sensor SSANGYONG MUSSO 1998 Workshop Repair Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1998, Model line: MUSSO, Model: SSANGYONG MUSSO 1998Pages: 1463, PDF Size: 19.88 MB

Page 1041 of 1463

5A-64 AUTOMATIC TRANSMISSION

Default Transmission Operating Modes

The TCU relies on accurate information from its inputs and complete control of its outputs to effectively control the

transmission. To ensure that it has both valid inputs and functioning outputs, the TCU carries out both hardware and

software fault detection routines. The TCU will respond to any faults detected by adopting the operating modes which

are detailed below.

The following symptoms of faults are the most obvious results of each fault under ‘normal’ conditions.

There is always the possibility that a fault may not be detected. If undetected fault conditions are present, the

operation of the transmission is difficult to predict.

1 Throttle Fault

lAll shifts will occur as if a nominal throttle (approx. 44%) were applied for shift scheduling.

lAll shifts will be firm as full throttle and hence high engine torque is assumed.

lThe torque converter will be unlocked at all times.

lAll downshifts initiated by the shift lever will occur as though they were ‘automatic’ shifts. That is the engine

braking effect will not occur until near the end of the shift.

lLine pressure will always stay high (solenoid 6 OFF) to cope with assumed high throttle/torque.

If a fault is undetected, the percent throttle is most likely to be interpreted as higher than actual, resulting in late

upshifts, early downshifts, firm shifting and a harsh 3-1 shift when stopping.

2 Throttle Not Learnt Fault

The transmission operates from default throttle calibration values which results in the evaluation of the throttle being

higher (more open) than it is. There(ore at zero throttle settings, the transmission may calculate that sufficient throttle

opening is present to justify high line pressure and switch solenoid 6 to OFF.

Other symptoms are:

a. late upshifts and

b. lock-up maintained at zero throttle when the vehicle speed is sufficiently high.

3 Engine Speed Fault

lAll shifts will be firm because an engine speed corresponding to peak engine torques is assumed.

If a fault is undetected, the engine speed is likely to be interpreted as stalled resulting in soft shifting possibly with an

end of shift bump.

4 Vehicle Speed Sensor Fault

lAll shifts will be controlled by the shift lever with skip downshifts disabled and downshifts only allowed if the

engine speed is low. Fourth gear will be inhibited.

lThe torque converter will be unlocked at all times.

If a fault is undetected, the vehicle is likely to be interpreted as being stationary resulting in first gear operation at all

times. Note that speedometer transducer faults are likely to cause the vehicle’s speedometer to become inoperative.

5 Gear Lever Fault (Inhibitor/PRNDL Switch)

lThe gear lever is assumed to be in the Drive position.

lThe transmission is limited to 2nd,3rd, and R gears only.

lThe rear band will apply at all times when the lever is shifted to P, R or N. (B2 inhibition and reverse lockout

protection is disabled.)

lThe torque converter will be unlocked at all times.

lManually (gear lever) initiated downshifts will not be available.

If a fault is undetected, the gear lever position is likely to be interpreted as being higher than actual. Where Park is the

highest position and Manual 1 is the lowest, the result being the availability of higher gears than selected by the gear

lever.

Page 1042 of 1463

AUTOMATIC TRANSMISSION 5A-65

If the gear lever is incorrectly adjusted, the transmission may shift gears on bumpy road surfaces.

6 Transmission Oil Temperature Sensing Fault

lAll shifts will be firm until the transmission has warmed up, because a high transmission oil temperature is

assumed.

If a fault is undetected, the temperature is likely to be evaluated as being lower than actual, resulting in softer shifts

with ‘end bump’ (very firm feel at the end of the shift).

7 Mode Setting Fault

lAll shifts will occur as if the mode is set to ‘NORMAL’.

lThe mode indicator will always be off indicating that ‘NORMAL’ mode is selected.

lThe mode indicator will not respond to changes in switch setting.

If a fault is undetected, the mode as indicated by the mode indicator is not likely to respond to the mode switch.

8 Battery Voltage Sensing Fault

If the battery voltage is low then shifts to first gear are inhibited.9 the battery voltage is high (>16.5V) then the

transmission goes into limp home (LHM) mode.

If a fault is undetected, the transmission is likely to incorrectly evaluate an ON/OFF solenoid fault resulting in limp

home mode (LHM) operation.

9 ON/OFF Solenoid Fault (Solenoids 1,2,3 and 4)

The transmission adopts its limp home mode (LHM) operation, described above. However, if solenoid 1 is faulty then

the fourth gear LHM strategy will be adopted independent of vehicle speed.

If a fault is undetected, the operation of the transmission is dependent on which solenoid is actually faulty. The

characteristics for different solenoid fault conditions are listed in table 6.1.2.

10 ON/OFF Solenoid Fault (Solenoids 6,7)

If solenoid 6 is found faulty it is always disabled resulting in high line pressure being applied continuously.

If solenoid 7 is found faulty it is disabled resulting in the transmission being locked always.

The transmission does not go into LHM.

11 Variable Pressure Solenoid Fault

The transmission adopts its LHM operation.

If a fault is undetected, the transmission shift feel is likely to be poor for all shifts.

12 Software Fault

The transmission adopts the third gear LHM strategy of operation, independent of vehicle speed. The operation of

the TCU under this condition is difficult to predict. Its operation may be erratic.

If a fault is undetected, the operation of the TCU is likely to be erratic.

13 Power Supply Fault

The transmission adopts the third gear LHM strategy of operation, independent of vehicle speed. If there is an

intermittent power supply connection, the TCU will power-up in fourth gear and then shift to the appropriate gear to

satisfy the conditions present. The power supply is not monitored for fault evaluation.

All faults except for solenoid faults can be recovered without having to turn the TCU off and back on. However, in

general the recovery requires that no faults are present for a period of time (approx. 3 or 30 seconds). Recovery from

a fault will not clear the fault from the keep alive memory

14 Transmission Sump Temperature Exceeding 135°C

lThe converter lockup clutch will be applied at lower speeds, causing a shudder through the vehicle.

lThe mode indicator will flash in some vehicles.

These faults can be due to the transmission oil overheating or due to an incorrect signal received from the temperature

sensor.

Page 1044 of 1463

AUTOMATIC TRANSMISSION 5A-67

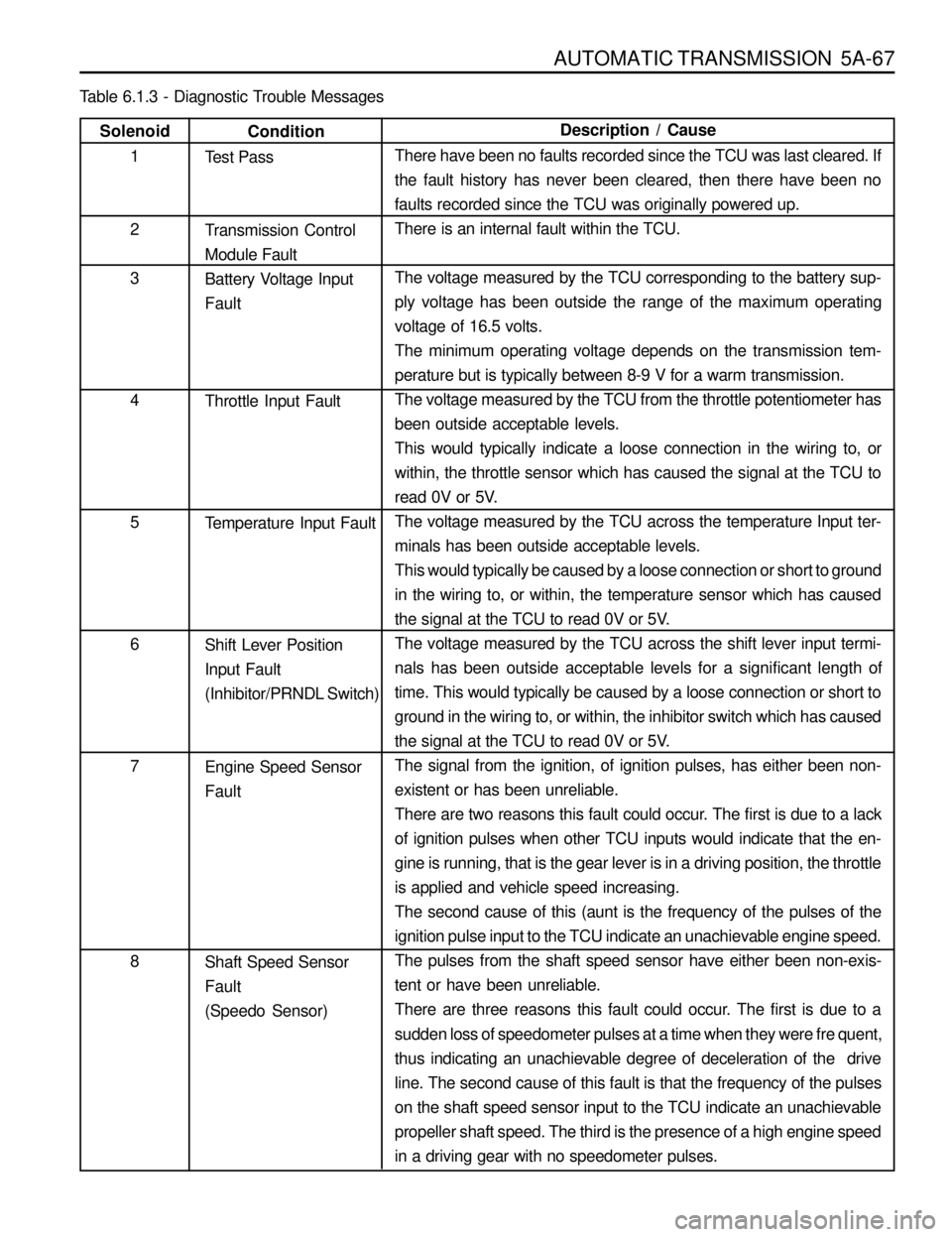

Table 6.1.3 - Diagnostic Trouble Messages

Description / Cause

There have been no faults recorded since the TCU was last cleared. If

the fault history has never been cleared, then there have been no

faults recorded since the TCU was originally powered up.

There is an internal fault within the TCU.

The voltage measured by the TCU corresponding to the battery sup-

ply voltage has been outside the range of the maximum operating

voltage of 16.5 volts.

The minimum operating voltage depends on the transmission tem-

perature but is typically between 8-9 V for a warm transmission.

The voltage measured by the TCU from the throttle potentiometer has

been outside acceptable levels.

This would typically indicate a loose connection in the wiring to, or

within, the throttle sensor which has caused the signal at the TCU to

read 0V or 5V.

The voltage measured by the TCU across the temperature Input ter-

minals has been outside acceptable levels.

This would typically be caused by a loose connection or short to ground

in the wiring to, or within, the temperature sensor which has caused

the signal at the TCU to read 0V or 5V.

The voltage measured by the TCU across the shift lever input termi-

nals has been outside acceptable levels for a significant length of

time. This would typically be caused by a loose connection or short to

ground in the wiring to, or within, the inhibitor switch which has caused

the signal at the TCU to read 0V or 5V.

The signal from the ignition, of ignition pulses, has either been non-

existent or has been unreliable.

There are two reasons this fault could occur. The first is due to a lack

of ignition pulses when other TCU inputs would indicate that the en-

gine is running, that is the gear lever is in a driving position, the throttle

is applied and vehicle speed increasing.

The second cause of this (aunt is the frequency of the pulses of the

ignition pulse input to the TCU indicate an unachievable engine speed.

The pulses from the shaft speed sensor have either been non-exis-

tent or have been unreliable.

There are three reasons this fault could occur. The first is due to a

sudden loss of speedometer pulses at a time when they were fre quent,

thus indicating an unachievable degree of deceleration of the drive

line. The second cause of this fault is that the frequency of the pulses

on the shaft speed sensor input to the TCU indicate an unachievable

propeller shaft speed. The third is the presence of a high engine speed

in a driving gear with no speedometer pulses. Condition

Test Pass

Transmission Control

Module Fault

Battery Voltage Input

Fault

Throttle Input Fault

Temperature Input Fault

Shift Lever Position

Input Fault

(Inhibitor/PRNDL Switch)

Engine Speed Sensor

Fault

Shaft Speed Sensor

Fault

(Speedo Sensor)Solenoid

1

2

3

4

5

6

7

8

Page 1050 of 1463

AUTOMATIC TRANSMISSION 5A-73

Table 6.2.3 - Shift Quality Faults

Action

Check the resistance. Replace the inhibitor

switch as necessary.

Inspect and replace the sensor as necessary.

Inspect and adjust the band as necessary.

Inspect and replace the’0’rings as necessary.

Inspect, repair or replace S5 as necessary.

Inspect, repair or replace S1 or S4 as neces-

sary.

Inspect, repair or replace the BAR as neces-

sary.

Inspect and repair as necessary.

Inspect and clean CCCV.

Inspect, repair or replace as necessary. Possible Cause

Faulty inhibitor switch.

Faulty throttle position sensor.

Incorrect front band adjustment.

Damaged front servo piston’0’rings.

Faulty or damaged variable pressure so-

lenoid (S5).

Faulty S1 or S4 solenoid.

Faulty band apply regulator valve (BAR).

Misassembled front servo return spring.

Jammed converter clutch control valve

(CCCV).

Faulty solenoid 7.Symptom

Harsh 1-2 shift

stalls when Drive

or Reverse

selected Shudder

on Rolldown

Page 1052 of 1463

AUTOMATIC TRANSMISSION 5A-75

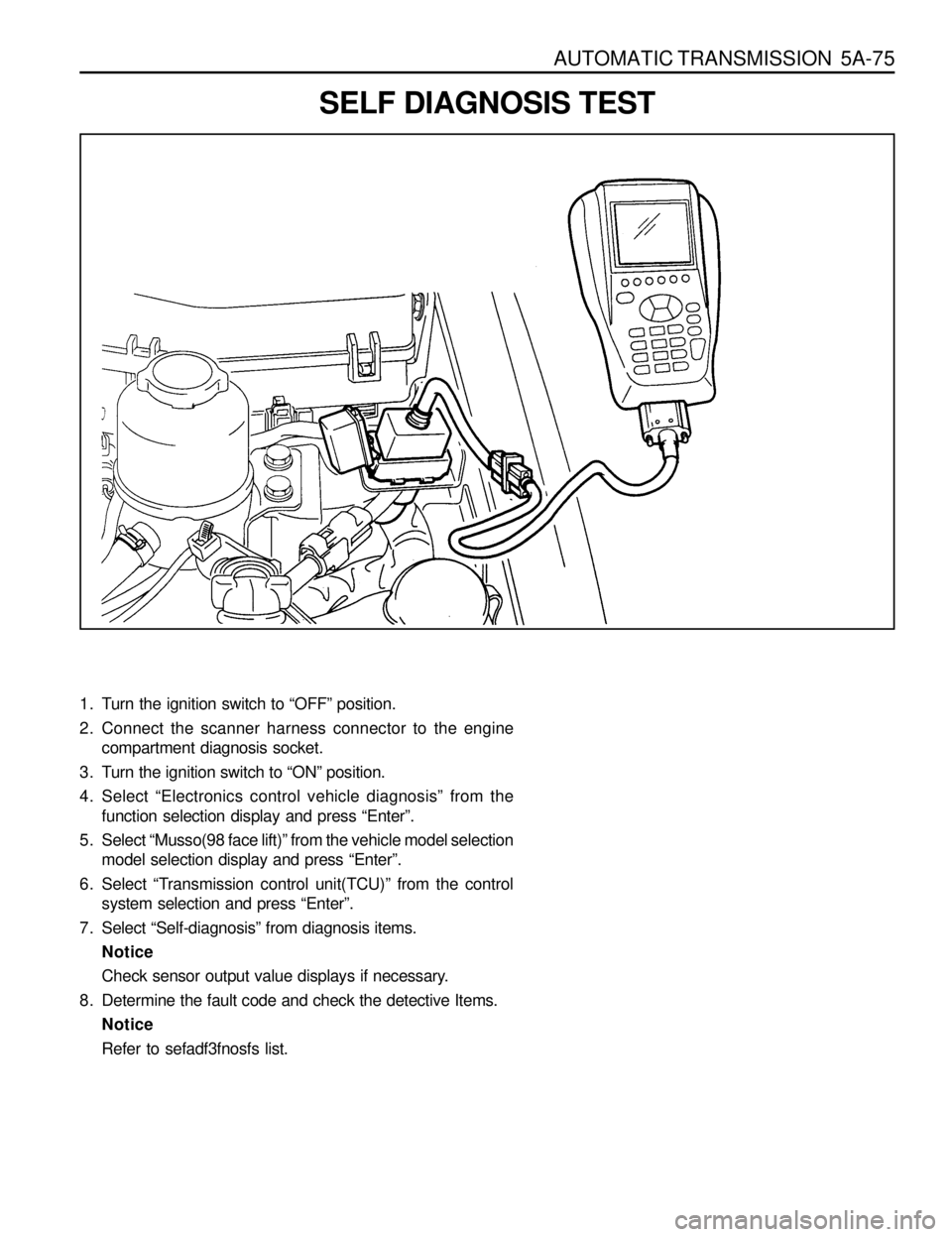

SELF DIAGNOSIS TEST

1. Turn the ignition switch to “OFF” position.

2. Connect the scanner harness connector to the engine

compartment diagnosis socket.

3. Turn the ignition switch to “ON” position.

4. Select “Electronics control vehicle diagnosis” from the

function selection display and press “Enter”.

5. Select “Musso(98 face lift)” from the vehicle model selection

model selection display and press “Enter”.

6. Select “Transmission control unit(TCU)” from the control

system selection and press “Enter”.

7. Select “Self-diagnosis” from diagnosis items.

Notice

Check sensor output value displays if necessary.

8. Determine the fault code and check the detective Items.

Notice

Refer to sefadf3fnosfs list.

Page 1053 of 1463

5A-76 AUTOMATIC TRANSMISSION

Action

lCheck cable for open / short.

lCheck connection of other connectors.

lCheck voltage between terminal 27 and 29 of TCU,

- Standard value : 0.2 - 4.7V

lCheck TPS.

lCheck cable for open / short.

lCheck connection of other connectors.

lCheck engine speed sensor.

lCheck resistance between terminal 8 and 24 of TCU (when the

connector is disconnected).

- Standard value : 1 .9 - 0.2 k

W

lCheck cable for open / short.

lCheck connection of other connectors.

lCheck vehicle speed sensor.

lCheck cable for open / short.

lCheck connection of other connectors.

lCheck engine speed sensor.

lCheck inhibitor switch resistance between terminal 34 and 37 of

TCU(when the connector is disconnected).

- Standard value : 1st gear - 4 - 4.4 k

W

2nd gear - 4,8 - 2.2 kW

3rd gear - 3 - 3.4 kW

D gear - 4.5 - 4.g kW

N gear - 6.8 - 7.2 kW

R gear - 10.8 -11.2 kW

P gear - 18.6 - 19 kW

lCheck voltage between terminal 31 and 37 of TCU.

- Standard value : 0-5V(P,R,N,D,L)

lCheck cable for open / short.

lCheck connection of other connectors.

lCheck mode switch.

lCheck condition between terminal 1 and 13 of TCU.

Winter mode :12V, Normal mode : Open status, Power mode : 0V

lCheck cable for open / short.

lCheck connection of other connectors.

lCheck voltage between terminal 32 and 38 of TCU.

- Standard value : 0-5V

lCheck oil temperature sensor.

lCheck cable for open / short.

lCheck connection of other connectors.

lCheck battery condition.

lCheck alternator. Possible Cause

Throttle position sensor

Engine RPM

Vehicle speed

Shift lever

W, E, P mode switch

T/M oil temperature

Battery voltage Symptom

P1702

P1703

P1704

P4705

P1706

P1707

P1708

Self-diagnosis List

Page 1054 of 1463

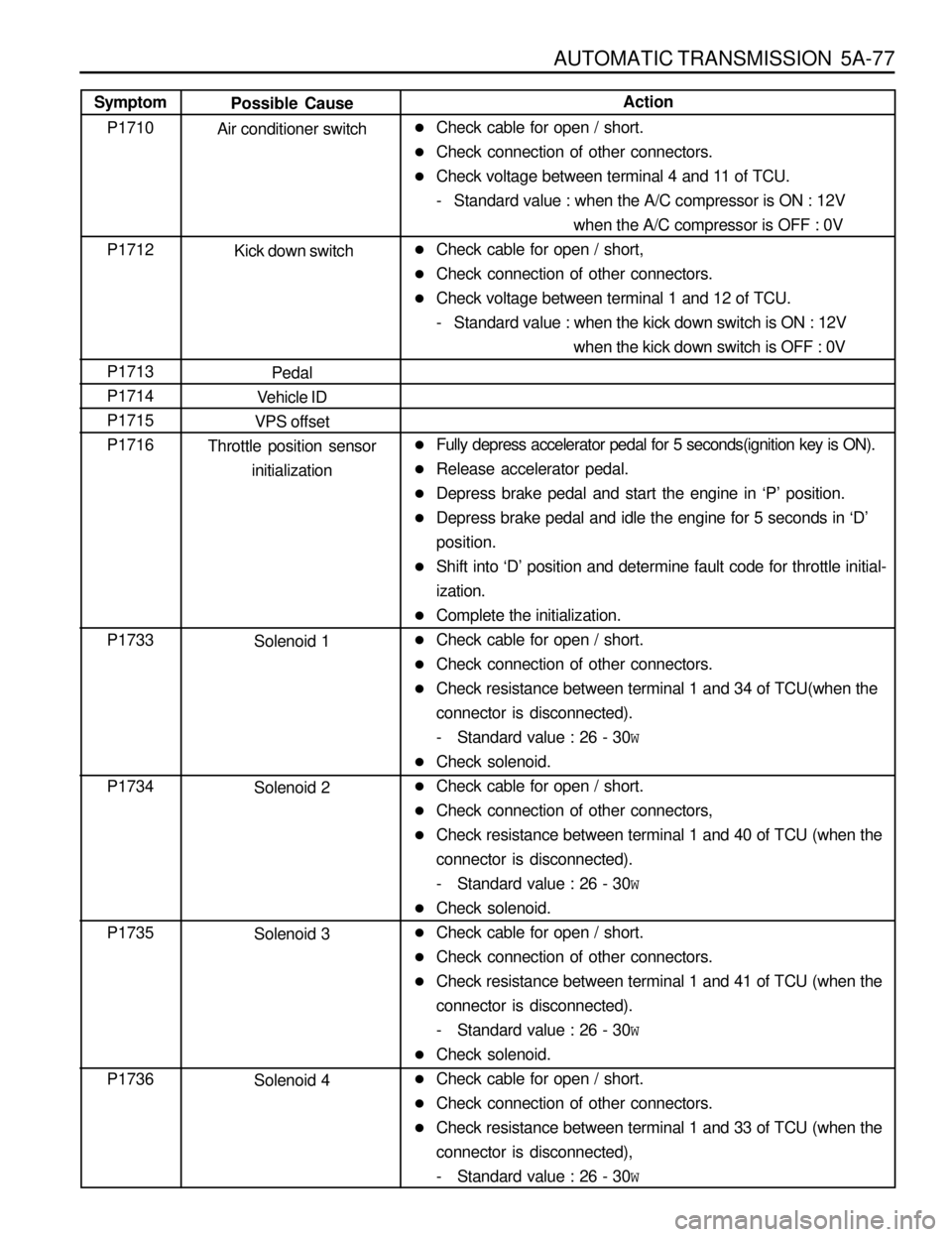

AUTOMATIC TRANSMISSION 5A-77

Action

lCheck cable for open / short.

lCheck connection of other connectors.

lCheck voltage between terminal 4 and 11 of TCU.

- Standard value : when the A/C compressor is ON : 12V

when the A/C compressor is OFF : 0V

lCheck cable for open / short,

lCheck connection of other connectors.

lCheck voltage between terminal 1 and 12 of TCU.

- Standard value : when the kick down switch is ON : 12V

when the kick down switch is OFF : 0V

lFully depress accelerator pedal for 5 seconds(ignition key is ON).

lRelease accelerator pedal.

lDepress brake pedal and start the engine in ‘P’ position.

lDepress brake pedal and idle the engine for 5 seconds in ‘D’

position.

lShift into ‘D’ position and determine fault code for throttle initial-

ization.

lComplete the initialization.

lCheck cable for open / short.

lCheck connection of other connectors.

lCheck resistance between terminal 1 and 34 of TCU(when the

connector is disconnected).

- Standard value : 26 - 30

W

lCheck solenoid.

lCheck cable for open / short.

lCheck connection of other connectors,

lCheck resistance between terminal 1 and 40 of TCU (when the

connector is disconnected).

- Standard value : 26 - 30

W

lCheck solenoid.

lCheck cable for open / short.

lCheck connection of other connectors.

lCheck resistance between terminal 1 and 41 of TCU (when the

connector is disconnected).

- Standard value : 26 - 30

W

lCheck solenoid.

lCheck cable for open / short.

lCheck connection of other connectors.

lCheck resistance between terminal 1 and 33 of TCU (when the

connector is disconnected),

- Standard value : 26 - 30

W

Possible Cause

Air conditioner switch

Kick down switch

Pedal

Vehicle ID

VPS offset

Throttle position sensor

initialization

Solenoid 1

Solenoid 2

Solenoid 3

Solenoid 4 Symptom

P1710

P1712

P1713

P1714

P1715

P1716

P1733

P1734

P1735

P1736

Page 1059 of 1463

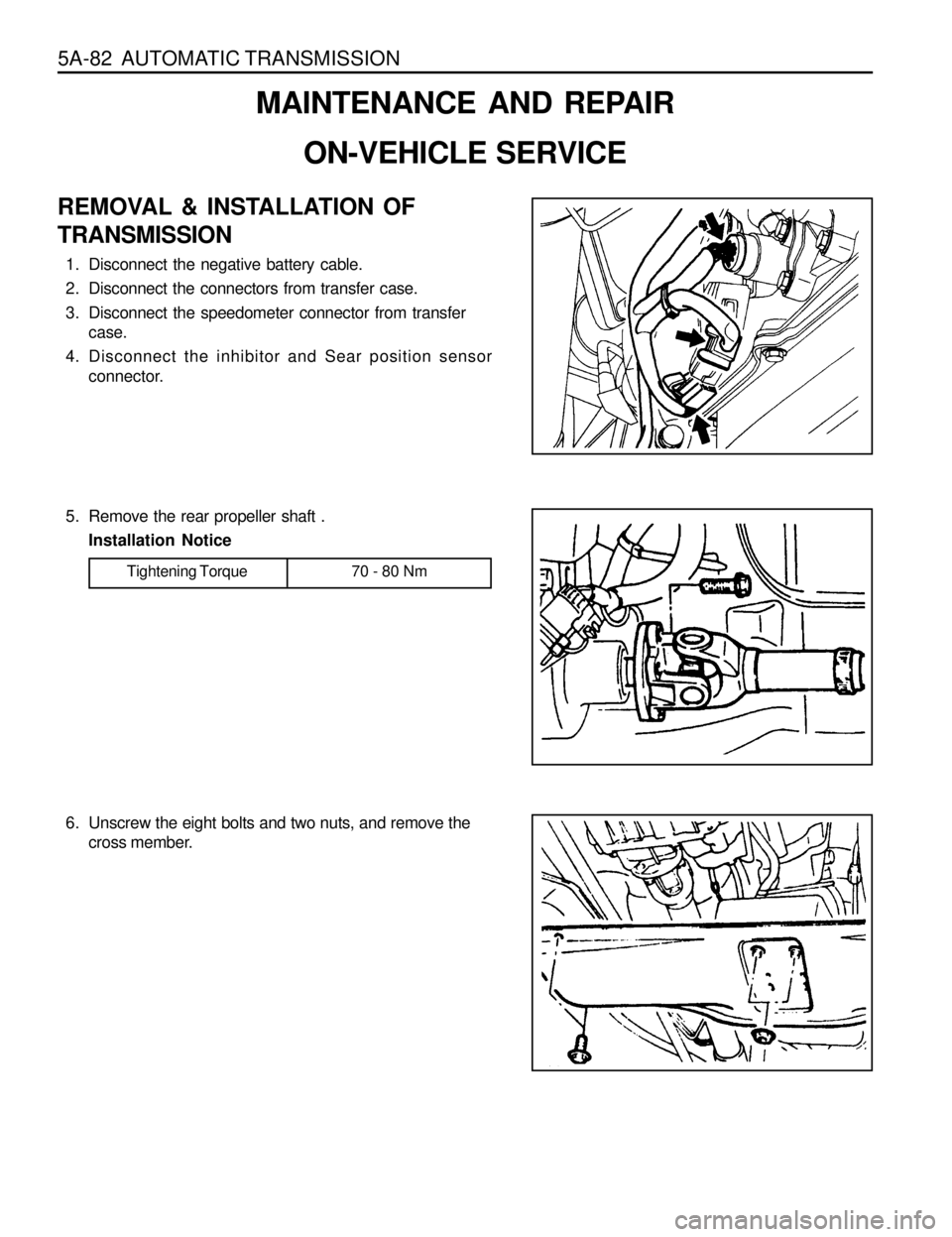

5A-82 AUTOMATIC TRANSMISSION

MAINTENANCE AND REPAIR

ON-VEHICLE SERVICE

Tightening Torque 70 - 80 Nm

5. Remove the rear propeller shaft .

Installation Notice

REMOVAL & INSTALLATION OF

TRANSMISSION

1. Disconnect the negative battery cable.

2. Disconnect the connectors from transfer case.

3. Disconnect the speedometer connector from transfer

case.

4. Disconnect the inhibitor and Sear position sensor

connector.

6. Unscrew the eight bolts and two nuts, and remove the

cross member.

Page 1173 of 1463

TRANSFER CASE (PART TIME 4408) 5D1-3

Cannot Front Wheel Drive when Shifted 4H,4L

DIAGNOSIS

Electric Shift Problems

Action

Overhaul and check, replace if necessary.

Overhaul and check for wear and damage.

Replace if necessary.

Check sliding parts, replace if necessary. Checks

Faulty or Damaged TCCU, Speed Sensor, Motor, Clutch

or Internal Wirings

Damaged or Worn Shift Cam, Hub, Fork and Rail Shift

Binding Shift Fork, Hub Collar or Gear

Checks

Broken Drive ChainAction

Check sliding parts, replace if necessary.

Noise in 4WD Operation

Checks

Improper or low oil

Loosened bolts or mounted parts

Noisy T/C bearing

Noisy gearsAction

Drain and replace with specified oil.

Retighten as specified.

Disassemble bearings and parts and check for wear or

damage. Replace if necessary.

Check for wear and damage including speedometer

gear, replace if necessary.

Noise in 4H or 4L

Checks

Worn or Damaged Sprockets or Drive Chain

Incorrect Tire PressureAction

Disassemble and check for wear and damage, replace

if necessary.

Adjust tire pressure.

Transfer Case Oil Leakage

Action

Replace the case.

Clean case and parts and check for leakage.

Remove breather hose and clean, replace if necessary.

Use specified oil and adjust oil level.

Retighten

Use specified sealant and retighten.

Replace Checks

Cracked Transfer Case

Leakage from Other Parts

Breather Clogging

Improper or too much Oil

Loosened Sealing Bolts

Improperly Applied Sealant

Worn or Damaged Oil Seal

Page 1174 of 1463

5D1-4 TRANSFER CASE (PART TIME 4408)

SELF-DIAGNOSIS

SYSTEM DESCRIPTION

1. TCCU detects transfer case system malfunctions and

indicates malfunctioning part(s) through flashing 4H,4L

indicator lights.

Using a service connector, connect it to the diagnosis box

in the engine room and read the flashing of the ‘4WD

CHECK’ indicator light.

The flashing indicator light will show you defective code(s).

2. Identify 7 defective codes after reading the flashing indicator

light.

lTCCU

lShift motor

lMagnetic synchronizer clutch

lSpeed sensor

lHub solenoid

lSelector switch

lMotor position sensor

3. Transfer case system is malfunctioning when:

l4H ,4L indicator lights are remain on after 0.6 second

when turning the ignition switch ‘ON’

l4H,4L indicator lights are continuously come on during

driving.

4. If only 1 part is malfunctioning, ‘4WD CHECK’ indicator light

will display defective code 3 times continuously.

5. If more then 2 part is malfunctioning, the first malfunctioning

part will be displayed 3 times and following malfunctioning

parts will be displayed .

6. To read defective code, connect the service connector and

turn the ignition switch 'ON'.

7. After repairing, eliminate the defective code stored in the

TCCU.

Notice

Before replacing the malfunction parts with defective code,

check the wires and connectors for proper condition.