transmission fluid SSANGYONG MUSSO 1998 Workshop Repair Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1998, Model line: MUSSO, Model: SSANGYONG MUSSO 1998Pages: 1463, PDF Size: 19.88 MB

Page 14 of 1463

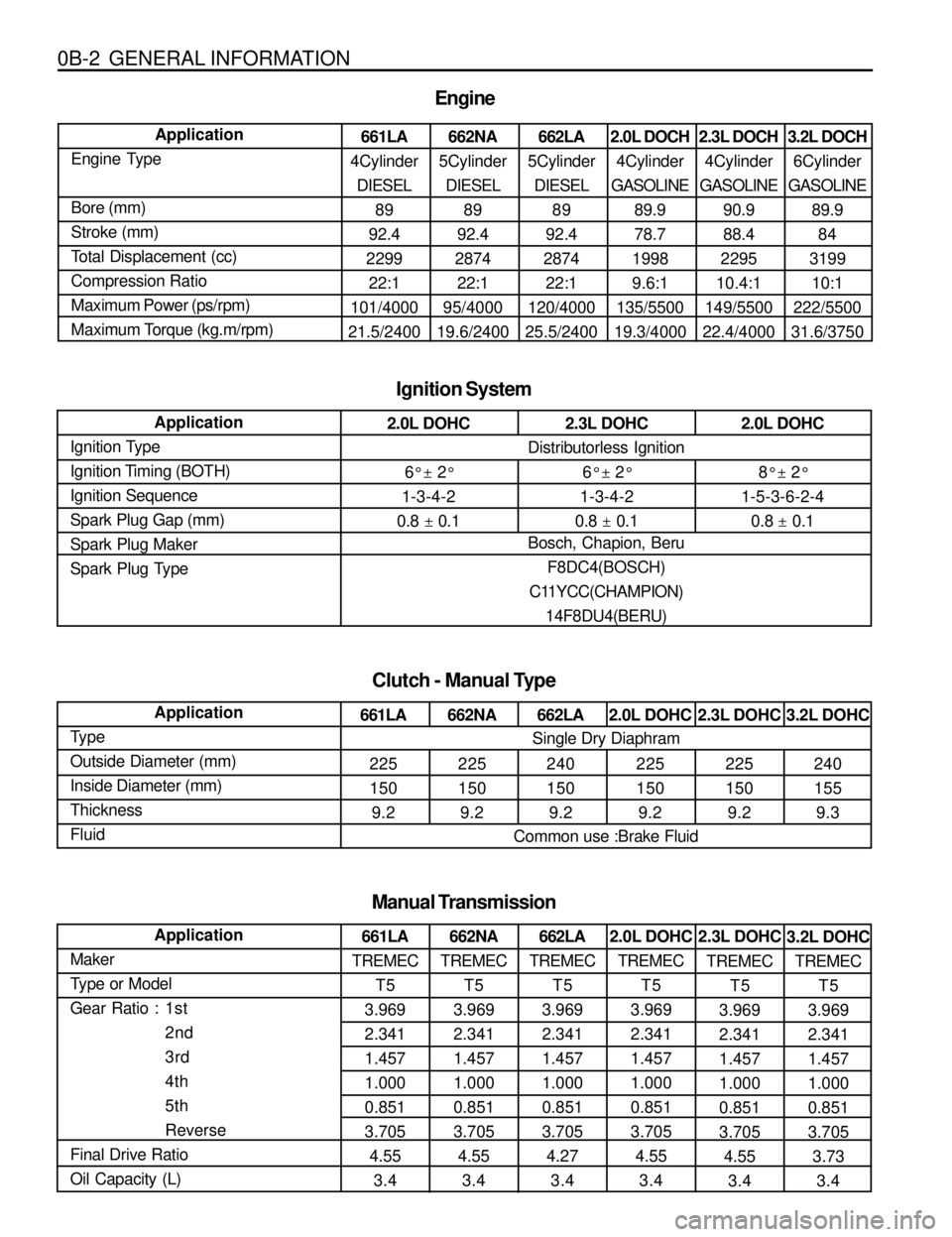

0B-2 GENERAL INFORMATION

661LA

4Cylinder

DIESEL

89

92.4

2299

22:1

101/4000

21.5/2400 Application

Engine Type

Bore (mm)

Stroke (mm)

Total Displacement (cc)

Compression Ratio

Maximum Power (ps/rpm)

Maximum Torque (kg.m/rpm)

Engine

662NA

5Cylinder

DIESEL

89

92.4

2874

22:1

95/4000

19.6/2400662LA

5Cylinder

DIESEL

89

92.4

2874

22:1

120/4000

25.5/24002.0L DOCH

4Cylinder

GASOLINE

89.9

78.7

1998

9.6:1

135/5500

19.3/40002.3L DOCH

4Cylinder

GASOLINE

90.9

88.4

2295

10.4:1

149/5500

22.4/40003.2L DOCH

6Cylinder

GASOLINE

89.9

84

3199

10:1

222/5500

31.6/3750

661LA

TREMEC

T5

3.969

2.341

1.457

1.000

0.851

3.705

4.55

3.4 Application

Ignition Type

Ignition Timing (BOTH)

Ignition Sequence

Spark Plug Gap (mm)

Spark Plug Maker

Spark Plug Type

Ignition System

Clutch - Manual Type

2.0L DOHC

6° ± 2°

1-3-4-2

0.8 ± 0.12.3L DOHC

6° ± 2°

1-3-4-2

0.8 ± 0.12.0L DOHC

8° ± 2°

1-5-3-6-2-4

0.8 ± 0.1 Distributorless Ignition

Bosch, Chapion, Beru

F8DC4(BOSCH)

C11YCC(CHAMPION)

14F8DU4(BERU)

661LA

225

150

9.2

662NA

225

150

9.2662LA

240

150

9.22.0L DOHC

225

150

9.22.3L DOHC

225

150

9.23.2L DOHC

240

155

9.3 Application

Type

Outside Diameter (mm)

Inside Diameter (mm)

Thickness

Fluid

Single Dry Diaphram

Common use :Brake Fluid

Application

Maker

Type or Model

Gear Ratio : 1st

2nd

3rd

4th

5th

Reverse

Final Drive Ratio

Oil Capacity (L)

Manual Transmission

662NA

TREMEC

T5

3.969

2.341

1.457

1.000

0.851

3.705

4.55

3.4662LA

TREMEC

T5

3.969

2.341

1.457

1.000

0.851

3.705

4.27

3.42.0L DOHC

TREMEC

T5

3.969

2.341

1.457

1.000

0.851

3.705

4.55

3.42.3L DOHC

TREMEC

T5

3.969

2.341

1.457

1.000

0.851

3.705

4.55

3.43.2L DOHC

TREMEC

T5

3.969

2.341

1.457

1.000

0.851

3.705

3.73

3.4

Page 21 of 1463

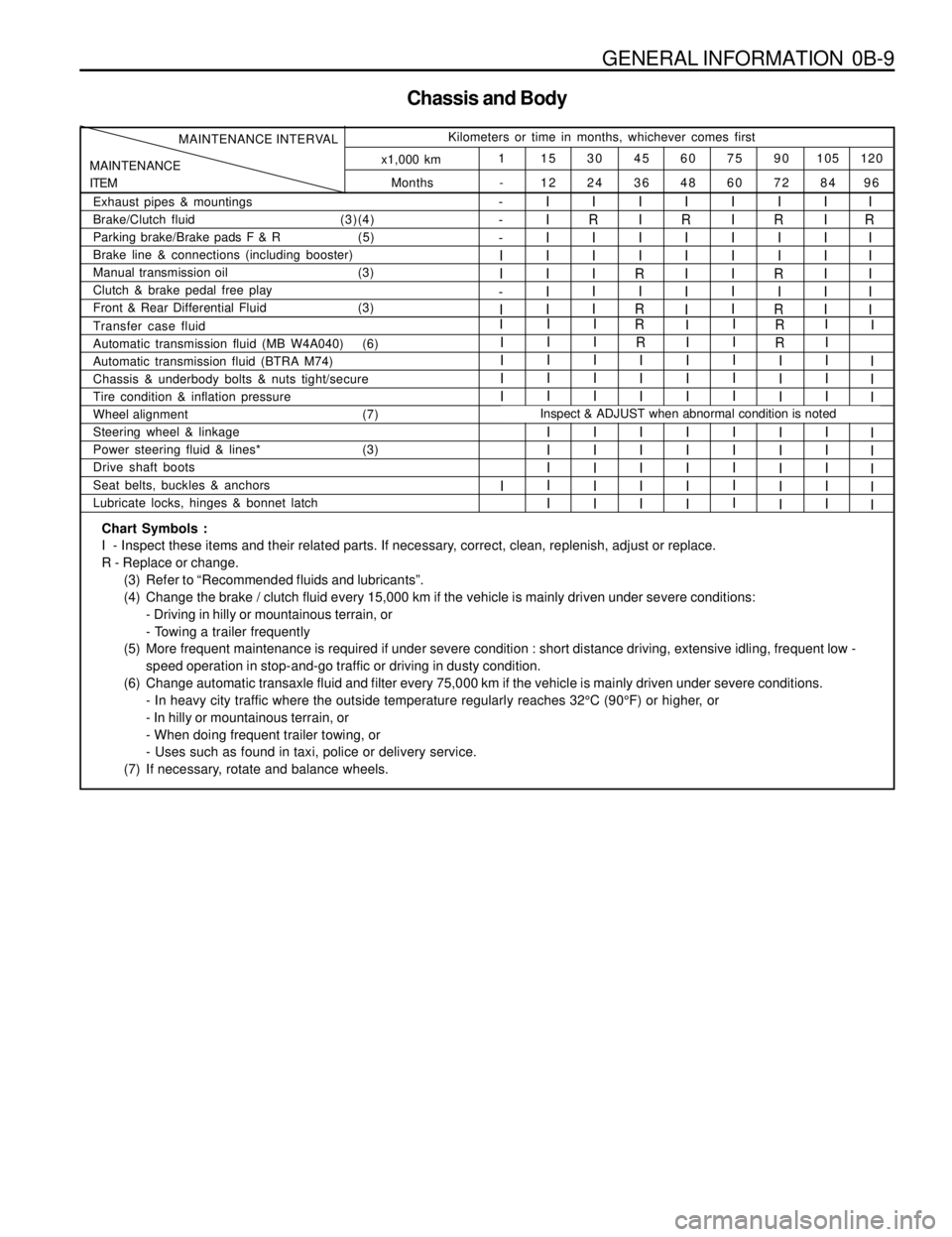

GENERAL INFORMATION 0B-9

Chassis and Body

Months

MAINTENANCE

ITEMMAINTENANCE INTERVALKilometers or time in months, whichever comes first

120 105 90 75 60 45 30 15 1

96 84 72 60 48 36 24 12

- x1,000 km

Exhaust pipes & mountings

Brake/Clutch fluid(3)(4)

Parking brake/Brake pads F & R (5)

Brake line & connections (including booster)

Manual transmission oil (3)

Clutch & brake pedal free play

Front & Rear Differential Fluid (3)I

R

I

I

I

I

I-

-

-

I

I

-

II

I

I

I

I

I

II

R

I

I

I

I

II

I

I

I

R

I

RI

I

I

I

I

I

II

R

I

I

R

I

RI

I

I

I

I

I

II

R

I

I

I

I

I

Automatic transmission fluid (MB W4A040) (6)

Automatic transmission fluid (BTRA M74)

Chassis & underbody bolts & nuts tight/secure

Tire condition & inflation pressure

Wheel alignment (7)

Steering wheel & linkage

Power steering fluid & lines* (3)

Drive shaft boots

Seat belts, buckles & anchors

Lubricate locks, hinges & bonnet latchI

I

I

I

II

I

I

I

I

I

I

I

I

II

I

I

I

I

I

I

I

I

IR

I

I

I

I

I

I

I

II

I

I

I

I

I

I

I

II

I

I

I

I

I

I

I

I

IR

R

I

I

I

I

I

I

I

II

I

I

I

I

I

I

I

I

Transfer case fluidRIII

Inspect & ADJUST when abnormal condition is noted

I

I

I

I

I

I

I

I

I

Chart Symbols :

I - Inspect these items and their related parts. If necessary, correct, clean, replenish, adjust or replace.

R - Replace or change.

(3) Refer to “Recommended fluids and lubricants”.

(4) Change the brake / clutch fluid every 15,000 km if the vehicle is mainly driven under severe conditions:

- Driving in hilly or mountainous terrain, or

- Towing a trailer frequently

(5) More frequent maintenance is required if under severe condition : short distance driving, extensive idling, frequent low -

speed operation in stop-and-go traffic or driving in dusty condition.

(6) Change automatic transaxle fluid and filter every 75,000 km if the vehicle is mainly driven under severe conditions.

- In heavy city traffic where the outside temperature regularly reaches 32°C (90°F) or higher, or

- In hilly or mountainous terrain, or

- When doing frequent trailer towing, or

- Uses such as found in taxi, police or delivery service.

(7) If necessary, rotate and balance wheels.

Page 23 of 1463

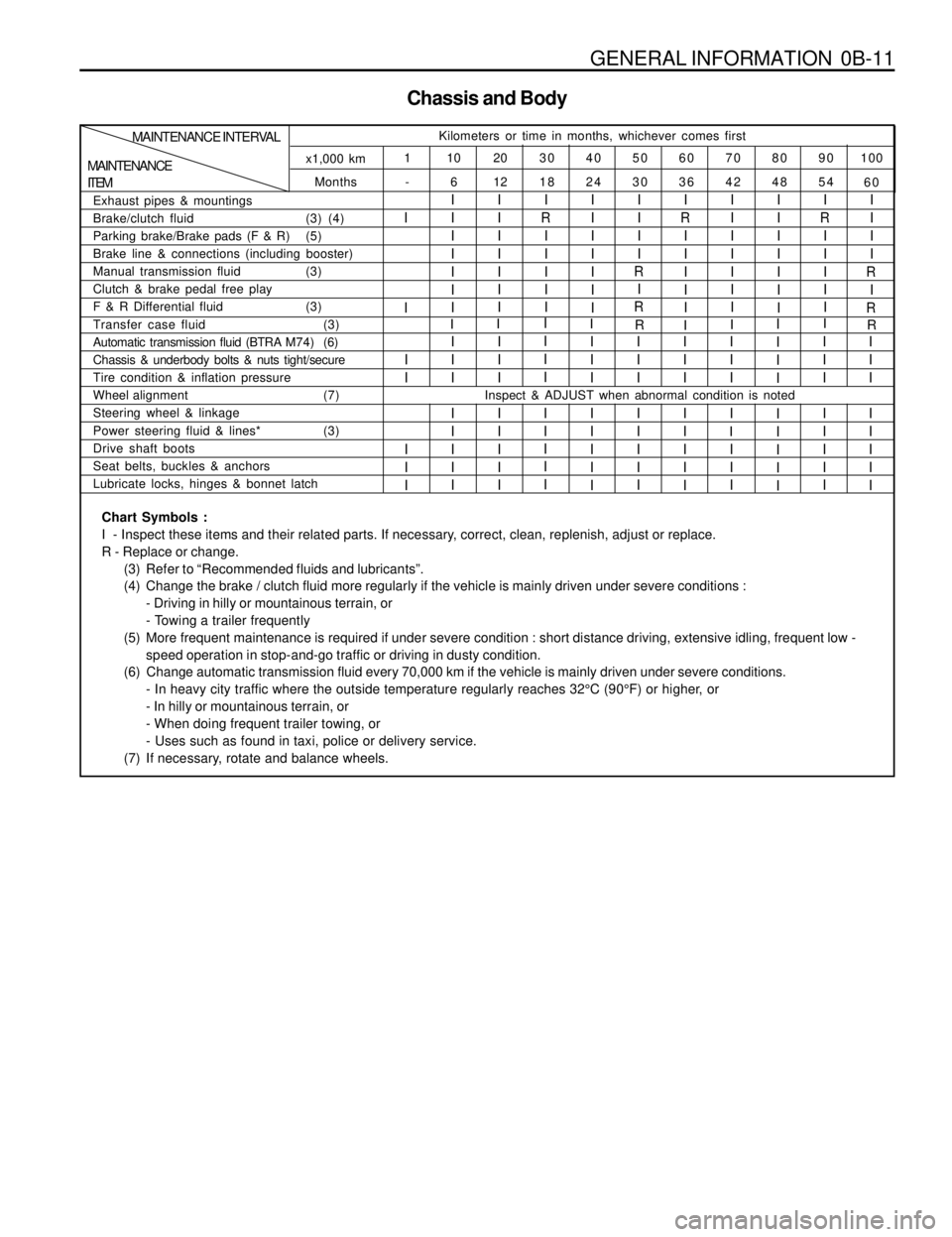

GENERAL INFORMATION 0B-11

Chassis and Body

Months

-

MAINTENANCE

ITEMMAINTENANCE INTERVAL

Kilometers or time in months, whichever comes first

100 90 80 70 60 50 40 30 20 10 1

60 54 48 42 36 30 24 18 12 6 x1,000 km

Exhaust pipes & mountings

Brake/clutch fluid(3) (4)

Parking brake/Brake pads (F & R) (5)

Brake line & connections (including booster)

Manual transmission fluid (3)

Clutch & brake pedal free play

F & R Differential fluid (3)

I

II

I

I

I

I

I

II

I

I

I

I

I

II

R

I

I

I

I

II

I

I

I

I

I

II

I

I

I

R

I

RI

R

I

I

I

I

II

I

I

I

I

I

II

I

I

I

I

I

II

R

I

I

I

I

II

I

I

I

R

I

R

Automatic transmission fluid (BTRA M74) (6)

Chassis & underbody bolts & nuts tight/secure

Tire condition & inflation pressure

Wheel alignment (7)

Steering wheel & linkage

Power steering fluid & lines* (3)

Drive shaft boots

Seat belts, buckles & anchors

Lubricate locks, hinges & bonnet latchI

I

I

I

I

I

I

II

I

I

I

I

I

I

II

I

I

I

I

I

I

I

II

I

I

I

I

I

I

II

I

I

I

I

I

I

II

I

I

I

I

I

I

II

I

I

I

I

I

II

I

I

I

I

I

I

II

I

I

I

I

I

I

I

Transfer case fluid (3)R

IR

I II

I

I

I

I

II

I

I

I

I

I

I

I

I

Inspect & ADJUST when abnormal condition is noted

II

I

Chart Symbols :

I - Inspect these items and their related parts. If necessary, correct, clean, replenish, adjust or replace.

R - Replace or change.

(3) Refer to “Recommended fluids and lubricants”.

(4) Change the brake / clutch fluid more regularly if the vehicle is mainly driven under severe conditions :

- Driving in hilly or mountainous terrain, or

- Towing a trailer frequently

(5) More frequent maintenance is required if under severe condition : short distance driving, extensive idling, frequent low -

speed operation in stop-and-go traffic or driving in dusty condition.

(6) Change automatic transmission fluid every 70,000 km if the vehicle is mainly driven under severe conditions.

- In heavy city traffic where the outside temperature regularly reaches 32°C (90°F) or higher, or

- In hilly or mountainous terrain, or

- When doing frequent trailer towing, or

- Uses such as found in taxi, police or delivery service.

(7) If necessary, rotate and balance wheels.

Page 38 of 1463

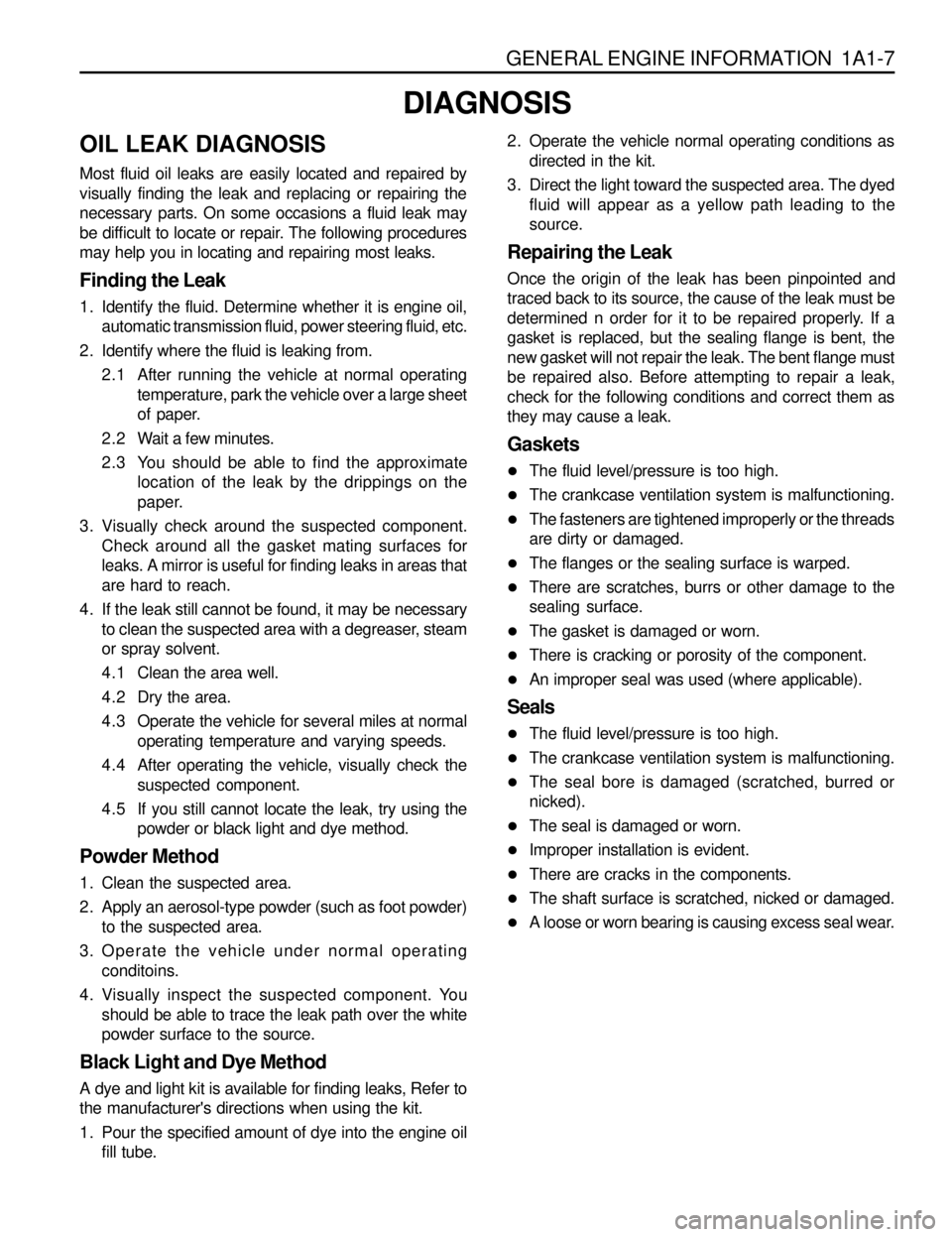

GENERAL ENGINE INFORMATION 1A1-7

OIL LEAK DIAGNOSIS

Most fluid oil leaks are easily located and repaired by

visually finding the leak and replacing or repairing the

necessary parts. On some occasions a fluid leak may

be difficult to locate or repair. The following procedures

may help you in locating and repairing most leaks.

Finding the Leak

1. Identify the fluid. Determine whether it is engine oil,

automatic transmission fluid, power steering fluid, etc.

2. Identify where the fluid is leaking from.

2.1 After running the vehicle at normal operating

temperature, park the vehicle over a large sheet

of paper.

2.2 Wait a few minutes.

2.3 You should be able to find the approximate

location of the leak by the drippings on the

paper.

3. Visually check around the suspected component.

Check around all the gasket mating surfaces for

leaks. A mirror is useful for finding leaks in areas that

are hard to reach.

4. If the leak still cannot be found, it may be necessary

to clean the suspected area with a degreaser, steam

or spray solvent.

4.1 Clean the area well.

4.2 Dry the area.

4.3 Operate the vehicle for several miles at normal

operating temperature and varying speeds.

4.4 After operating the vehicle, visually check the

suspected component.

4.5 If you still cannot locate the leak, try using the

powder or black light and dye method.

Powder Method

1. Clean the suspected area.

2. Apply an aerosol-type powder (such as foot powder)

to the suspected area.

3. Operate the vehicle under normal operating

conditoins.

4. Visually inspect the suspected component. You

should be able to trace the leak path over the white

powder surface to the source.

Black Light and Dye Method

A dye and light kit is available for finding leaks, Refer to

the manufacturer's directions when using the kit.

1. Pour the specified amount of dye into the engine oil

fill tube.2. Operate the vehicle normal operating conditions as

directed in the kit.

3. Direct the light toward the suspected area. The dyed

fluid will appear as a yellow path leading to the

source.

Repairing the Leak

Once the origin of the leak has been pinpointed and

traced back to its source, the cause of the leak must be

determined n order for it to be repaired properly. If a

gasket is replaced, but the sealing flange is bent, the

new gasket will not repair the leak. The bent flange must

be repaired also. Before attempting to repair a leak,

check for the following conditions and correct them as

they may cause a leak.

Gaskets

lThe fluid level/pressure is too high.

lThe crankcase ventilation system is malfunctioning.

lThe fasteners are tightened improperly or the threads

are dirty or damaged.

lThe flanges or the sealing surface is warped.

lThere are scratches, burrs or other damage to the

sealing surface.

lThe gasket is damaged or worn.

lThere is cracking or porosity of the component.

lAn improper seal was used (where applicable).

Seals

lThe fluid level/pressure is too high.

lThe crankcase ventilation system is malfunctioning.

lThe seal bore is damaged (scratched, burred or

nicked).

lThe seal is damaged or worn.

lImproper installation is evident.

lThere are cracks in the components.

lThe shaft surface is scratched, nicked or damaged.

lA loose or worn bearing is causing excess seal wear.

DIAGNOSIS

Page 52 of 1463

1A2-8 GENERAL ENGINE INFORMATION

OIL LEAK DIAGNOSIS

Most fluid oil leaks are easily located and repaired by

visually finding the leak and replacing or repairing the

necessary parts. On some occasions a fluid leak may

be difficult to locate or repair. The following procedures

may help you in locating and repairing most leaks.

Finding the Leak

1. Identify the fluid. Determine whether it is engine oil,

automatic transmission fluid, power steering fluid, etc.

2. Identify where the fluid is leaking from.

2.1 After running the vehicle at normal operating

temperature, park the vehicle over a large sheet

of paper.

2.2 Wait a few minutes.

2.3 You should be able to find the approximate

location of the leak by the drippings on the

paper.

3. Visually check around the suspected component.

Check around all the gasket mating surfaces for

leaks. A mirror is useful for finding leaks in areas that

are hard to reach.

4. If the leak still cannot be found, it may be necessary

to clean the suspected area with a degreaser, steam

or spray solvent.

4.1 Clean the area well.

4.2 Dry the area.

4.3 Operate the vehicle for several miles at normal

operating temperature and varying speeds.

4.4 After operating the vehicle, visually check the

suspected component.

4.5 If you still cannot locate the leak, try using the

powder or black light and dye method.

Powder Method

1. Clean the suspected area.

2. Apply an aerosol-type powder (such as foot powder)

to the suspected area.

3. Operate the vehicle under normal operating

conditoins.

4. Visually inspect the suspected component. You

should be able to trace the leak path over the white

powder surface to the source.

Black Light and Dye Method

A dye and light kit is available for finding leaks, Refer to

the manufacturer's directions when using the kit.

1. Pour the specified amount of dye into the engine oil

fill tube.

2. Operate the vehicle normal operating conditions as

directed in the kit.

3. Direct the light toward the suspected area. The dyed

fluid will appear as a yellow path leading to the

source.

Repairing the Leak

Once the origin of the leak has been pinpointed and

traced back to its source, the cause of the leak must be

determined n order for it to be repaired properly. If a

gasket is replaced, but the sealing flange is bent, the

new gasket will not repair the leak. The bent flange must

be repaired also. Before attempting to repair a leak,

check for the following conditions and correct them as

they may cause a leak.

Gaskets

lThe fluid level/pressure is too high.

lThe crankcase ventilation system is malfunctioning.

lThe fasteners are tightened improperly or the threads

are dirty or damaged.

lThe flanges or the sealing surface is warped.

lThere are scratches, burrs or other damage to the

sealing surface.

lThe gasket is damaged or worn.

lThere is cracking or porosity of the component.

lAn improper seal was used (where applicable).

Seals

lThe fluid level/pressure is too high.

lThe crankcase ventilation system is malfunctioning.

lThe seal bore is damaged (scratched, burred or

nicked).

lThe seal is damaged or worn.

lImproper installation is evident.

lThere are cracks in the components.

lThe shaft surface is scratched, nicked or damaged.

lA loose or worn bearing is causing excess seal wear.

DIAGNOSIS

Page 68 of 1463

1A3-10 GENERAL ENGINE INFORMATION

OIL LEAK DIAGNOSIS

Most fluid oil leaks are easily located and repaired by

visually finding the leak and replacing or repairing the

necessary parts. On some occasions a fluid leak may

be difficult to locate or repair. The following

procedures may help you in locating and repairing

most leaks.

Finding the Leak

1. Identify the fluid. Determine whether it is engine

oil, automatic transmission fluid, power steering

fluid, etc.

2. Identify where the fluid is leaking from.

2.1 After running the vehicle at normal operating

temperature, park the vehicle over a large

sheet of paper.

2.2 Wait a few minutes.

2.3 You should be able to find the approximate

location of the leak by the drippings on the

paper.

3. Visually check around the suspected component.

Check around all the gasket mating surfaces for

leaks. A mirror is useful for finding leaks in areas

that are hard to reach.

4. If the leak still cannot be found, it may be

necessary to clean the suspected area with a

degreaser, steam or spray solvent.

4.1 Clean the area well.

4.2 Dry the area.

4.3 Operate the vehicle for several miles at

normal operating temperature and varying

speeds.

4.4 After operating the vehicle, visually check the

suspected component.

4.5 If you still cannot locate the leak, try using the

powder or black light and dye method.

Powder Method

1. Clean the suspected area.

2. Apply an aerosol-type powder (such as foot

powder) to the suspected area.

3. Operate the vehicle under normal operating

conditions.

4. Visually inspect the suspected component. You

should be able to trace the leak path over the white

powder surface to the source.

Black Light and Dye Method

A dye and light kit is available for finding leaks, Refer

to the manufacturer's directions when using the kit.1. Pour the specified amount of dye into the engine

oil fill tube.

2. Operate the vehicle normal operating conditions

as directed in the kit.

3. Direct the light toward the suspected area. The

dyed fluid will appear as a yellow path leading to

the source.

Repairing the Leak

Once the origin of the leak has been pinpointed and

traced back to its source, the cause of the leak must

be determined n order for it to be repaired properly. If

a gasket is replaced, but the sealing flange is bent,

the new gasket will not repair the leak. The bent flange

must be repaired also. Before attempting to repair a

leak, check for the following conditions and correct

them as they may cause a leak.

Gaskets

lThe fluid level/pressure is too high.

lThe crankcase ventilation system is malfunctioning.

lThe fasteners are tightened improperly or the

threads are dirty or damaged.

lThe flanges or the sealing surface is warped.

lThere are scratches, burrs or other damage to the

sealing surface.

lThe gasket is damaged or worn.

lThere is cracking or porosity of the component.

lAn improper seal was used (where applicable).

Seals

lThe fluid level/pressure is too high.

lThe crankcase ventilation system is malfunctioning.

lThe seal bore is damaged (scratched, burred or

nicked).

lThe seal is damaged or worn.

lImproper installation is evident.

lThere are cracks in the components.

lThe shaft surface is scratched, nicked or damaged.

lA loose or worn bearing is causing excess seal

wear.

DIAGNOSIS

Page 318 of 1463

1B3-16 OM600 ENGINE MECHANICAL

16. Remove the power steering pump lines.

Notice

Completely drain the fluid.

17. Disconnect the fuel feed line with prefilter from the feed

pump on injection pump.

18. Vehicle with automatic transmission.

Remove the hydraulic lines (19, 20) from oil cooler (2).

19. Disconnect the engine harness.

20. Disconnect the preheating time relay cable.

Page 978 of 1463

SECTION 5A

AUTOMATIC TRANSMISSION

TABLE OF CONTENTS

Specifications . . . . . . . . . . . . . . . . . . . . . . . . 5A-2

Model Part Numbers and Applications . . . . . . 5A-2

Model Specifications . . . . . . . . . . . . . . . . . . . . 5A-2

Clutch Pack Details . . . . . . . . . . . . . . . . . . . . . 5A-3

Special Tools . . . . . . . . . . . . . . . . . . . . . . . . 5A-4

Special Tools Table . . . . . . . . . . . . . . . . . . . . . 5A-4

Schematic and Routing Diagrams . . . . . . . . 5A-5

TCU Circuit (Diesel) . . . . . . . . . . . . . . . . . . . . 5A-5

TCU Circuit (Gasoline) . . . . . . . . . . . . . . . . . . 5A-6

Shift Pattern Diagram . . . . . . . . . . . . . . . . . 5A-7

661LA Normal Mode . . . . . . . . . . . . . . . . . . . . 5A-7

661LA Power Mode . . . . . . . . . . . . . . . . . . . . 5A-8

662LA Normal Mode . . . . . . . . . . . . . . . . . . . . 5A-9

662LA Power Mode . . . . . . . . . . . . . . . . . . . 5A-10

662LA Low Mode . . . . . . . . . . . . . . . . . . . . . 5A-11

E32 Power Mode . . . . . . . . . . . . . . . . . . . . . 5A-12

E32 Normal Mode . . . . . . . . . . . . . . . . . . . . . 5A-13

E32 Low Mode . . . . . . . . . . . . . . . . . . . . . . . 5A-14

E23 Power Mode . . . . . . . . . . . . . . . . . . . . . 5A-15

E23 Normal Mode . . . . . . . . . . . . . . . . . . . . . 5A-16

E23 Low Mode . . . . . . . . . . . . . . . . . . . . . . . 5A-17

Introduction . . . . . . . . . . . . . . . . . . . . . . . . 5A-18

Operator Interfaces . . . . . . . . . . . . . . . . . . 5A-20

Gear Select Lever Operation . . . . . . . . . . . . 5A-20

Driving Mode Selector . . . . . . . . . . . . . . . . . 5A-21

Control Systems . . . . . . . . . . . . . . . . . . . . . 5A-22

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5A-22

Electronic Control System . . . . . . . . . . . . . . . 5A-22

Hydraulic Control System . . . . . . . . . . . . . . . 5A-31

Power Train System . . . . . . . . . . . . . . . . . . 5A-42

Torque Converter . . . . . . . . . . . . . . . . . . . . . 5A-43

Clutch Packs . . . . . . . . . . . . . . . . . . . . . . . . . 5A-44Bands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5A-45

One Way Clutches . . . . . . . . . . . . . . . . . . . . 5A-45

Planetary Gear Set . . . . . . . . . . . . . . . . . . . . 5A-45

Parking Mechanism . . . . . . . . . . . . . . . . . . . 5A-46

Power Flows . . . . . . . . . . . . . . . . . . . . . . . . 5A-47

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . 5A-47

Power Flow - Park and Neutral . . . . . . . . . . . 5A-48

Power Flow - Reverse . . . . . . . . . . . . . . . . . . 5A-49

Power Flow - Manual 1 . . . . . . . . . . . . . . . . . 5A-50

Power Flow - Drive 1 . . . . . . . . . . . . . . . . . . . 5A-51

Power Flow - Drive 2 and Manual 2 . . . . . . . 5A-52

Power Flow - Drive 3 and Manual 3 . . . . . . . 5A-54

Power Flow - Drive 3 Lock Up and Manual

3 Lock Up . . . . . . . . . . . . . . . . 5A-56

Power Flow - Drive 4 (Overdrive) . . . . . . . . . 5A-57

Power Flow - Drive 4 Lock Up . . . . . . . . . . . . 5A-59

Diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . 5A-60

Diagnostic System . . . . . . . . . . . . . . . . . . . . 5A-60

Mechanical Tests . . . . . . . . . . . . . . . . . . . . . 5A-69

Self Diagnosis Test . . . . . . . . . . . . . . . . . . 5A-75

Adjustments . . . . . . . . . . . . . . . . . . . . . . . . 5A-79

Hydraulic System . . . . . . . . . . . . . . . . . . . . . 5A-79

Transmission Fluid Test Procedure . . . . . . . . 5A-79

Electronic Adjustments . . . . . . . . . . . . . . . . . 5A-80

Maintenance and Repair . . . . . . . . . . . . . . 5A-82

On-Vehicle Service . . . . . . . . . . . . . . . . . . . . 5A-82

Removal and Installation of Transmission . . . 5A-82

Unit Repair . . . . . . . . . . . . . . . . . . . . . . . . . 5A-85

Rebuild Warnings . . . . . . . . . . . . . . . . . . . . . 5A-85

Disassembly Procedure . . . . . . . . . . . . . . . . 5A-85

Assembly Procedure . . . . . . . . . . . . . . . . . . . 5A-94

Front and Rear Band Adjustment . . . . . . . . 5A-128

Page 979 of 1463

5A-2 AUTOMATIC TRANSMISSION

SPECIFICATIONS

MODEL PART NUMBERS AND APPLICATIONS

Transmission

0574-000001 (9)

0574-000002 (8)

0574-000004 (10)

0574-000005 (7)Torque Converter

179K

160K

160K

179KEngine Version

661LA

E32

662LA(Turbo)

E23

MODEL SPECIFICATIONS

Application

Torque Converter

Mean diameter of fluid circuit

Maximum torque multiplication

Stall speed (rpm)

0574-000001 (D23LA)

0574-000002 (E32)

0574-000004 (D29LA)

0574-000005 (E23)

0574-000020

0574-000021

Gear Ratios

First

Second

Third

Fourth

Reverse

Lubricant

Type

Capacity

Dry System

Service Refill

Gear Train End Float

Gear Set Pinion End FloatDescriprtion

260

2.0 : 1

2100 - 2250

2050 - 2250

2100 - 2200

1800 - 2100

2.741 : 1

1.508 : 1

1.000 : 1

0.708 : 1

2.429 : 1

Castrol TQ95 or other approved fluid

9.0 Litres (approx)

4.5 Litres (approx)

0.50 - 0.65 mm

0.10 - 0.50 mm DWMC P/NO

36100-05420 (1)

36100-05430 (1)

36100-05410 (1)

36100-05440 (1)

Page 1019 of 1463

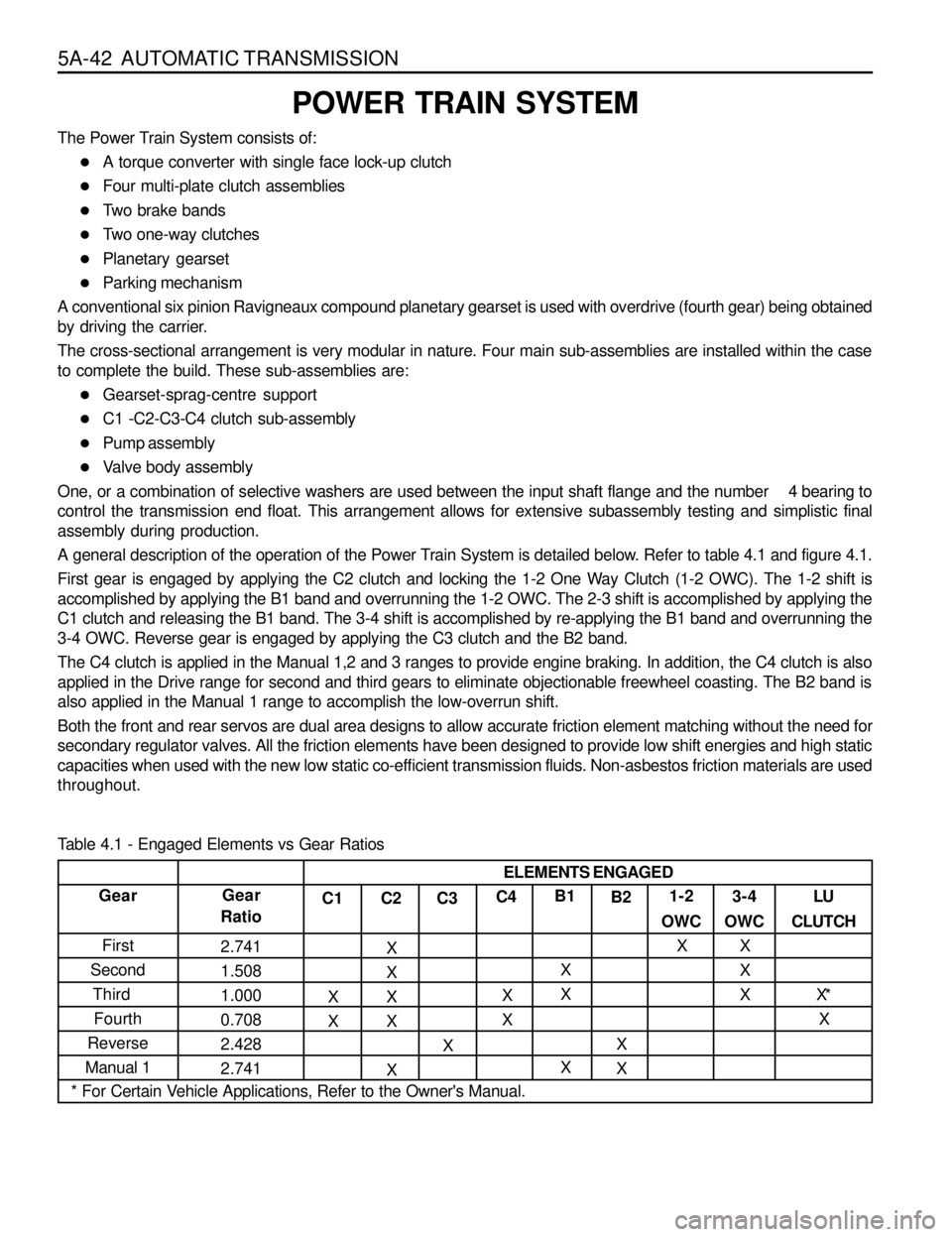

5A-42 AUTOMATIC TRANSMISSION

POWER TRAIN SYSTEM

The Power Train System consists of:

lA torque converter with single face lock-up clutch

lFour multi-plate clutch assemblies

lTwo brake bands

lTwo one-way clutches

lPlanetary gearset

lParking mechanism

A conventional six pinion Ravigneaux compound planetary gearset is used with overdrive (fourth gear) being obtained

by driving the carrier.

The cross-sectional arrangement is very modular in nature. Four main sub-assemblies are installed within the case

to complete the build. These sub-assemblies are:

lGearset-sprag-centre support

lC1 -C2-C3-C4 clutch sub-assembly

lPump assembly

lValve body assembly

One, or a combination of selective washers are used between the input shaft flange and the number 4 bearing to

control the transmission end float. This arrangement allows for extensive subassembly testing and simplistic final

assembly during production.

A general description of the operation of the Power Train System is detailed below. Refer to table 4.1 and figure 4.1.

First gear is engaged by applying the C2 clutch and locking the 1-2 One Way Clutch (1-2 OWC). The 1-2 shift is

accomplished by applying the B1 band and overrunning the 1-2 OWC. The 2-3 shift is accomplished by applying the

C1 clutch and releasing the B1 band. The 3-4 shift is accomplished by re-applying the B1 band and overrunning the

3-4 OWC. Reverse gear is engaged by applying the C3 clutch and the B2 band.

The C4 clutch is applied in the Manual 1,2 and 3 ranges to provide engine braking. In addition, the C4 clutch is also

applied in the Drive range for second and third gears to eliminate objectionable freewheel coasting. The B2 band is

also applied in the Manual 1 range to accomplish the low-overrun shift.

Both the front and rear servos are dual area designs to allow accurate friction element matching without the need for

secondary regulator valves. All the friction elements have been designed to provide low shift energies and high static

capacities when used with the new low static co-efficient transmission fluids. Non-asbestos friction materials are used

throughout.

Gear

First

Second

Third

Fourth

Reverse

Manual 1Gear

Ratio

2.741

1.508

1.000

0.708

2.428

2.741C1

X

XC2

X

X

X

X

XC3

XC4

X

XB1

X

X

XB2

X

X1-2

OWC

X3-4

OWC

X

X

XLU

CLUTCH

X*

X ELEMENTS ENGAGED

* For Certain Vehicle Applications, Refer to the Owner's Manual. Table 4.1 - Engaged Elements vs Gear Ratios