wheel torque SSANGYONG MUSSO 1998 Workshop User Guide

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1998, Model line: MUSSO, Model: SSANGYONG MUSSO 1998Pages: 1463, PDF Size: 19.88 MB

Page 868 of 1463

TIRES AND WHEELS 2E-7

lTo correct unbalance, install equal weights 180° opposite

each other, one on the inside of the wheel and one on

the outside, at the point of unbalance.

lBalance Weight

6. Cautions for installation and removal.

lClean the mounting surfaces of hub and wheel.

lDo not apply grease or oil on the nuts and bolts (It will

cause looseness and poor tightening).

lUsing a jack, lift up the tire about 3cm from the ground.

lTighten nuts in a criss-cross pattern 2-3 times.

10g

0.4oz20g

0.7oz30g

1.10oz40g

1.40oz50g

1.80oz60g

2.1oz

Steel : 80 - 120Nm

Aluminium : 110 - 130NmTighten Torque

Page 877 of 1463

FRONT DRIVE AXLE 3A-9

Removal & Installation Procedure

1. Remove the tire.

Installation Notice

Steel Wheel

Aluminum WheelTightening Torque80 - 120 Nm

110 - 130 Nm

2. Remove the autolocking hub vacuum hose.

3. With ABS

Remove the wheel speed sensor from the steering knuckle.

Installation Notice

4. Remove the mounting bolts and pull off the caliper assembly.

Installation Notice

Tightening Torque 6 - 8 Nm

Hose Bolt

Mounting BoltTightening Torque25 - 35 Nm

85 - 105 Nm

Notice

Be careful not to damage the brake hose.

Page 905 of 1463

REAR DRIVE AXLE 3D-7

Removal & Installation Procedure

1. Remove the tire.

Installation Notice

2. Release the parking brake.Steel Wheel

Aluminum Wheel

Tightening Torque

3. Remove the bolts and the brake caliper.

Installation Notice

Be careful not to damage the brake hose.

Tightening Torque 85 - 100 Nm

4. Remove the brake disc.

Notice

To remove the disc, install the bolts (M8 x 1.25) into the

service hole and uniformly tighten the bolts.

5. Disconnect the parking brake cable.

80 - 120 Nm

110 - 130 Nm

Page 922 of 1463

HYDRAULIC BRAKES 4A-7

MAINTENANCE AND REPAIR

ON-VEHICLE SERVICE

BLEEDING THE BRAKES

For Master Cylinder Replacement

1. Add oil after master cylinder replacement.

2. Run the engine and depress the brake pedal several times

to build pressure and then keep the pedal fully depressed.

3. Loosen the screws of primary and secondary pipe at the

master cylinder outlets to bleed air.

4. Repeat above step No.3 several times until there are no

more air bubbles.

5. Bleed air in the system at the hydraulic unit outlet pipe and

wheel if pressure building is not enough by depressing the

pedal only after above air bleeding.

For Caliper and Brake Hose Replacement

1. Check the oil level from the oil reservoir and refill if necessary.

2. Run the engine and depress the pedal several times to

build pressure and then keep the pedal fully depressed.

3. Connect a vinyl tube to the caliper breather and prepare a

container to coentain brake oil.

4. Loosen the breather screw until there are no more bubbles.

5. Bleed air in the system at four (4) wheels in order as shown

in right figure if pressure building is not enough by depressing

the pedal after above air bleeding.

Tightening Torque

9 - 14 Nm

Item

Front Bleeder Screw

Rear Bleeder Screw

Notice

lDo not reuse the bled brake fluid.

lAlways bleed the air after replacing brake fluid or

master cylinder, caliper, brake hose and pipe.

lAlways operate in normal order.

Page 941 of 1463

FRONT DISC BRAKES 4D-3

Removal & Installation Procedure

1. MANDO Brake

Tightening Torque 25 - 35 Nm

2. PBR Brake

Remove the eye-hose bolt and disconnect the hose.

Installation Notice

Tightening Torque 15 - 18 Nm

3. Remove the wheel speed sensor (for ABS vehicies).

Installation Notice

Tightening Torque 6 - 8 Nm

4. Remove the mounting bolts and then caliper assembly.

Installation Notice

Tightening Torque 85 - 105 Nm

Remove the hose mounting nut and disconnect the hose.

Installation Notice

Page 946 of 1463

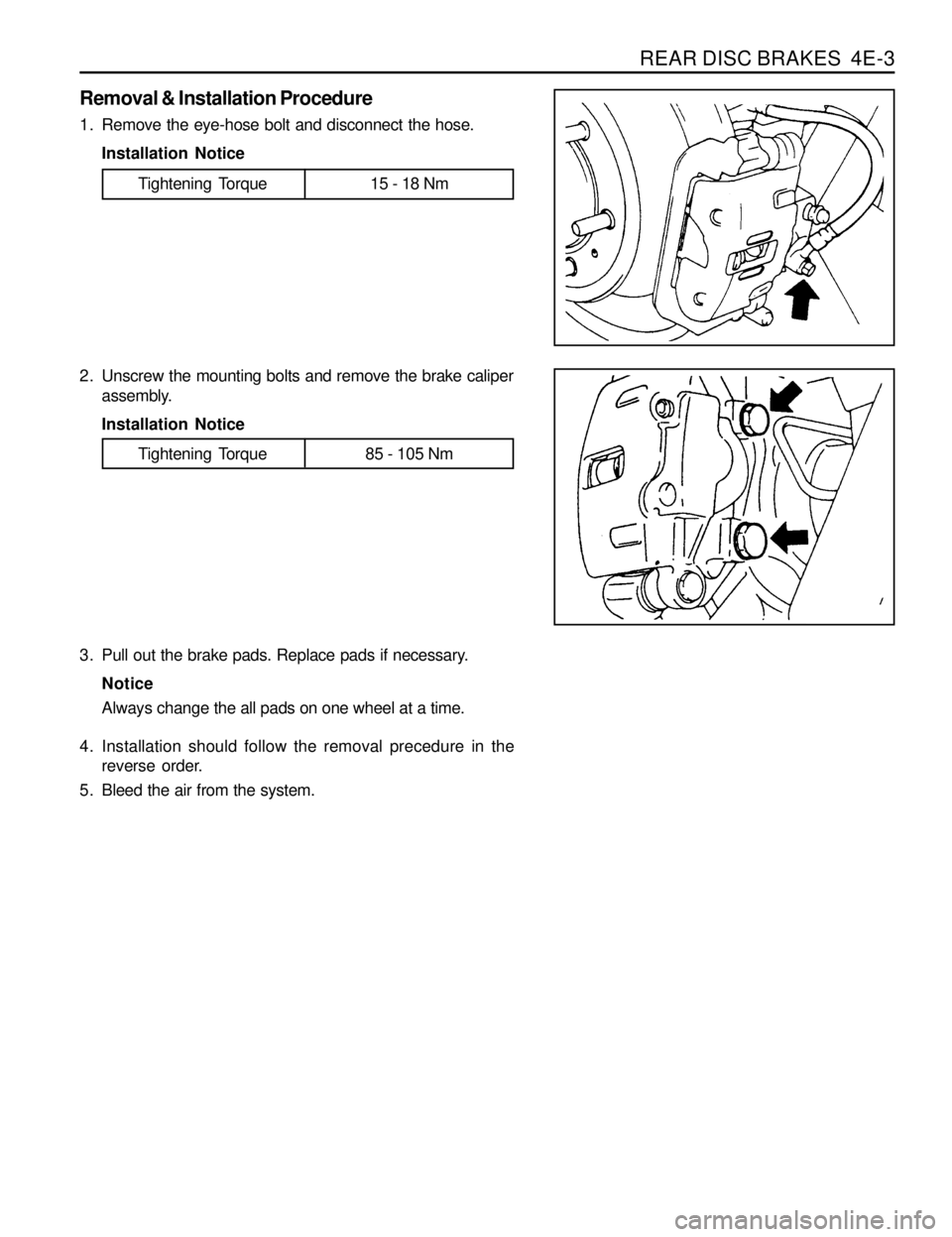

REAR DISC BRAKES 4E-3

Tightening Torque 15 - 18 Nm

Tightening Torque 85 - 105 Nm

Removal & Installation Procedure

1. Remove the eye-hose bolt and disconnect the hose.

Installation Notice

2. Unscrew the mounting bolts and remove the brake caliper

assembly.

Installation Notice

3. Pull out the brake pads. Replace pads if necessary.

Notice

Always change the all pads on one wheel at a time.

4. Installation should follow the removal precedure in the

reverse order.

5. Bleed the air from the system.

Page 954 of 1463

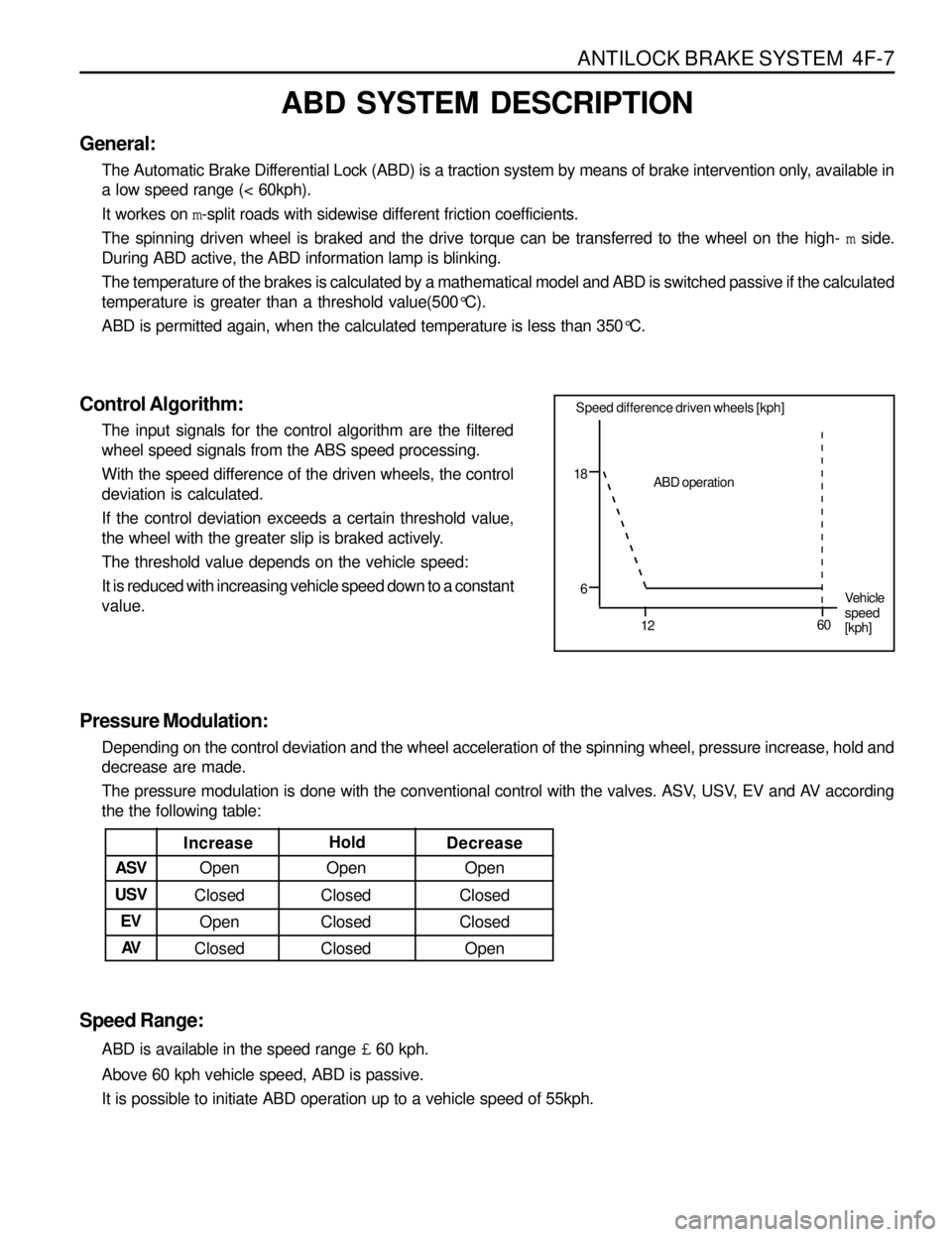

ANTILOCK BRAKE SYSTEM 4F-7

ABD SYSTEM DESCRIPTION

General:

The Automatic Brake Differential Lock (ABD) is a traction system by means of brake intervention only, available in

a low speed range (< 60kph).

It workes on m-split roads with sidewise different friction coefficients.

The spinning driven wheel is braked and the drive torque can be transferred to the wheel on the high- m side.

During ABD active, the ABD information lamp is blinking.

The temperature of the brakes is calculated by a mathematical model and ABD is switched passive if the calculated

temperature is greater than a threshold value(500°C).

ABD is permitted again, when the calculated temperature is less than 350°C.

Control Algorithm:

The input signals for the control algorithm are the filtered

wheel speed signals from the ABS speed processing.

With the speed difference of the driven wheels, the control

deviation is calculated.

If the control deviation exceeds a certain threshold value,

the wheel with the greater slip is braked actively.

The threshold value depends on the vehicle speed:

It is reduced with increasing vehicle speed down to a constant

value.

Pressure Modulation:

Depending on the control deviation and the wheel acceleration of the spinning wheel, pressure increase, hold and

decrease are made.

The pressure modulation is done with the conventional control with the valves. ASV, USV, EV and AV according

the the following table:

Speed Range:

ABD is available in the speed range £ 60 kph.

Above 60 kph vehicle speed, ABD is passive.

It is possible to initiate ABD operation up to a vehicle speed of 55kph.

Increase

Open Open Open ASVDecrease Hold

Closed Closed Closed

Closed Closed Open

Open Closed Closed USV

EV

AV

Speed difference driven wheels [kph]

18

6

1260ABD operation

Vehicle

speed

[kph]

Page 1019 of 1463

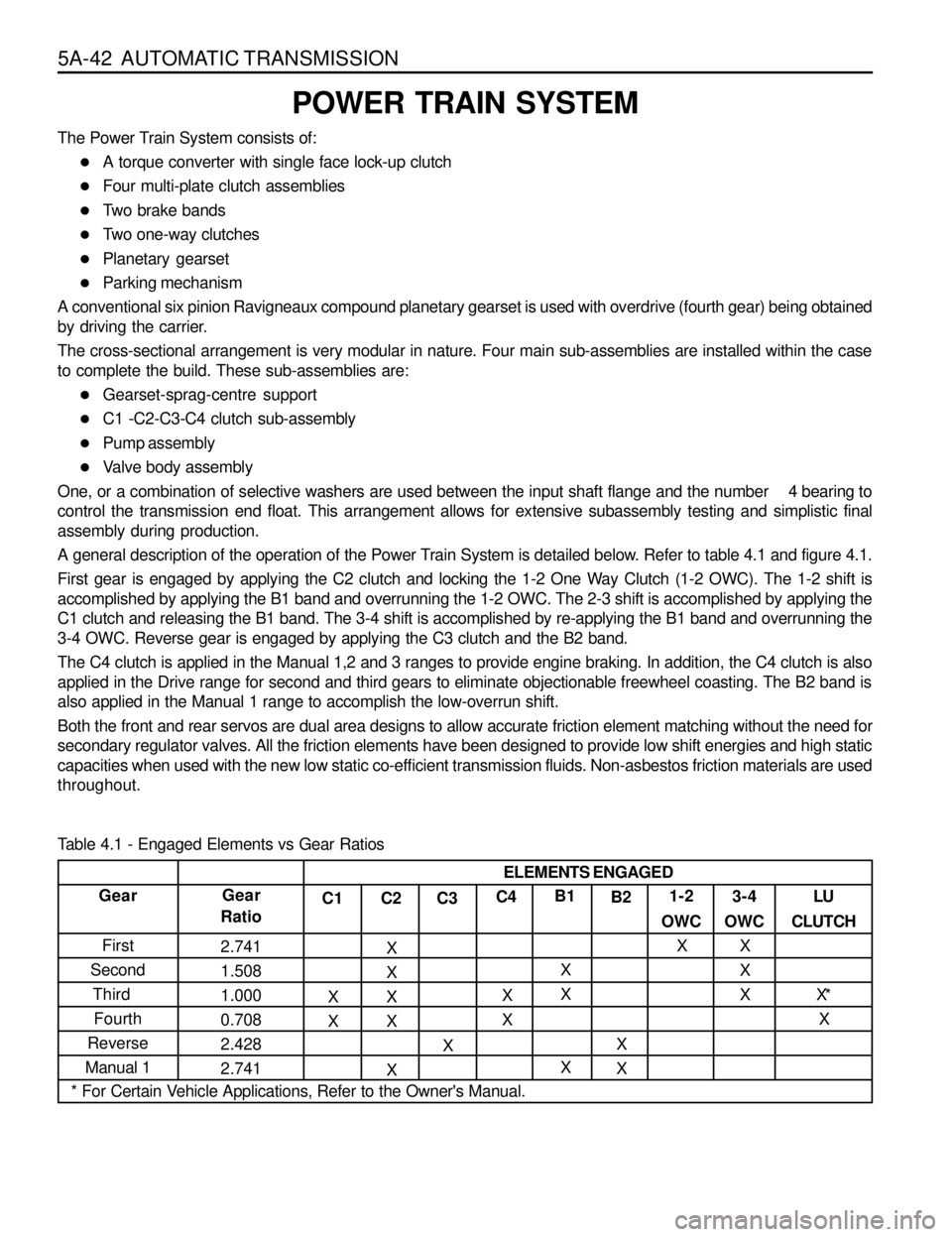

5A-42 AUTOMATIC TRANSMISSION

POWER TRAIN SYSTEM

The Power Train System consists of:

lA torque converter with single face lock-up clutch

lFour multi-plate clutch assemblies

lTwo brake bands

lTwo one-way clutches

lPlanetary gearset

lParking mechanism

A conventional six pinion Ravigneaux compound planetary gearset is used with overdrive (fourth gear) being obtained

by driving the carrier.

The cross-sectional arrangement is very modular in nature. Four main sub-assemblies are installed within the case

to complete the build. These sub-assemblies are:

lGearset-sprag-centre support

lC1 -C2-C3-C4 clutch sub-assembly

lPump assembly

lValve body assembly

One, or a combination of selective washers are used between the input shaft flange and the number 4 bearing to

control the transmission end float. This arrangement allows for extensive subassembly testing and simplistic final

assembly during production.

A general description of the operation of the Power Train System is detailed below. Refer to table 4.1 and figure 4.1.

First gear is engaged by applying the C2 clutch and locking the 1-2 One Way Clutch (1-2 OWC). The 1-2 shift is

accomplished by applying the B1 band and overrunning the 1-2 OWC. The 2-3 shift is accomplished by applying the

C1 clutch and releasing the B1 band. The 3-4 shift is accomplished by re-applying the B1 band and overrunning the

3-4 OWC. Reverse gear is engaged by applying the C3 clutch and the B2 band.

The C4 clutch is applied in the Manual 1,2 and 3 ranges to provide engine braking. In addition, the C4 clutch is also

applied in the Drive range for second and third gears to eliminate objectionable freewheel coasting. The B2 band is

also applied in the Manual 1 range to accomplish the low-overrun shift.

Both the front and rear servos are dual area designs to allow accurate friction element matching without the need for

secondary regulator valves. All the friction elements have been designed to provide low shift energies and high static

capacities when used with the new low static co-efficient transmission fluids. Non-asbestos friction materials are used

throughout.

Gear

First

Second

Third

Fourth

Reverse

Manual 1Gear

Ratio

2.741

1.508

1.000

0.708

2.428

2.741C1

X

XC2

X

X

X

X

XC3

XC4

X

XB1

X

X

XB2

X

X1-2

OWC

X3-4

OWC

X

X

XLU

CLUTCH

X*

X ELEMENTS ENGAGED

* For Certain Vehicle Applications, Refer to the Owner's Manual. Table 4.1 - Engaged Elements vs Gear Ratios

Page 1038 of 1463

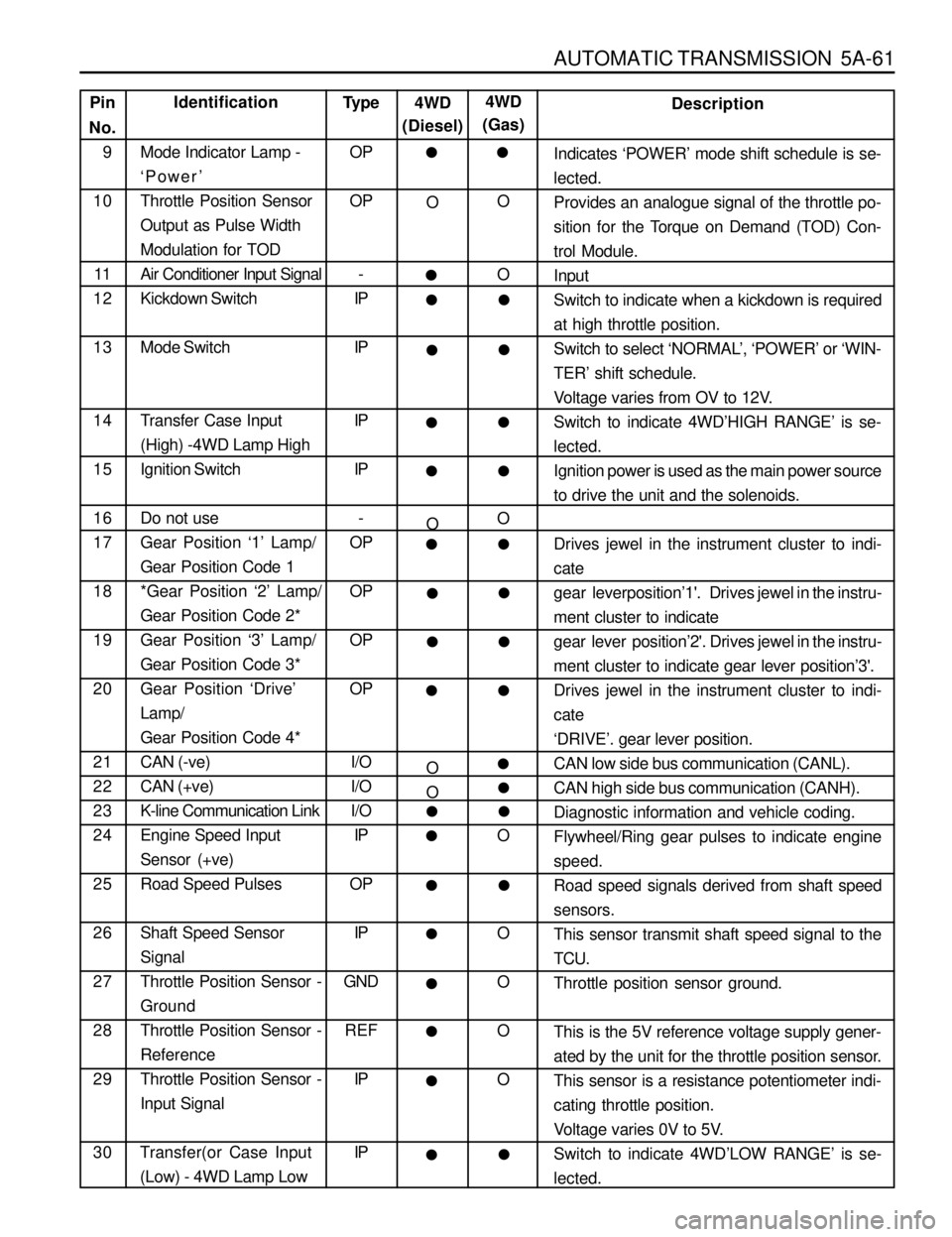

AUTOMATIC TRANSMISSION 5A-61

Pin

No.

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30Identification

Mode Indicator Lamp -

‘Power’

Throttle Position Sensor

Output as Pulse Width

Modulation for TOD

Air Conditioner Input Signal

Kickdown Switch

Mode Switch

Transfer Case Input

(High) -4WD Lamp High

Ignition Switch

Do not use

Gear Position ‘1’ Lamp/

Gear Position Code 1

*Gear Position ‘2’ Lamp/

Gear Position Code 2*

Gear Position ‘3’ Lamp/

Gear Position Code 3*

Gear Position ‘Drive’

Lamp/

Gear Position Code 4*

CAN (-ve)

CAN (+ve)

K-line Communication Link

Engine Speed Input

Sensor (+ve)

Road Speed Pulses

Shaft Speed Sensor

Signal

Throttle Position Sensor -

Ground

Throttle Position Sensor -

Reference

Throttle Position Sensor -

Input Signal

Transfer(or Case Input

(Low) - 4WD Lamp LowType

OP

OP

-

IP

IP

IP

IP

-

OP

OP

OP

OP

I/O

I/O

I/O

IP

OP

IP

GND

REF

IP

IPDescription

Indicates ‘POWER’ mode shift schedule is se-

lected.

Provides an analogue signal of the throttle po-

sition for the Torque on Demand (TOD) Con-

trol Module.

Input

Switch to indicate when a kickdown is required

at high throttle position.

Switch to select ‘NORMAL’, ‘POWER’ or ‘WIN-

TER’ shift schedule.

Voltage varies from OV to 12V.

Switch to indicate 4WD’HIGH RANGE’ is se-

lected.

Ignition power is used as the main power source

to drive the unit and the solenoids.

Drives jewel in the instrument cluster to indi-

cate

gear leverposition’1'. Drives jewel in the instru-

ment cluster to indicate

gear lever position’2'. Drives jewel in the instru-

ment cluster to indicate gear lever position’3'.

Drives jewel in the instrument cluster to indi-

cate

‘DRIVE’. gear lever position.

CAN low side bus communication (CANL).

CAN high side bus communication (CANH).

Diagnostic information and vehicle coding.

Flywheel/Ring gear pulses to indicate engine

speed.

Road speed signals derived from shaft speed

sensors.

This sensor transmit shaft speed signal to the

TCU.

Throttle position sensor ground.

This is the 5V reference voltage supply gener-

ated by the unit for the throttle position sensor.

This sensor is a resistance potentiometer indi-

cating throttle position.

Voltage varies 0V to 5V.

Switch to indicate 4WD’LOW RANGE’ is se-

lected. 4WD

(Diesel)

O

O

O

O

l

l

l

4WD

(Gas)

O

O

O

O

O

O

O

O

l

l

l

ll

ll

ll

ll

ll

ll

l

l

ll

l

ll

l

l

l

l

ll l

Page 1163 of 1463

5C-10 CLUTCH

Removal & Installation Procedure

1. Remove the starter motor. Install the special tool to the

flywheel through the starter motor mounting holes.

Tightening Torque

47 Nm

Engine Lock 602 589 00 40 00

2. Unscren the release cylinder mounting bolts and remove

the release cylinder.

Installation Notice

3. Unscrew the clutch housing bolts and remove the clutch

housing, release fork and release bearing.

Installation Notice

4. Insert the centering pin into the clutch spline.

Loosen the clutch cover bolts 1/2 turn in crisscross sequence

until the spring tension is released.

Notice

Do not remove the bolts at a time, or clutchcover can be

damaged or deformed.

Centering Pin 661 589 00 15 00

Tightening Torque

30 - 40 Nm