wheel torque SSANGYONG MUSSO 1998 Workshop Owner's Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1998, Model line: MUSSO, Model: SSANGYONG MUSSO 1998Pages: 1463, PDF Size: 19.88 MB

Page 1164 of 1463

CLUTCH 5C-11

5. Unscrew the bolts and remove the clutch cover, pressure

plate and clutch disc.

Notice

Be careful not to drop the pressure plate and clutch disc.

Installation Notice

Tightening Torque 21 - 27 Nm

6. Installation should follow the removal procedure in the

reverse order.

Notice

lBefore installation, clean oil and grease on the

flywheel surface.

lDo not clean the clutch disc and release bearing in

solvent.

Page 1211 of 1463

5D2-4 TRANSFER CASE (TOD)

FUNCTION DESCRIPTION

lTOD System Select Mode (4H and 4L)

4H is the mode when drive normally of which gear ratio is 1:1 and 4L mode distributes power to front and rear

wheels 50:50 of which gear ratio is 2.48:1.

lTOD System Function (select 4H mode)

TOD system controls clutch mechanism to comply with rotation in front and rear propeller shaft and if its difference

exceeds the permissible range, corresponding power is distributed into front wheel through EMC (Electro-Magnetic

Clutch).

Hall effect sensor signals speed on front and rear propeller shafts going through with TOD control unit.

Transfercase clutch coil is activated by variable current on exceeding difference of speed in front and rear propeller

shafts.

lFunction of 4L Mode

When select 4L mode, EMC is locked to apply maximum torque into front and rear propeller shafts. Shift motor

rotates also 4L position by rotation of cam thus propeller shaft torque changes from 1:1 to 2.48:1 by planetary

gear set.

lShift Motor

It locates backside transfer case, which drives rotary helical cam.

When mode select switch changes to 4L, shift fork is on position for 2.48:1 by rotation of helical cam.

lTransfer Case

TOD transfer case distributes power into front and rear axle by operation of 4H/4L switch and shift motor.

Shifting 4H to 4L, is performed towards reducing HI-LO collar by means for connection HI-LO shift fork with

output shaft in order to join with planetary gear. Torque transmits input shaft then sun gear rotating front planetary

gear. Front planetary gear join with output shaft and drives LO position.

Page 1212 of 1463

TRANSFER CASE (TOD) 5D2-5

Definitions

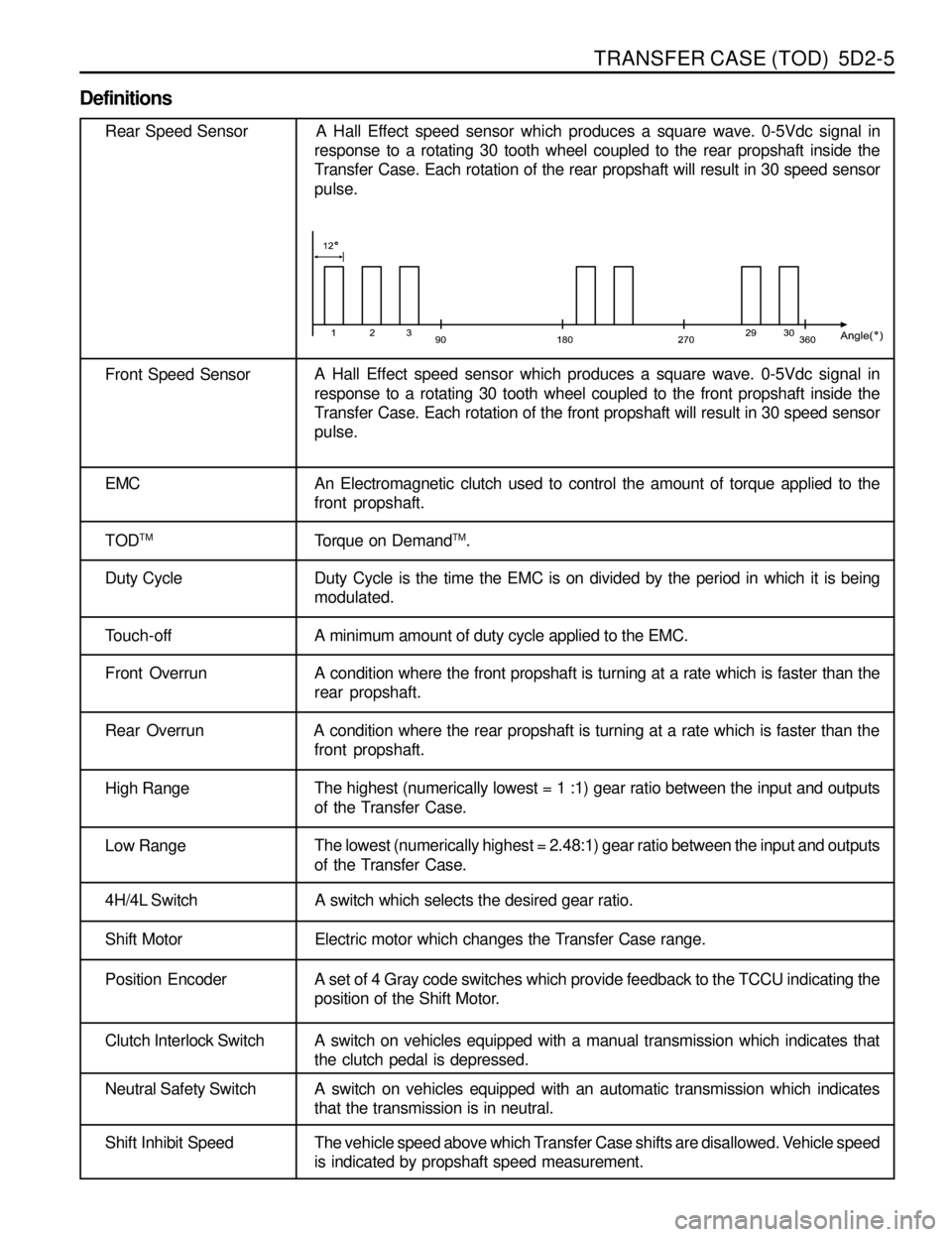

Rear Speed Sensor A Hall Effect speed sensor which produces a square wave. 0-5Vdc signal in

response to a rotating 30 tooth wheel coupled to the rear propshaft inside the

Transfer Case. Each rotation of the rear propshaft will result in 30 speed sensor

pulse.

Front Speed SensorA Hall Effect speed sensor which produces a square wave. 0-5Vdc signal in

response to a rotating 30 tooth wheel coupled to the front propshaft inside the

Transfer Case. Each rotation of the front propshaft will result in 30 speed sensor

pulse.

EMC An Electromagnetic clutch used to control the amount of torque applied to the

front propshaft.

TOD

TMTorque on DemandTM.

Duty Cycle Duty Cycle is the time the EMC is on divided by the period in which it is being

modulated.

Touch-off A minimum amount of duty cycle applied to the EMC.

Front OverrunA condition where the front propshaft is turning at a rate which is faster than the

rear propshaft.

Rear Overrun A condition where the rear propshaft is turning at a rate which is faster than the

front propshaft.

High RangeThe highest (numerically lowest = 1 :1) gear ratio between the input and outputs

of the Transfer Case.

Low RangeThe lowest (numerically highest = 2.48:1) gear ratio between the input and outputs

of the Transfer Case.

4H/4L Switch A switch which selects the desired gear ratio.

Shift Motor Electric motor which changes the Transfer Case range.

Position Encoder A set of 4 Gray code switches which provide feedback to the TCCU indicating the

position of the Shift Motor.

Clutch Interlock Switch A switch on vehicles equipped with a manual transmission which indicates that

the clutch pedal is depressed.

Neutral Safety Switch A switch on vehicles equipped with an automatic transmission which indicates

that the transmission is in neutral.

Shift Inhibit Speed The vehicle speed above which Transfer Case shifts are disallowed. Vehicle speed

is indicated by propshaft speed measurement.

Page 1218 of 1463

TRANSFER CASE (TOD) 5D2-11

4. Electric Shift Default Mode

If the motor fails to reach its destination, the TCCU will attempt the following (in order):

a. The TCCU will wait 3 seconds then attempt the shift again.

b. If the second attempt to reach the destination fails the TCCU will wait 3 seconds then attempt to rotate the

motor back to the original position. If successful, all future shifts will be inhibited until the Ignition is cycled.

c. If the attempt to return to the original position fails, the TCCU will wait 3 seconds then attempt to rotate the

motor to the original position again. If the second attempt to return to the original position is successful, the

“4WD CHECK” lamp will be illuminated, and all future shifts will be inhibited until the Ignition is cycled.

d. If the second attempt to return to the original position fails the motor will be turned off, the “4WD CHECK” lamp

will be illuminated, and all future shifts will be inhibited until the Ignition is cycled.

TODTM System Operation

The TODTM System is responsible for distributing torque between the front and rear axles. The TCCU monitors the

propshaft speeds, operating range (High/Low), and ABS activity and then applies a calculated amount of torque to

the front axle by Pulse Width Modulating the current applied to the EMC.

1. Touch-off Torque

The minimum EMC Duty Cycle is based on the vehicle speed and throttle position

The TCCU receives the TPS signal from the following sources:

On vehicles equipped with CAN, the TCCU receives the TPS signal from the CAN bus.

2. When Slip Detection

The TCCU continuously monitors the front and rear propshaft speeds to detect wheel slip.

3. Wheel Slip Control

When wheel slip is detected the TCCU controls the EMC duty cycle as necessary until the wheel slip is reduced

below the allowable limit. The EMC Duty Cycle will then be reduced to the Touch-Off value.

4. Brake/ABS Strategy

When the ABS System is active, the EMC Duty Cycle is set to a fixed duty cycle (30%) to aid in braking without

counteracting the ABS System.

5. 4L Strategy

When the system is operating in 4L, the TCCU continues TOD

TM (operation provided that the propshaft speed is

below 175 rpm (5220 pulses/minute)). When the speed increases above 175 rpm, the EMC Duty Cycle is set to

the maximum value (88%) which applies the maximum available torque to the front axle.

Page 1258 of 1463

TRANSFER CASE (TOD) 5D2-51

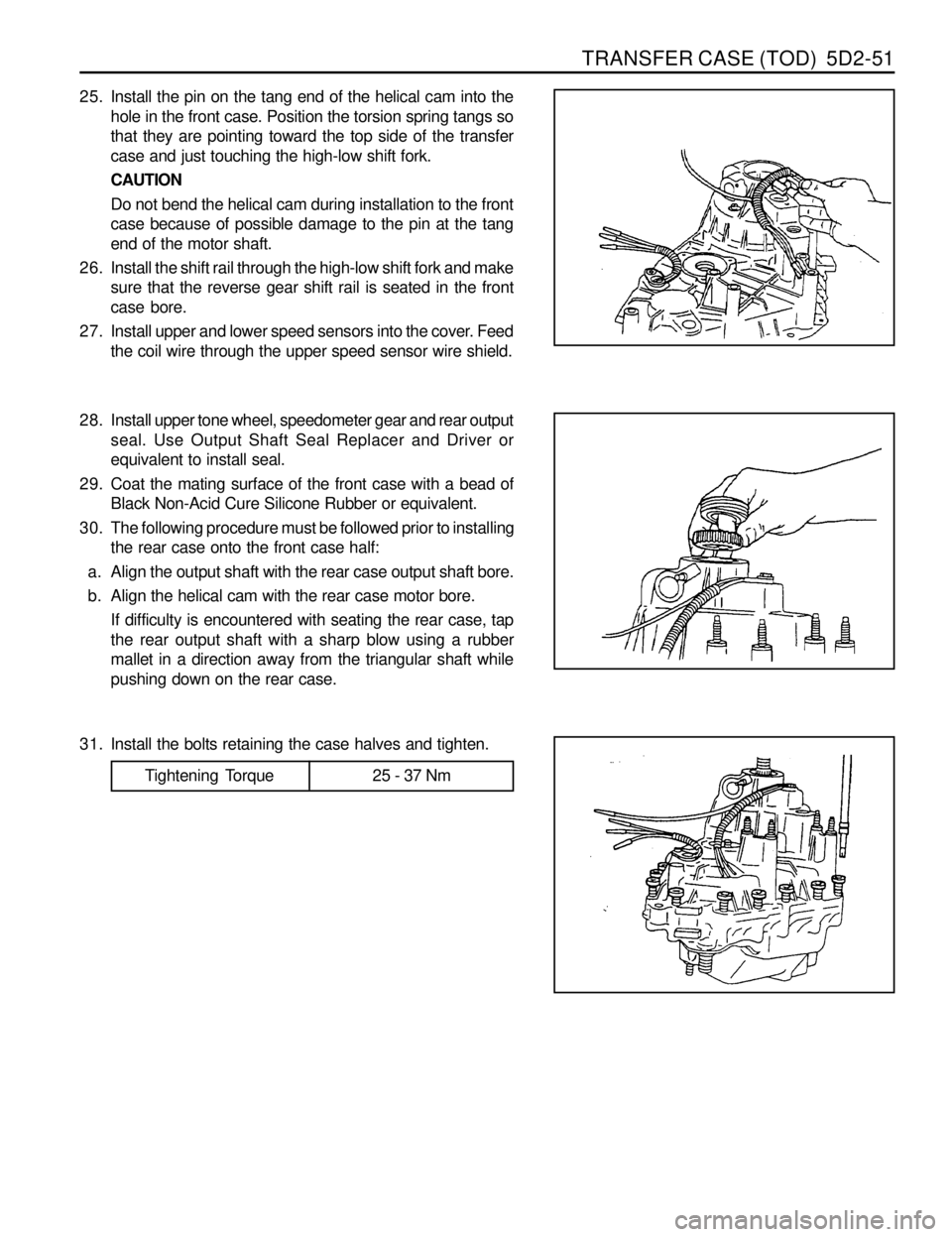

25. Install the pin on the tang end of the helical cam into the

hole in the front case. Position the torsion spring tangs so

that they are pointing toward the top side of the transfer

case and just touching the high-low shift fork.

CAUTION

Do not bend the helical cam during installation to the front

case because of possible damage to the pin at the tang

end of the motor shaft.

26. Install the shift rail through the high-low shift fork and make

sure that the reverse gear shift rail is seated in the front

case bore.

27. Install upper and lower speed sensors into the cover. Feed

the coil wire through the upper speed sensor wire shield.

28. Install upper tone wheel, speedometer gear and rear output

seal. Use Output Shaft Seal Replacer and Driver or

equivalent to install seal.

29. Coat the mating surface of the front case with a bead of

Black Non-Acid Cure Silicone Rubber or equivalent.

30. The following procedure must be followed prior to installing

the rear case onto the front case half:

a. Align the output shaft with the rear case output shaft bore.

b. Align the helical cam with the rear case motor bore.

If difficulty is encountered with seating the rear case, tap

the rear output shaft with a sharp blow using a rubber

mallet in a direction away from the triangular shaft while

pushing down on the rear case.

Tightening Torque 25 - 37 Nm 31. Install the bolts retaining the case halves and tighten.

Page 1272 of 1463

STEERING WHEEL AND COLUMN 6E-3

Removal & Installation Procedure

1. Remove the horn pad from the steering wheel and

disconnect the connectors .

2. Place an alignment marks on the column shaft end and

fixing nut and then remove the fixing nut.

Installation Notice

3. Remove the steering wheel.

4. Remove the combination switch upper cover .

Tightening Torque 50 - 80 Nm

5. Release the crash pad panel.

Notice

Remove the hood release wire and the other switch

connectors.

Page 1273 of 1463

6E-4 STEERING WHEEL AND COLUMN

6. Disconnect each connectors.

7. Remove the vacuum hose from the ignition switch(Diesel

only) .

9. Remove the lower shaft by removing the bolt of the steering

column shaft.

Installation Notice

Tightening Torque 9 - 14 Nm

8. Remove the combination switch assembly.

10. Remove the dash panel mounting bolts.

Installation Notice

Tightening Torque 30 - 40 Nm

Page 1274 of 1463

STEERING WHEEL AND COLUMN 6E-5

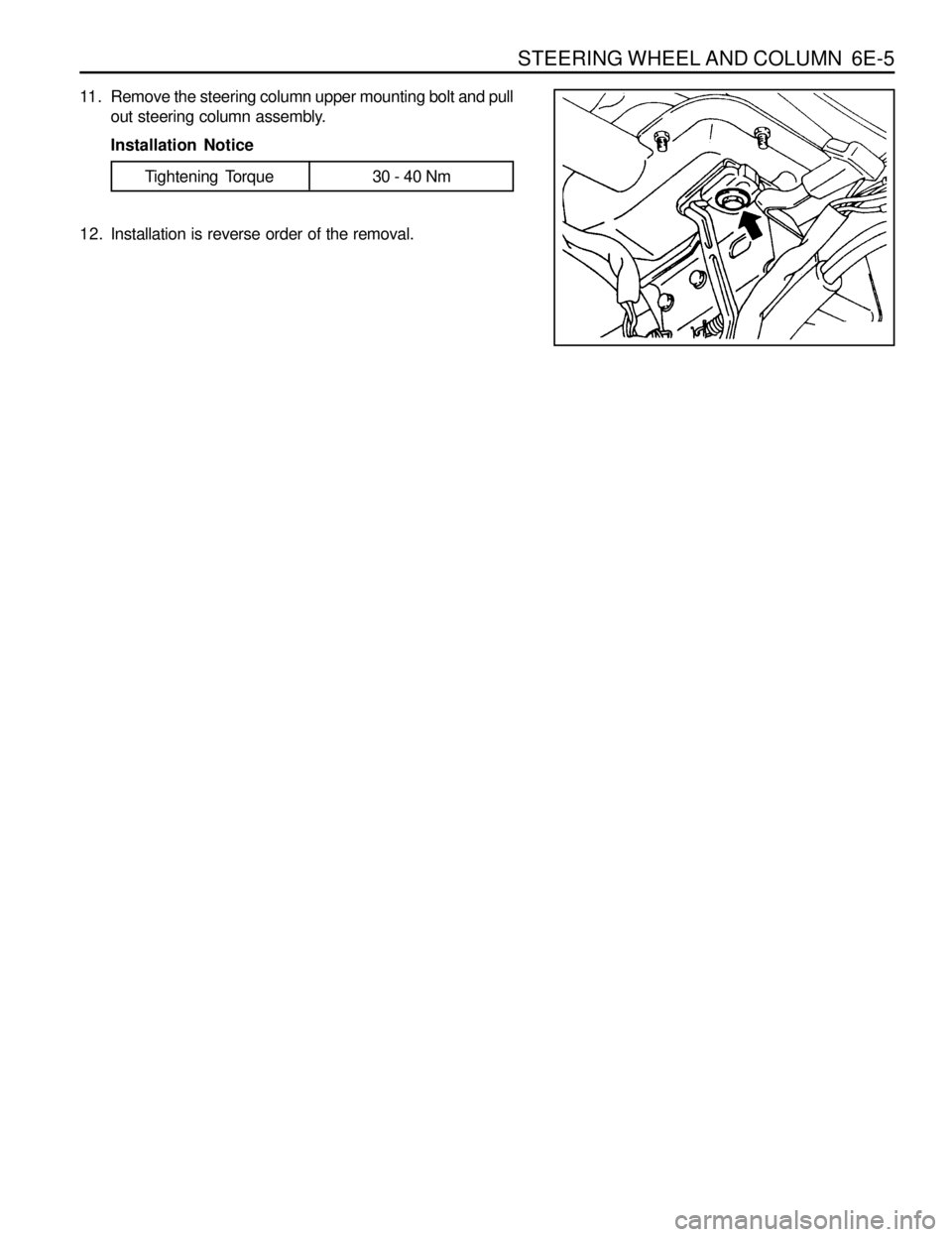

Tightening Torque 30 - 40 Nm 11. Remove the steering column upper mounting bolt and pull

out steering column assembly.

Installation Notice

12. Installation is reverse order of the removal.

Page 1322 of 1463

8B-18 SUPPLEMENTAL RESTRAINT SYSTEM(SRS)

MAINTENANCE AND REPAIR

ON-VEHICLE SERVICE

AIR BAG MODULE

Removal & Installation Procedure

1. Remove the steering wheel rid (LH,RH) with a screwdriver.

Installation Notice

Each position mark (LH,RH) is stamped on the inner surface

of the rids.

Tightening Torque 7 - 11 Nm

3. Disconnect the connectors and remove the air bag module.

4. Installation should follow the removal procedure in the

reverse order. 2. Unscrew the bolts from both sides.

Installation Notice