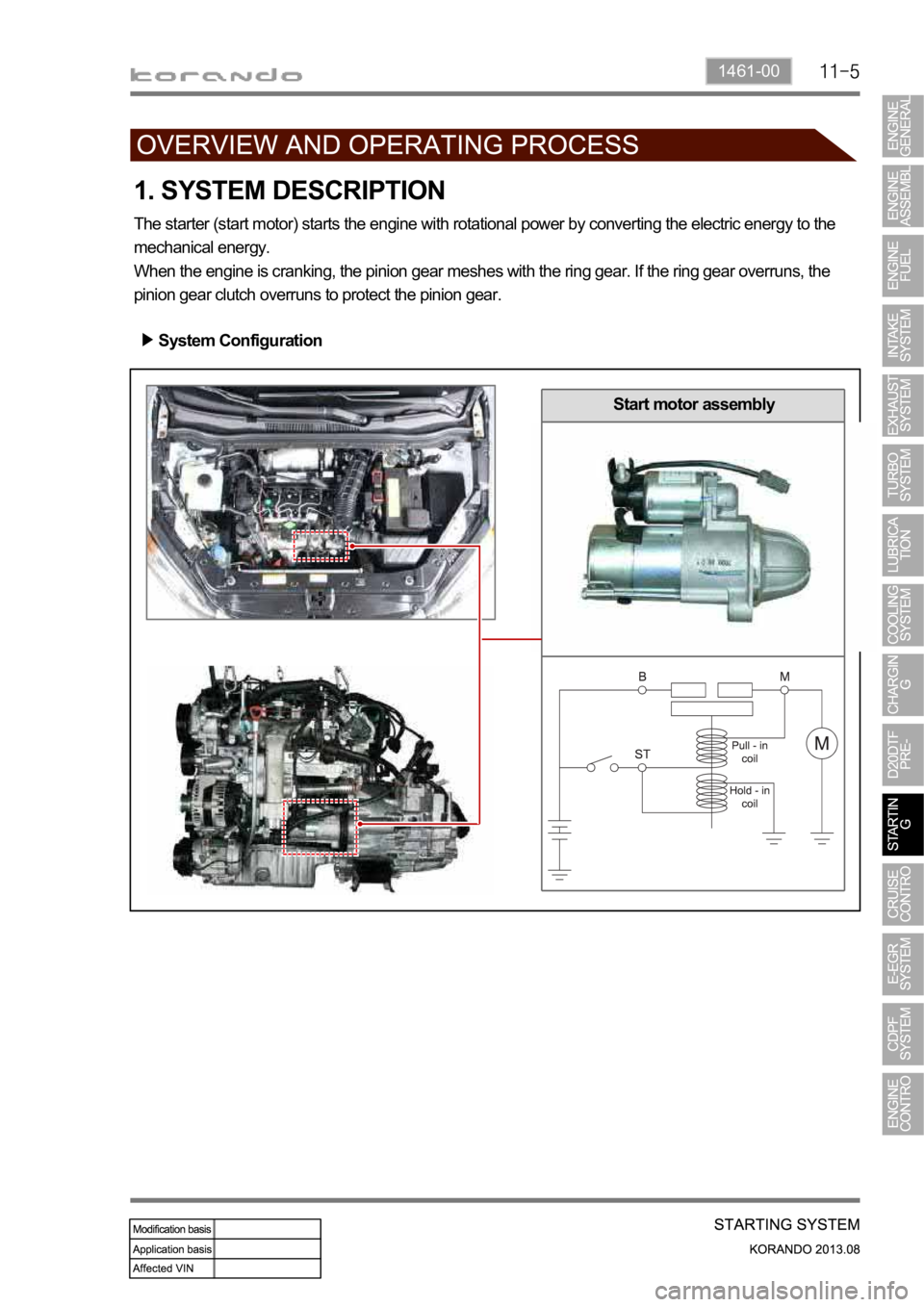

1461-00

Start motor assembly

1. SYSTEM DESCRIPTION

The starter (start motor) starts the engine with rotational power by converting the electric energy to the

mechanical energy.

When the engine is cranking, the pinion gear meshes with the ring gear. If the ring gear overruns, the

pinion gear clutch overruns to protect the pinion gear.

System Configuration

Page 352 of 1336

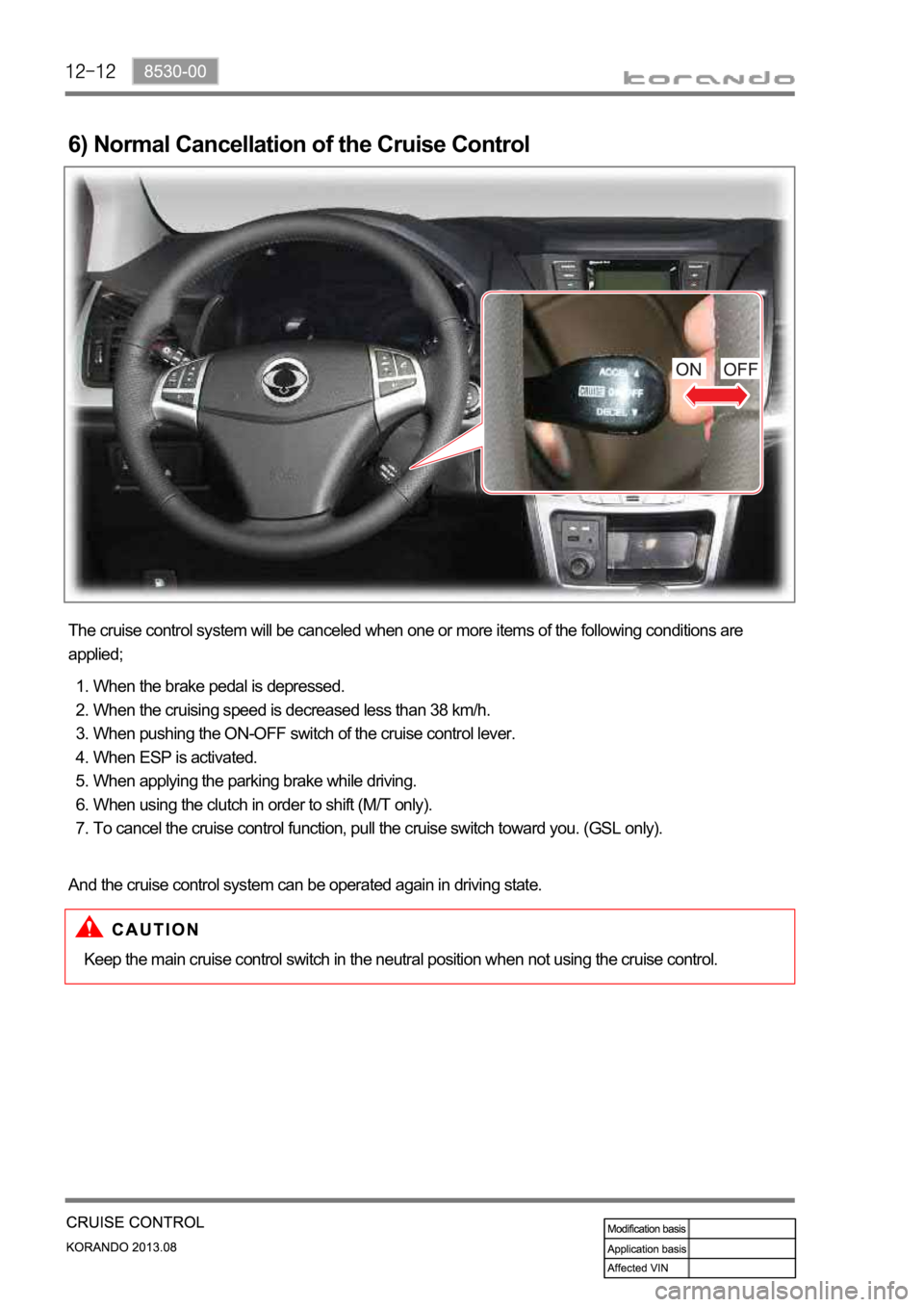

6) Normal Cancellation of the Cruise Control

The cruise control system will be canceled when one or more items of the following conditions are

applied;

When the brake pedal is depressed.

When the cruising speed is decreased less than 38 km/h.

When pushing the ON-OFF switch of the cruise control lever.

When ESP is activated.

When applying the parking brake while driving.

When using the clutch in order to shift (M/T only).

To cancel the cruise control function, pull the cruise switch toward you. (GSL only). 1.

2.

3.

4.

5.

6.

7.

Keep the main cruise control switch in the neutral position when not using the cruise control.

And the cruise control system can be operated again in driving state.

Page 460 of 1336

1130-13

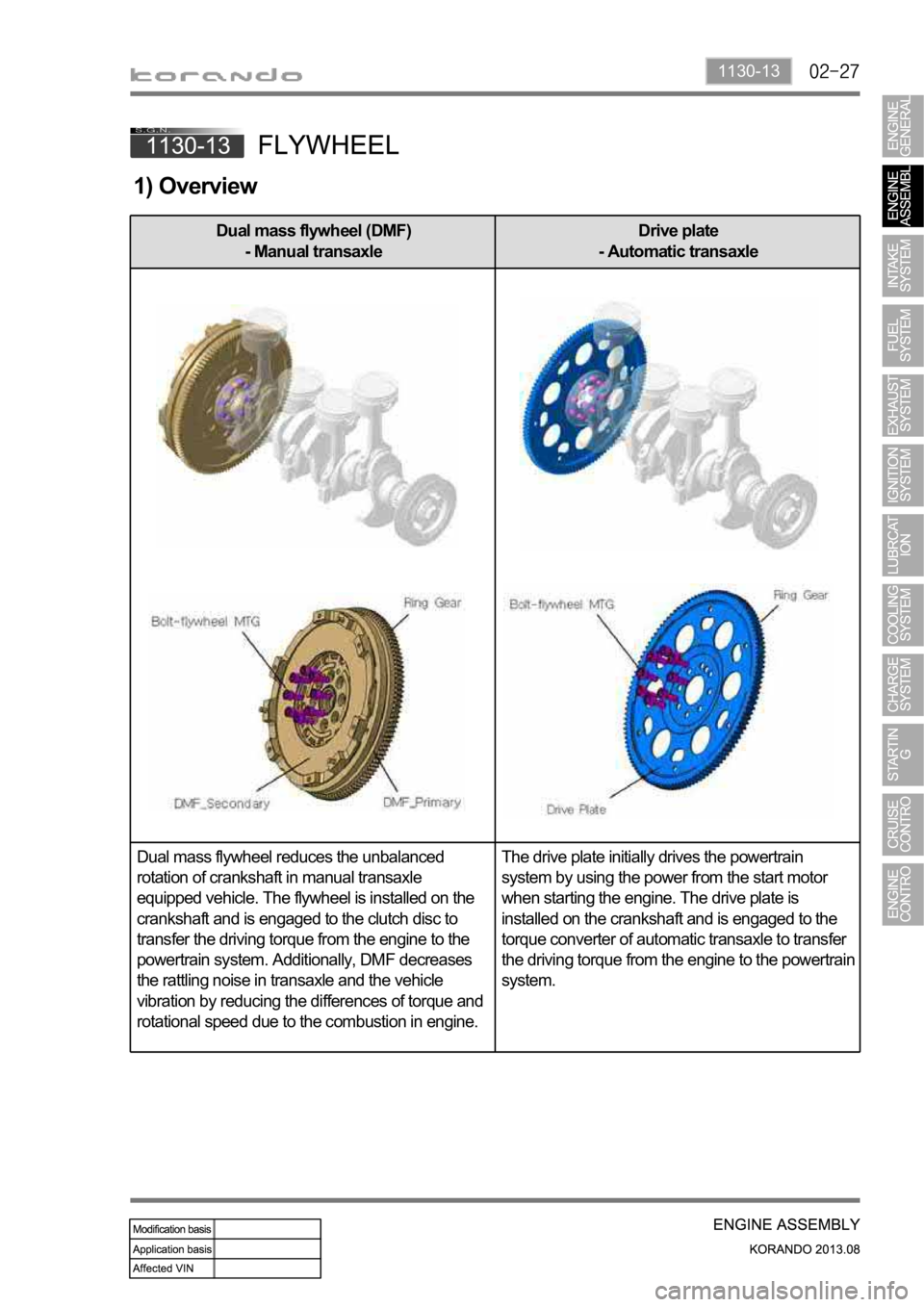

1) Overview

Dual mass flywheel (DMF)

- Manual transaxleDrive plate

- Automatic transaxle

Dual mass flywheel reduces the unbalanced

rotation of crankshaft in manual transaxle

equipped vehicle. The flywheel is installed on the

crankshaft and is engaged to the clutch disc to

transfer the driving torque from the engine to the

powertrain system. Additionally, DMF decreases

the rattling noise in transaxle and the vehicle

vibration by reducing the differences of torque and

rotational speed due to the combustion in engine.The drive plate initially drives the powertrain

system by using the power from the start motor

when starting the engine. The drive plate is

installed on the crankshaft and is engaged to the

torque converter of automatic transaxle to transfer

the driving torque from the engine to the powertrain

system.

Page 555 of 1336

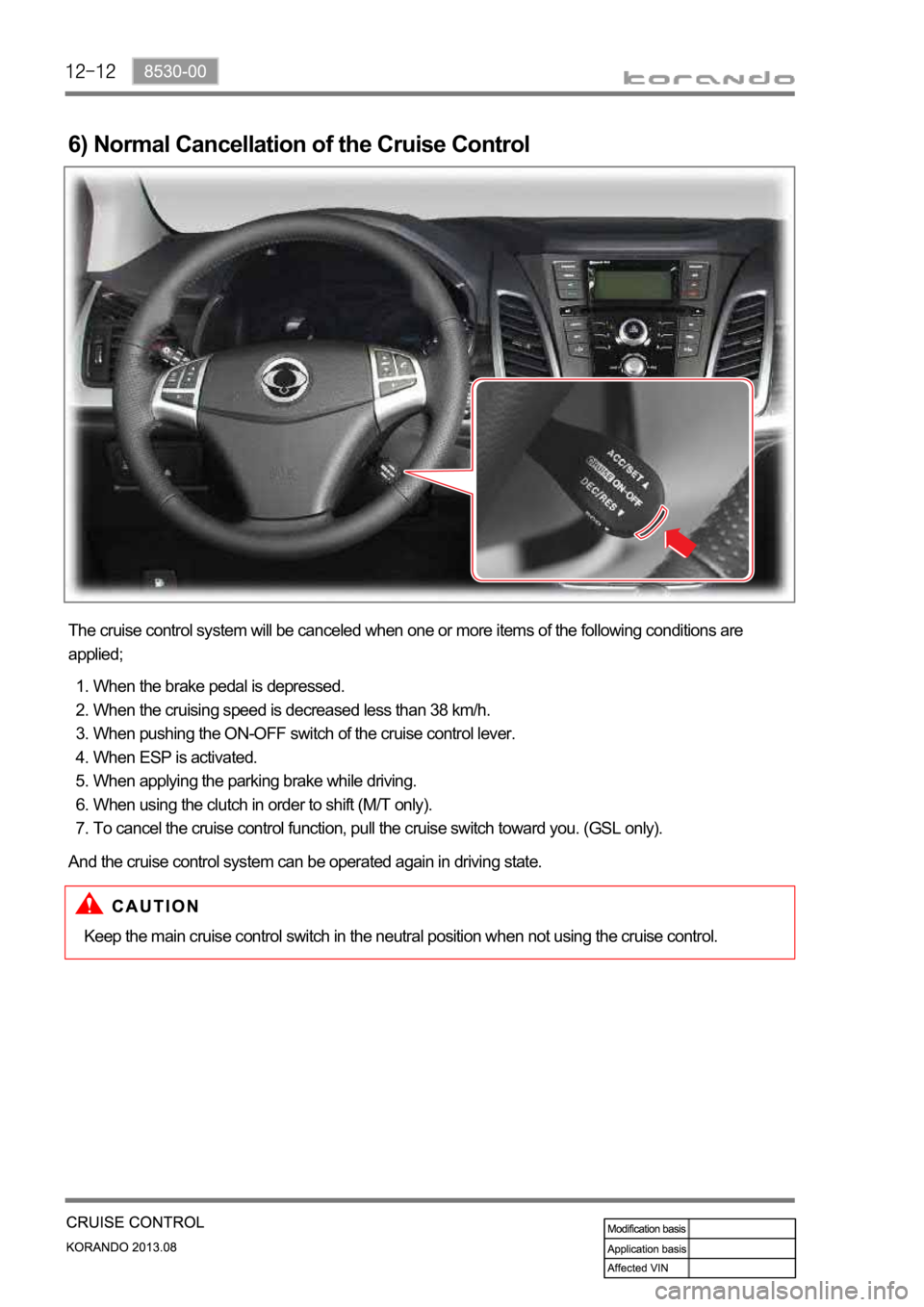

6) Normal Cancellation of the Cruise Control

The cruise control system will be canceled when one or more items of the following conditions are

applied;

When the brake pedal is depressed.

When the cruising speed is decreased less than 38 km/h.

When pushing the ON-OFF switch of the cruise control lever.

When ESP is activated.

When applying the parking brake while driving.

When using the clutch in order to shift (M/T only).

To cancel the cruise control function, pull the cruise switch toward you. (GSL only). 1.

2.

3.

4.

5.

6.

7.

Keep the main cruise control switch in the neutral position when not using the cruise control. And the cruise control system can be operated again in driving state.

Page 784 of 1336

(10) Brake not working alert

The SKM sends the brake not working alert signal for 10 sec. every time the ignition status is changed

after the 1st cycle (OFF-ACC-IGN-ACC-OFF)

while the brake is not operated.

when the brake pedal is depressed, the system is reset and alert deactivation signal is sent.

when the 10 min. timer is terminated -

-

(11) Smart key slot detection alert

The SKM sends the smart key slot detection alert signal for 10 sec. when a smart key inserted into

the slot is detected with IGN OFF and the driver's door open. -

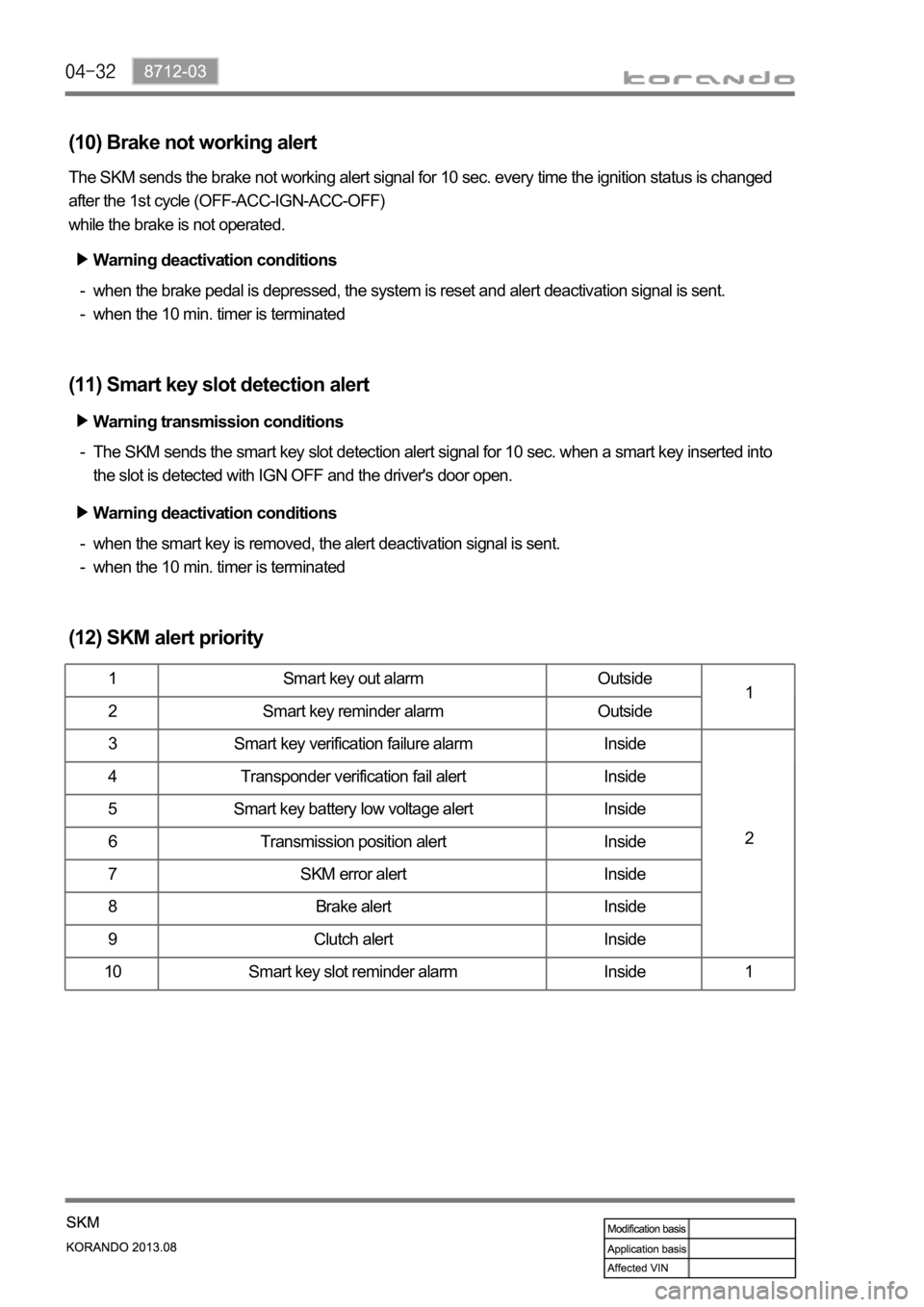

(12) SKM alert priority

1 Smart key out alarm Outside

1

2 Smart key reminder alarm Outside

3 Smart key verification failure alarm Inside

2 4 Transponder verification fail alert Inside

5 Smart key battery low voltage alert Inside

6 Transmission position alert Inside

7 SKM error alert Inside

8 Brake alert Inside

9 Clutch alert Inside

10 Smart key slot reminder alarm Inside 1

Warning deactivation conditions

Warning transmission conditions

Warning deactivation conditions

when the smart key is removed, the alert deactivation signal is sent.

when the 10 min. timer is terminated -

-

Page 1008 of 1336

1. OVERVIEW

Engine power reaches the transaxle via a torque converter with integral converter lock-up clutch. The six

forward gears and one reverse gear are obtained from a single planetary set, followed by a double

planetary set. This type of gear-set arrangement is commonly known as Lepelletier type gear-set.

The Model M11 6 speed automatic transaxle is electronically controlled. The control system is

comprised of the following components:

External transaxle control unit (TCU)

Internal embedded memory module (EMM)

Input and output speed sensors

Valve body unit comprised of four ON/OFF solenoid valves and six variable bleed solenoids (VBS)

Torque converter -

-

-

-

-

TCU controls the oil pressure for various internal clutches and bands to select the gear. It also controls

the electronic elements, shift pressure and torque converter slip. If the system is defective, TCU provides

FMEC (Failure Mode Effect Control) to maintain the functionality of transaxle. This keeps the basic

function of transaxle (gear selection) even when there are failure in controls and power supply.

There are selector shaft position sensor (inhibitor switch) and oil temperature sensor in transaxle. In

manual mode, TCU receives the information from TGS (Transmission Gear Selector) through PCB

(Printed Circuit Board) when driver selects the manual shift mode. TCU communicates with other

electric control modules through CAN. In order to ensure a safe driving state and to prevent damage to

the automatic transmission, TCU switches to Limp-Home mode in the event of critical faults.

Page 1009 of 1336

3680-01

2. FEATURES

1) Advantages

Early Downshift with Hard Braking and Skip Shifts

When heavy braking is detected, the transaxle downshifts early and skips gears to provide increased

engine braking to provide gear selection for tip-in.

Gear Hold going Uphill/Downhill

If the accelerator pedal is released when traveling uphill, upshifts are prevented to reduce busyness on

grades. If the accelerator pedal is released when traveling downhill, upshifts are prevented to enhance

engine braking.

Drive and Reverse Engagement

A soft engagement feature avoids harsh take up of drive when selecting Drive or Reverse. This is

achieved by limiting engine speed and engine torque which results in a rapid, but progressive

engagement of either Drive or Reverse when moving from the Park or Neutral positions. Drive and

Reverse engagements from either Park or Neutral are performed in less than 2.2 seconds. There is no

drive engagement prevention strategy implemented on the transaxle system as there is sufficient engine

strategy to protect the system. However, reverse engagement is prevented until engine speed is less

than 1,400 rpm and the accelerator pedal position is less than 12% and vehicle speed is less than 10

km/h.

Converter Clutch Lock-Up In All Gears

The transaxle features converter clutch lock-up in all gears. This feature provides improved fuel economy

and vehicle performance. It also improves transaxle cooling efficiency when towing heavy loads at low

speeds, e.g. in city driving or hill terrain.

Embedded Memory Module (EMM)

The embedded memory module (EMM) is

transaxle assembly to ensure refined shift quality.

The EMM is used to store data such as valve body

calibration data and valve body serial number.

Upon installation, the TCU will download the data

from the EMM and utilize this data in the operation

of the transaxle.

Page 1010 of 1336

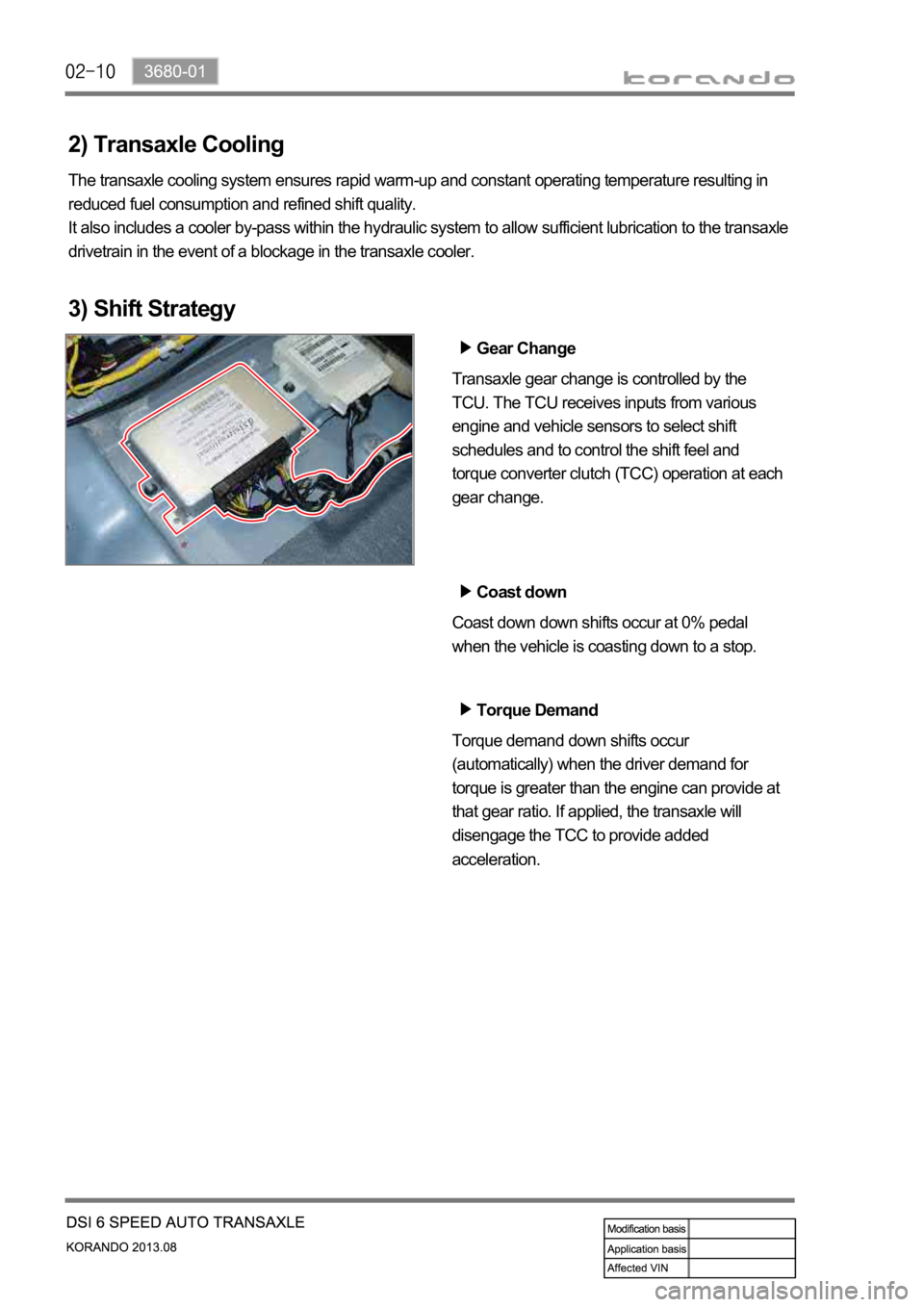

2) Transaxle Cooling

The transaxle cooling system ensures rapid warm-up and constant operating temperature resulting in

reduced fuel consumption and refined shift quality.

It also includes a cooler by-pass within the hydraulic system to allow sufficient lubrication to the transaxle

drivetrain in the event of a blockage in the transaxle cooler.

3) Shift Strategy

Gear Change

Transaxle gear change is controlled by the

TCU. The TCU receives inputs from various

engine and vehicle sensors to select shift

schedules and to control the shift feel and

torque converter clutch (TCC) operation at each

gear change.

Coast down

Coast down down shifts occur at 0% pedal

when the vehicle is coasting down to a stop.

Torque Demand

Torque demand down shifts occur

(automatically) when the driver demand for

torque is greater than the engine can provide at

that gear ratio. If applied, the transaxle will

disengage the TCC to provide added

acceleration.

Page 1013 of 1336

3680-01

4. LIMP HOME MODE

When the transaxle is defective

In the event of a system fault, the TCU also provides for failure mode effect control (FMEC) to maintain

maximum functional operation of the transaxle.

In the event of a total loss of control or electrical power, the basic transaxle functions (Park, Reverse,

Neutral and Drive) are retained. The 4th and reverse gear ratios with the torque converter clutch in the

unlocked state are the retained gear states the hydraulic system supports without any electrical

assistance.

The TCU communicates with other vehicle electronic control modules by the controller area network

(CAN). If a major fault develops, the transaxle may automatically operate in a "limp home" (failure)

mode to enable the vehicle to be driven to an authorized dealer for repair.

The TCU also provides for transaxle diagnostics, which meet the requirements of OBD II legislation,

monitoring all components which may effect vehicle emissions. 1.

2.

3.

4.

When the transaxle overheats

Limp home mode may also be engaged if the battery charge falls below 8V.

If the transaxle overheats, the shift patterns will automatically change to enable improved transaxle

cooling.

During transaxle overheat, the instrument cluster transaxle selector position display and the over

cluster until normal transaxle operating temperature is reached. 1.

2.

3.

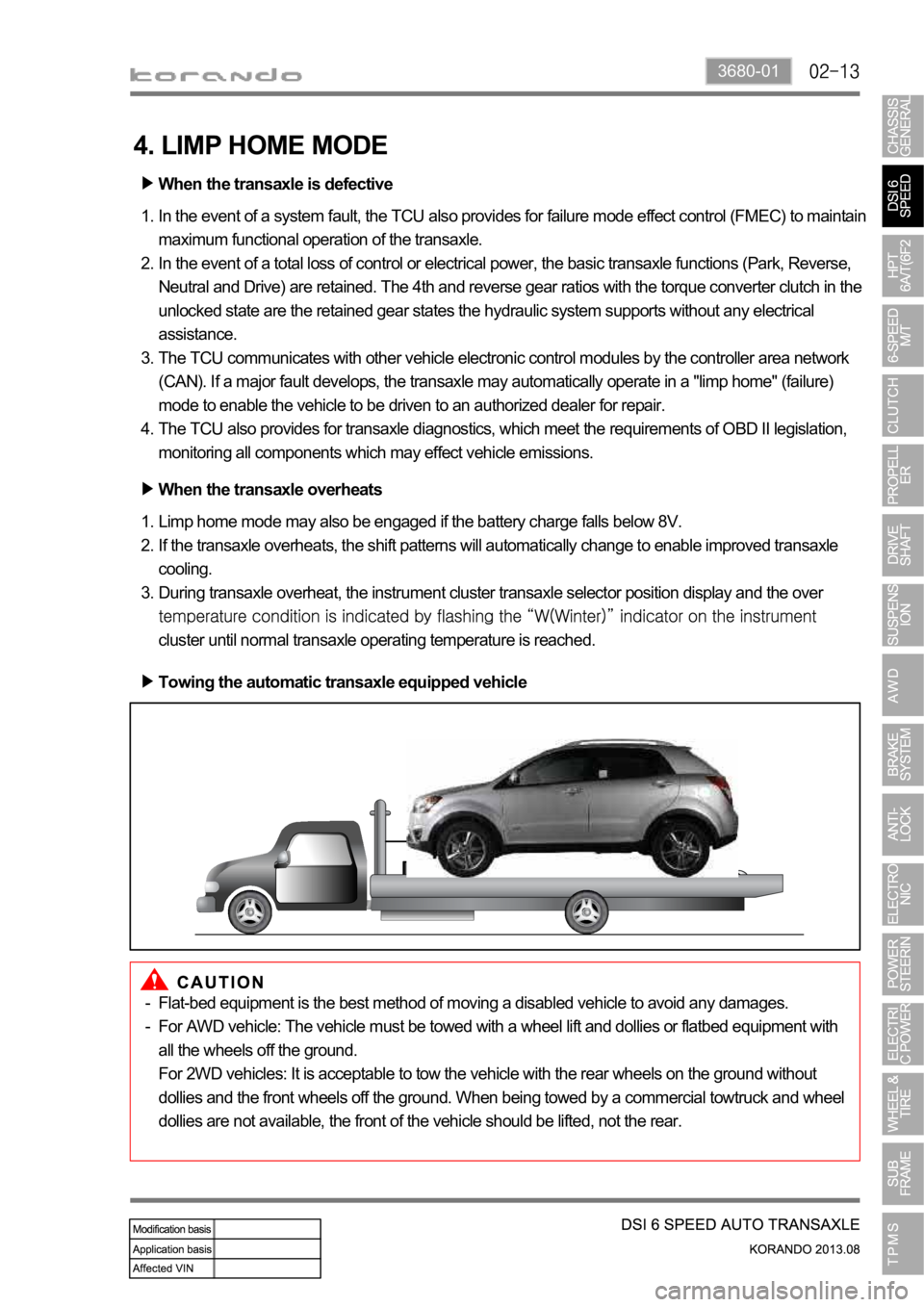

Towing the automatic transaxle equipped vehicle

Flat-bed equipment is the best method of moving a disabled vehicle to avoid any damages.

For AWD vehicle: The vehicle must be towed with a wheel lift and dollies or flatbed equipment with

all the wheels off the ground.

For 2WD vehicles: It is acceptable to tow the vehicle with the rear wheels on the ground without

dollies and the front wheels off the ground. When being towed by a commercial towtruck and wheel

dollies are not available, the front of the vehicle should be lifted, not the rear. -

-

Page 1014 of 1336

5. TRANSAXLE ELECTRONIC CONTROL SYSTEM

1) General Information

The transmission control unit (TCU) and its input/output network control the following transmission

operations:

Shift timing

Line pressure

Clutch pressure (shift feel)

Torque converter clutch -

-

-

-

also uses these signals when determining transaxle operating strategy. Using all of these input signals,

the TCU can determine when the time and conditions are right for a shift, or when to apply or release the

torque converter clutch. It will also determine the pressure needed to optimise shift feel. To accomplish

this, the TCU operates six variable bleed control solenoids and four on/off solenoids to control transaxle

operation.

2) TCU (Transmission Control Unit)

The transaxle control unit (TCU) is mounted

under the driver's seat and controls the operation

of the transaxle.

The TCU is activated and deactivated by the

ignition power supply and is connected to the

transaxle link harness by a 26 pin connector. The

TCU processes information received from internal

sensors and signals received across the CAN

bus in analogue and digital forms such as:

Transaxle input speed

Transaxle output speed

Accelerator pedal position

Gear selector position

Engine torque

Engine speed

Transaxle fluid temperature

Brake pedal status

Engine oil temperature

Engine coolant temperature

Ambient air temperature

Barometric pressure -

-

-

-

-

-

-

-

-

-

-

-