SSANGYONG KYRON 2010 Service Manual

KYRON 2010

SSANGYONG

SSANGYONG

https://www.carmanualsonline.info/img/67/57505/w960_57505-0.png

SSANGYONG KYRON 2010 Service Manual

Trending: stop start, cooling, fuel, oil change, ESP, fuse, oil filter

Page 201 of 650

ENGINE FUEL SYSTEM

undefined

1881-01

5. COMPONENTS OF HIGH PRESSURE TRANSFER LINE

In the high pressure section, sufficient fuel pressure that injectors requires will be generated

and stored. The components are as below:

High pressure pump

Rail pressure sensor

Pressure limit valve

Common rail

High pressure pipe

Injector

Fuel pressure regulating valve (IMV) -

-

-

-

-

-

-

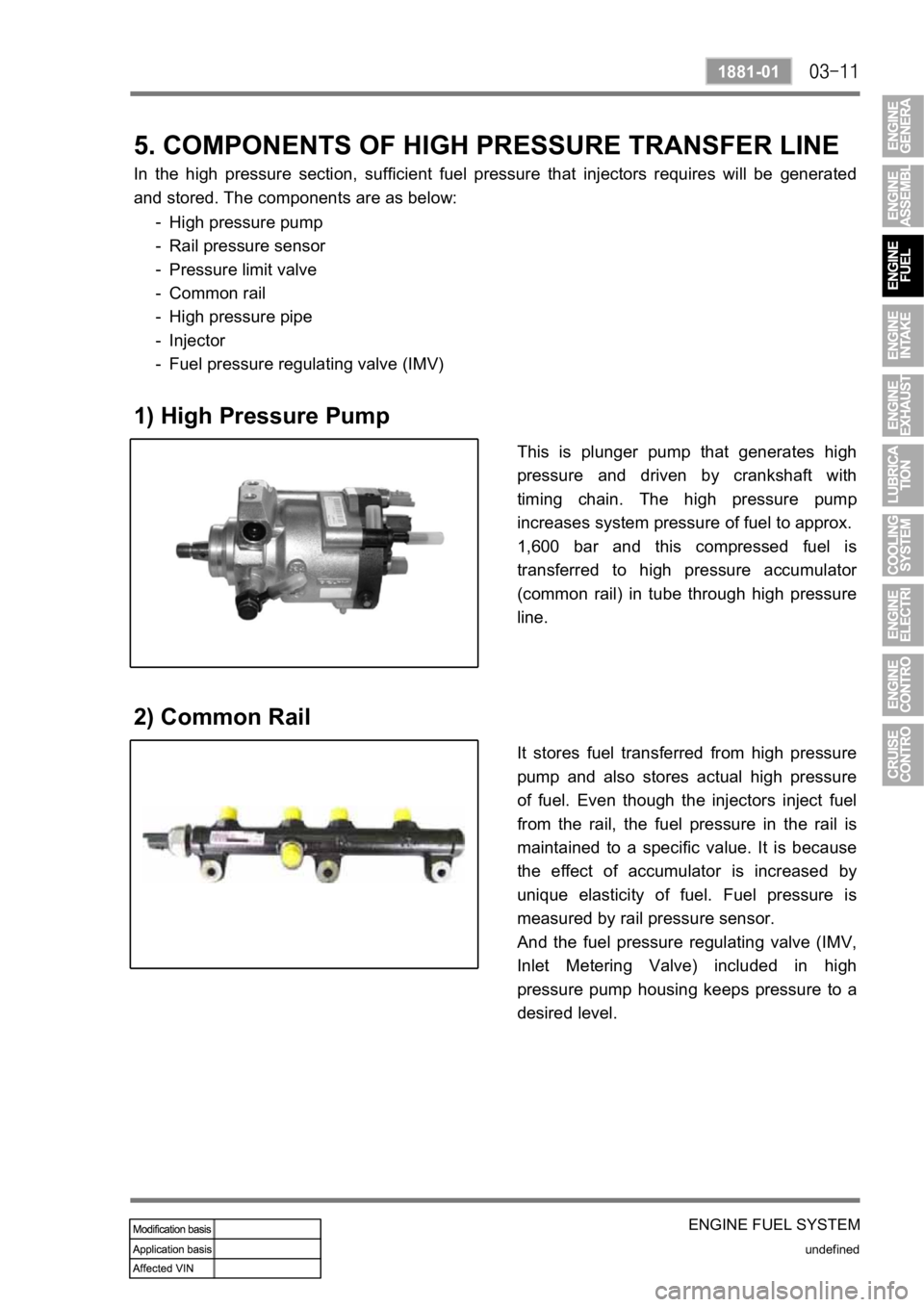

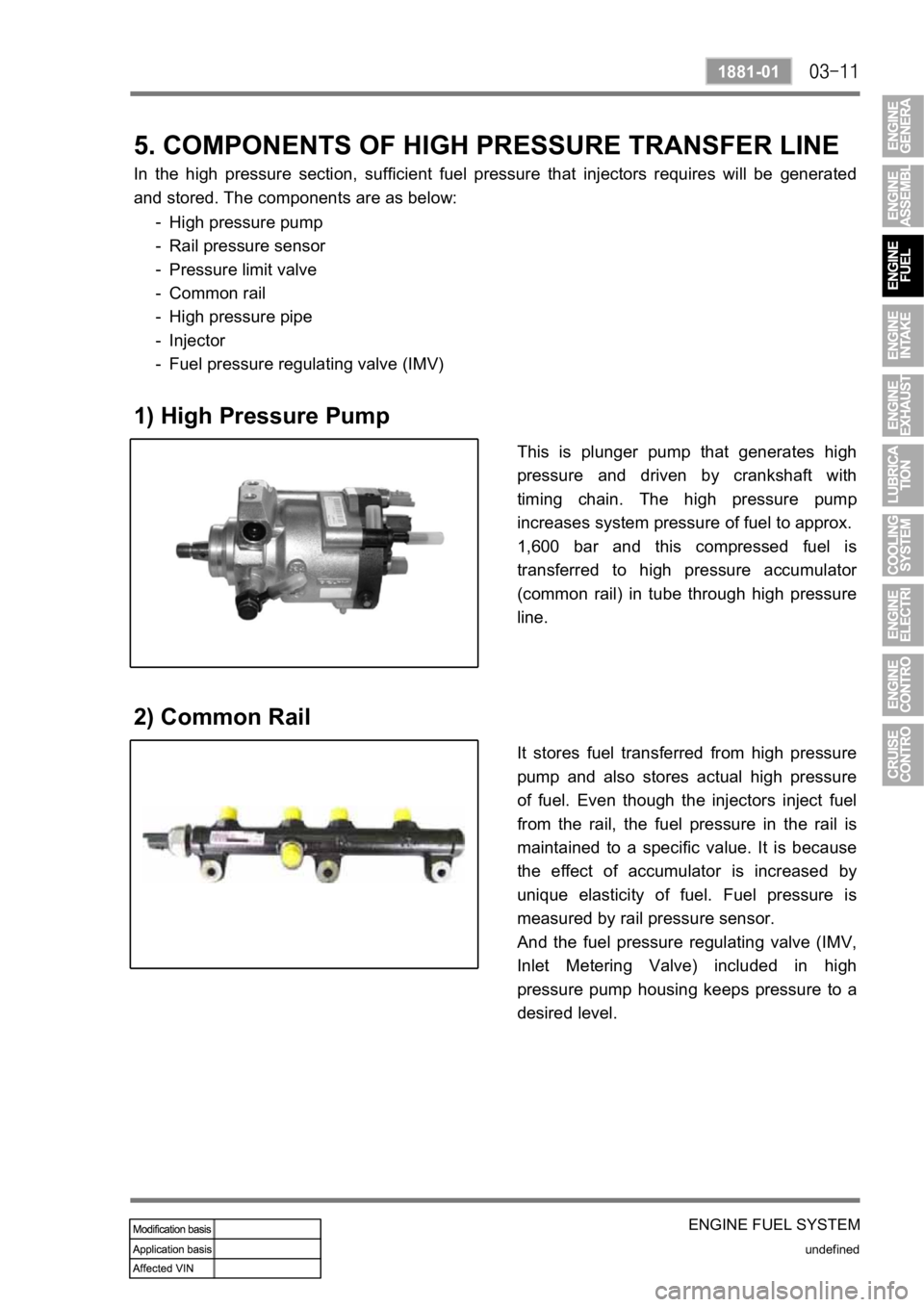

This is plunger pump that generates high

pressure and driven by crankshaft with

timing chain. The high pressure pump

increases system pressure of fuel to approx.

1,600 bar and this compressed fuel is

transferred to high pressure accumulato

r

(common rail) in tube through high pressure

line.

1) High Pressure Pump

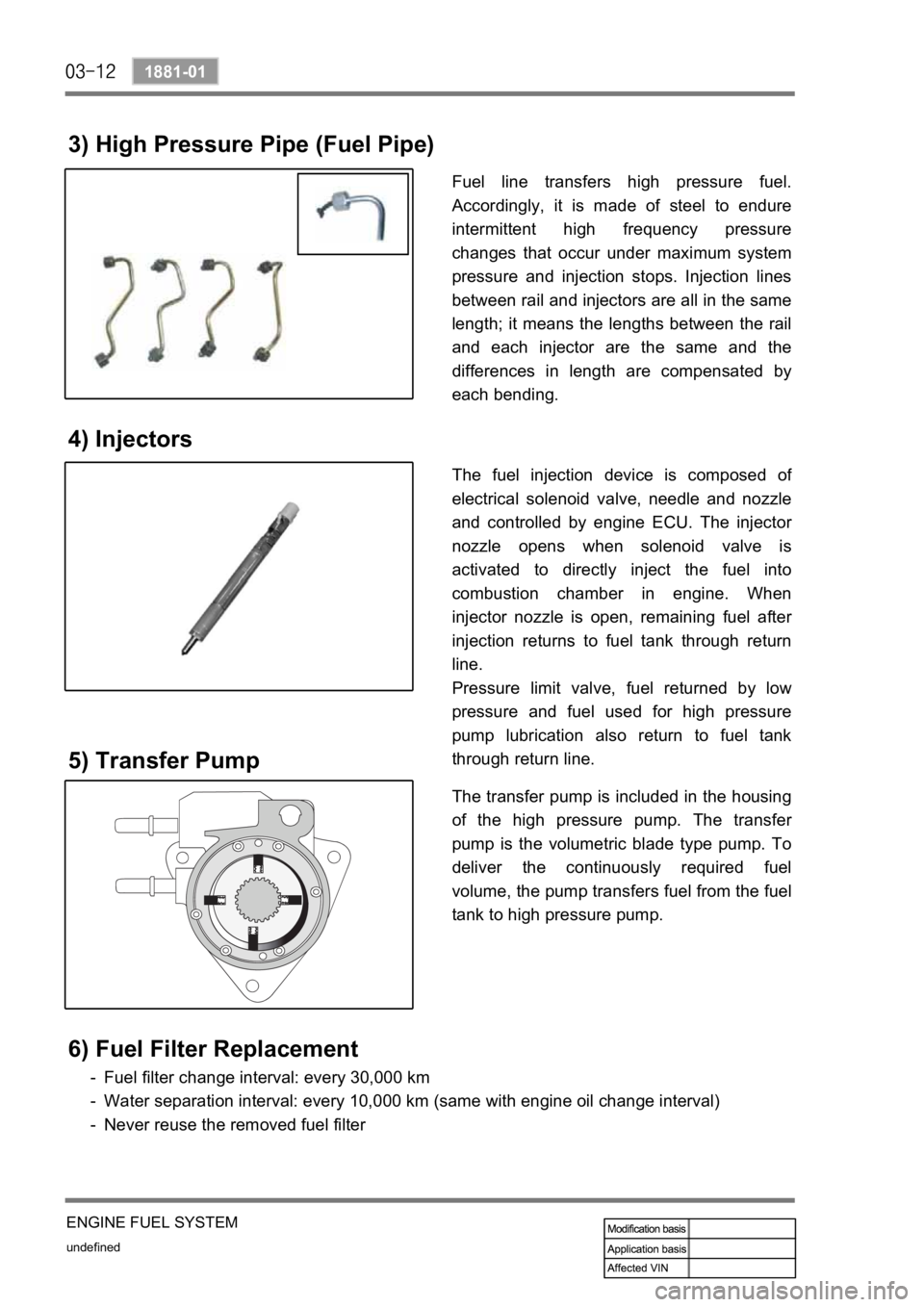

It stores fuel transferred from high pressure

pump and also stores actual high pressure

of fuel. Even though the injectors inject fuel

from the rail, the fuel pressure in the rail is

maintained to a specific value. It is because

the effect of accumulator is increased by

unique elasticity of fuel. Fuel pressure is

measured by rail pressure sensor.

And the fuel pressure regulating valve (IMV,

Inlet Metering Valve) included in high

pressure pump housing keeps pressure to a

desired level.

2) Common Rail

Page 202 of 650

undefined

1881-01

ENGINE FUEL SYSTEM

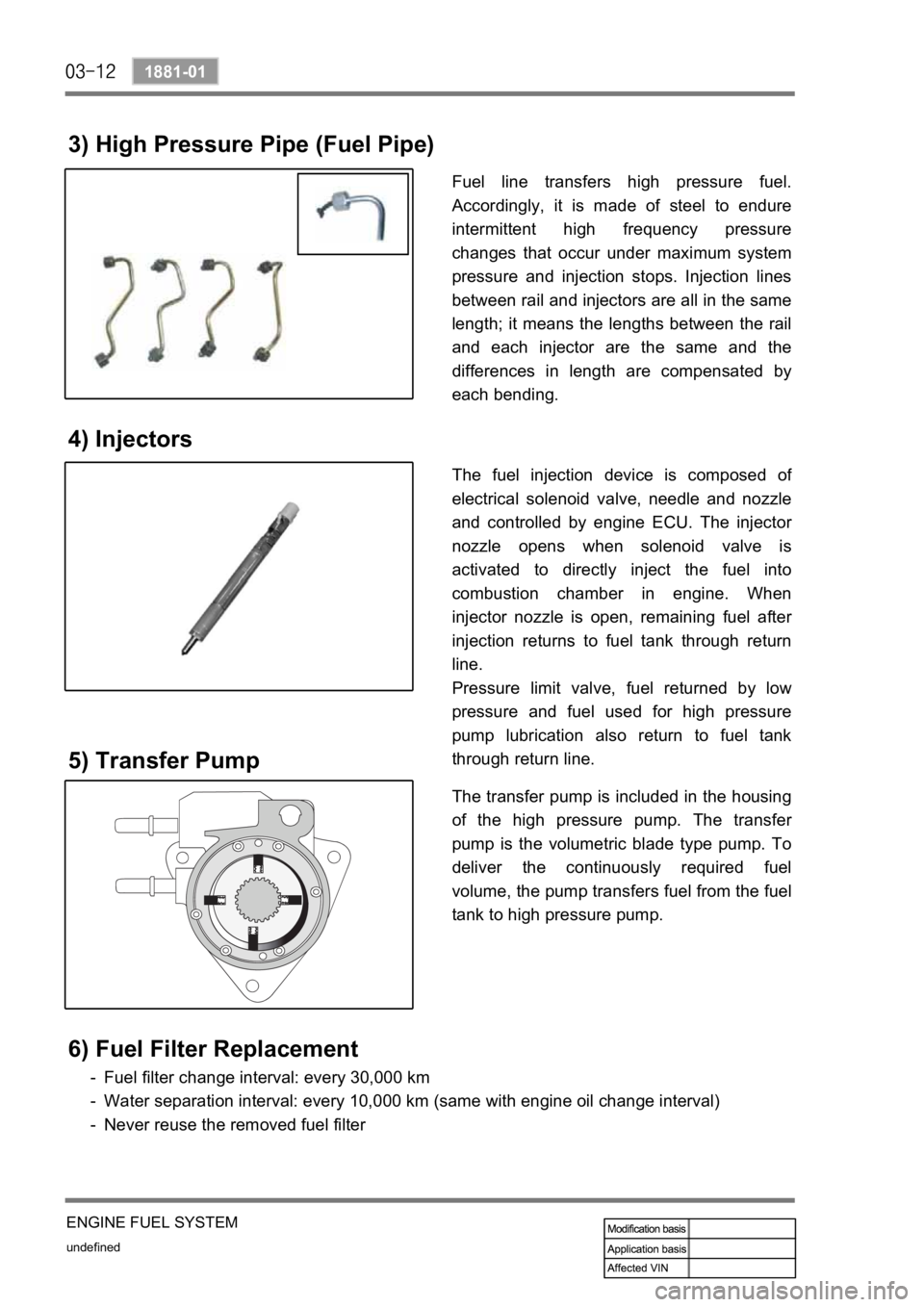

3) High Pressure Pipe (Fuel Pipe)

Fuel line transfers high pressure fuel.

Accordingly, it is made of steel to endure

intermittent high frequency pressure

changes that occur under maximum system

pressure and injection stops. Injection lines

between rail and injectors are all in the same

length; it means the lengths between the rail

and each injector are the same and the

differences in length are compensated by

each bending.

4) Injectors

The fuel injection device is composed of

electrical solenoid valve, needle and nozzle

and controlled by engine ECU. The injecto

r

nozzle opens when solenoid valve is

activated to directly inject the fuel into

combustion chamber in engine. When

injector nozzle is open, remaining fuel afte

r

injection returns to fuel tank through return

line.

Pressure limit valve, fuel returned by low

pressure and fuel used for high pressure

pump lubrication also return to fuel tank

through return line.

6) Fuel Filter Replacement

Fuel filter change interval: every 30,000 km

Water separation interval: every 10,000 km (same with engine oil change interval)

Never reuse the removed fuel filter -

-

-

The transfer pump is included in the housing

of the high pressure pump. The transfe

r

pump is the volumetric blade type pump. To

deliver the continuously required fuel

volume, the pump transfers fuel from the fuel

tank to high pressure pump.

5) Transfer Pump

Page 203 of 650

ENGINE FUEL SYSTEM

undefined

1881-01

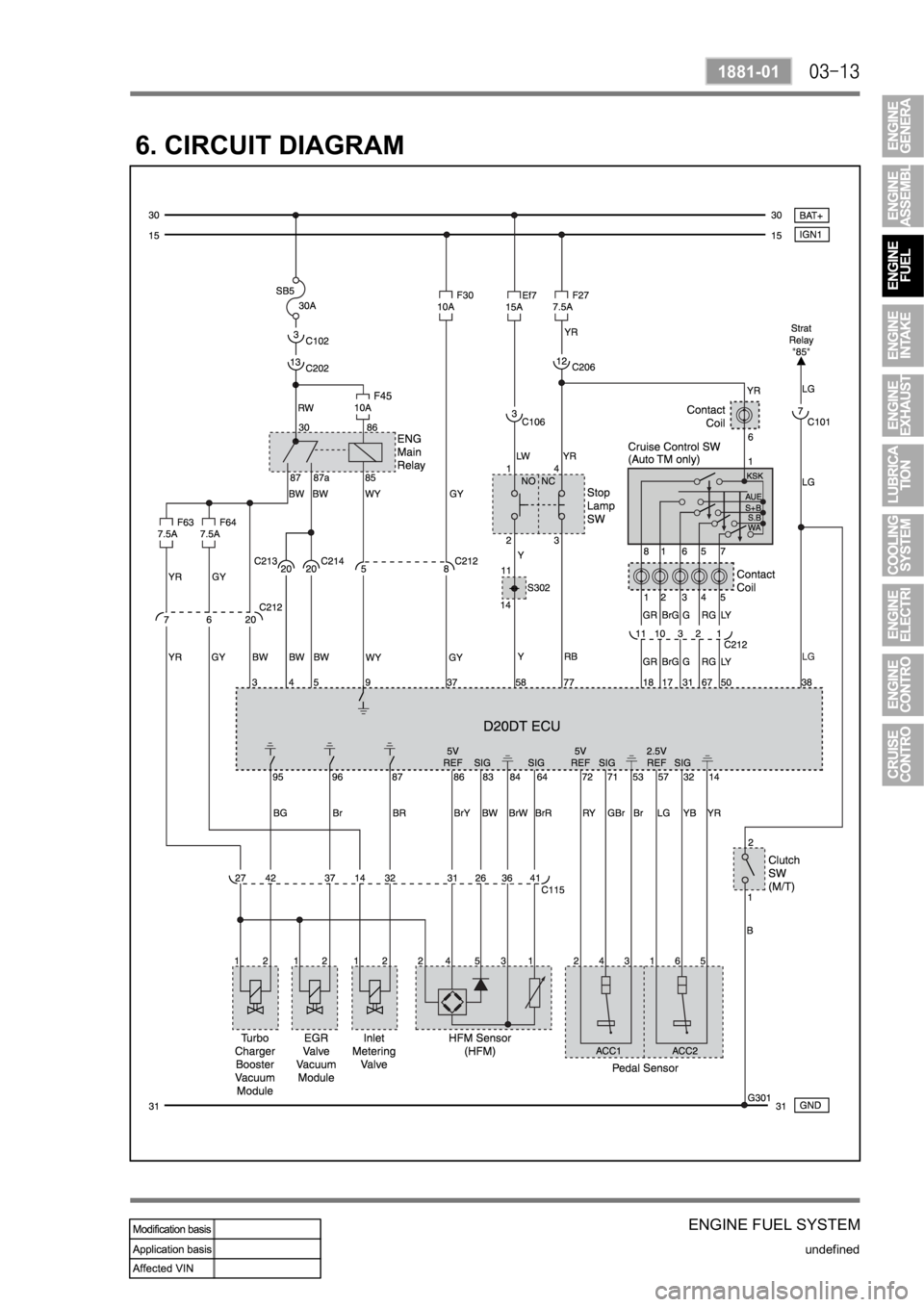

6. CIRCUIT DIAGRAM

Page 204 of 650

undefined

1881-01

ENGINE FUEL SYSTEM

Page 205 of 650

ENGINE FUEL SYSTEM

undefined

1881-01

Page 206 of 650

Page 207 of 650

ENGINE INTAKE SYSTEM

undefined

2321-01

GENERAL

1. ENGINE INTAKE SPECIFICATIONS

1) Specifications

Element Type Dry-Element Type

Service Interval- Initial cleaning: 5,000 km, Clean or change every 10,000 km as

required. However, change every 30,000 km.

- If the vehicle is operated under severe condition (short distance

driving, extensive ldling or driving in dusty condition): More frequent

maintenance is required.

2321-01ENGINE INTAKE SYSTEM

Page 208 of 650

undefined

2321-01

ENGINE INTAKE SYSTEM

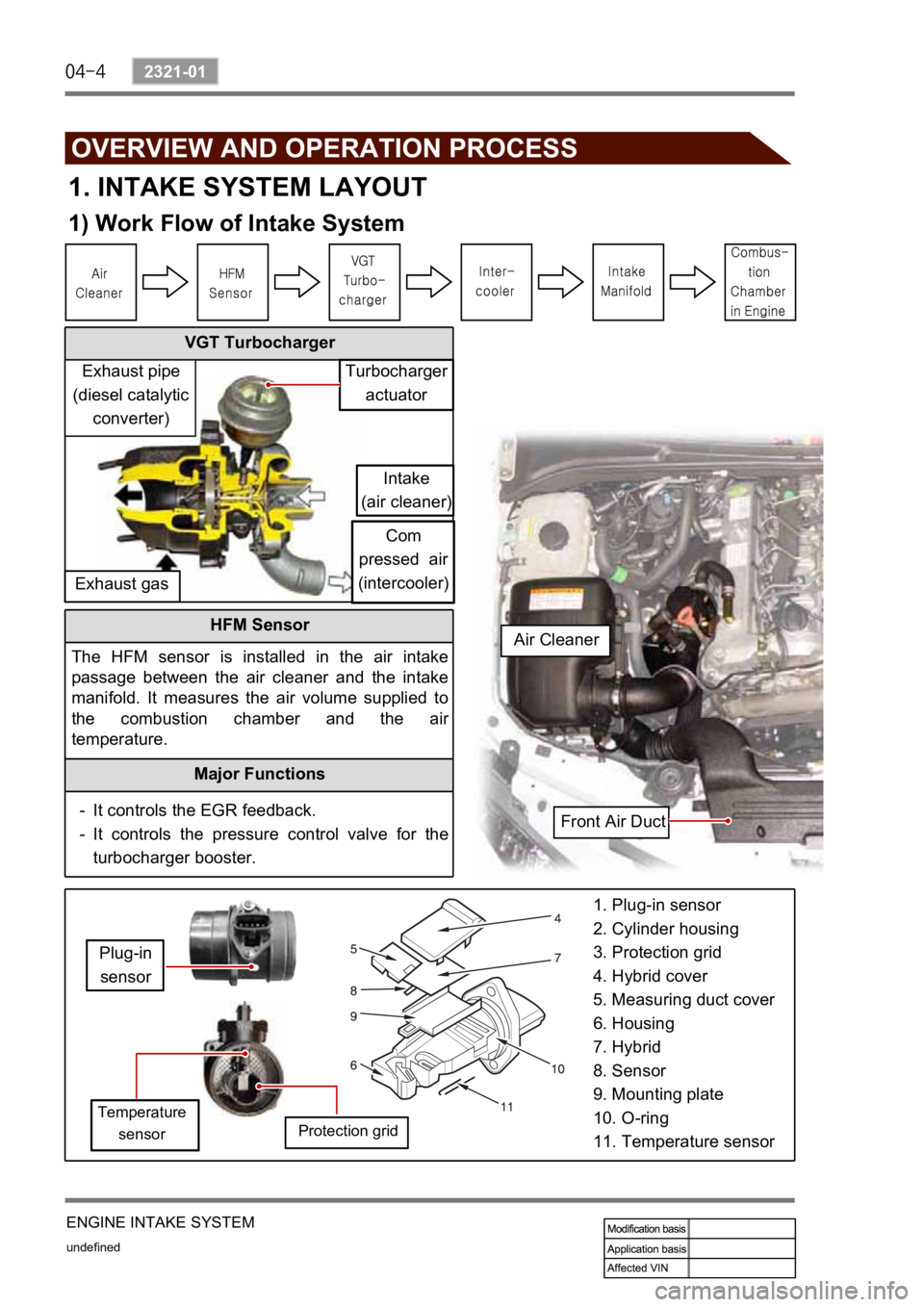

VGT Turbocharger

OVERVIEW AND OPERATION PROCESS

1. INTAKE SYSTEM LAYOUT

1) Work Flow of Intake System

HFM Sensor

The HFM sensor is installed in the air intake

passage between the air cleaner and the intake

manifold. It measures the air volume supplied to

the combustion chamber and the ai

r

temperature.

Major Functions

It controls the EGR feedback.

It controls the pressure control valve for the

turbocharger booster. -

-

1. Plug-in sensor

2. Cylinder housing

3. Protection grid

4. Hybrid cover

5. Measuring duct cover

6. Housing

7. Hybrid

8. Sensor

9. Mounting plate

10. O-ring

11. Temperature sensor

Turbocharger

actuator

Intake

(air cleaner)

Com

pressed air

(intercooler)

Exhaust gasExhaust pipe

(diesel catalytic

converter)

Plug-in

sensor

Temperature

sensorProtection grid

Front Air Duct Air Cleaner

Page 209 of 650

ENGINE INTAKE SYSTEM

undefined

2321-01

EGR Valve and Its Location

(* For details, refer to "EGR" section.)

Vacuum Modulator

Turbocharger Intercooler

The charging efficiency may be lowered or the

knocking may happen as the intake air is

heated and the density of air is lowered. The

intercooler is the device which cools the

supercharged air.

Intake

manifoldIntake

air

Exhaust

gasExhaust gasIntake manifold

Vacuum modulator

for turbocharger

actuator

EGR vacuum

modulator

Vacuum

pump EGR

valve

IP interior fuse (RH)

No.63-7.5AEngine ECU

No. 96

Intake Manifold

Intake air

Page 210 of 650

undefined

2321-01

ENGINE INTAKE SYSTEM

2) Layout

Trending: light, ECU, charging, engine, warning lights, fuel cap, stop start