change wheel SSANGYONG MUSSO 1998 Workshop Repair Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1998, Model line: MUSSO, Model: SSANGYONG MUSSO 1998Pages: 1463, PDF Size: 19.88 MB

Page 19 of 1463

GENERAL INFORMATION 0B-7

MAINTENANCE AND REPAIR

MAINTENANCE AND LUBRICATION

Fuel Filter Replacement

Replace the engine fuel filter every.

lGasoline Engine : 60,000km (36,000 miles)

lDiesel Engine : 45,000km (24,000 miles)

Spark Plug Replacement

Replace spark plugs with same type.

lType : BOSCH : F8DC4

BERU : 14F-8DU4

Champion : C11YCC

lGap : 0.8 ± 0.1 mm

Spark Plug Wire Replacement

Clean wires and inspect them for burns, cracks or other

damage. Check the wire boot fit at the Distributor and at

the spark plugs. Replace the wires as needed.

Brake System Service

Check the disc brake pads or the drum brake linings.

Check the pad and the lining thickness carefully.

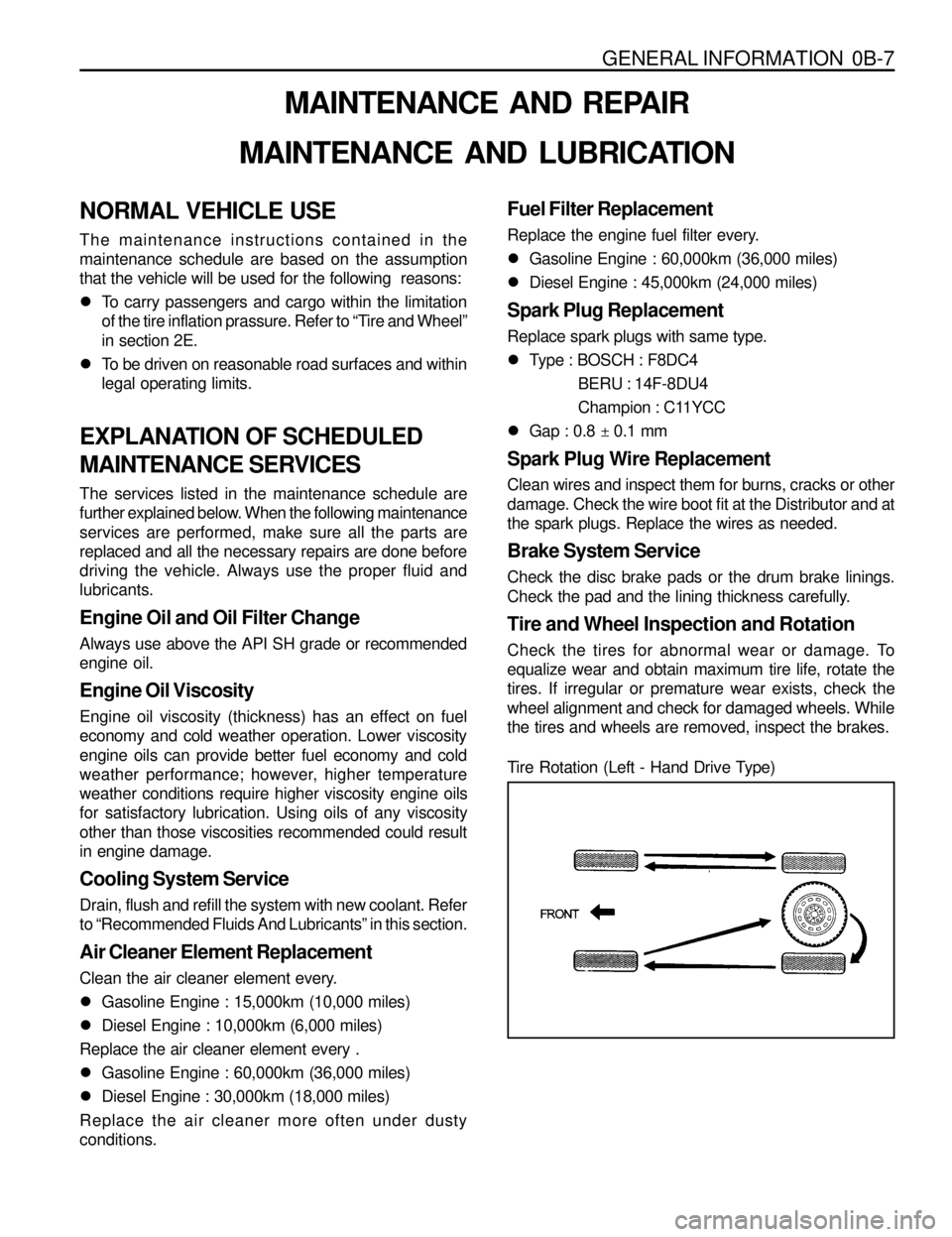

Tire and Wheel Inspection and Rotation

Check the tires for abnormal wear or damage. To

equalize wear and obtain maximum tire life, rotate the

tires. If irregular or premature wear exists, check the

wheel alignment and check for damaged wheels. While

the tires and wheels are removed, inspect the brakes.

NORMAL VEHICLE USE

The maintenance instructions contained in the

maintenance schedule are based on the assumption

that the vehicle will be used for the following reasons:

lTo carry passengers and cargo within the limitation

of the tire inflation prassure. Refer to “Tire and Wheel”

in section 2E.

lTo be driven on reasonable road surfaces and within

legal operating limits.

EXPLANATION OF SCHEDULED

MAINTENANCE SERVICES

The services listed in the maintenance schedule are

further explained below. When the following maintenance

services are performed, make sure all the parts are

replaced and all the necessary repairs are done before

driving the vehicle. Always use the proper fluid and

lubricants.

Engine Oil and Oil Filter Change

Always use above the API SH grade or recommended

engine oil.

Engine Oil Viscosity

Engine oil viscosity (thickness) has an effect on fuel

economy and cold weather operation. Lower viscosity

engine oils can provide better fuel economy and cold

weather performance; however, higher temperature

weather conditions require higher viscosity engine oils

for satisfactory lubrication. Using oils of any viscosity

other than those viscosities recommended could result

in engine damage.

Cooling System Service

Drain, flush and refill the system with new coolant. Refer

to “Recommended Fluids And Lubricants” in this section.

Air Cleaner Element Replacement

Clean the air cleaner element every.

lGasoline Engine : 15,000km (10,000 miles)

lDiesel Engine : 10,000km (6,000 miles)

Replace the air cleaner element every .

lGasoline Engine : 60,000km (36,000 miles)

lDiesel Engine : 30,000km (18,000 miles)

Replace the air cleaner more often under dusty

conditions.

Tire Rotation (Left - Hand Drive Type)

Page 21 of 1463

GENERAL INFORMATION 0B-9

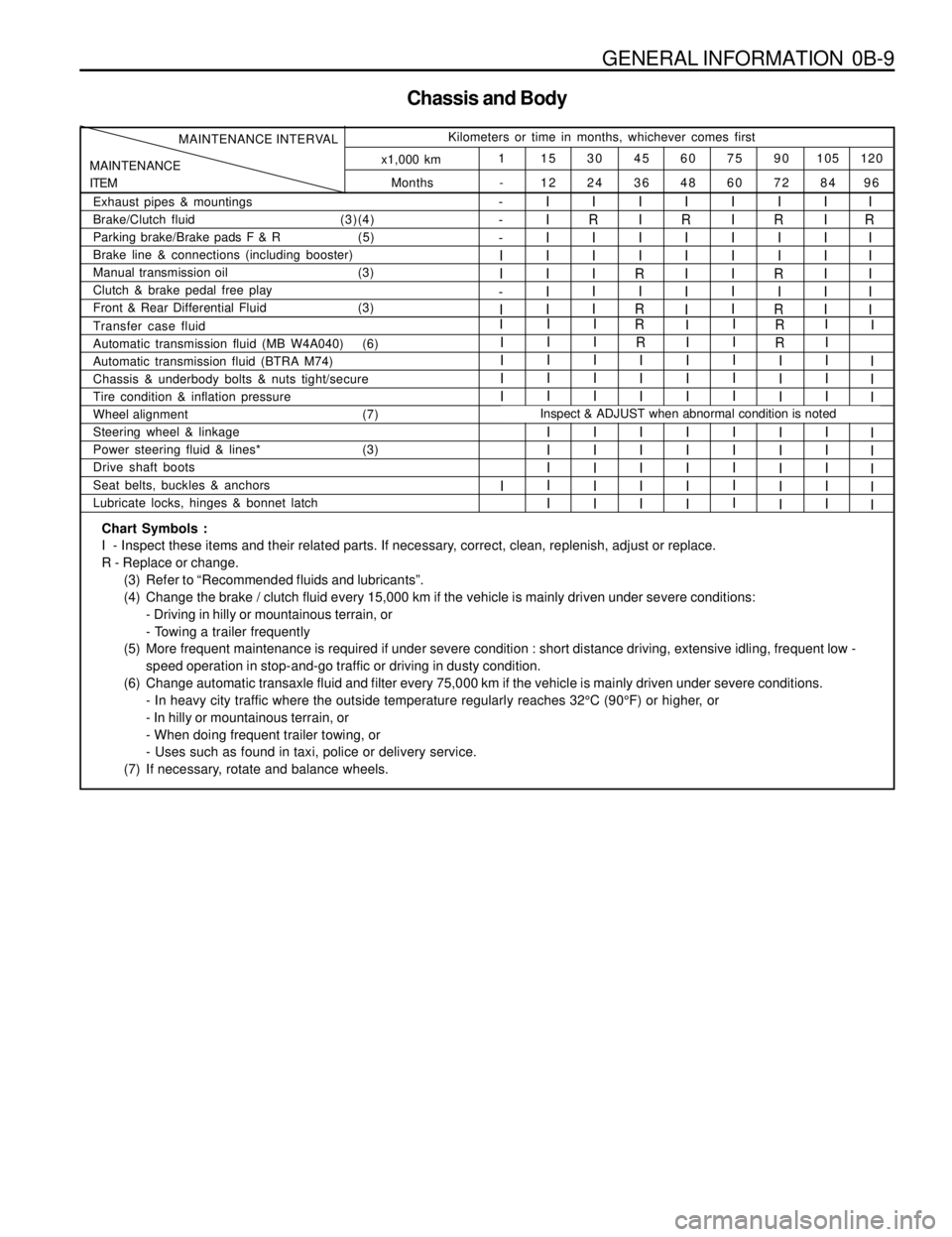

Chassis and Body

Months

MAINTENANCE

ITEMMAINTENANCE INTERVALKilometers or time in months, whichever comes first

120 105 90 75 60 45 30 15 1

96 84 72 60 48 36 24 12

- x1,000 km

Exhaust pipes & mountings

Brake/Clutch fluid(3)(4)

Parking brake/Brake pads F & R (5)

Brake line & connections (including booster)

Manual transmission oil (3)

Clutch & brake pedal free play

Front & Rear Differential Fluid (3)I

R

I

I

I

I

I-

-

-

I

I

-

II

I

I

I

I

I

II

R

I

I

I

I

II

I

I

I

R

I

RI

I

I

I

I

I

II

R

I

I

R

I

RI

I

I

I

I

I

II

R

I

I

I

I

I

Automatic transmission fluid (MB W4A040) (6)

Automatic transmission fluid (BTRA M74)

Chassis & underbody bolts & nuts tight/secure

Tire condition & inflation pressure

Wheel alignment (7)

Steering wheel & linkage

Power steering fluid & lines* (3)

Drive shaft boots

Seat belts, buckles & anchors

Lubricate locks, hinges & bonnet latchI

I

I

I

II

I

I

I

I

I

I

I

I

II

I

I

I

I

I

I

I

I

IR

I

I

I

I

I

I

I

II

I

I

I

I

I

I

I

II

I

I

I

I

I

I

I

I

IR

R

I

I

I

I

I

I

I

II

I

I

I

I

I

I

I

I

Transfer case fluidRIII

Inspect & ADJUST when abnormal condition is noted

I

I

I

I

I

I

I

I

I

Chart Symbols :

I - Inspect these items and their related parts. If necessary, correct, clean, replenish, adjust or replace.

R - Replace or change.

(3) Refer to “Recommended fluids and lubricants”.

(4) Change the brake / clutch fluid every 15,000 km if the vehicle is mainly driven under severe conditions:

- Driving in hilly or mountainous terrain, or

- Towing a trailer frequently

(5) More frequent maintenance is required if under severe condition : short distance driving, extensive idling, frequent low -

speed operation in stop-and-go traffic or driving in dusty condition.

(6) Change automatic transaxle fluid and filter every 75,000 km if the vehicle is mainly driven under severe conditions.

- In heavy city traffic where the outside temperature regularly reaches 32°C (90°F) or higher, or

- In hilly or mountainous terrain, or

- When doing frequent trailer towing, or

- Uses such as found in taxi, police or delivery service.

(7) If necessary, rotate and balance wheels.

Page 23 of 1463

GENERAL INFORMATION 0B-11

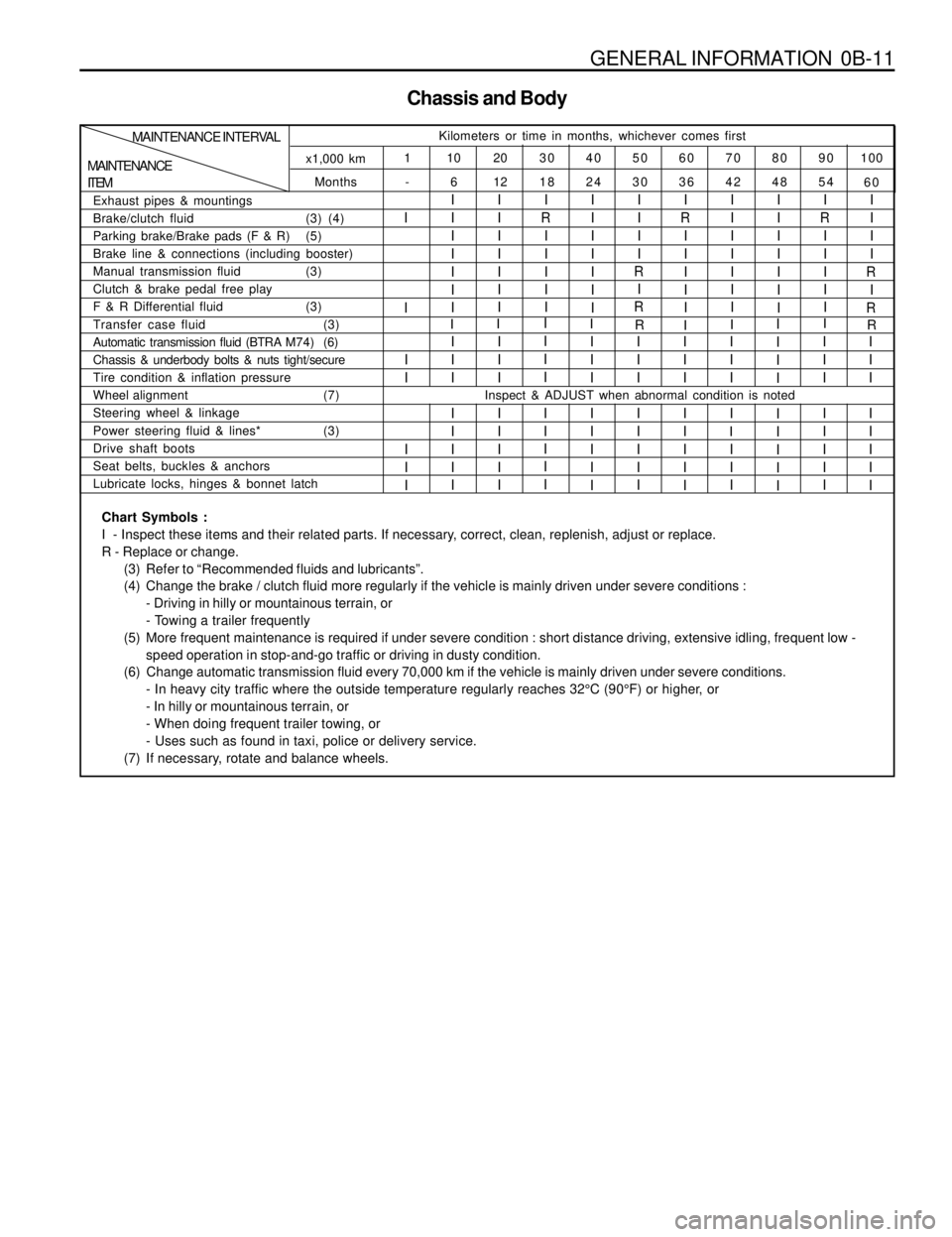

Chassis and Body

Months

-

MAINTENANCE

ITEMMAINTENANCE INTERVAL

Kilometers or time in months, whichever comes first

100 90 80 70 60 50 40 30 20 10 1

60 54 48 42 36 30 24 18 12 6 x1,000 km

Exhaust pipes & mountings

Brake/clutch fluid(3) (4)

Parking brake/Brake pads (F & R) (5)

Brake line & connections (including booster)

Manual transmission fluid (3)

Clutch & brake pedal free play

F & R Differential fluid (3)

I

II

I

I

I

I

I

II

I

I

I

I

I

II

R

I

I

I

I

II

I

I

I

I

I

II

I

I

I

R

I

RI

R

I

I

I

I

II

I

I

I

I

I

II

I

I

I

I

I

II

R

I

I

I

I

II

I

I

I

R

I

R

Automatic transmission fluid (BTRA M74) (6)

Chassis & underbody bolts & nuts tight/secure

Tire condition & inflation pressure

Wheel alignment (7)

Steering wheel & linkage

Power steering fluid & lines* (3)

Drive shaft boots

Seat belts, buckles & anchors

Lubricate locks, hinges & bonnet latchI

I

I

I

I

I

I

II

I

I

I

I

I

I

II

I

I

I

I

I

I

I

II

I

I

I

I

I

I

II

I

I

I

I

I

I

II

I

I

I

I

I

I

II

I

I

I

I

I

II

I

I

I

I

I

I

II

I

I

I

I

I

I

I

Transfer case fluid (3)R

IR

I II

I

I

I

I

II

I

I

I

I

I

I

I

I

Inspect & ADJUST when abnormal condition is noted

II

I

Chart Symbols :

I - Inspect these items and their related parts. If necessary, correct, clean, replenish, adjust or replace.

R - Replace or change.

(3) Refer to “Recommended fluids and lubricants”.

(4) Change the brake / clutch fluid more regularly if the vehicle is mainly driven under severe conditions :

- Driving in hilly or mountainous terrain, or

- Towing a trailer frequently

(5) More frequent maintenance is required if under severe condition : short distance driving, extensive idling, frequent low -

speed operation in stop-and-go traffic or driving in dusty condition.

(6) Change automatic transmission fluid every 70,000 km if the vehicle is mainly driven under severe conditions.

- In heavy city traffic where the outside temperature regularly reaches 32°C (90°F) or higher, or

- In hilly or mountainous terrain, or

- When doing frequent trailer towing, or

- Uses such as found in taxi, police or delivery service.

(7) If necessary, rotate and balance wheels.

Page 24 of 1463

0B-12 GENERAL INFORMATION

OWNER INSPECTIONS

AND SERVICES

WHILE OPERATING THE VEHICLE

Horn Operation

Blow the horn occasionally to make sure it works. Check

all the button locations.

Brake System Operation

Be alert for abnormal sounds, increased brake pedal

travel or repeated puling to one side when braking. Also,

if the brake warning light goes on, or flashes, something

may be wrong with part of the brake system.

Exhaust System Operation

Be alert to any changes in the sound of the system or

the smell of the fumes. These are signs that the system

may be leaking or overheating. Have the system

inspected and repaired immediately.

Tires, Wheels and Alignment Operation

Be alert to any vibration of the steering wheel or the

seats at normal highway speeds. This may mean a wheel

needs to be balanced. Also, a pull right or left on a

straight, level road may show the need for a tire pressure

adjustment or a wheel alignment.

Steering System Operation

Be alert to changes in the steering action. An inspection

is needed when the steering wheel is hard to turn or

has too much free play, or is unusual sounds are noticed

when turning or parking.

Headlight Aim

Take note of the light pattern occasionally. Adjust the

headlights if the beams seem improperly aimed.

AT EACH FUEL FILL

A fluid loss in any (except windshield washer) system

may indicate a problem. Have the system inspected and

repaired immediately.

Engine Oil Level

Check the oil level and add oil if necessary. The best

time to check the engine oil level is when the oil is warm.

1. After stopping the engine, wait a few minutes for the

oil to drain back to the oil pan.

2. Pull out the oil level indicator (dip stick).

3. Wipe it clean, and push the oil level indicator back

down all the way.

4. Pull out the oil level indicator and look at the oil level

on it.5. Add oil, if needed, to keep the oil level above the

lower mark. Avoid overfilling the engine, since this

may cause engine damage.

6. Push the indicator all the way back down into the

engine after taking the reading.

If you check the oil level when the oil is cold, do not run

the engine first. The cold oil will not drain back to the

pan fast enough to give a true oil level reading.

Engine Coolant Level and Condition

Check the coolant level in the coolant reservoir tank

and add coolant if necessary. Inspect the coolant.

Replace dirty or rusty coolant.

Windshield Washer Fluid Level

Check the washer fluid level in the reservoir. Add fluid if

necessary.

AT LEAST TWICE A MONTH

Tire And Wheel Inspection and Pressure

Check

Check the tire for abnormal wear or damage. Also check

for damaged wheels. Check the tire pressure when the

tires are cold ( check the spare also, unless it is a

stowaway). Maintain the recommended pressures. Refer

to “Tire and Wheel” is in section 0B.

AT LEAST MONTHLY

Light Operation

Check the operation of the license plate light, the

headlights (including the high beams), the parking lights,

the fog lights, the taillight, the brake lights, the turn

signals, the backup lights and the hazard warning flasher.

Fluid Leak Check

Periodically inspect the surface beneath the vehicle for

water, oil, fuel or other fluids, after the vehicle has been

parked for a while. Water dripping from the air

conditioning system after use is normal. If you notice

fuel leaks or fumes, find the cause and correct it at once.

AT LEAST TWICE A YEAR

Power Steering System Reservoir Level

Check the power steering fluid level. Keep the power

steering fluid at the proper level. Refer to

Section 6A,

Power Steering System.

Brake Master Cylinder Reservoir Level

Check the fluid and keep it at the proper level. A low

fluid level can indicate worn disc brake pads which may

need to be serviced. Check the breather hole in the

reservoir cover to be free from dirt and check for an

open passage.

Page 25 of 1463

GENERAL INFORMATION 0B-13

Weather-Strip Lubrication

Apply a thin film silicone grease using a clean cloth.

EACH TIME THE OIL IS CHANGED

Brake System Inspection

This inspection should be done when the wheels are

removed for rotation. Inspect the lines and the hoses

for proper hookup, binding, leaks, cracks, chafing, etc.

Inspect the disc brake pads for wear. Inspect the rotors

for surface condition. Inspect other brake parts, the

parking brake, etc., at the same time. Inspect the brakes

more often if habit or conditions result in frequent braking.

Steering, Suspension and Front Drive Axle

Boot And Seal Inspection

Inspect the front and rear suspension and the steering

system for damaged, loose or missing parts, signs of

wear or lack of lubrication. Inspect the power steering

line and the hoses for proper hookup, binding, leaks,

cracks, chafing, etc. Clean and inspect the drive axle

boot and seals for damage, tears or leakage. Replace

the seals if necessary.

Exhaust System Inspection

Inspect the complete system (including the catalytic

converter if equipped). Inspect the body near the exhaust

system. Look for broken, damaged, missing, or out-of-

position parts as well as open seams, holes, loose

connections, or other conditions which could cause heat

buildup in the floor pan or could let exhaust fumes seep

into the trunk or passenger compartment.

Throttle Linkage Inspection

Inspect the throttle linkage for interference or binding,

damaged, or missing parts. Lubricate all linkage joints

and throttle cable joints, the intermediate throttle shaft

bearing, the return spring at throttle valve assembly, and

the accelerator pedal sliding face with suitable grease.

Check the throttle cable for free movements.

Engine Drive Belts

Inspect all belts for cracks, fraying, wear and proper

tension. Adjust or replace the belts as needed.

Hood Latch Operation

When opening the hood, note the operation of the

secondary latch. It should keep the hood from opening

all the way when the primary latch is released. The hood

must close firmly.

AT LEAST ANNUALLY

Lap and Shoulder Belts Condition and

Operation

Inspect the belt system including: the webbing, the

buckles, the latch plates, the retractor, the guide loops

and the anchors.

Movable Head Restraint Operation

On vehicles with movable head restraints, the restraints

must stay in the desired position.

Spare Tire and Jack Storage

Be alert to rattles in the rear of the vehicle. The spare

tire, all the jacking equipment, and the tools must be

securely stowed at all times. Oil the jack ratchet or the

screw mechanism after each use.

Key Lock Service

Lubricate the key lock cylinder.

Body Lubrication Service

Lubricate all the body door hinges including the hood,

the fuel door, the rear compartment hinges and the

latches, the glove box and the console doors, and any

folding seat hardware.

Underbody Flushing

Flushing the underbody will remove any corrosive

materials used for ice and snow removal and dust control.

At least every spring clean the underbody. First, loosen

the sediment packed in closed areas of the vehicle. Then

flush the underbody with plain water.

Engine Cooling System

Inspect the coolant and freeze protection fluid. If the fluid

is dirty or rusty, drain, flush and refill the engine cooling

system with new coolant. Keep the coolant at the proper

mixture in order to ensure proper freeze protection,

corrosion protection and engine operating temperature.

Inspect the hoses. Replace the cracked, swollen, or

deteriorated hoses. Tighten the clamps. Clean the

outside of the radiator and the air conditioning

condenser. Wash the filler cap and the neck. Pressure

test the cooling system and the cap in order to help

ensure proper operation.

Page 830 of 1463

2B-2 WHEEL ALIGNMENT

DIAGNOSIS

TIRE DIAGNOSIS

Irregular and Premature Wear

Irregular and premature tire wear has many causes.

Some of them are incorrect inflation pressures, lack of

regular rotation, poor driving habits, or improper wheel

alignment.

Rotate the tires if :

lThe front tire wear is different from the rear.

lThe left and right front tire wear is unequal.

lThe left and right rear tire wear is unequal, Check

wheel alignment if :

lThe left and right front tire wear is unequal.

lThe wear is uneven across the tread of either front

tire.

lThe front tire treads are scuffed with “feather” edges

on the side of the tread ribs or blocks.

Tread Wear Indicators

The original equipment tires have built-in tread wear

indicators to show when the tires need replacement.

These indicators appear as bands when the tire tread

depth becomes shallow. Tire replacement is

recommended when the indicators appear in three or

more grooves at six locations.

Radial Tire Waddle

Waddle is side-to-side movement at the front or rear of

the vehicle. It is caused by the steel belt not being straight

within the tire, or by excessive lateral runout of the tire

or wheel.

The vehicle must be road tested to determine which end

of the vehicle has the faulty tire. The rear end of the

vehicle will shake from side to side or “waddle” if the

waddle tire is on the rear of the vehicle. From the driver’s

seat, it feels as though someone is pushing on the side

of the vehicle. If the faulty tire is on the front of the vehicle,

the waddle is more visual. The front sheet meld appears

to be moving back and forth, and the drivers seat feels

like the pivot point in the vehicle.

Waddle can be diagnosed using the method of

substituting known good tire and wheel assemblies on

the problem vehicle

1. Road test the vehicle to determine if the waddle is

coming from the front or the rear of the vehicle.

2. Install good tires and wheels from a similar vehicle in

place of those on the offending end of the problem

vehicle. If the source of the waddle is not obvious,

change the rear tires.

Page 835 of 1463

WHEEL ALIGNMENT 2B-7

Camber

1. Remove the free wheel hub.

2. Measure camber with a wheel alignment equipment.

3. If camber measurements are not within specification, adjust

it by increasing or decreasing the number of adjusting shims

(1) inserted between the upper arm shaft and cross bracket.

Camber Change

Notice

Difference between the left and right should be adjusted

within 30’.

Specification0°±30’

Caster

1. Remove the free wheel hub.

2. Measure caster with a wheel alignment equipment and a

turning radius gauge.

Specification2° 30’ ± 30’

Adjusting Shims

1.6 Iarge

3.2 largeIncreasing 1 ea

+ 19’

+ 38’Decreasing 1 ea

- 19’

- 38’

Page 836 of 1463

2B-8 WHEEL ALIGNMENT

Increasing 1ea

- 11’

- 43’

3. If caster measurements are not within specification, adjust

it by increasing 1ea (rear) or decreasing 1ea (front).

Caster Change

Notice

Difference between the left and right should be adjusted

within 30’.

0.4 small

1.6 small

Decreasing 1ea

+ 11’

+ 43’

FRONT

Adjusting Shims

Increasing 1ea

+ 11’

+ 43’ 0.4 small

1.6 small

Decreasing 1ea

- 11’

- 43’

REAR

Adjusting Shims

Page 942 of 1463

4D-4 FRONT DISC BRAKES

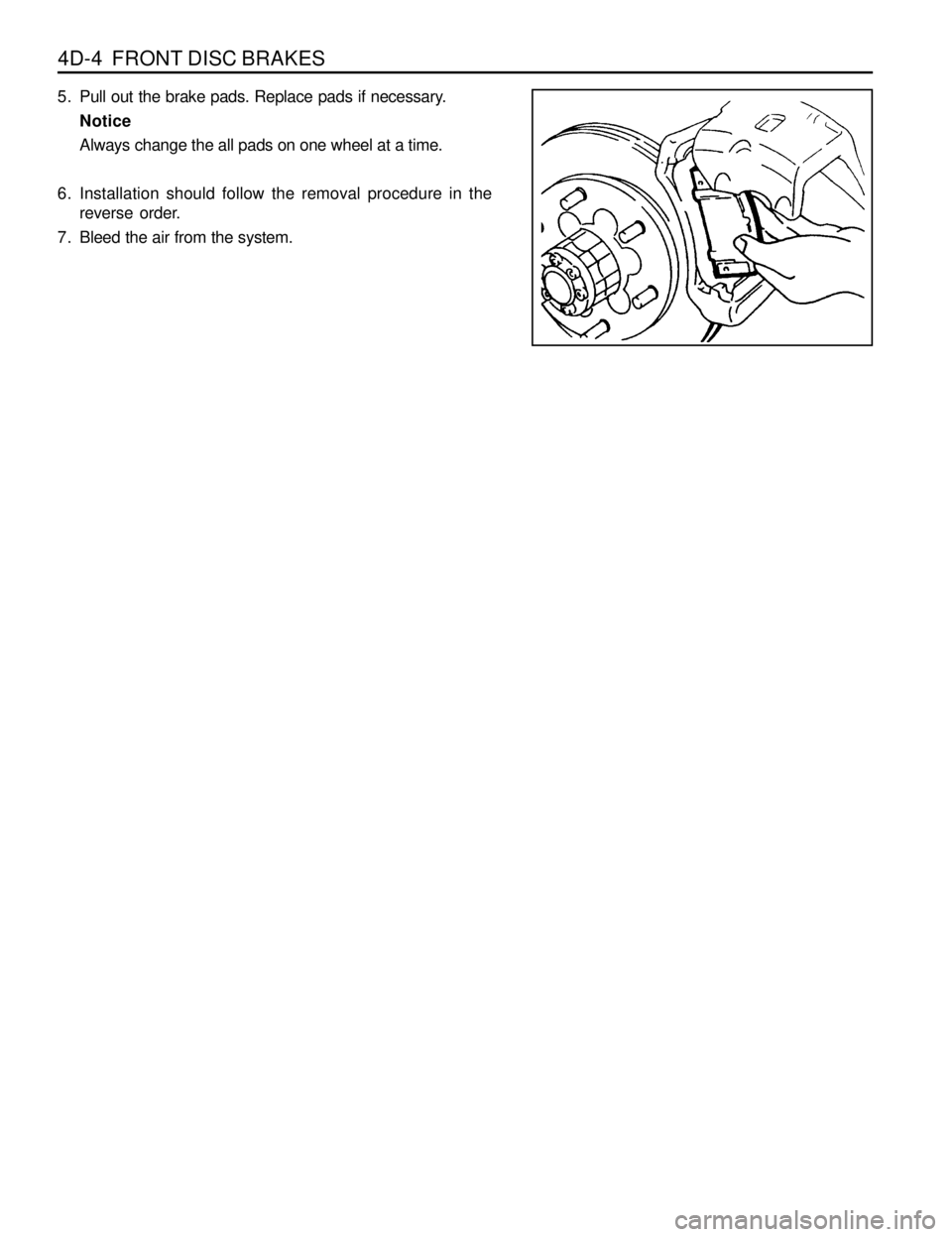

5. Pull out the brake pads. Replace pads if necessary.

Notice

Always change the all pads on one wheel at a time.

6. Installation should follow the removal procedure in the

reverse order.

7. Bleed the air from the system.

Page 943 of 1463

FRONT DISC BRAKES 4D-5

4. Measure rotor disc thickness.

UNIT REPAIR

FRONT DISC BRAKE

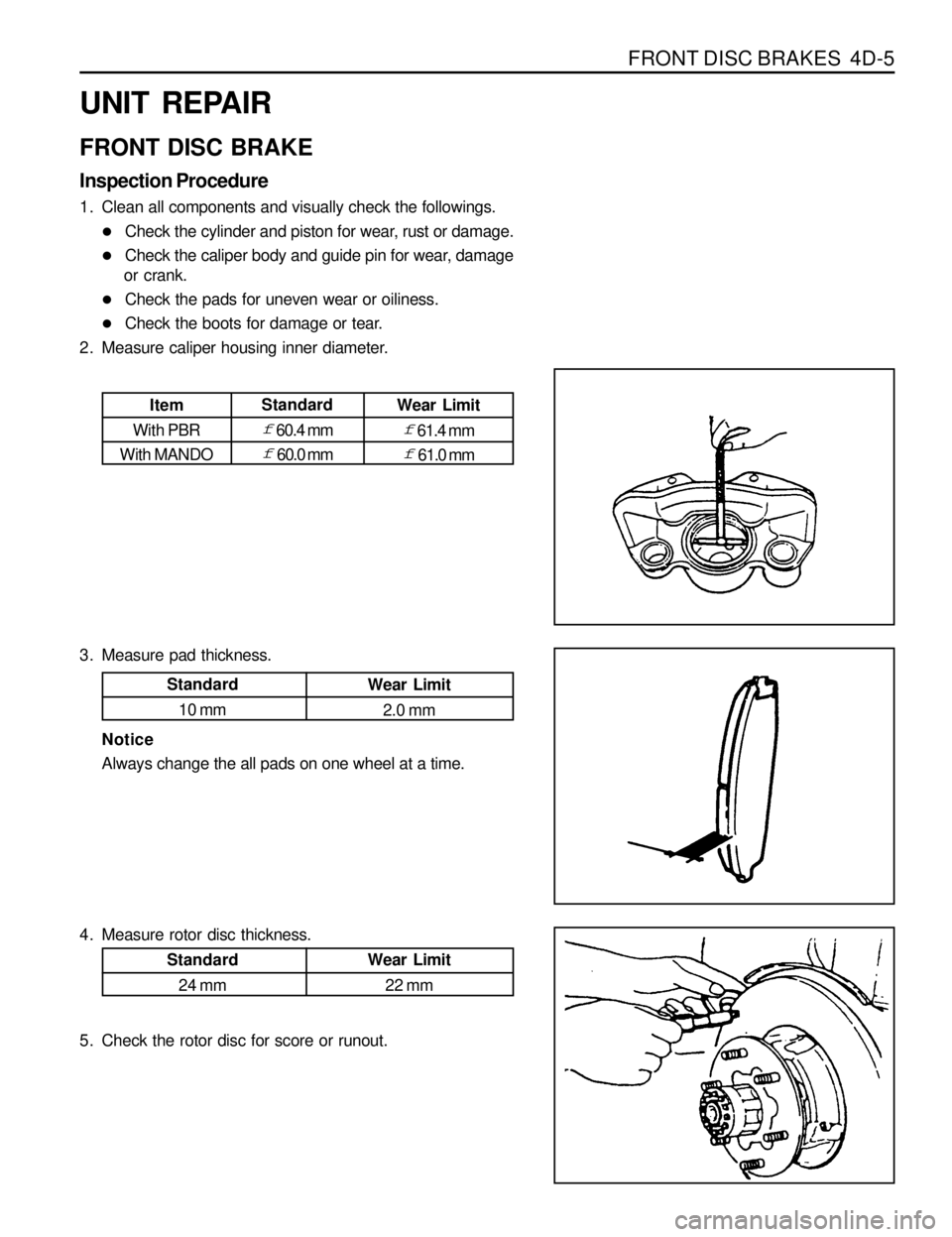

Inspection Procedure

1. Clean all components and visually check the followings.

lCheck the cylinder and piston for wear, rust or damage.

lCheck the caliper body and guide pin for wear, damage

or crank.

lCheck the pads for uneven wear or oiliness.

lCheck the boots for damage or tear.

2. Measure caliper housing inner diameter.

Item

With PBR

With MANDOWear Limit

f 61.4 mm

f 61.0 mm

Standard

10 mmWear Limit

2.0 mm

Standard

f 60.4 mm

f 60.0 mm

3. Measure pad thickness.

Notice

Always change the all pads on one wheel at a time.

5. Check the rotor disc for score or runout.

Standard

24 mmWear Limit

22 mm