SSANGYONG KYRON 2010 Service Manual

Manufacturer: SSANGYONG, Model Year: 2010, Model line: KYRON, Model: SSANGYONG KYRON 2010Pages: 650, PDF Size: 74.38 MB

Page 191 of 650

Page 192 of 650

Page 193 of 650

ENGINE FUEL SYSTEM

undefined

1881-01

1881-01ENGINE FUEL SYSTEM

GENERAL

1. CAUTIONS FOR DI ENGINE

This chapter describes the cautions for DI engine equipped vehicle. This includes the water

separation from engine, warning lights, symptoms when engine malfunctioning, causes and

actions.

1) DI Engine

Comparatively conventional diesel engines, DI engine controls the fuel injection and timing

electrically, delivers high power and reduces less emission.

2) System Safety Mode

When a severe failure has been occurred in a vehicle, the system safety mode is activated to

protect the system. It reduces the driving force, restricts the engine speed (rpm) and stops

engine operation. Refer to "Diagnosis" section in this manual.

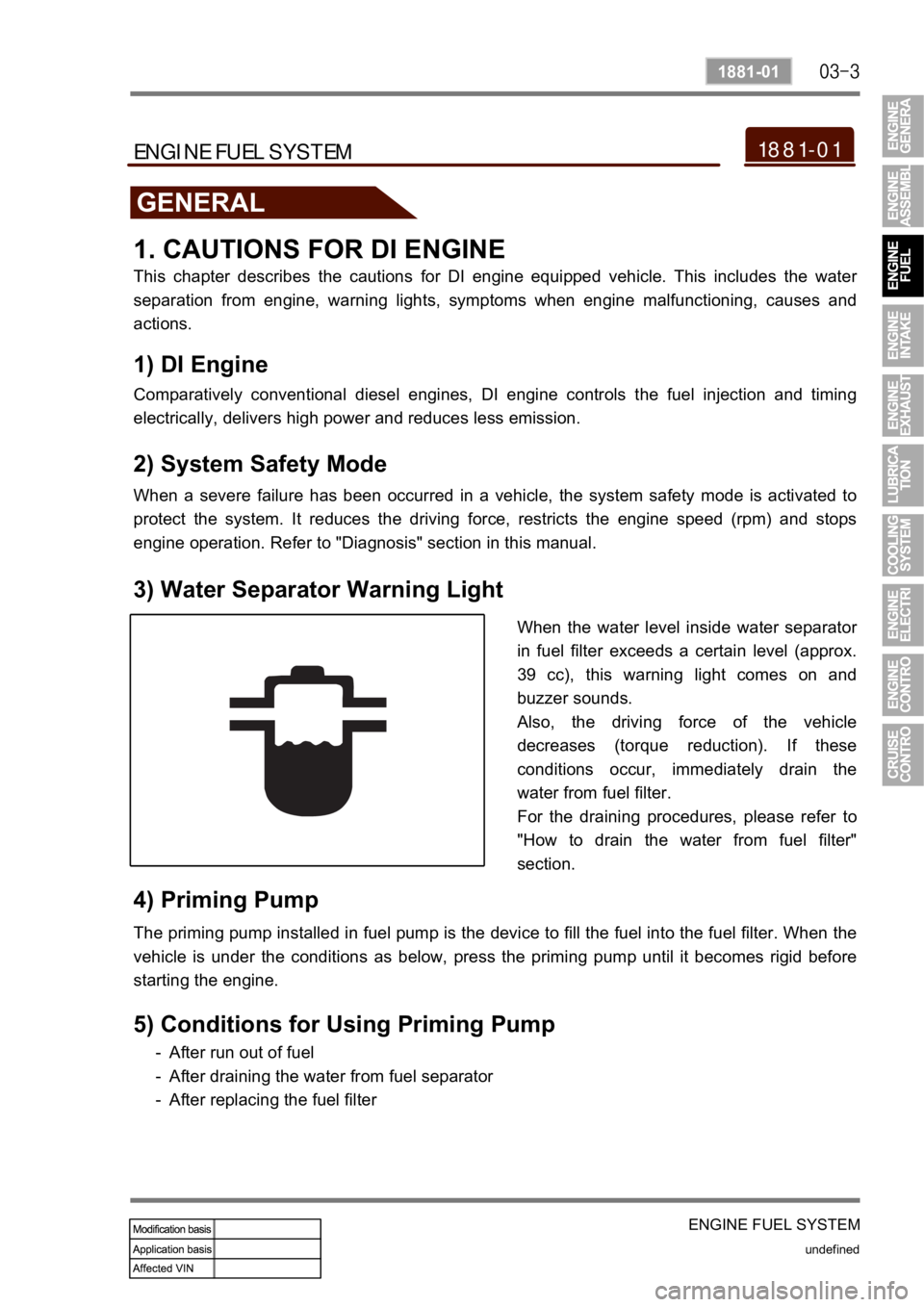

3) Water Separator Warning Light

When the water level inside water separator

in fuel filter exceeds a certain level (approx.

39 cc), this warning light comes on and

buzzer sounds.

Also, the driving force of the vehicle

decreases (torque reduction). If these

conditions occur, immediately drain the

water from fuel filter.

For the draining procedures, please refer to

"How to drain the water from fuel filter"

section.

4) Priming Pump

The priming pump installed in fuel pump is the device to fill the fuel into the fuel filter. When the

vehicle is under the conditions as below, press the priming pump until it becomes rigid before

starting the engine.

5) Conditions for Using Priming Pump

After run out of fuel

After draining the water from fuel separator

After replacing the fuel filter -

-

-

Page 194 of 650

undefined

1881-01

ENGINE FUEL SYSTEM

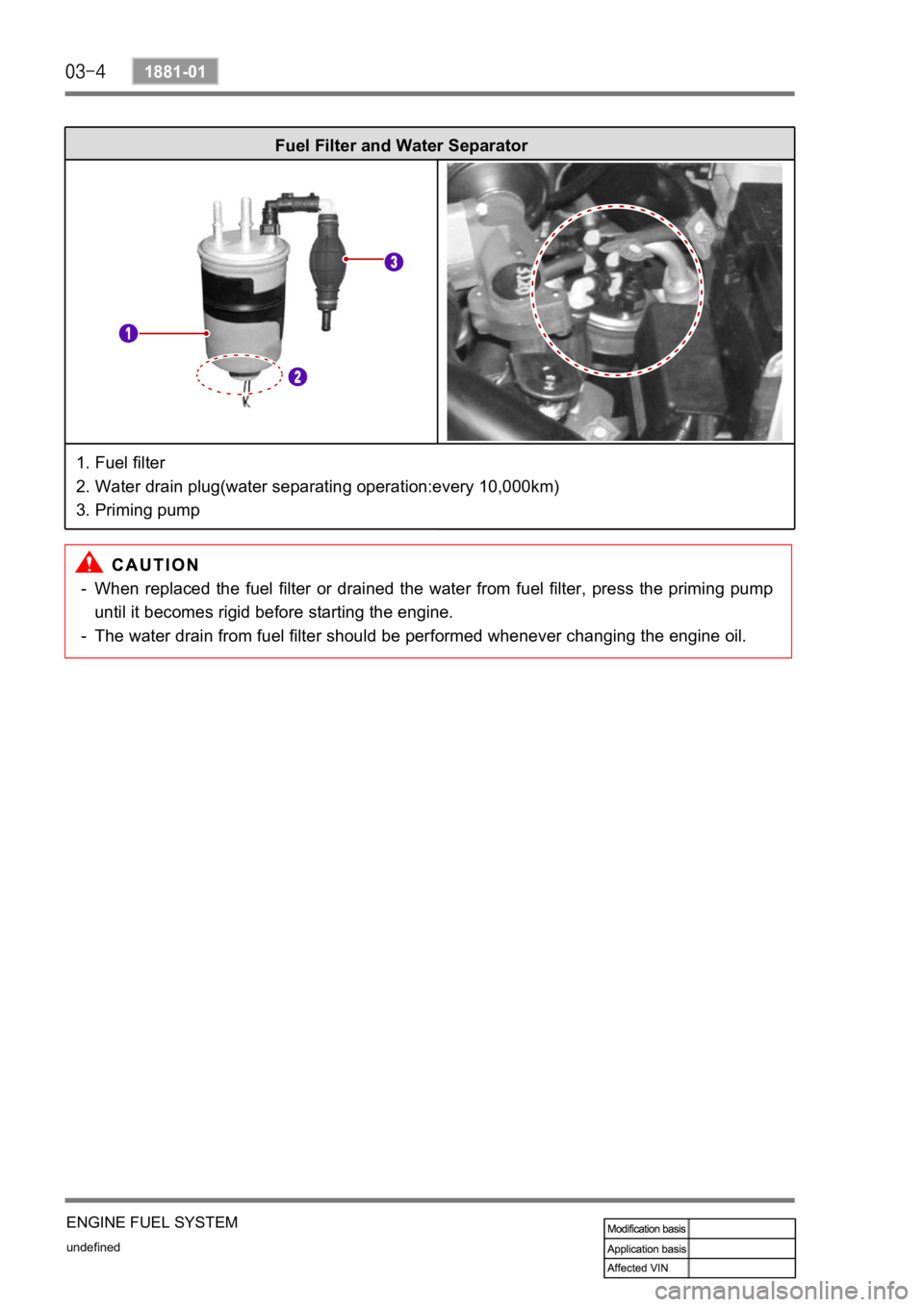

Fuel Filter and Water Separator

1. Fuel filter

2. Water drain plug(water separating operation:every 10,000km)

3. Priming pump

When replaced the fuel filter or drained the water from fuel filter, press the priming pump

until it becomes rigid before starting the engine.

The water drain from fuel filter should be performed whenever changing the engine oil. -

-

Page 195 of 650

ENGINE FUEL SYSTEM

undefined

1881-01

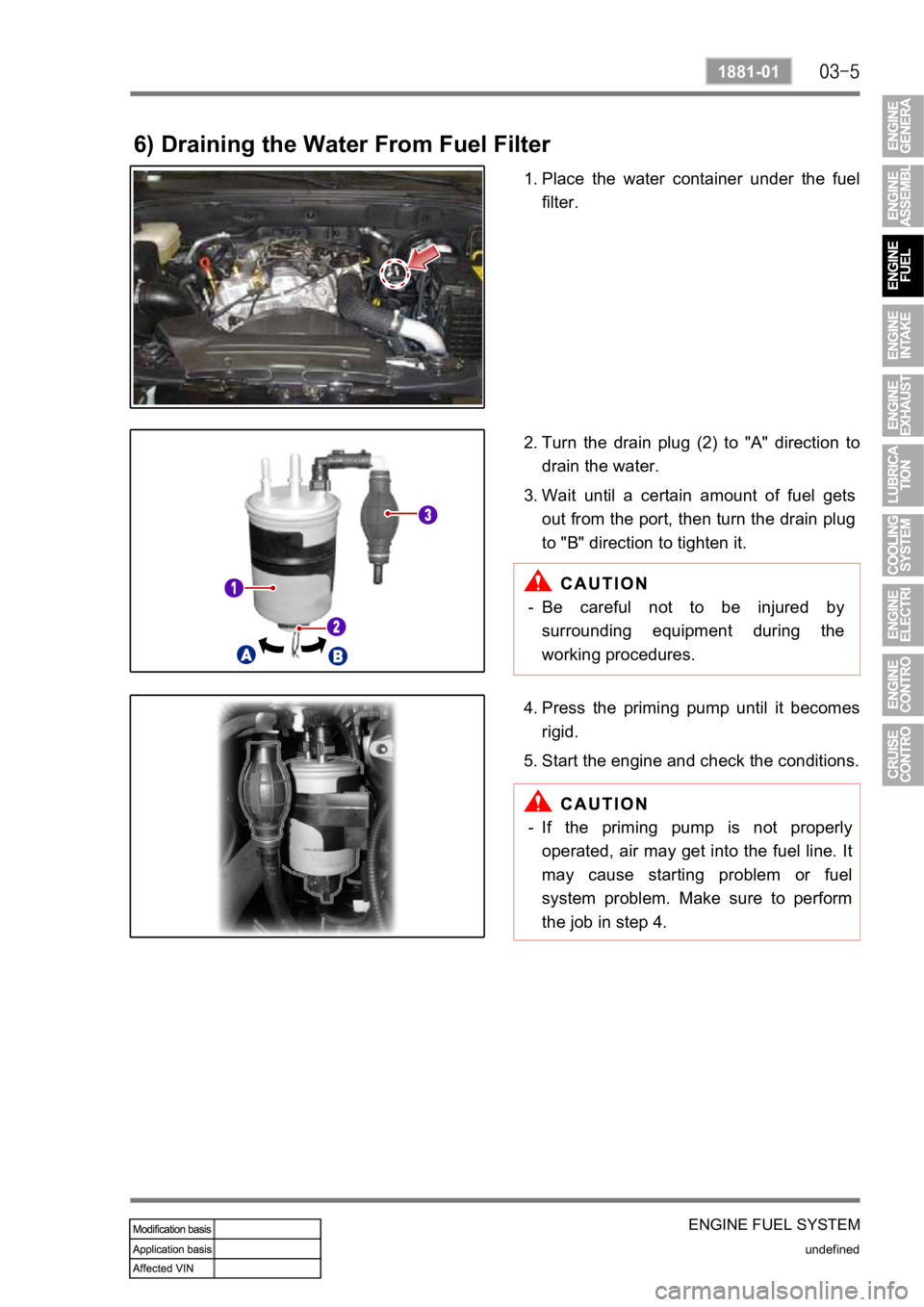

6) Draining the Water From Fuel Filter

Place the water container under the fuel

filter. 1.

Turn the drain plug (2) to "A" direction to

drain the water. 2.

Wait until a certain amount of fuel gets

out from the port, then turn the drain plug

to "B" direction to tighten it. 3.

Be careful not to be injured by

surrounding equipment during the

working procedures. -

Press the priming pump until it becomes

rigid. 4.

Start the engine and check the conditions. 5.

If the priming pump is not properly

operated, air may get into the fuel line. It

may cause starting problem or fuel

system problem. Make sure to perform

the job in step 4. -

Page 196 of 650

undefined

1881-01

ENGINE FUEL SYSTEM

OVERVIEW AND OPERATION PROCESS

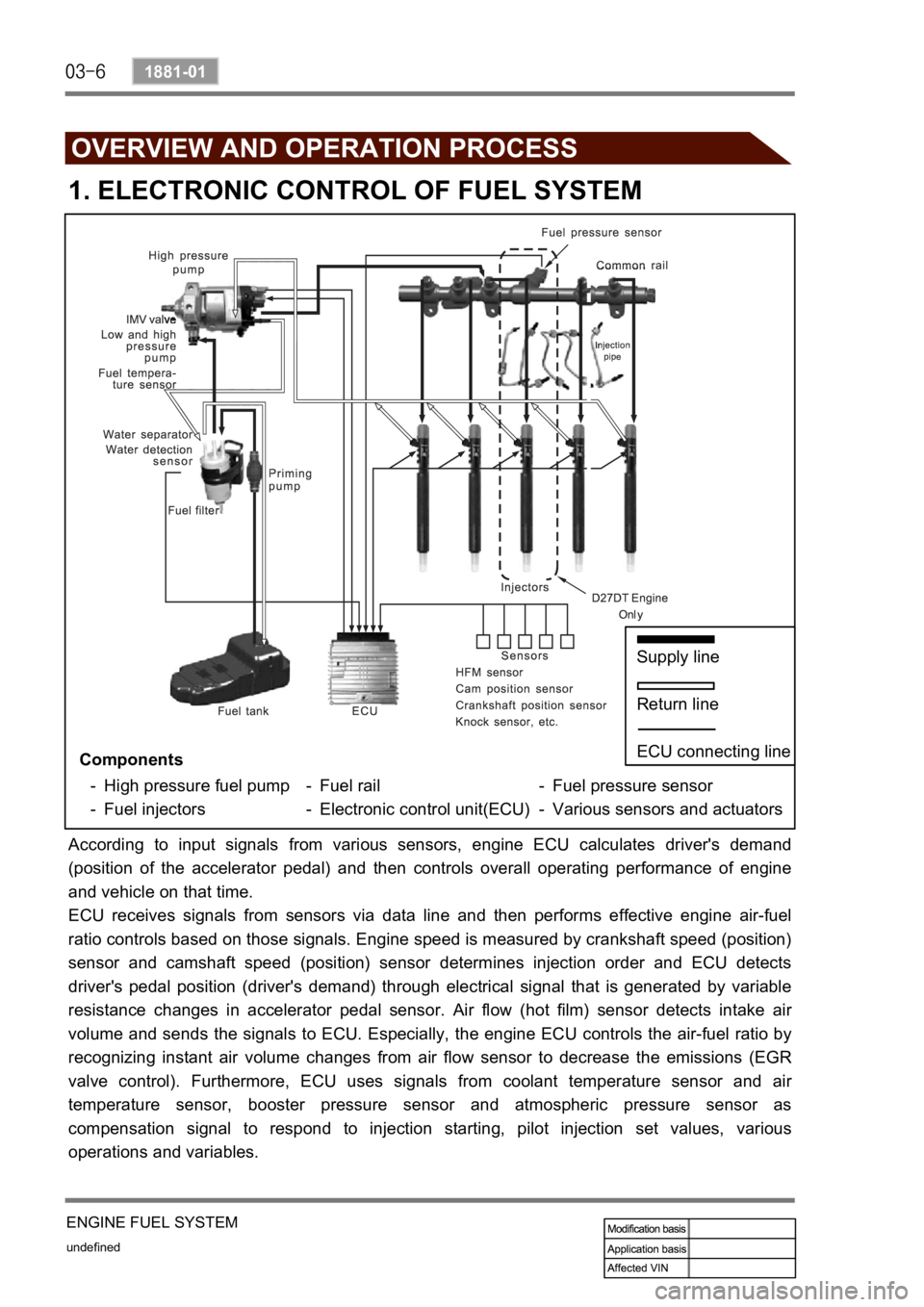

1. ELECTRONIC CONTROL OF FUEL SYSTEM

According to input signals from various sensors, engine ECU calculates driver's demand

(position of the accelerator pedal) and then controls overall operating performance of engine

and vehicle on that time.

ECU receives signals from sensors via data line and then performs effective engine air-fuel

ratio controls based on those signals. Engine speed is measured by crankshaft speed (position)

sensor and camshaft speed (position) sensor determines injection order and ECU detects

driver's pedal position (driver's demand) through electrical signal that is generated by variable

resistance changes in accelerator pedal sensor. Air flow (hot film) sensor detects intake ai

r

volume and sends the signals to ECU. Especially, the engine ECU controls the air-fuel ratio by

recognizing instant air volume changes from air flow sensor to decrease the emissions (EGR

valve control). Furthermore, ECU uses signals from coolant temperature sensor and ai

r

temperature sensor, booster pressure sensor and atmospheric pressure sensor as

compensation signal to respond to injection starting, pilot injection set values, various

operations and variables.Components

High pressure fuel pump

Fuel injectors -

-Fuel rail

Electronic control unit(ECU) -

-Fuel pressure sensor

Various sensors and actuators -

-Supply line

Return line

ECU connecting line

Page 197 of 650

ENGINE FUEL SYSTEM

undefined

1881-01

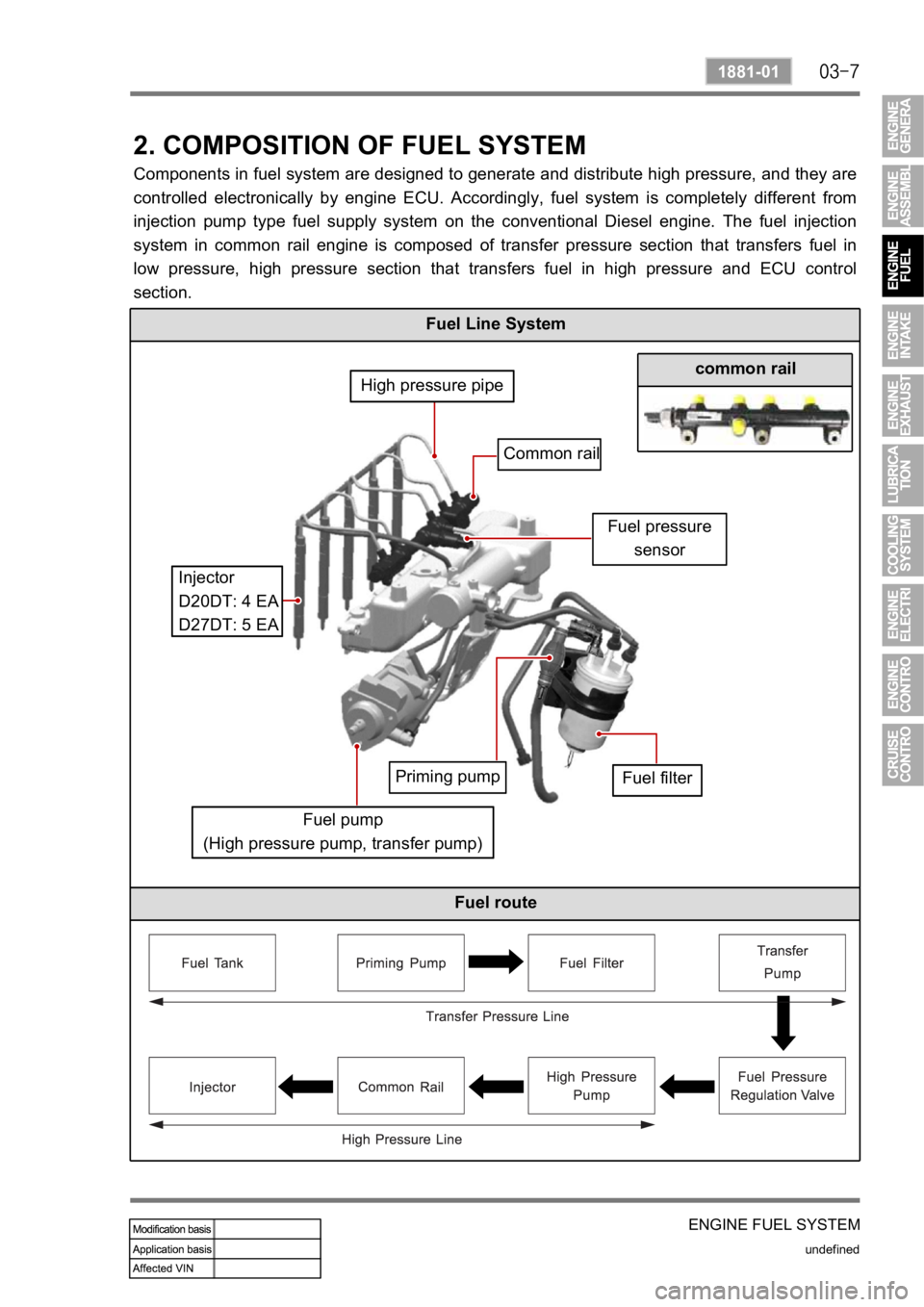

Fuel Line System

Fuel route

2. COMPOSITION OF FUEL SYSTEM

Components in fuel system are designed to generate and distribute high pressure, and they are

controlled electronically by engine ECU. Accordingly, fuel system is completely different from

injection pump type fuel supply system on the conventional Diesel engine. The fuel injection

system in common rail engine is composed of transfer pressure section that transfers fuel in

low pressure, high pressure section that transfers fuel in high pressure and ECU control

section.

High pressure pipe

Common rail

Fuel pressure

sensor

Priming pump

Fuel pump

(High pressure pump, transfer pump)

Fuel filter

Injector

D20DT: 4 EA

D27DT: 5 EA

common rail

Page 198 of 650

undefined

1881-01

ENGINE FUEL SYSTEM

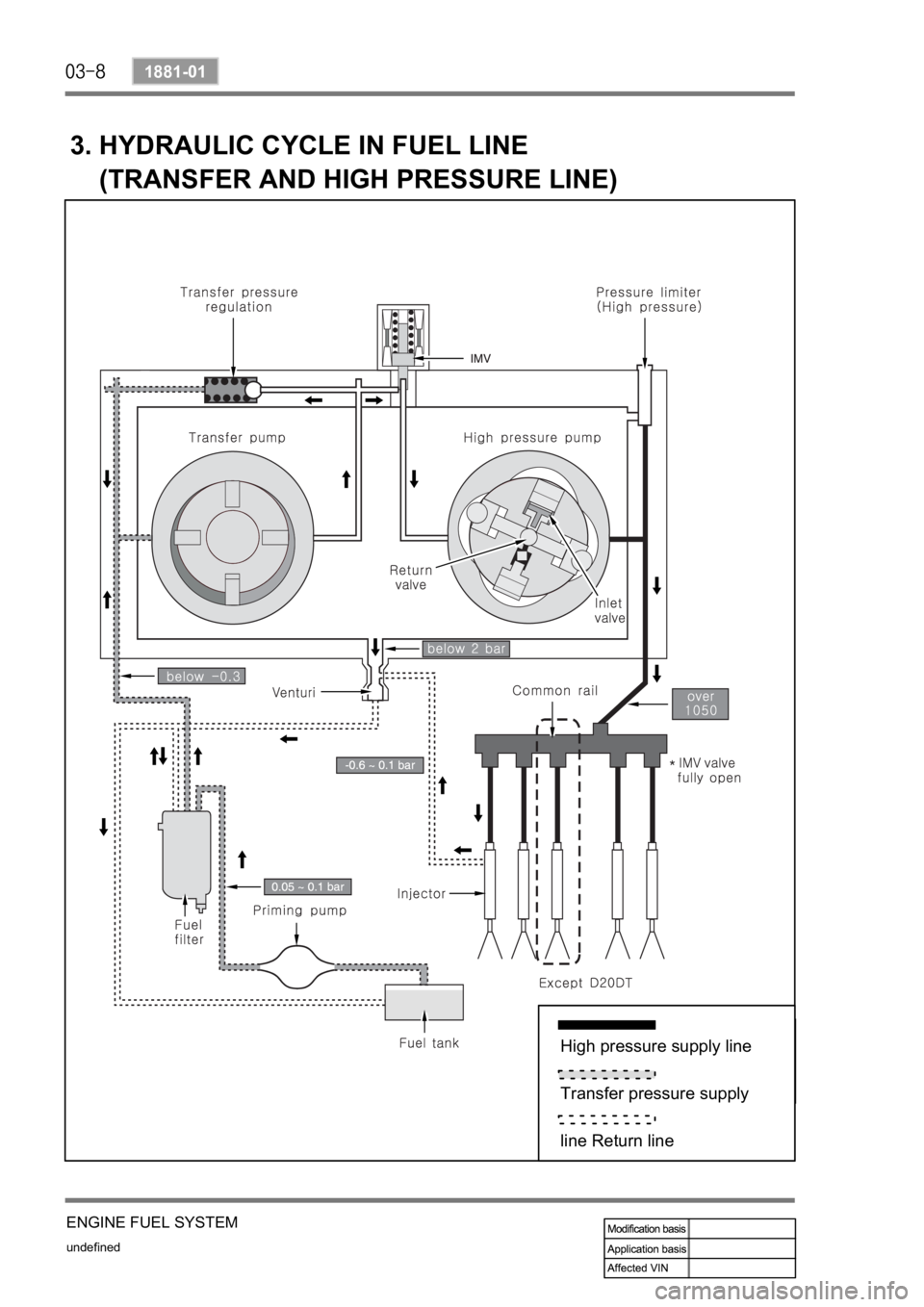

3. HYDRAULIC CYCLE IN FUEL LINE

(TRANSFER AND HIGH PRESSURE LINE)

High pressure supply line

Transfer pressure supply

line Return line

Page 199 of 650

ENGINE FUEL SYSTEM

undefined

1881-01

4. COMPONENTS OF LOW PRESSURE TRANSFER LINE

Low pressure stage is to supply sufficient fuel to high pressure section and components are as

below.

Fuel tank (including strainer)

Hand priming pump

Fuel filter

Transfer pump

Other low pressure fuel hoses -

-

-

-

-

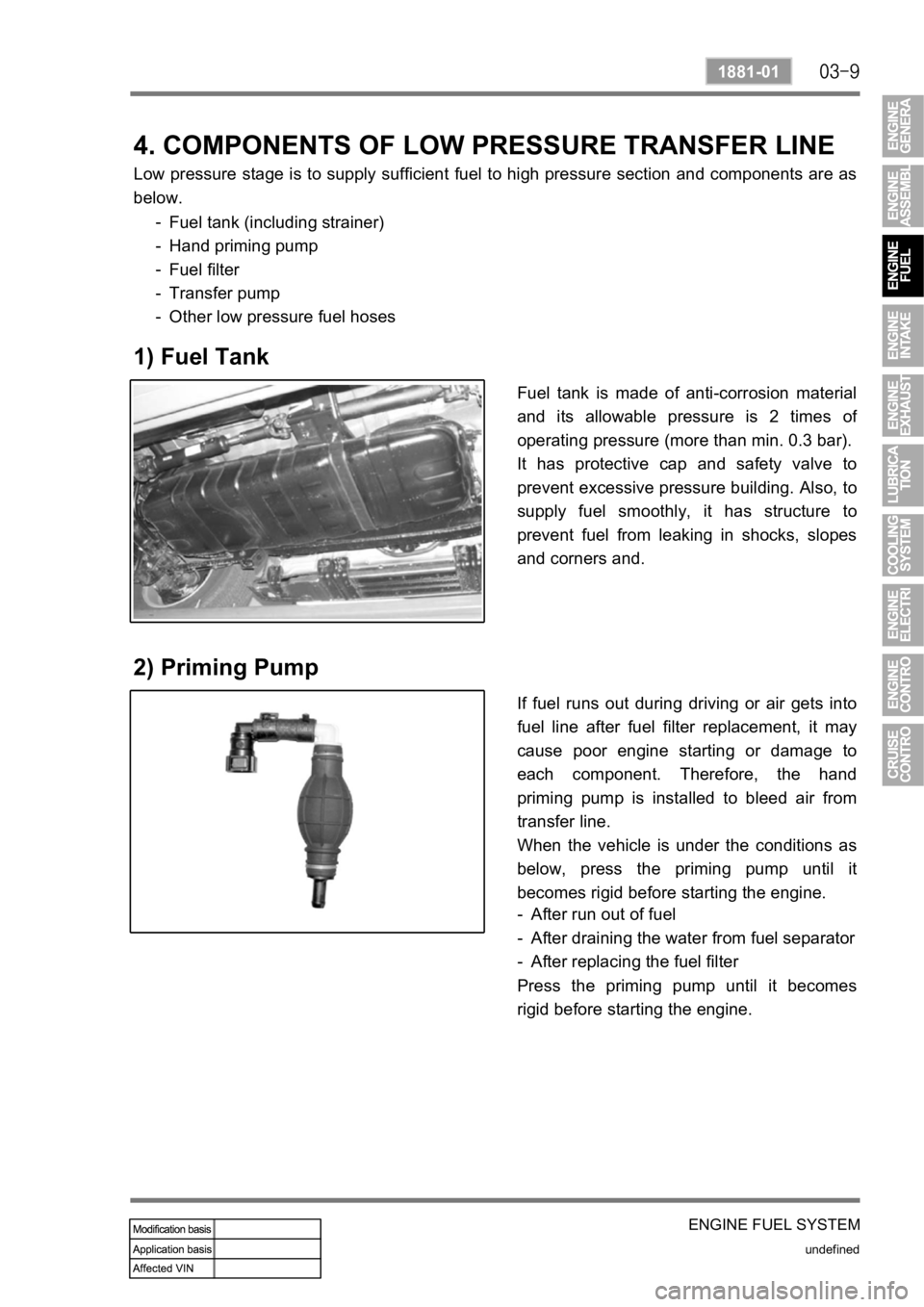

1) Fuel Tank

Fuel tank is made of anti-corrosion material

and its allowable pressure is 2 times o

f

operating pressure (more than min. 0.3 bar).

It has protective cap and safety valve to

prevent excessive pressure building. Also, to

supply fuel smoothly, it has structure to

prevent fuel from leaking in shocks, slopes

and corners and.

If fuel runs out during driving or air gets into

fuel line after fuel filter replacement, it may

cause poor engine starting or damage to

each component. Therefore, the hand

priming pump is installed to bleed air from

transfer line.

When the vehicle is under the conditions as

below, press the priming pump until it

becomes rigid before starting the engine.

2) Priming Pump

After run out of fuel

After draining the water from fuel separator

After replacing the fuel filter -

-

-

Press the priming pump until it becomes

rigid before starting the engine.

Page 200 of 650

undefined

1881-01

ENGINE FUEL SYSTEM

It requires more purified fuel supply than

conventional diesel engine. If there are

foreign materials in the fuel, fuel system

including pump components, delivery valve

and injector nozzles may be damaged.

Fuel filter purifies fuel before it reaches to

high pressure pump to help prope

r

operations in high pressure pump.

And more, it separates water from fuel to

prevent water from getting into FIE system

(high pressure line).

3) Fuel Filter