ESP SSANGYONG MUSSO 1998 Workshop Owner's Guide

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1998, Model line: MUSSO, Model: SSANGYONG MUSSO 1998Pages: 1463, PDF Size: 19.88 MB

Page 1238 of 1463

TRANSFER CASE (TOD) 5D2-31

Position incoder and position 1,2,3,4 malfunction

:Fault code®1750,1751,1752,1753, 1754

lPhenomenon

The ‘4WD check’ lamp can not go out when the ignition

switch positioned to ‘ON’.

The fault code display 1750, 1751, 1752, 1753, 1754 by

diagnosis of SCAN-100.

lCause

The portion of position incoder malfunction, each wiring is

shorted with ground.

Ye s

No

F1

Ye s

No

Ye s

No F2Test Stage / Contents

Result

Stage Test Contents and ProcedureSpecified Value

/Yes/NoCountermeasure

Check the installation condition of connector.

1. Check the installation condition between 30 pin connector

of TOD control unit and motor connector of T/C portion.

- Is it installed properly ?

2. If the connector installation is improper, install properly

and then execute follow procedure.

a. Delete the all fault code from memory by scan scope.

b. Turn off ignition switch.

c.Turn on ignition switch.

d. Rediagnosis the system.

- Does the fault codes display one or more among

1750 ~ 1754.

Check the each wiring whether it is shorted or not.

1. Turn off the ignition switch

2. Detach the 30 pin connector of TOD control unit.

3. Perform short test each connector, No.27 (Position 1),

No.10 (Position 2), No.28 (Position 3),No.30 (Position

4), No.6 with body.

- Is there resistance of 0W?Perform F2 stage

Perform F1-2 stage

Perform F2 stage

Normal system

Repair or replace

due to wiring short

1. Replace the

motor Ass’y due

the defective

position incoder

portion.

2. And then, perform

F1-2 stage.

Page 1239 of 1463

5D2-32 TRANSFER CASE (TOD)

lPhenomenon

“4L” lamp on cluster continuous blinking and can not go off,

when operated 4H/4L switch as 4L« 4H.

lCause

Shifting failure.

1. Stop the vehicle

2. Return the 4H/4L switch to first position (before

operating).

- The blinking of 4L indicator lamp is stopped.

Note

If the first position before switch operating is ‘4L’,

lamp goes on after stopping blink, otherwise it

is ‘4H’ lamp goes off.

3. Reoperate 4H/4L switch to 4H«4L on the below

condition.

• Positioned Auto T/M to neutral.

• At this time, keep the neutral position for 2 second.

• Stop the vehicle (The R.P.M of front & Rear propeller

shaft is below 80).

4. ‘4L’ lamp blinks based on 0.3 second.

5. When the shifting is engaged, the blinking of ‘4L’ lamp

is stopped.

-4H®4L : goes on ‘4L’ lamp

-4L®4H : goes on ‘4L’ lamp

6. When the ‘4L’ indicator lamp continuous blinking,

repositioned to first position and diagnose the system

and then fix it.Ye s

No

G1

Ye s

No Test Stage / Contents

Result

Stage Test Contents and ProcedureSpecified Value

/Yes/NoCountermeasure

Perform 2 stage

Diagnose TOD

control unit

Normal system

Perform system test

Auto T/N positioned

to neutral

Check/Replace the

relay

Page 1240 of 1463

TRANSFER CASE (TOD) 5D2-33

9 - 16 Vdc

6 - 16 Vdc

2 mA

1 A

7 A

20 A

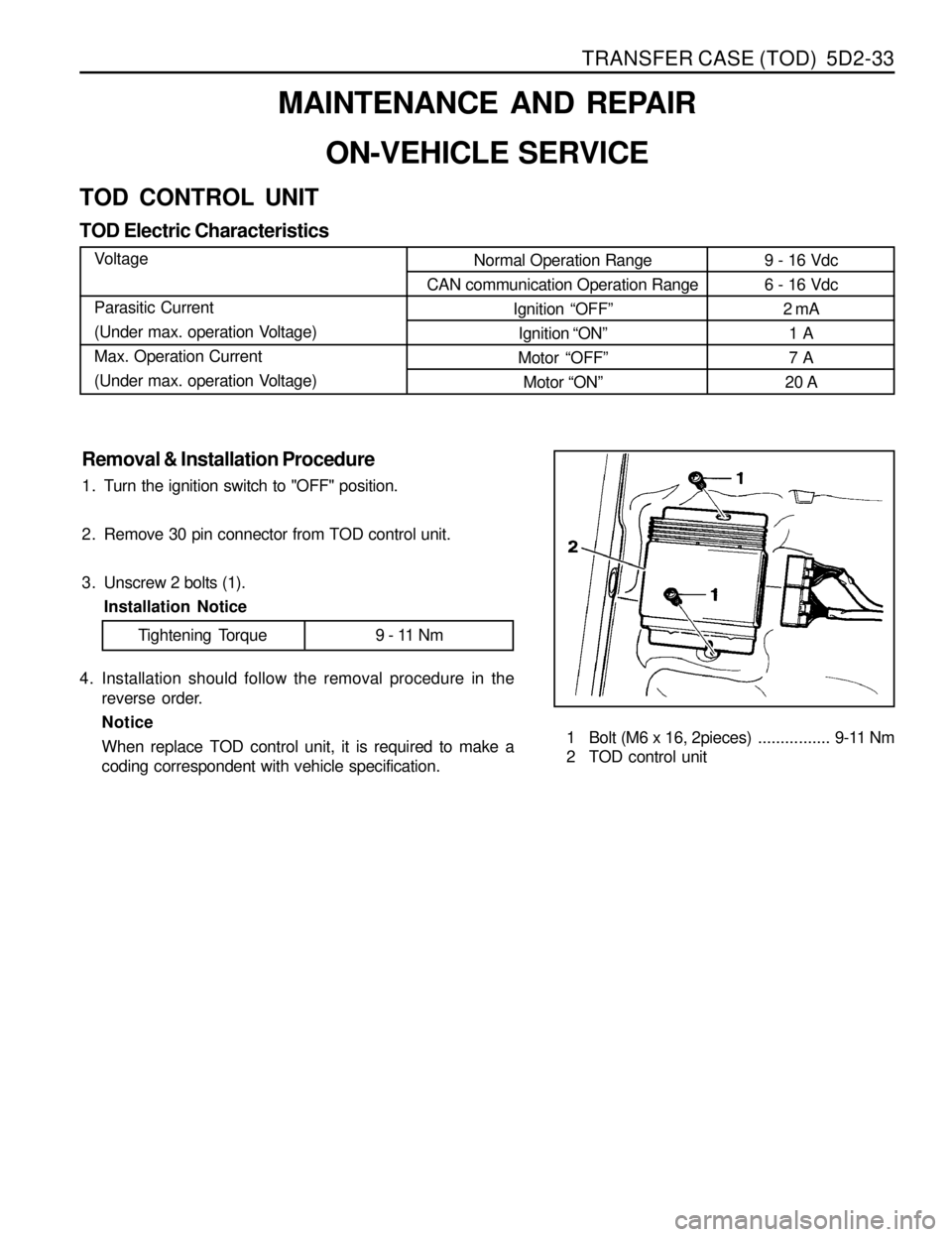

Removal & Installation Procedure

1. Turn the ignition switch to "OFF" position.

2. Remove 30 pin connector from TOD control unit.

3. Unscrew 2 bolts (1).

Installation Notice

1 Bolt (M6 x 16, 2pieces)................ 9-11 Nm

2 TOD control unit

MAINTENANCE AND REPAIR

ON-VEHICLE SERVICE

TOD CONTROL UNIT

TOD Electric Characteristics

Voltage

Parasitic Current

(Under max. operation Voltage)

Max. Operation Current

(Under max. operation Voltage)Normal Operation Range

CAN communication Operation Range

Ignition “OFF”

Ignition “ON”

Motor “OFF”

Motor “ON”

4. Installation should follow the removal procedure in the

reverse order.

Notice

When replace TOD control unit, it is required to make a

coding correspondent with vehicle specification.

Tightening Torque 9 - 11 Nm