tow SSANGYONG MUSSO 1998 Workshop User Guide

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1998, Model line: MUSSO, Model: SSANGYONG MUSSO 1998Pages: 1463, PDF Size: 19.88 MB

Page 469 of 1463

OM600 ENGINE MECHANICAL 1B3-167

6. Coat the cylinder bore, connecting rod bearing journal,

connecting rod bearing shell and piston with oil.

7. Compress the piston rings with a tensioning strap (7).

Tensioning Strap 000 589 04 14 00

8. Insert the piston assembly into the cylinder with a wooden

stick (18).

Notice

The arrow on the piston crown must point toward the front

of vehicle.

9. Insert the connecting rod bearing shells (9, 10).

Notice

Be careful of the difference in upper and lower bearing

shells and not to be changed.

10. Position the connecting rod bearings caps.

Notice

Position so that the retaining lugs are on the same side of

the connecting rod bearing(arrow).

11. Measure stretch shaft diameter (C) of the connecting rod

bolts.

Limit ‘C’ 7.1mm

Page 757 of 1463

1F3-28 OM600 ENGINE CONTROLS

Tools Required

001 589 65 09 00 Socket Wrench Insert

000 589 00 68 00 Cleaning Set

Repair Procedure

1. Clamp the nozzle holder (1) in a vice and remove the nozzle

tensioning nut (8).

Notice

Use protective jaws for clamping.

2. Disassemble the fuel injection nozzle.

Socket Wrench Insert 001 589 65 09 00

3. Clean the nozzle needle (6) and nozzle body (7) with an

abradant.

4. Clean the nozzle seat with cleaning cutter.

Cleaning Set 000 589 00 68 00

5. Immerse nozzle needle (6) and nozzle body (7) in filtered

diesel fuel. When the nozzle body is held vertical, the weight

of the nozzle needle must cause it to slide down toward the

nozzle needle seat.

6. Assemble the injection nozzle so that the tip of the thrust

(4) pin is facing toward the nozzle holder.

Tightening Torque 80 Nm

Notice

Nozzle needle (6) and nozzle body (7) should always be

replaced as a pair.

Page 788 of 1463

1G1-8 M162 ENGINE INTAKE & EXHAUST

Function Description

A pneumatically actuated resonance flap (5) is located on the

intake manifold, and will be opened and closed by load, which

operates resonance flap according to engine and controlled

by ECU and rpm.

1. Resonance flap closed (at idle/partial load : less than

3,800/rpm)

The switch valve (7) will be adjusted by ECU and resonance

falp will be colosed. By increasing air flow passage through

dividing intaking air flow toward both air collection housing

(8). This leads to a signficant increase in the torque in the

lower speed range.

2. Resonance flap open (at full load : over 3,800/rpm)

The switch valve (7) will not be adjusted by ECU and

resonance falp (5) will be open. The colllected air in the air

collection housing (8) will not be divided and intaking air

passage will be shorten.

Page 837 of 1463

WHEEL ALIGNMENT 2B-9

GENERAL DESCRIPTION AND SYSTEM OPERATION

FOUR WHEEL ALIGNMENT

CASTER

Caster is the tilting 91 the uppermost point of the steering

axis either forward or backward from the vertical when

viewed from the side of the vehicle. A backward tilt is

positive, and a forward tilt is negative. Caster influences

directional control of the steering but does not affect

tire wear. Weak springs or overloading a vehicle will affect

caster. One wheel with more positive caster will pull

toward the center of the car. This condition will cause

the car to move or lean toward the side with the least

amount of positive caster. Caster is measured in degrees.

CAMBER

Camber is the tilting of the top of the tire from the vertical

when viewed from the front of the vehicle. When the

tires tilt outward, the camber is positive. When the tires

tilt inward, the camber is negative. The camber angle is

measured in degrees from the vertical. Camber

influences both directional control and tire wear.

If the vehicle has too much positive camber, the outside

shoulder of the tire will wear. If the vehicle has too much

negative camber, the inside shoulder of the tire will wear. The first responsibility of engineering is to design safe

steering and suspension systems. Each component

must be strong enough to withstand and absorb extreme

punishment. Both the steering system and the front and

the rear suspension must function geometrically with

thebody mass.

The steering and the suspension systems require that

the front wheels self-return and that the tire rolling effort

and the road friction be held to a negligible force in order

to allow the customer to direct the vehicle with the least

effort and the most comfort.

A complete wheel alignment check should include

measurements of the rear toe and camber.

Four-wheel alignment assures that all four wheels will

be running in precisely the same direction.

When the vehicle is geometrically aligned, fuel economy

and tire life are at their peak, and steering and

performance are maximized.

TOE

Toe-in is the turning in of the tires, while toe-out is the

turning out of the tires from the geometric centerline or

thrust line. The toe ensures parallel rolling of the wheels.

The toe serves to offset the small deflections of the wheel

support system which occur when the vehicle is rolling

forward. The specified toe angle is the setting which

achieves 0 degrees of toe when the vehicle is moving.

Incorrect toe-in or toe-out will cause tire wear and

reduced fuel economy. As the individual steering and

suspension components wear from vehicle mileage,

additional toe will be needed to compensate for the wear.

Always correct the toe dimension last.

Page 890 of 1463

3A-22 FRONT DRIVE AXLE

Inspection of Ring Gear Tooth Contact Pattern

Normal Contact

Apply gear-marking compound (prussian blue / red lead) on

the ring gear teeth. Rotate the ring gear and check the tooth

contact pattern.

Abnormal Contact

Tooth Contact patternPossible CauseRemedy

1. Heel Contact

2. Toe Contact

3. Face Contact

4. Flank ContactInsufficient backlash (little)

lTooth can be damaged

or broken under heavy

load

Excessive backlash (much)

lDrive pinion shaft is apart

from the ring gear

lNoise can be occurred

Insufficient backlash (much)

lGear contacts on the low

flank

lGear can be damaged or

worn

lNoise can be occurredAdjust backlash(Decrease backlash)

lSelect proper shim(s) to move the

drive pinion toward the ring gear

(toward toe)

Adjust backlash(Increase backlash)

lSelect proper shim(s) to move the

drive pinion against the ring gear

(toward heel)

Adjust backlash(Increase pinion shim)

lMove the drive pinion toward the ring

gear (toward center of ring gear)

Adjust backlash(Decrease pinion shim)

lMove the ring gear toward the drive

pinion (toward ring gear center line) Excessive backlash (little)

lNoise can be occurred

Page 913 of 1463

REAR DRIVE AXLE 3D-15

Inspection of Ring Gear Tooth Contact Pattern

Normal Contact

Apply gear-marking compound (prussian blue / red lead) on

the ring gear teeth. Rotate the ring gear and check the tooth

contact pattern.

Abnormal Contact

Tooth Contact patternPossible CauseRemedy

1. Heel Contact

2. Toe Contact

3. Face Contact

4. Flank ContactInsufficient backlash (little)

lTooth can be damaged

or broken under heavy

load

Excessive backlash (much)

lDrive pinion shaft is apart

from the ring gear

lNoise can be occurred

Insufficient backlash (much)

lGear contacts on the low

flank

lGear can be damaged or

worn

lNoise can be occurredAdjust backlash(Decrease backlash)

lSelect proper shim(s) to move the

drive pinion toward the ring gear

(toward toe)

Adjust backlash(Increase backlash)

lSelect proper shim(s) to move the

drive pinion against the ring gear

(toward heel)

Adjust backlash(Increase pinion shim)

lMove the drive pinion toward the ring

gear (toward center of ring gear)

Adjust backlash(Decrease pinion shim)

lMove the ring gear toward the drive

pinion (toward ring gear center line) Excessive backlash (little)

lNoise can be occurred

Page 1125 of 1463

5B-18 MANUAL TRANSMISSION

8. Remove the counter shaft thrust race and bearing.

9. Carefully remove the oiling funnel from the end of the

counter shaft.

10. Using a 10 mm wrench, remove the 10 bolts from the shift

cover.

Notice

For assembly, note the location of the two bolts.

11. Lift up the shift cover after sliding it toward the drain plug

about 3 cm. At this time remove sealer bond.

12. Using a needle nose pliers, remove the 5-R lever clip.

Page 1211 of 1463

5D2-4 TRANSFER CASE (TOD)

FUNCTION DESCRIPTION

lTOD System Select Mode (4H and 4L)

4H is the mode when drive normally of which gear ratio is 1:1 and 4L mode distributes power to front and rear

wheels 50:50 of which gear ratio is 2.48:1.

lTOD System Function (select 4H mode)

TOD system controls clutch mechanism to comply with rotation in front and rear propeller shaft and if its difference

exceeds the permissible range, corresponding power is distributed into front wheel through EMC (Electro-Magnetic

Clutch).

Hall effect sensor signals speed on front and rear propeller shafts going through with TOD control unit.

Transfercase clutch coil is activated by variable current on exceeding difference of speed in front and rear propeller

shafts.

lFunction of 4L Mode

When select 4L mode, EMC is locked to apply maximum torque into front and rear propeller shafts. Shift motor

rotates also 4L position by rotation of cam thus propeller shaft torque changes from 1:1 to 2.48:1 by planetary

gear set.

lShift Motor

It locates backside transfer case, which drives rotary helical cam.

When mode select switch changes to 4L, shift fork is on position for 2.48:1 by rotation of helical cam.

lTransfer Case

TOD transfer case distributes power into front and rear axle by operation of 4H/4L switch and shift motor.

Shifting 4H to 4L, is performed towards reducing HI-LO collar by means for connection HI-LO shift fork with

output shaft in order to join with planetary gear. Torque transmits input shaft then sun gear rotating front planetary

gear. Front planetary gear join with output shaft and drives LO position.

Page 1222 of 1463

TRANSFER CASE (TOD) 5D2-15

DIAGNOSIS

While the TCCU is active it periodically monitors its inputs and outputs. If a fault is detected the “4WD CHECK” lamp

is illuminated and a fault code is stored in the TCCU memory.

When requested, fault codes are downloaded to a diagnostic connector (K-line) serial communications using SCAN-

100.

DIAGNOSTIC TESTS

1.TCCU Internal Function

When the Ignition is turned on the TCCU tests its ROM and RAM. If there is a fault, the TCCU immediately resets

itself and re-tests the ROM and RAM. If the fault persists the TCCU continues to reset and re-test until the fault is

corrected or the ignition is turned off. All TCCU functions are inhibited until the fault is corrected. The “4WD

CHECK” lamp is not illuminated if there is a ROM or RAM fault.

If the ROM/RAM passes the EEPROM memory is tested. If there is a fault the “4WD CHECK” lamp is illuminated

and the TCCU continues to operate using the default calibration data stored in ROM. Fault codes are not stored

when there is an EEPROM fault.

An EEPROM fault can only be cleared by cycling ignition off-on.

2.Shift Motor Assembly Test

If the TCCU detects a shift motor or position encoder fault continuously for one second the ‘4WD CHECK” lamp is

turned on and the appropriate fault code is stored in memory.

a. A shift motor fault when the motor is off is defined as follows:

Motor H-L shorted to Ground

Motor L-H shorted to Ground

Motor open circuit

b. A shift motor fault when the motor is energized is defined as follows:

Motor H-L shorted to Ground

Motor L-H shorted to Ground

Motor H-L shorted to Motor L-H

Motor open circuit

c. A position encoder fault is defined as follows:

Any position code which does not correspond to the valid 9 codes.

A short to ground on any of the encoder lines.

d. If no shifts are in progress when a failure occurs the TCCU will not respond to any shift commands.

e. If a shift command has been received, but not acted upon when a failure occurs the TCCU will cancel the

command and not respond to any subsequent shift commands.

f. If a shift command is in progress when an invalid position code is confirmed it will be halted and the TCCU will

turn the motor toward the high position. Afterwards the TCCU will not respond to any shift commands.

Page 1230 of 1463

TRANSFER CASE (TOD) 5D2-23

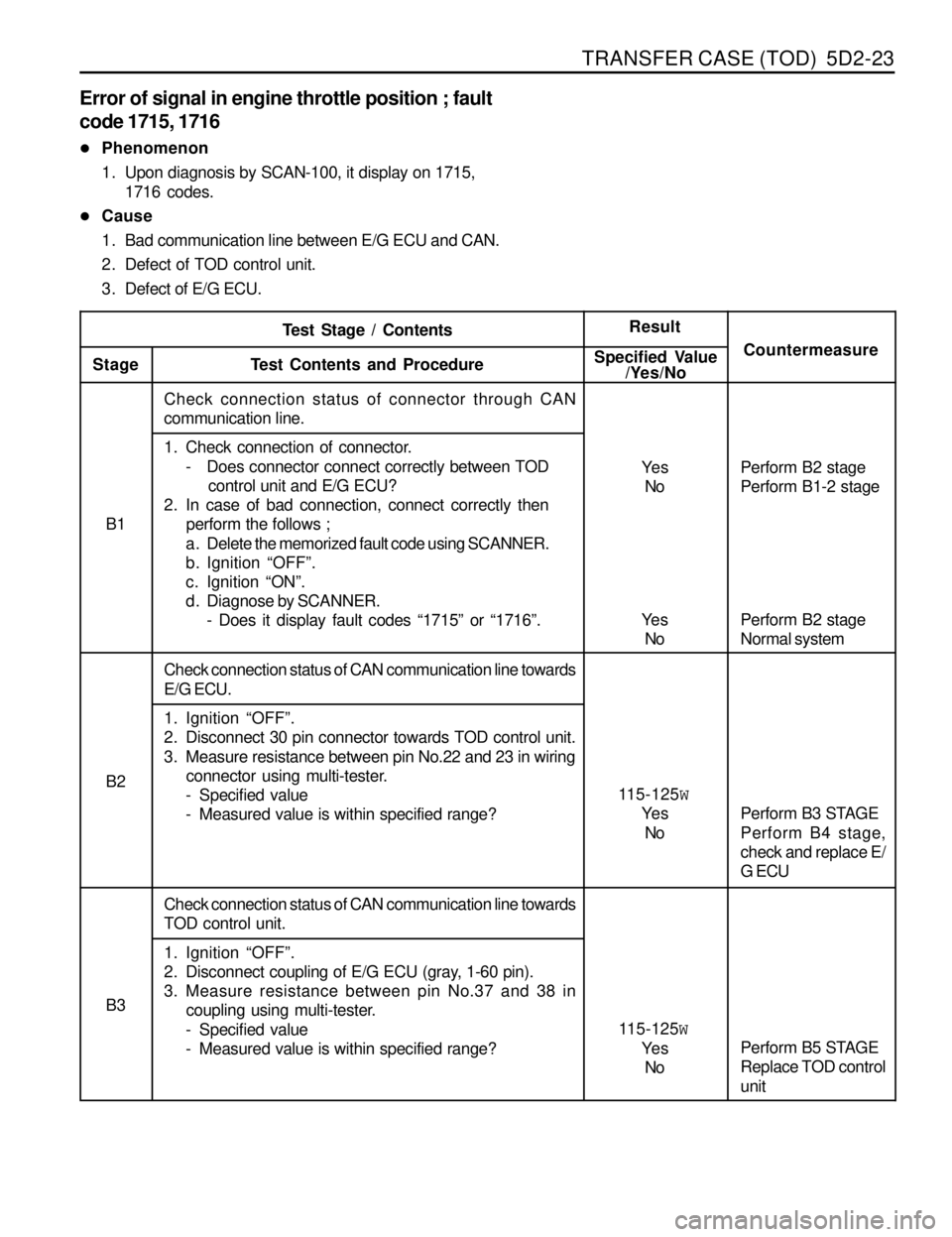

Error of signal in engine throttle position ; fault

code 1715, 1716

lPhenomenon

1. Upon diagnosis by SCAN-100, it display on 1715,

1716 codes.

lCause

1. Bad communication line between E/G ECU and CAN.

2. Defect of TOD control unit.

3. Defect of E/G ECU.

Check connection status of connector through CAN

communication line.

1. Check connection of connector.

- Does connector connect correctly between TOD

control unit and E/G ECU?

2. In case of bad connection, connect correctly then

perform the follows ;

a. Delete the memorized fault code using SCANNER.

b. Ignition “OFF”.

c. Ignition “ON”.

d. Diagnose by SCANNER.

- Does it display fault codes “1715” or “1716”.Ye s

No

B1

Ye s

No

Check connection status of CAN communication line towards

E/G ECU.

1. Ignition “OFF”.

2. Disconnect 30 pin connector towards TOD control unit.

3. Measure resistance between pin No.22 and 23 in wiring

connector using multi-tester.

- Specified value

- Measured value is within specified range? B2

115-125W

Ye s

No

Check connection status of CAN communication line towards

TOD control unit.

1. Ignition “OFF”.

2. Disconnect coupling of E/G ECU (gray, 1-60 pin).

3. Measure resistance between pin No.37 and 38 in

coupling using multi-tester.

- Specified value

- Measured value is within specified range? B3

115-125W

Ye s

No Test Stage / Contents

Result

Stage Test Contents and ProcedureSpecified Value

/Yes/NoCountermeasure

Perform B2 stage

Perform B1-2 stage

Perform B2 stage

Normal system

Perform B3 STAGE

Perform B4 stage,

check and replace E/

G ECU

Perform B5 STAGE

Replace TOD control

unit