battery SSANGYONG MUSSO 1998 Workshop Workshop Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1998, Model line: MUSSO, Model: SSANGYONG MUSSO 1998Pages: 1463, PDF Size: 19.88 MB

Page 684 of 1463

M161 ENGINE CONTROLS 1F2-35

Location

Engine ECU is located at the inside of cowl side trim in right

bottom of instrument panel of passenger side.

Removal & Installation Procedure

1. Turn the ignition switch to "OFF" position.

2. Disconnect the battery negative cable

3. Remove the cowl side trim form passenger side.

4. Unscrew four securing nuts for ECU from mounting bracket.

Installation Notice

5. Pulling out the ECU from bracket.

6. Disconnect the vehicle side coupling(B).

7. Installation should follow the removal procedure in the

reverse order.

Tightening Torque 9 - 11 Nm

Page 685 of 1463

1F2-36 M161 ENGINE CONTROLS

Pin No.Abbreviation Description

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20-

TM.50

-

-

GND

-

LSH2

-

LSH1

TM.31

TM.87

TM.30

WFS I/O

WFS O

-

GND

LS1

-

GND

LS2 -

Starter motor TM.50

-

-

Electronic ground

-

Lambda probe 2 heating

-

Lambda probe 1 heating

Power ground TM.31

V-BATTERY TM.87

V-BATTERY TM.30

Immobilizer crypto read

Immobilizer crypto write

-

Lambda probe 1 ground

Lambda probe 1 signal

-

Lambda probe 2 ground

Lambda probe 2 signal

ECU Pin Numbers and Descriptions

Vehecle Connector

Page 689 of 1463

1F2-40 M161 ENGINE CONTROLS

Application

Pin No.Abbreviation Description

-

Starter motor TM.50

-

-

Electronic ground

-

Lambda probe 2 heating

-

Lambda probe 1 heating

Power ground TM.31

V-BATTERY TM.87

V-BATTERY TM.30

Immobilizer crypto read

Immobilizer crypto write

-

Lambda probe 1 ground

Lambda probe 1 signal

-

-

-

Brake switch

-

-

-

-

-

Air conditioning clutch relay

-

-

-1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30-

TM.50

-

-

GND

-

LSH2

-

LSH1

TM.31

TM.87

TM.30

WFS I/O

WFS O

-

GND

LS1

-

-

-

BRS

-

-

-

-

-

KLIKU

-

-

--

l

-

-

l

-

-

-

l

l

l

l

l

l

-

l

l

-

-

-

¡

-

-

-

-

-

l

-

-

--

l

-

-

l

-

-

-

l

l

l

l

l

l

-

l

l

-

-

-

¡

-

-

-

-

-

l

-

-

-

l: Standard, ¡: OptionE23 ENG,

4speed A/T E23 ENG,

5speed A/T

Page 693 of 1463

1F2-44 M161 ENGINE CONTROLS

Removal & Installation Procedure

· ·· ·

·When removing the ECU only

1. Turn the ignition switch to "OFF" position.

2. Disconnect the negative battery cable.

3. Disconnect the couplings from ECU.

4. Unscrew the left and right bolt (3) on bolt (1) and auxiliarly

bracket and remove the auxiliarly bracket from the bracket

assembly (2).

Installation Notice

5. Unscrew the four bolts (5) and disconnect the ECU (6) from

the bracket assenbly.

Installation Notice

6. Installation should follow the removal procedure in the

reverse order.

Tightening Torque6 - 8 Nm

5 - 7 Nm(1)

(3)

Tightening Torque 5 - 7 Nm

8. Unscrew the bolts (5) and disconnect the ECU (6) from the

bracket assenbly.

Installation Notice · ·· ·

·When Removing the ECU with ABS or ABS/ASR Unit

1. Turn the ignition switch to "OFF" position.

2. Disconnect the negative battery cable.

3. Disconnect the couplings from ECU.

4. Disconnect the coupling from ABS or ABS/ASR unit.

5. Unscrew the bolt (1) and the left and right flange nuts.

6. Remove the ECU with ABS or ABS/ASR unit assembly.

7. Unscrew the left and right bolt (3) on the auxiliary bracket

and remove the auxiliary bracket from the bracket assembly.

Installation Notice

Tightening Torque 6 - 8 Nm

Tightening Torque 5 - 7 Nm

Tightening Torque 5 - 7 Nm

9. Installation should follow the removal procedure in the

reverse order.

Page 699 of 1463

1F2-50 M161 ENGINE CONTROLS

Tightening Torque

22.5 - 27.5 Nm

Tightening Torque22.5 - 27.5 Nm

Removal & Installation Procedure

1. Discharge the fuel pressure from the fuel pressure test

connector by pushing service valve (arrow).

2. Disconnect the battery ground cable.

3. Disconnect the vacuum hose from the fuel pressure

regulator.

4. Disconnect the cable from ignition coil.

5. Remove the fuel return and supply line.

Installation Notice

Notice

lFor removal, cover around parts with cloths not to

bestained by fuel.

lIn case of checking the injector only, do not remove the

fuel return and supply line.

6. Remove the four injector connectors (arrows).

7. Unscrew the two combination bolts (8).

Installation Notice

Page 709 of 1463

1F2-60 M161 ENGINE CONTROLS

Tools Required

661 589 00 46 00 Cap Remover

Removal & Installation Procedure

1. Disconnect the negative battery cable.

2. Disconnect the harness connector (1).

3. Disconnect the fuel supply (6) and return (5) pipes.

4. Using a special tool, Unscrew the eight fuel retaining bolts

and remove the pump from fuel tank.

Notice

Check the condition of the seal and replace if necessary.

Drain the fuel before removing the pump.

Page 730 of 1463

SECTION 1F3

OM600 ENGINE CONTROLS

Specifications . . . . . . . . . . . . . . . . . . . . . . . 1F3-1

Fastener Tightening Specifications . . . . . . . . 1F3-1

Maintenance and Repair . . . . . . . . . . . . . . 1F3-2

On-Vehicle Service . . . . . . . . . . . . . . . . . . . . 1F3-2

Fuel System . . . . . . . . . . . . . . . . . . . . . . . . . 1F3-2

Fuel Injection Pump Coding . . . . . . . . . . . . . 1F3-3

Fuel Tank . . . . . . . . . . . . . . . . . . . . . . . . . . . 1F3-4

Vacuum Control System Test . . . . . . . . . . . . 1F3-5

Vacuum Pump(Sectional View) . . . . . . . . . . 1F3-10

Vacuum Pump Test . . . . . . . . . . . . . . . . . . . 1F3-11

Vacuum Pump . . . . . . . . . . . . . . . . . . . . . . 1F3-13

Vacuum Unit Replacement . . . . . . . . . . . . . 1F3-15Idle Speed Adjustment . . . . . . . . . . . . . . . . 1F3-16

Fuel Pump Test . . . . . . . . . . . . . . . . . . . . . . 1F3-18

Fuel Pump . . . . . . . . . . . . . . . . . . . . . . . . . 1F3-21

Injection Nozzle Test . . . . . . . . . . . . . . . . . . 1F3-22

Injection Nozzles . . . . . . . . . . . . . . . . . . . . . 1F3-25

Injection Nozzle Repair . . . . . . . . . . . . . . . . 1F3-27

Removal and Installation of

Injection Timing Device . . . . . . . . . . . . . . 1F3-30

Injection Timing Device . . . . . . . . . . . . . . . . 1F3-35

Start of Delivery Test

(Position Sensor, RIV Method) . . . . . . . . . 1F3-37

Fuel Injection Pump . . . . . . . . . . . . . . . . . . 1F3-46

TABLE OF CONTENTS

Caution: Disconnect the negative battery cable before removing or installing any electrical unit or when a

tool or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable

will help prevent personal injury and damage to the vehicle. The ignition must also be in LOCK unless otherwise

noted.

SPECIFICATIONS

FASTENER TIGHTENING SPECIFICATIONS

Application

Fuel Tank Mounting Nut

Fuel Pump Pressure Line

Fuel Injection Nozzle

Fuel Injection Pipe

Nozzle Tensioning Nut

Screw Plug

Left-Hand Thread BoltN·m

28 - 47

13

35 - 40

18

80

30

46

Page 766 of 1463

OM600 ENGINE CONTROLS 1F3-37

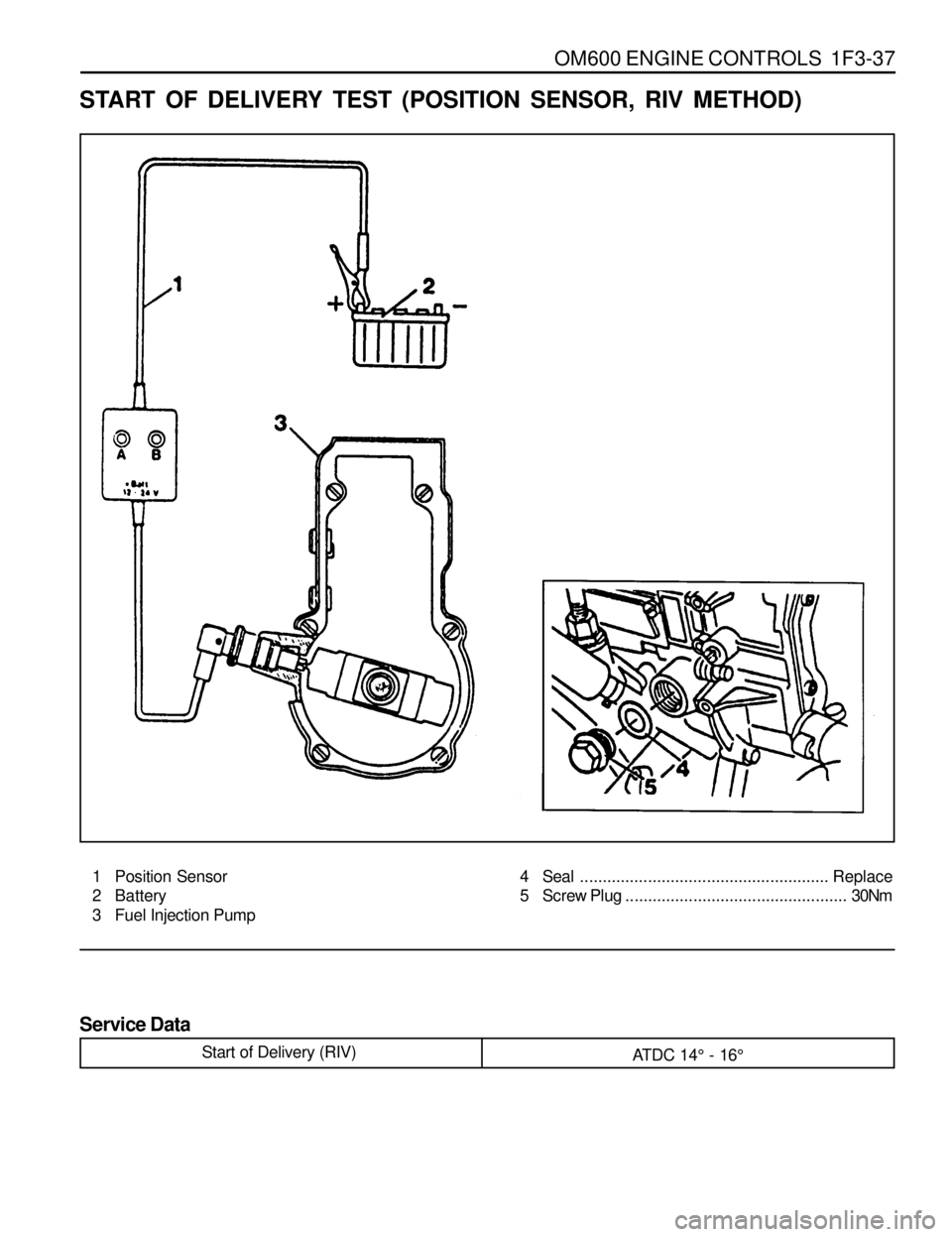

START OF DELIVERY TEST (POSITION SENSOR, RIV METHOD)

1 Position Sensor

2 Battery

3 Fuel Injection Pump4 Seal....................................................... Replace

5 Screw Plug.................................................30Nm

Service Data

Start of Delivery (RIV)

ATDC 14° - 16°

Page 767 of 1463

1F3-38 OM600 ENGINE CONTROLS

Tools Required

617 589 08 21 00 Position Sensor

Test Procedure

1. Remove the screw plug (5) and seal (4) and collect oil in a

suitable vessel.

2. Install the position sensor (1) into the governor housing of

the injection pump to be the guide pin of the position sensor

facing up.

3. Connect the battery terminal of position sensor (1) to positive

terminal (+) of battery.

Position Sensor 617 589 08 21 00

4. Rotate the crankshaft by hand (in direction of engine rotation)

until the lamp ‘B’ lights up. Rotate the crankshaft carefully

further until both lamps ‘A and B’ come on. In this position,

check the Rl value on the crankshaft vibration damper.

Notice

If only lamp ‘A’ lights up, repeat the test and if out of

specification, adjust start of delivery.

Specification ATDC 14° - 16°

Page 768 of 1463

OM600 ENGINE CONTROLS 1F3-39

Digital Tester, RIV Method

(Connection Diagram for Testers Without Adapter)

1 Fuel Injection Pump

2 Rl Sensor

3 Digital Tester4 TDC Pulse Sender Unit

5 Battery