display SSANGYONG MUSSO 1998 Workshop User Guide

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1998, Model line: MUSSO, Model: SSANGYONG MUSSO 1998Pages: 1463, PDF Size: 19.88 MB

Page 1231 of 1463

5D2-24 TRANSFER CASE (TOD)

Ye s

No B4

B5

Ye s

No

B6

4.75-5.25Vdc

Ye s

No

B70.3-0.9Vdc

4.6-4.9Vdc

Ye s

No

4.6-4.9Vdc

0.3-0.9Vdc

Ye s

No Test Stage / Contents

Result

Stage Test Contents and ProcedureSpecified Value

/Yes/NoCountermeasure

Check CAN communication line by diagnosis of E/G ECU.

1. Diagnose E/G ECU with SCANNER.

2. Does it display on fault code “27” ?

Check power supply and signal output on throttle valve

position sensor (potentiometer) 1,2.

1. Diagnose E/G ECU with SCANNER.

- Fault codes : 104, 105, 108, 109, 119, 185

Does it display on above code ?

Check power supply (5V) of throttle valve position sensor.

1. Ignition “ON”

2. Measure voltage between pin 112(+) and 84(-) keeping

coupling connection status using multi - tester.

- Specified value

- Measured value is within specified range ?

Check output signal from throttle position sensor 1 and 2.

1. Keep E/G idle status.

2. Measure output voltage between pin 87 (+) and 84 (-)

keeping E/G ECU coupling connection status using multi-

tester. (potentiometer 1)

- Specified value min. acc. Pedal

max. acc. Pedal

- Measured value is within specified range ?

3. Measure output voltage between pin 85 (+) and 84 (-)

keeping E/G ECU coupling connection status using multi-

tester. (potentiometer 2)

- Specified value min. acc. Pedal

max. acc. Pedal

- Measured value is within specified range ?

Replace TOD control

unit

Replace throttle body

actuator or check

cable Perform B1, B2, B3

stages

Perform B5 stage

Perform B6 stage

Replace TOD control

unit or perform A1-

A5 stages

Perform B7 stage

Replace E/G ECU or

perform B1-2 stage

after checking cable.

Perform B7-3 stage

Replace throttle body

actuator or check

cable.

Page 1232 of 1463

TRANSFER CASE (TOD) 5D2-25

Error in electro - magnetic clutch : fault code

“1721”, “1722”

lPhenomenon

1. Upon diagnosis by SCAN-100, it displays on fault

codes “1721,1722”.

lCause

1. Defect in electro - magnetic clutch

2. Defect in connector or wiring

- Open or short from EMC to the supply : 1721

- Short EMC to ground : 1722

Ye s

No

C1

Ye s

No Ye s

No

11-15Vdc

Ye s

No

C2

Ye s

No

Test Stage / ContentsResult

Stage Test Contents and ProcedureSpecified Value

/Yes/NoCountermeasure

Check relevant connector connection status.

1. Check relevant connector connection status with TOD

control unit.

- Does it connect correctly ?

2. Check connection status of speed sensor and clutch

coil connector (7 pin) in transfer case.

- Does it connect correctly ?

3. In case of bad connection, connect it correctly then

perform the follows :

a. Delete the memorized fault code in control unit with

Scan - 100.

b. Ignition “OFF”.

c. Ignition “ON”.

d. Diagnose by SCAN-100

- Does it display on fault codes “1721,1722” ?

Check supply voltage into electro-magnetic clutch.

1. Ignition “ON”

2. Measure voltage between pin 4/19(+) and 17/18(-) in

TOD control unit connector.

- Specified value

- Measured value is within specified range ?

3. If the specified value would not be measured, perform

the follows :

a. Check battery voltage (charging condition)

b. Check open circuit on No.13 fuse (20A)

c. Check relevant wires.

- Is the above 3a, 3b, 3c normal ?Perform C1-2 stage

Perform C1-3 stage

Perform C2 stage

Normal system Perform C2 stage

Perform C1-3 stage

Perform C3 stage

Perform C2-3 stage

Perform C3 stage

lCharging/

Replace battery

lReplace fuse

lRepair wires

Page 1234 of 1463

TRANSFER CASE (TOD) 5D2-27

Defect in speed sensor : fault code 1731, 1732,

1733, 1734, 1735,1736

lPhenomenon

1. Upon diagnosis by SCANNER, it displays on fault code

1731, 1732, 1733, 1734, 1735 and 1736.

2. “4WD CHECK” lamp illuminates continuously when

ignition “ON”.

lCause

1. Defect of speed sensor (front, rear).

2. Defect of power supply.

4.75-5.25Vdc

Ye s

No D1

Ye s

No

D2

Ye s

Ye s

Ye s

No D3Test Stage / Contents

Result

Stage Test Contents and ProcedureSpecified Value

/Yes/NoCountermeasure

Check power supply of speed sensor.

1. Ignition “ON” or driving mode

2. Measure supply voltage between pin 16 (+) and 13 (-) in

TOD control unit connector using digital multi-tester.

- Specified value

- Measured value is within specified range ?

Check connection status of connector.

1. Check connection status of speed sensor/clutch coil

connector and TOD control unit connector.

- Does it connect correctly ?

2. In case of bad connection, connect it correctly then

perform the follows:

a. Delete the memorized fault code in control unit by

SCANNER.

b. Ignition “OFF”.

c. Ignition “ON”.

d. Diagnose by SCANNER.

- It does not display fault code.

- It displays one or more fault code among 1731 to

1736.

Check output wave of front and rear speed sensor.

1. Upon driving mode.

2. Check output wave of each speed sensor by SCANNER.

3. Is it normal on output wave ?Perform D3 stage

Perform D2 stage

Perform D3 stage

Perform D2-2 stage

Normal system

Perform D3 stage

Perform D4 stage

Replace speed

sensor then

perform D2-2 stage

Page 1236 of 1463

TRANSFER CASE (TOD) 5D2-29

Shift motor malfunction : Fault code ® 1741,

1742, 1743

lPhenomenon

1. When change the 4H/4L switch from 4H to 4L, ‘4L’

indicator lamp turn off after blinking for a time and then

‘4WD CHECK’ indicator lamp turn on.

2. Fault codes display by diagnosis of SCAN-100 : 1741,

1742, 1743

3. The shifting operation is not occurred when 4H / 4L switch,

is operating.

lCause

Defect in shift motor, improper voltage provided, incorrect

connection in connector, short of wiring.

11-14 V

(Battery voltage)

Ye s

No E1

11-14 V

(Battery voltage)

Ye s

No

Ye s

No

E2

Ye s

No Test Stage / Contents

Result

Stage Test Contents and ProcedureSpecified Value

/Yes/NoCountermeasure

Check the input voltage of shift motor.

1. Turn the ignition switch to “ON” position.

2. Measure the Hi/Low voltage of motor which is located

between No.1/No.14 and No.2/No.15 connector of TOD

control unit with digital Multi-tester or which is located

between No.G connector and body after detaching T/C

motor connector.

- The specified value (When operates 4H/4L switch)

- Measured value is within specified range ?

3. Measure the Hi/Low voltage of motor which is located

between No.2/No.5 and No.1/No.14 connector or which

is located No.B connector and body after detaching T/C

motor connector

- The specified value (When operates 4H/4L switch)

- Measured value is within specified range ?

Check the fault condition of the relevant connector.

1. Check the installation condition of TOD control unit 30pin

connector and T/C shift motor connector.

- Is it installed properly ?

2. If the connector installation is improper, install properly

and then perform follows :

a. Delete the fault code of control unit by scan scope

b. Turn off the ignition switch

c. Turn on the ignition switch

d. Re-diagnosis of system

It displays one or more fault code among 1741 to 1743.Perform E1-3 stage

Perform E2 stage

Perform E4 stage

Perform E2 stage

Perform E3 stage

Perform E2-2 stage

Perform E3 stage

Normal system

Page 1238 of 1463

TRANSFER CASE (TOD) 5D2-31

Position incoder and position 1,2,3,4 malfunction

:Fault code®1750,1751,1752,1753, 1754

lPhenomenon

The ‘4WD check’ lamp can not go out when the ignition

switch positioned to ‘ON’.

The fault code display 1750, 1751, 1752, 1753, 1754 by

diagnosis of SCAN-100.

lCause

The portion of position incoder malfunction, each wiring is

shorted with ground.

Ye s

No

F1

Ye s

No

Ye s

No F2Test Stage / Contents

Result

Stage Test Contents and ProcedureSpecified Value

/Yes/NoCountermeasure

Check the installation condition of connector.

1. Check the installation condition between 30 pin connector

of TOD control unit and motor connector of T/C portion.

- Is it installed properly ?

2. If the connector installation is improper, install properly

and then execute follow procedure.

a. Delete the all fault code from memory by scan scope.

b. Turn off ignition switch.

c.Turn on ignition switch.

d. Rediagnosis the system.

- Does the fault codes display one or more among

1750 ~ 1754.

Check the each wiring whether it is shorted or not.

1. Turn off the ignition switch

2. Detach the 30 pin connector of TOD control unit.

3. Perform short test each connector, No.27 (Position 1),

No.10 (Position 2), No.28 (Position 3),No.30 (Position

4), No.6 with body.

- Is there resistance of 0W?Perform F2 stage

Perform F1-2 stage

Perform F2 stage

Normal system

Repair or replace

due to wiring short

1. Replace the

motor Ass’y due

the defective

position incoder

portion.

2. And then, perform

F1-2 stage.

Page 1311 of 1463

SUPPLEMENTAL RESTRAINT SYSTEM(SRS) 8B-7

DIAGNOSIS

DESCRIPTION

Air bag control unit continuously controls system function as follows during ignition ON or driving.

- Recognition of collision

- Internal diagnosis

- External diagnosis

If recognize or detect defects, warning lamp will turn on. If there is danger of improper deployment, the system will

enter overall shutdown status and the air bag will not inflate.

Air bag control unit will store detected internal and external defects in the EEPROM.

System Control

Battery Voltage Check

Battery voltage will be monitored continuously. If voltage is out of normal operating range, all system diagnosis will

stop and warning lamp turn on.

Battery Voltage (V)

< 8.7

9 - 16

> 16.3

Function

System diagnosis stops and warning lamp turns on

Normal operation range

System diagnosis stops and warning lamp turns on

Squib Diagnosis

It checks not only high (4.50.5) or low (1.40.5) resistance but also short resistance (1- 10k) status between the

battery and ground to indicate defects in squib line by blinking warning lamp. Air bag control unit (AC4) can measure

squib resistance.

Warning Lamp Turning On

Air bag control unit detects system defects during ignition ON or driving and displays following 2 warning lamps.

- Warning lamp ON: internal defects of the air bag control unit

- Warning lamp blinking: higher resistance than standard in the squib line or short at the battery or ground,

Safety Function Check

It checks defects during operation of the arming sensor If the sensor is shorted for more than 2 seconds, the module

will enter overall shutdown mode.

Temperature Sensor

Function of the temperature sensor will be monitored continuously. If there is fault due to defective sensor or short,

the lamp will turn on and program will take calibration temperature (25) of collision conditions.

Power Supply

Airbag control unit operates in 9-16v and the characteristic of the system has backup condenser to supply the power

for max.150ms if there is power defect during collision.

Page 1314 of 1463

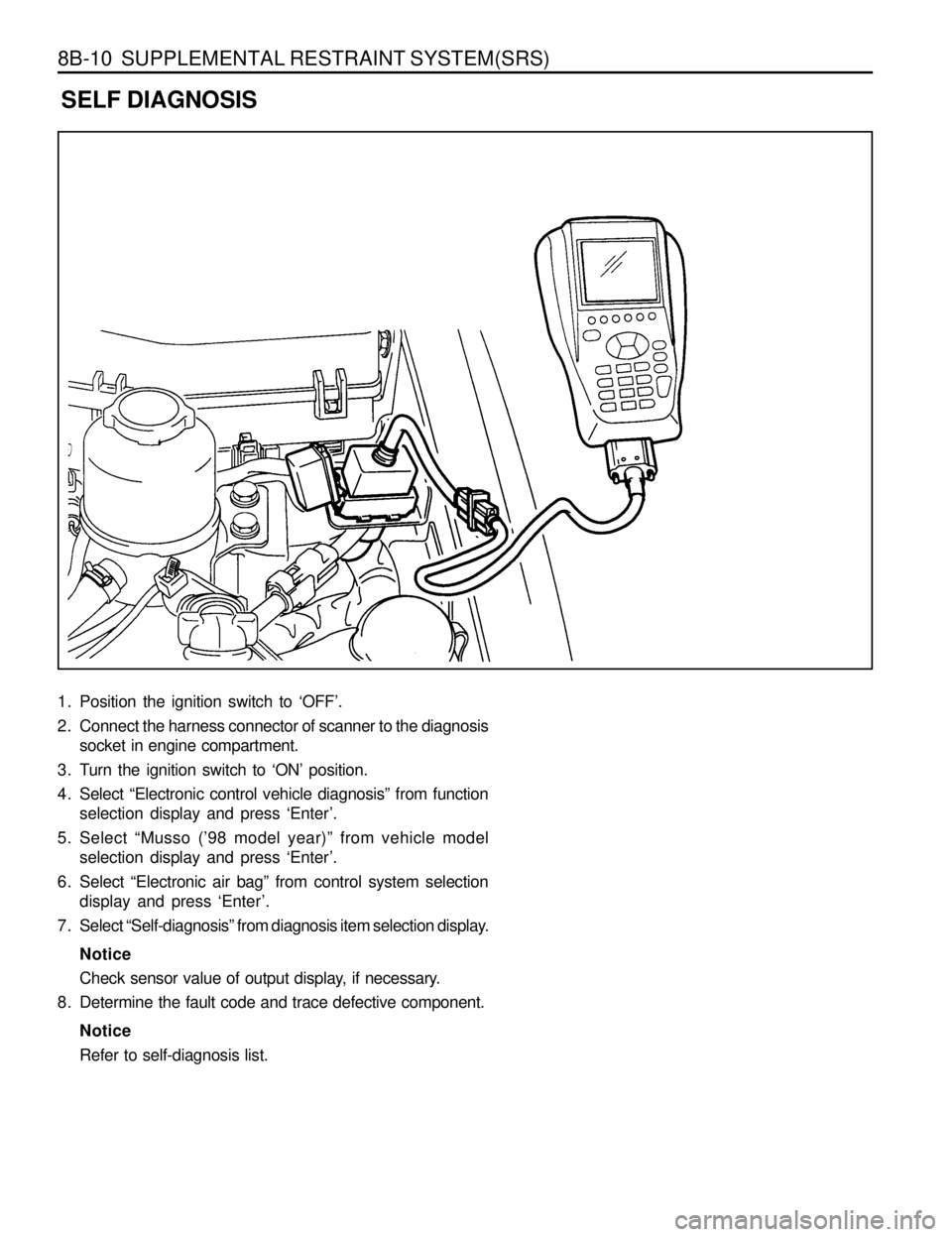

8B-10 SUPPLEMENTAL RESTRAINT SYSTEM(SRS)

1. Position the ignition switch to ‘OFF’.

2. Connect the harness connector of scanner to the diagnosis

socket in engine compartment.

3. Turn the ignition switch to ‘ON’ position.

4. Select “Electronic control vehicle diagnosis” from function

selection display and press ‘Enter’.

5. Select “Musso (’98 model year)” from vehicle model

selection display and press ‘Enter’.

6. Select “Electronic air bag” from control system selection

display and press ‘Enter’.

7. Select “Self-diagnosis” from diagnosis item selection display.

Notice

Check sensor value of output display, if necessary.

8. Determine the fault code and trace defective component.

Notice

Refer to self-diagnosis list.

SELF DIAGNOSIS

Page 1449 of 1463

9W-2 IMMOBILIZER SYSTEM

Notice

lIf vehicle is equipped with immobilizer system and the engine

cranks normally but not start, check immobilizer system first

rather than ignition and other electrical systems because it

can be disabled fuel supply of injectors by ECU due to

defective immobilizer system.

lProgramming of the immobilizer system will be performed

by authorized personnel only. If following defective codes

for immobilizer system appear during diagnosis of vehicle

with SCANNER, ask immobilizer programming to authorized

personnel and actual programming should be performed

by authorized personnel only.

Display of defectives relevant to immobilizer system :

SCANNER

1. No communication with transponder

2. No immobilizer programming

lThe transponder in the key can be damaged by shocks of

dropping or hitting other objectives, so handle it with care.

lEach supplied key has programming of code on its own.

Accordingly if ECU needs to be replaced, replace the

transponder in the key.

lThe vehicle equipped with immobilizer system will never be

started with remote ignition device, so do not attempt to

install it.

lThe immobilizer system will never be removed from the

vehicle. So never attempt to remove it to install a remote

ignition device or others.

lIf engine does not start during service, use every key to

start the engine and then check immobilizer system finally.

FUNCTION DESCRIPTION

Immobilizer is a device disabling vehicle ignition unless a speific key is used and designed to help prevent vehicle

theft.

Immobilizer is comprised of two devices, a key with encoded transponder and engine control unit(ECU) with the same

encoding of the transponder. When a key is inserted into the key hole to start vehicle and turned to ‘ON’, the ECU

reads and decodes the transponder code and, if the same, starts the engine, it is called immobilizer. It means

immobilizer system disables starting by stopping fuel supply if the code in the transponder does not match the code

stored in ECU each other.

Cases that requires immobilizer

programming

1. Replacement ECU

In this case, replace the every transponder

of the key at once.

2. Replacement of the transponder

3. Additional key for lost 1 or 2 keys

1 ) Clear all codes for current keys from the

ECU

2 ) When using current key : clear code of

the transponder and re-program it

3) Additional (purchased) key : perform

programming

4. When lost all keys

1 ) Clear all memorized key codes from the

ECU

2 ) Replace the key and key set

3 ) Immobilizer programming