sensor SSANGYONG MUSSO 1998 Workshop Repair Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1998, Model line: MUSSO, Model: SSANGYONG MUSSO 1998Pages: 1463, PDF Size: 19.88 MB

Page 1214 of 1463

TRANSFER CASE (TOD) 5D2-7

1. K-LINE : Communication line for coding and diagnosis with SCANNER.

Classification of Pin No.

ClassificationPin No. Pin NameDescription

Power Supply17,18Ground

TOD control unit ground

4,19Battery

TOD control unit battery supply : (Fuse No 13,20A)

5IgnitionIgnition ON / OFF

27Position 1

Position encoder 1 : check of shift motor position

10Position 2

Position encoder 2 : check of shift motor position

28Position 3

Position encoder 3 : check of shift motor position

30Position 4

Position encoder 4 : check of shift motor position

94H/4L SwitchTransfer case mode input

24Auto T/M Neutral

Check of neutral gear position in Auto T/M

16Speed5V supply (TPS / speed sensor)

11Front Speed

Front speed sensor signal input Signal Input

29Rear Speed

Rear speed sensor signal input

25ABS Operation

ABS ON / OFF

6Position Return

Position encoder ground

13Speed / TPS ReturnGround for speed sensor / TPS

22CAN-LCAN bus low line

23CAN-HCAN bus high line

2,15Motor LO-HIMotor output port

- LO to HI : join with battery

- HI to LO (or motor brake) : join with ground

1,14Motor HI-LO

Motor output port

- HI to LO : join with battery

- LO to HI (or motor brake) : join with ground

3EMCTOD output

Signal Output

214L IlluminationIlluminates “4L” indicator

7Diagnosis Display

4WD check lamp illuminator

- Upon defect ; Ground circuit

20K-LINE1)Diagnosis

Page 1216 of 1463

TRANSFER CASE (TOD) 5D2-9

4H/4L Switch Input

4H

4H

4H

4H

4H

4H

4H

4H

4H

4L

4L

4L

4L

4L

4L

4L

4L

4L

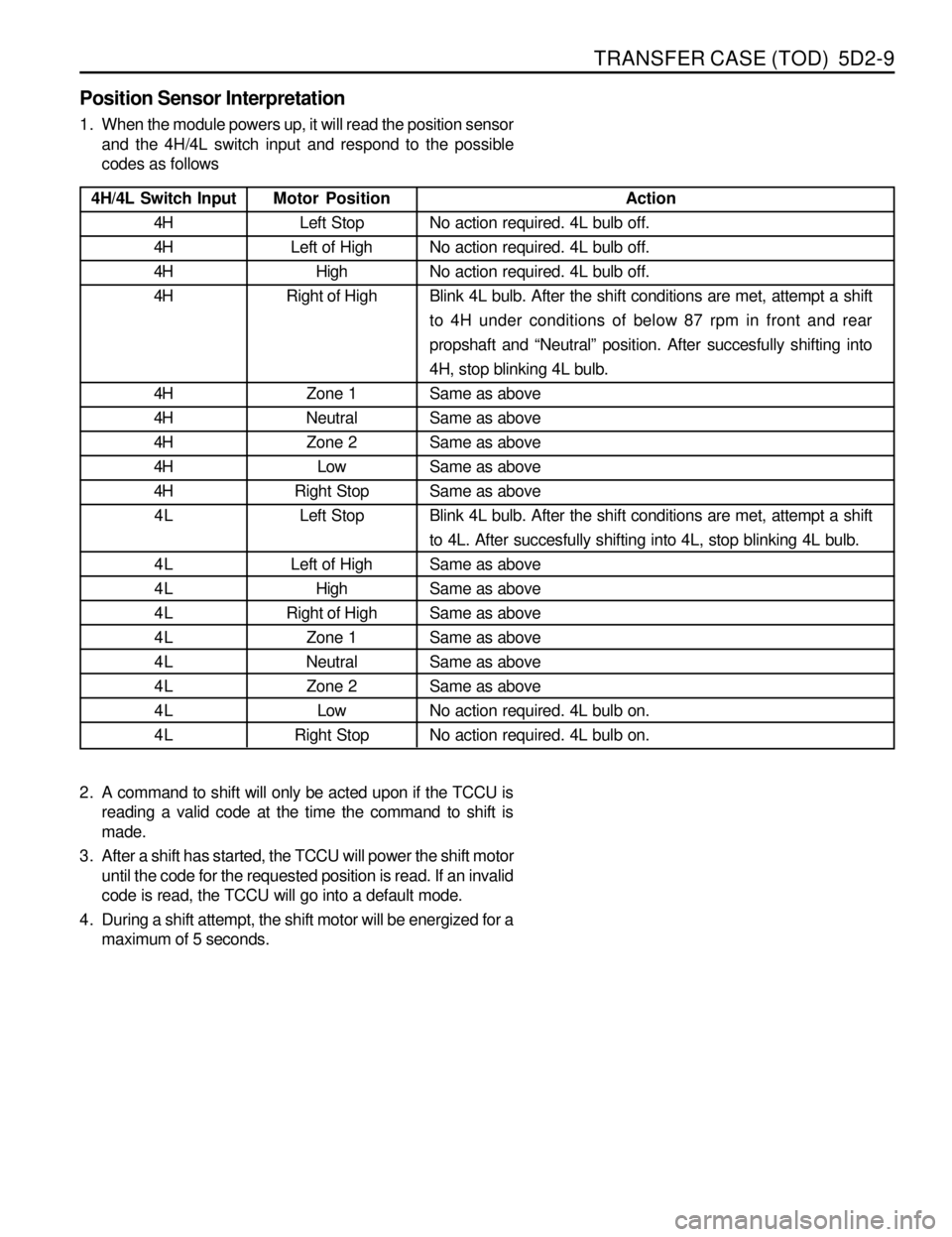

Position Sensor Interpretation

1. When the module powers up, it will read the position sensor

and the 4H/4L switch input and respond to the possible

codes as follows

2. A command to shift will only be acted upon if the TCCU is

reading a valid code at the time the command to shift is

made.

3. After a shift has started, the TCCU will power the shift motor

until the code for the requested position is read. If an invalid

code is read, the TCCU will go into a default mode.

4. During a shift attempt, the shift motor will be energized for a

maximum of 5 seconds.Motor Position

Left Stop

Left of High

High

Right of High

Zone 1

Neutral

Zone 2

Low

Right Stop

Left Stop

Left of High

High

Right of High

Zone 1

Neutral

Zone 2

Low

Right StopAction

No action required. 4L bulb off.

No action required. 4L bulb off.

No action required. 4L bulb off.

Blink 4L bulb. After the shift conditions are met, attempt a shift

to 4H under conditions of below 87 rpm in front and rear

propshaft and “Neutral” position. After succesfully shifting into

4H, stop blinking 4L bulb.

Same as above

Same as above

Same as above

Same as above

Same as above

Blink 4L bulb. After the shift conditions are met, attempt a shift

to 4L. After succesfully shifting into 4L, stop blinking 4L bulb.

Same as above

Same as above

Same as above

Same as above

Same as above

Same as above

No action required. 4L bulb on.

No action required. 4L bulb on.

Page 1217 of 1463

5D2-10 TRANSFER CASE (TOD)

Electric Shift System Operation

The Electric Shift System is responsible for changing the Transfer Case gear ratio by controlling the electric shift

motor. The TCCU monitors the 4H/4L switch, neutral switch, speed sensors, position encoder, and ignition switch.

A range change is initiated when

1. The 4H/4L Switch is changed from 4H to 4L or from 4L to 4H.

2. The motor position (as indicated by the position encoder) does not match the 4H/4L Switch immediately after the

ignition is turned on.

1. Shift Criteria

When a range change is initiated a Diagnostic Test will be completed on the motor, speed sensors, and position

encoder. If the Diagnostic Test fails, the shift will not be attempted. If all components are operating properly, the

TCCU will attempt a range change after the following shift criteria are met:

a. The transmission is in neutral for 2 seconds after the shift is requested.

b. Both propshaft speeds are below 87 rpm (2580 pulses/minute).

If the transmission is taken out of neutral before 2 seconds has elapsed, or either propshaft speed increases

above the limit, the shift will be suspended and the 4L Indicator will continue to blink until the criteria are met again

or the 4H/4L Switch is returned to the original position.

2. Range Change

When the shift criteria are met, the motor is rotated in the appropriate direction (as determined by the selector

switch) until one of the following occurs:

a. The motor reaches its destination.

b. The motor is on for 5 seconds without reaching its destination. The shift has failed and the TCCU will respond

as default mode.

c. A fault occurs with either the motor or position encoder. Refer to the diagnosis requirement.

When the motor is energized, the Ignition, 4H/4L Switch, propshaft speeds, and transmission neutral inputs are

ignored.

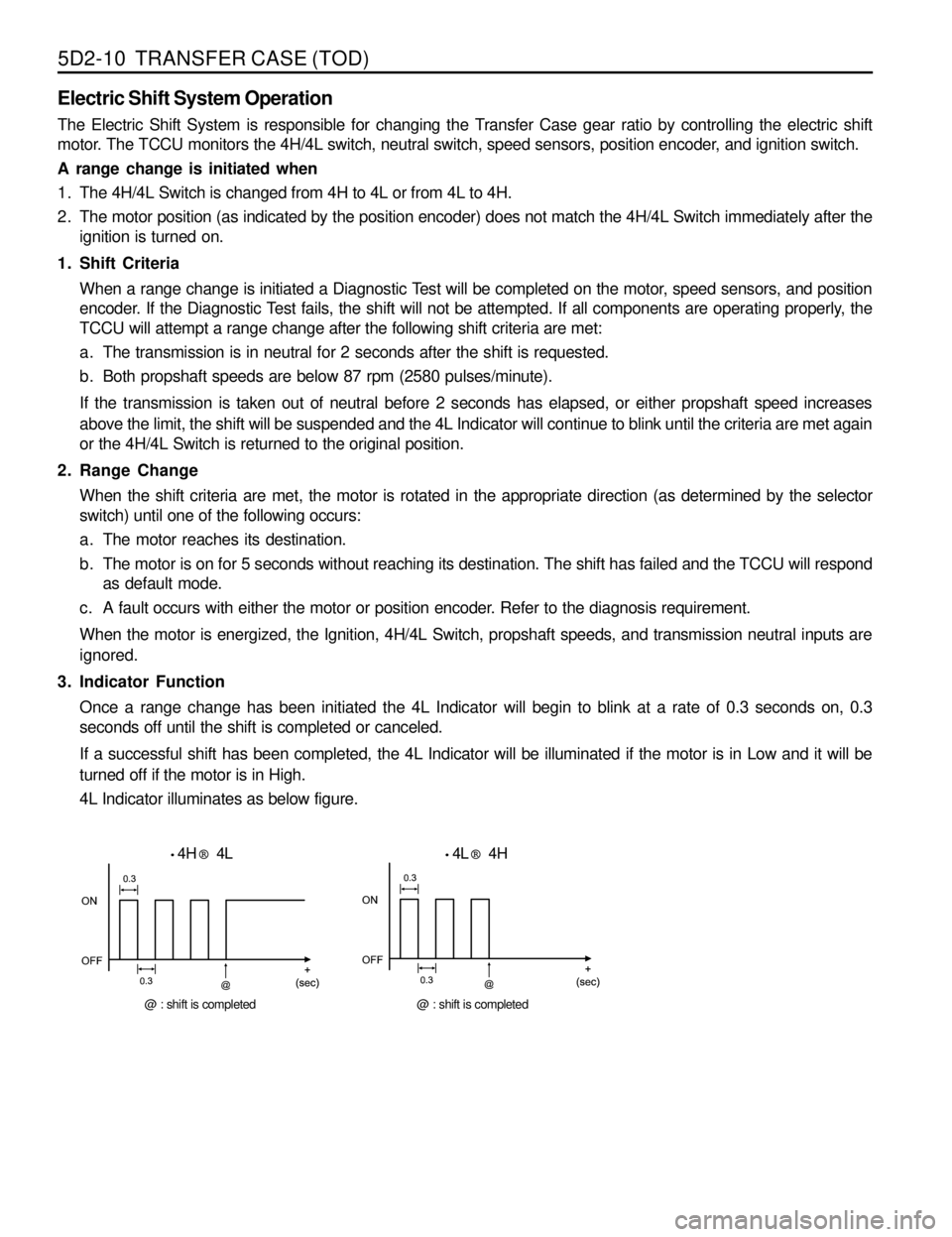

3. Indicator Function

Once a range change has been initiated the 4L Indicator will begin to blink at a rate of 0.3 seconds on, 0.3

seconds off until the shift is completed or canceled.

If a successful shift has been completed, the 4L Indicator will be illuminated if the motor is in Low and it will be

turned off if the motor is in High.

4L Indicator illuminates as below figure.

· 4H ® 4L

@ : shift is completed

· 4L ® 4H

@ : shift is completed

Page 1220 of 1463

TRANSFER CASE (TOD) 5D2-13

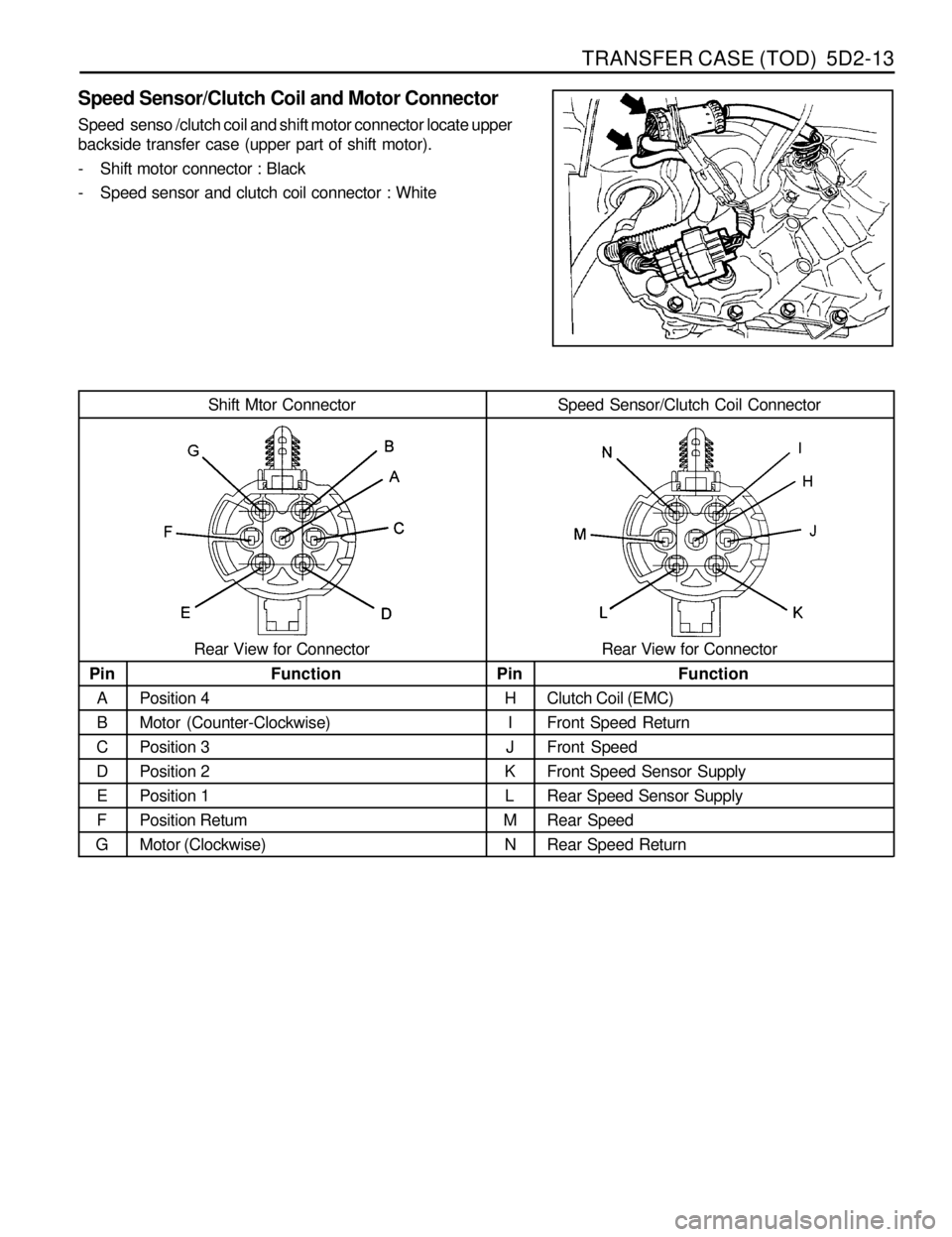

Speed Sensor/Clutch Coil and Motor Connector

Speed senso /clutch coil and shift motor connector locate upper

backside transfer case (upper part of shift motor).

- Shift motor connector : Black

- Speed sensor and clutch coil connector : White

Shift Mtor Connector Speed Sensor/Clutch Coil Connector

Rear View for Connector

Pin

A

B

C

D

E

F

GFunction

Position 4

Motor (Counter-Clockwise)

Position 3

Position 2

Position 1

Position Retum

Motor (Clockwise)Pin

H

I

J

K

L

M

NFunction

Clutch Coil (EMC)

Front Speed Return

Front Speed

Front Speed Sensor Supply

Rear Speed Sensor Supply

Rear Speed

Rear Speed Return Rear View for Connector

Page 1223 of 1463

5D2-16 TRANSFER CASE (TOD)

g. If the shift motor/position encoder assembly failure (other than a motor failure which occurs when the motor is

energized) recovers continuously for one second the TCCU will function normally. The “4WD CHECK” lamp is

turned off but the fault code will remain in memory.

h. A motor failure (i.e. open or short circuit) which occurs when the motor is energized can only be cleared by

cycling the ignition off-on.

3. Front Speed Sensor Test

If a Front Speed Sensor fault is detected continuously for 0.5 second the “4WD CHECK” lamp is illuminated. The

TCCU then responds as follows:

a. If the system is in High Range the TCCU uses the Rear Speed Sensor to determine the EMC Touch Off level

and wheel slip control is suspended.

b. If the system is in Low Range, the EMC Duty Cycle is set to maximum (independent of vehicle speed) until the

system is shifted out of 4L.

c. All Electric Shift activity is halted until the Ignition is cycled. If a shift is in progress it will be completed.

If the Front Speed Sensor recovers continuously for O.5 second the TCCU will function normally. The “4WD

CHECK” lamp is turned off but the fault code will remain in memory.

4. Rear Speed Sensor Test

If a Rear Speed Sensor fault is detected continuously for 0.5 second the “4WD CHECK” lamp is illuminated. The

TCCU then responds as follows:

a. If the system is in High Range the TCCU uses the Front Speed Sensor to determine the EMC Touch Off level

and wheel slip control is suspended.

b. If the system is in Low Range, the EMC Duty Cycle is set to maximum (independent of vehicle speed) until the

system is shifted out of 4L.

c. All Electric Shift activity is halted until the Ignition is cycled. If a shift is in progress it will be completed.

If the Rear Speed Sensor recovers continuously for 0.5 second the TCCU will function normally. The “4WD

CHECK” lamp is turned off but the fault code will remain in memory.

5. Both Speed Sensor Faulty

If both the Front and Rear Speed Sensors are faulty continuously for 0.5 seconds the “4WD CHECK” lamp is

illuminated. The TCCU then responds as follows:

a. If the system is in High Range the TCCU sets the EMC Touch Off level based on a vehicle speed of 0 and wheel

slip control is suspended.

b. If the system is in Low Range, the EMC Duty Cycle is set to maximum until the system is shifted out of 4L.

c. All Electric Shift activity is halted until the Ignition is cycled. If a shift is in progress it will be completed.

If both Speed Sensors recover continuously for 0.5 second the TCCU will function normally. The “4WD CHECK”

lamp is turned off but the fault code will remain in memory.

6. EMC Test

The EMC is tested for open circuit or short circuit to ground. If a fault is detected continuously for 0.8 second the

“4WD CHECK” lamp is turned on and all TODTM activity is halted.

If the EMC recovers continuously for 0.8 second the TCCU will function normally. The “4WD CHECK” lamp is

turned off but the fault code will remain in memory.

Page 1224 of 1463

TRANSFER CASE (TOD) 5D2-17

Classification

TCCU

EMC

Speed Sensor

Shift Motor

Position Encoder

DIAGNOSTIC TROUBLE CODES

(DTC’S)

1. Diagnostic Trouble Code Retention

The first time a fault is detected a DTC is stored in the TCCU’s

Non-Volatile memory. This DTC will remain in memory until

the TCCU is instructed to erase DTC’s by SCAN-100. DTC’s

will not be erased by disconnecting power to the TCCU.

2. Diagnostic Trouble Code Assignments

Code

1714

1715

1716

1721

1722

1731

1732

1733

1734

1735

1736

1741

1742

1743

1750

1751

1752

1753

1754Description

EEPROM Checksum Fault

TPS Loss of Signal

TPS Out of Range

EMC Open / Short to Battery

EMC Short to ground

Front Speed Sensor Voltage Low

Front Speed Sensor Voltage High

Rear Speed Sensor Voltage Low

Rear Speed Sensor Voltage High

Speed Sensor Reference Voltage Low

Speed Sensor Reference Voltage High

Motor Open / Shorted to Battery

Motor Output Shorted to Ground

Shift System Timeout

General Position Encoder Fault (Invalid Code)

Position 1 Shorted to Ground

Position 2 Shorted to Ground

Position 3 Shorted to Ground

Position 4 Shorted to Ground

Page 1231 of 1463

5D2-24 TRANSFER CASE (TOD)

Ye s

No B4

B5

Ye s

No

B6

4.75-5.25Vdc

Ye s

No

B70.3-0.9Vdc

4.6-4.9Vdc

Ye s

No

4.6-4.9Vdc

0.3-0.9Vdc

Ye s

No Test Stage / Contents

Result

Stage Test Contents and ProcedureSpecified Value

/Yes/NoCountermeasure

Check CAN communication line by diagnosis of E/G ECU.

1. Diagnose E/G ECU with SCANNER.

2. Does it display on fault code “27” ?

Check power supply and signal output on throttle valve

position sensor (potentiometer) 1,2.

1. Diagnose E/G ECU with SCANNER.

- Fault codes : 104, 105, 108, 109, 119, 185

Does it display on above code ?

Check power supply (5V) of throttle valve position sensor.

1. Ignition “ON”

2. Measure voltage between pin 112(+) and 84(-) keeping

coupling connection status using multi - tester.

- Specified value

- Measured value is within specified range ?

Check output signal from throttle position sensor 1 and 2.

1. Keep E/G idle status.

2. Measure output voltage between pin 87 (+) and 84 (-)

keeping E/G ECU coupling connection status using multi-

tester. (potentiometer 1)

- Specified value min. acc. Pedal

max. acc. Pedal

- Measured value is within specified range ?

3. Measure output voltage between pin 85 (+) and 84 (-)

keeping E/G ECU coupling connection status using multi-

tester. (potentiometer 2)

- Specified value min. acc. Pedal

max. acc. Pedal

- Measured value is within specified range ?

Replace TOD control

unit

Replace throttle body

actuator or check

cable Perform B1, B2, B3

stages

Perform B5 stage

Perform B6 stage

Replace TOD control

unit or perform A1-

A5 stages

Perform B7 stage

Replace E/G ECU or

perform B1-2 stage

after checking cable.

Perform B7-3 stage

Replace throttle body

actuator or check

cable.

Page 1232 of 1463

TRANSFER CASE (TOD) 5D2-25

Error in electro - magnetic clutch : fault code

“1721”, “1722”

lPhenomenon

1. Upon diagnosis by SCAN-100, it displays on fault

codes “1721,1722”.

lCause

1. Defect in electro - magnetic clutch

2. Defect in connector or wiring

- Open or short from EMC to the supply : 1721

- Short EMC to ground : 1722

Ye s

No

C1

Ye s

No Ye s

No

11-15Vdc

Ye s

No

C2

Ye s

No

Test Stage / ContentsResult

Stage Test Contents and ProcedureSpecified Value

/Yes/NoCountermeasure

Check relevant connector connection status.

1. Check relevant connector connection status with TOD

control unit.

- Does it connect correctly ?

2. Check connection status of speed sensor and clutch

coil connector (7 pin) in transfer case.

- Does it connect correctly ?

3. In case of bad connection, connect it correctly then

perform the follows :

a. Delete the memorized fault code in control unit with

Scan - 100.

b. Ignition “OFF”.

c. Ignition “ON”.

d. Diagnose by SCAN-100

- Does it display on fault codes “1721,1722” ?

Check supply voltage into electro-magnetic clutch.

1. Ignition “ON”

2. Measure voltage between pin 4/19(+) and 17/18(-) in

TOD control unit connector.

- Specified value

- Measured value is within specified range ?

3. If the specified value would not be measured, perform

the follows :

a. Check battery voltage (charging condition)

b. Check open circuit on No.13 fuse (20A)

c. Check relevant wires.

- Is the above 3a, 3b, 3c normal ?Perform C1-2 stage

Perform C1-3 stage

Perform C2 stage

Normal system Perform C2 stage

Perform C1-3 stage

Perform C3 stage

Perform C2-3 stage

Perform C3 stage

lCharging/

Replace battery

lReplace fuse

lRepair wires

Page 1234 of 1463

TRANSFER CASE (TOD) 5D2-27

Defect in speed sensor : fault code 1731, 1732,

1733, 1734, 1735,1736

lPhenomenon

1. Upon diagnosis by SCANNER, it displays on fault code

1731, 1732, 1733, 1734, 1735 and 1736.

2. “4WD CHECK” lamp illuminates continuously when

ignition “ON”.

lCause

1. Defect of speed sensor (front, rear).

2. Defect of power supply.

4.75-5.25Vdc

Ye s

No D1

Ye s

No

D2

Ye s

Ye s

Ye s

No D3Test Stage / Contents

Result

Stage Test Contents and ProcedureSpecified Value

/Yes/NoCountermeasure

Check power supply of speed sensor.

1. Ignition “ON” or driving mode

2. Measure supply voltage between pin 16 (+) and 13 (-) in

TOD control unit connector using digital multi-tester.

- Specified value

- Measured value is within specified range ?

Check connection status of connector.

1. Check connection status of speed sensor/clutch coil

connector and TOD control unit connector.

- Does it connect correctly ?

2. In case of bad connection, connect it correctly then

perform the follows:

a. Delete the memorized fault code in control unit by

SCANNER.

b. Ignition “OFF”.

c. Ignition “ON”.

d. Diagnose by SCANNER.

- It does not display fault code.

- It displays one or more fault code among 1731 to

1736.

Check output wave of front and rear speed sensor.

1. Upon driving mode.

2. Check output wave of each speed sensor by SCANNER.

3. Is it normal on output wave ?Perform D3 stage

Perform D2 stage

Perform D3 stage

Perform D2-2 stage

Normal system

Perform D3 stage

Perform D4 stage

Replace speed

sensor then

perform D2-2 stage

Page 1235 of 1463

5D2-28 TRANSFER CASE (TOD)

Ye s

No D4Test Stage / Contents

Result

Stage Test Contents and ProcedureSpecified Value

/Yes/NoCountermeasure

Check output voltage of front and rear speed sensor.

1. Upon driving mode

2. Measure output voltage of front and rear speed sensor

by multi-tester. Check voltage whether it varies within

specified range.

- Specified value

• Front speed sensor

: Pin 11(+), 13(-) in TOD control unit connector

• Rear speed sensor

: Pin 29(+), 13(-) in TOD control unit connector

- Measure value is within specified range ?Check function of

control unit.

It necessary,

replace then delete

fault codes and re-

diagnose .

Perform D5 stage

Ye s

No

D5

Check short/open in cable.

1. Ignition"OFF"

2. Disconnect TOD control unit connector

3. Make a test for open circuit between pin 11 and 13, 16

and 13, 29 and 13 in wiring connector by multi-tester.

- Is there a resistance of " ¥ " ?

4. Make a test for short between pin 11 and ground 13

and ground, 29 and ground by multi-tester.

- Is there a resistance of " ¥ W " ?Repair wire Perform

D5-4 stge

Ye s

NoWiring short, repair

Perform D3 stage,

then delete fault

codes with

rediagnosis