gas type SSANGYONG MUSSO 1998 Workshop Repair Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1998, Model line: MUSSO, Model: SSANGYONG MUSSO 1998Pages: 1463, PDF Size: 19.88 MB

Page 14 of 1463

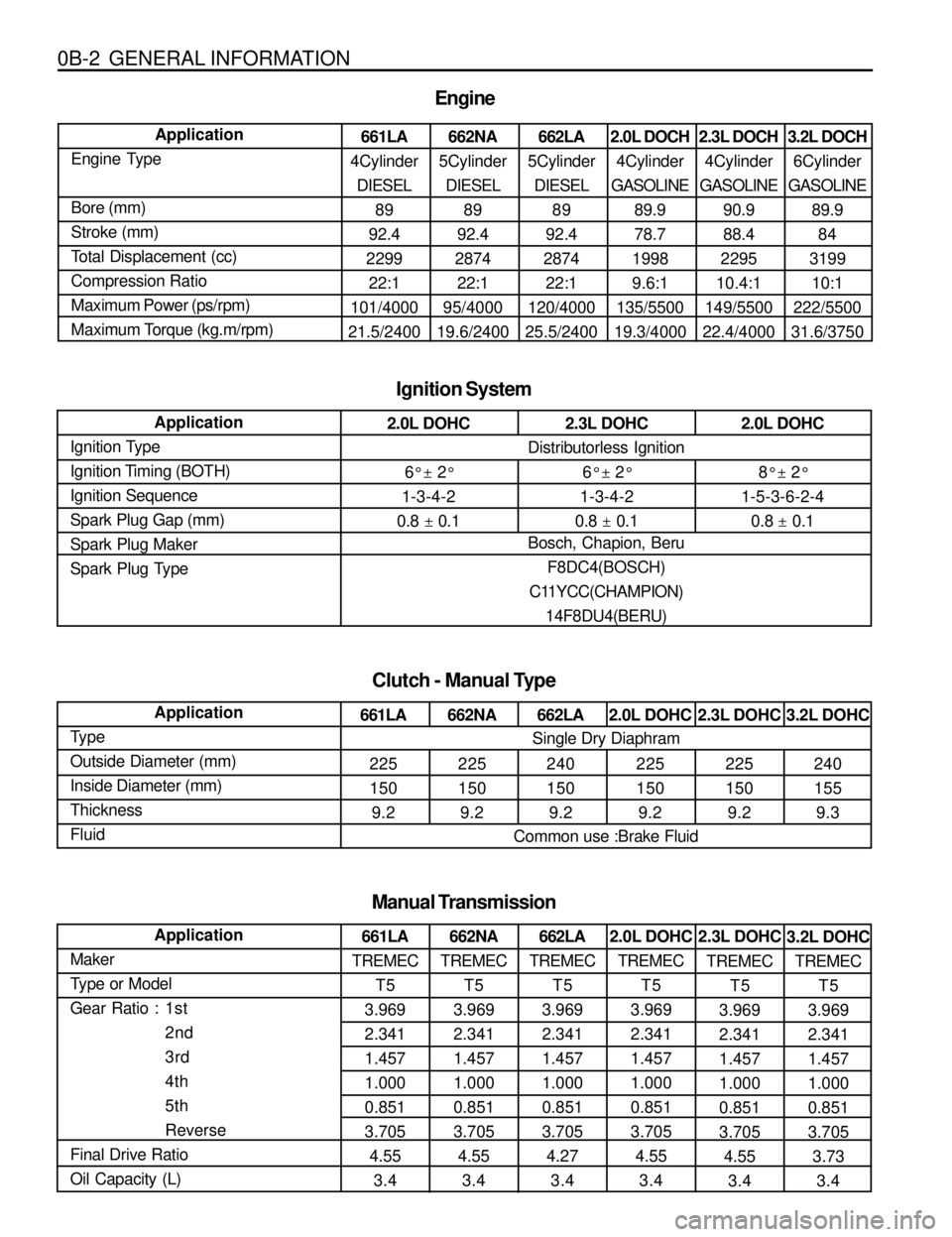

0B-2 GENERAL INFORMATION

661LA

4Cylinder

DIESEL

89

92.4

2299

22:1

101/4000

21.5/2400 Application

Engine Type

Bore (mm)

Stroke (mm)

Total Displacement (cc)

Compression Ratio

Maximum Power (ps/rpm)

Maximum Torque (kg.m/rpm)

Engine

662NA

5Cylinder

DIESEL

89

92.4

2874

22:1

95/4000

19.6/2400662LA

5Cylinder

DIESEL

89

92.4

2874

22:1

120/4000

25.5/24002.0L DOCH

4Cylinder

GASOLINE

89.9

78.7

1998

9.6:1

135/5500

19.3/40002.3L DOCH

4Cylinder

GASOLINE

90.9

88.4

2295

10.4:1

149/5500

22.4/40003.2L DOCH

6Cylinder

GASOLINE

89.9

84

3199

10:1

222/5500

31.6/3750

661LA

TREMEC

T5

3.969

2.341

1.457

1.000

0.851

3.705

4.55

3.4 Application

Ignition Type

Ignition Timing (BOTH)

Ignition Sequence

Spark Plug Gap (mm)

Spark Plug Maker

Spark Plug Type

Ignition System

Clutch - Manual Type

2.0L DOHC

6° ± 2°

1-3-4-2

0.8 ± 0.12.3L DOHC

6° ± 2°

1-3-4-2

0.8 ± 0.12.0L DOHC

8° ± 2°

1-5-3-6-2-4

0.8 ± 0.1 Distributorless Ignition

Bosch, Chapion, Beru

F8DC4(BOSCH)

C11YCC(CHAMPION)

14F8DU4(BERU)

661LA

225

150

9.2

662NA

225

150

9.2662LA

240

150

9.22.0L DOHC

225

150

9.22.3L DOHC

225

150

9.23.2L DOHC

240

155

9.3 Application

Type

Outside Diameter (mm)

Inside Diameter (mm)

Thickness

Fluid

Single Dry Diaphram

Common use :Brake Fluid

Application

Maker

Type or Model

Gear Ratio : 1st

2nd

3rd

4th

5th

Reverse

Final Drive Ratio

Oil Capacity (L)

Manual Transmission

662NA

TREMEC

T5

3.969

2.341

1.457

1.000

0.851

3.705

4.55

3.4662LA

TREMEC

T5

3.969

2.341

1.457

1.000

0.851

3.705

4.27

3.42.0L DOHC

TREMEC

T5

3.969

2.341

1.457

1.000

0.851

3.705

4.55

3.42.3L DOHC

TREMEC

T5

3.969

2.341

1.457

1.000

0.851

3.705

4.55

3.43.2L DOHC

TREMEC

T5

3.969

2.341

1.457

1.000

0.851

3.705

3.73

3.4

Page 19 of 1463

GENERAL INFORMATION 0B-7

MAINTENANCE AND REPAIR

MAINTENANCE AND LUBRICATION

Fuel Filter Replacement

Replace the engine fuel filter every.

lGasoline Engine : 60,000km (36,000 miles)

lDiesel Engine : 45,000km (24,000 miles)

Spark Plug Replacement

Replace spark plugs with same type.

lType : BOSCH : F8DC4

BERU : 14F-8DU4

Champion : C11YCC

lGap : 0.8 ± 0.1 mm

Spark Plug Wire Replacement

Clean wires and inspect them for burns, cracks or other

damage. Check the wire boot fit at the Distributor and at

the spark plugs. Replace the wires as needed.

Brake System Service

Check the disc brake pads or the drum brake linings.

Check the pad and the lining thickness carefully.

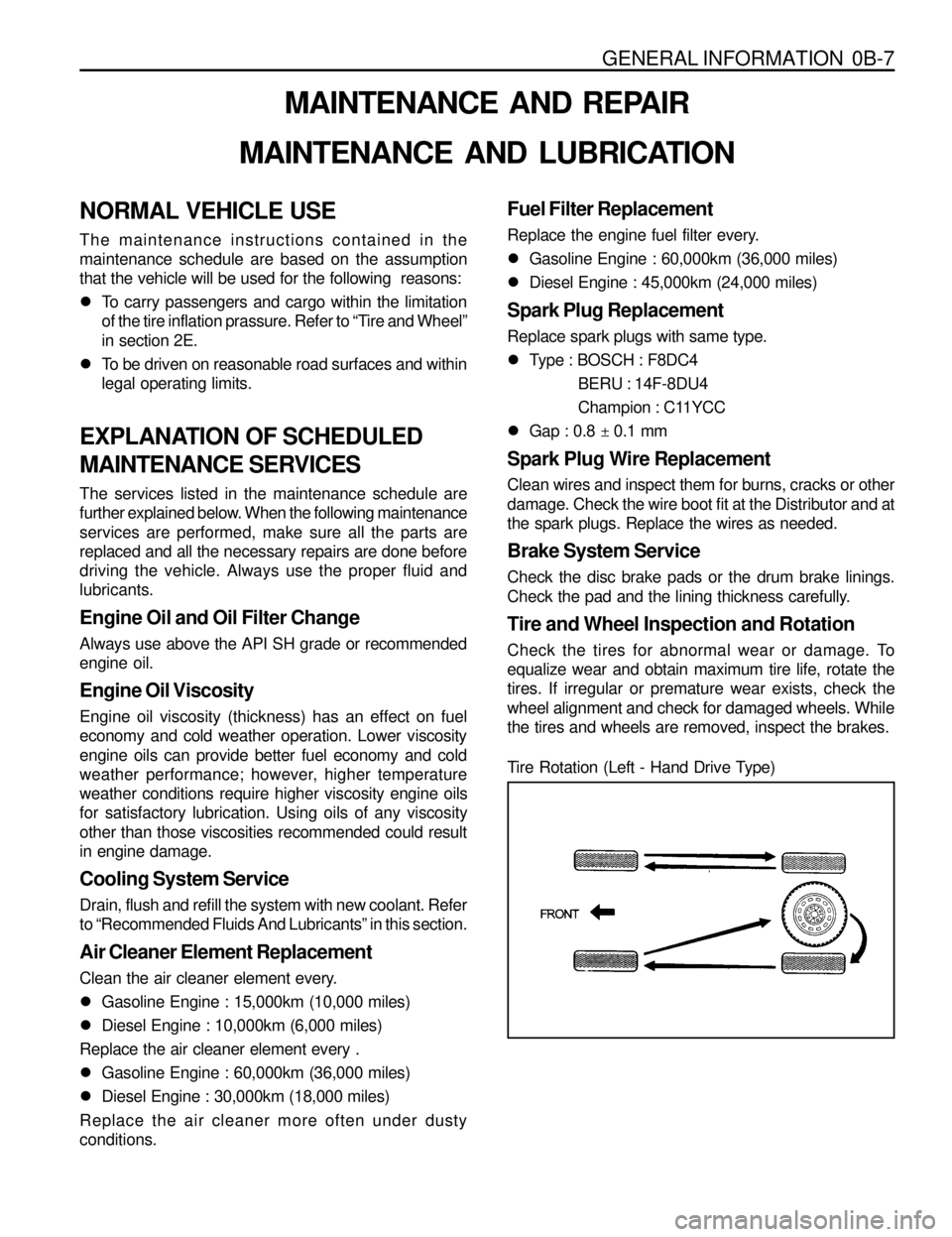

Tire and Wheel Inspection and Rotation

Check the tires for abnormal wear or damage. To

equalize wear and obtain maximum tire life, rotate the

tires. If irregular or premature wear exists, check the

wheel alignment and check for damaged wheels. While

the tires and wheels are removed, inspect the brakes.

NORMAL VEHICLE USE

The maintenance instructions contained in the

maintenance schedule are based on the assumption

that the vehicle will be used for the following reasons:

lTo carry passengers and cargo within the limitation

of the tire inflation prassure. Refer to “Tire and Wheel”

in section 2E.

lTo be driven on reasonable road surfaces and within

legal operating limits.

EXPLANATION OF SCHEDULED

MAINTENANCE SERVICES

The services listed in the maintenance schedule are

further explained below. When the following maintenance

services are performed, make sure all the parts are

replaced and all the necessary repairs are done before

driving the vehicle. Always use the proper fluid and

lubricants.

Engine Oil and Oil Filter Change

Always use above the API SH grade or recommended

engine oil.

Engine Oil Viscosity

Engine oil viscosity (thickness) has an effect on fuel

economy and cold weather operation. Lower viscosity

engine oils can provide better fuel economy and cold

weather performance; however, higher temperature

weather conditions require higher viscosity engine oils

for satisfactory lubrication. Using oils of any viscosity

other than those viscosities recommended could result

in engine damage.

Cooling System Service

Drain, flush and refill the system with new coolant. Refer

to “Recommended Fluids And Lubricants” in this section.

Air Cleaner Element Replacement

Clean the air cleaner element every.

lGasoline Engine : 15,000km (10,000 miles)

lDiesel Engine : 10,000km (6,000 miles)

Replace the air cleaner element every .

lGasoline Engine : 60,000km (36,000 miles)

lDiesel Engine : 30,000km (18,000 miles)

Replace the air cleaner more often under dusty

conditions.

Tire Rotation (Left - Hand Drive Type)

Page 28 of 1463

0B-16 GENERAL INFORMATION

VEHICLE IDENTIFICATION NUMBER SYSTEM

K P T P 0 A 1 9 S W P 122357

12~17.Production Serial Number

: 000001- 999999

11.Plant Code

P : PyongTaek Plant

10.Model Year

M : 1991

N : 1992

P : 1993

R : 1994

S : 1995

T : 1996

V : 1997

W : 1998

X : 1999

Y : 2000

9. Check Digit

Constant “S”

8. Engine Type

3 : 2299cc, In-line 4Cylinder, Diesel (OM601)

4 : 2874cc, In-line 5Cylinder, Diesel (OM602)

8 : 1998cc, In-line 4Cylinder, Gasoline (E20)

6 : 2295cc, In-line 4Cylinder, Gasoline (E23)

9 : 3199cc, In-line 6Cylinder, Gasoline (E32)

A : 2299cc, In-line 4Cylinder, Diesel (OM601)

B : 2874cc, In-line 5Cylinder, Diesel (OM602)

C : 2299cc, In-line 4Cylinder, Diesel (SY662LA)

D : 2874cc, In-line 5Cylinder, Diesel (SY662LA)

7. Restraint System

0 : NO Seat Belt,

1 : 3-Point Seat Belts, 2 : 2-Point Seat Belts

6. Trim Level

A : Standard, B : Deluxe, C : Super Deluxe

5. Body Type

0 : 5-Door

1 : 4-Door

2 : 3-Door

4. Line Models

P : Musso, LHD, R : Musso, RHD

3. Vehicle Type

T (Passengr Cars)

2. Name of Mamufacturer : P

1. Nation : K

Page 29 of 1463

GENERAL INFORMATION 0B-17

Manufacturer’s Plate

Manufacturer’s Plate Location

1.Type Approval No. 2.Vehicle Identification Number.

Diesel Engine Gasoline Engine

Page 30 of 1463

0B-18 GENERAL INFORMATION

Engine Number Location

Diesel Engine

The engine number is stamped on the cylinder block in

front of injection pump.

IL6 3200

The engine number is stamped on the lower rear side

of the alternator.

Gasolind Engine Number

1 6 2 9 9 0 1 0 012345

Serial Number

0 : Manual T/M

1 : Hydr - Auto Coupling

2 : Automatic T/M

99 : 3.2L

97 : 2.3L

94 : 2.0L

0 : Common

1 : Left - Hand Drive

2 : Right - Hand Drive

ENGINE TYPE

0 : MUSSO

Diesel Engine Number

662 920 1 0 012345

Serial Number

0 : Manual T/M

1 : Hydr - Auto Coupling

2 : Automatic T/M

910 : Non-Intercooler Engine

920 : Intercooler Engine

0 : Common

1 : Left - Hand Drive

2 : Right - Hand Drive

661 : 2299cc

662 : 2874cc

Page 33 of 1463

1A1-2 GENERAL ENGINE INFORMATION

Application

Idle Speed (rpm)

Fuel Injection Pressure (kg/cm²)

Oil Capacity (liter)

Lubrication Type

Oil Filter Type

Fuel

ENGINE SPECIFICATIONS (Cont'd)

E32 Engine

700 ± 50

3 - 4

8.2

Forced by Gear Pump

Full Flow with Paper Filter

Unleaded Gasoline

MSE 3.62S/3.53S (Motorsteuer Elektronik : German)

MSE : Engine Control Electronic

3.62S : 6 Cylinder Version

3.53S : 4 Cylinder Version

Page 38 of 1463

GENERAL ENGINE INFORMATION 1A1-7

OIL LEAK DIAGNOSIS

Most fluid oil leaks are easily located and repaired by

visually finding the leak and replacing or repairing the

necessary parts. On some occasions a fluid leak may

be difficult to locate or repair. The following procedures

may help you in locating and repairing most leaks.

Finding the Leak

1. Identify the fluid. Determine whether it is engine oil,

automatic transmission fluid, power steering fluid, etc.

2. Identify where the fluid is leaking from.

2.1 After running the vehicle at normal operating

temperature, park the vehicle over a large sheet

of paper.

2.2 Wait a few minutes.

2.3 You should be able to find the approximate

location of the leak by the drippings on the

paper.

3. Visually check around the suspected component.

Check around all the gasket mating surfaces for

leaks. A mirror is useful for finding leaks in areas that

are hard to reach.

4. If the leak still cannot be found, it may be necessary

to clean the suspected area with a degreaser, steam

or spray solvent.

4.1 Clean the area well.

4.2 Dry the area.

4.3 Operate the vehicle for several miles at normal

operating temperature and varying speeds.

4.4 After operating the vehicle, visually check the

suspected component.

4.5 If you still cannot locate the leak, try using the

powder or black light and dye method.

Powder Method

1. Clean the suspected area.

2. Apply an aerosol-type powder (such as foot powder)

to the suspected area.

3. Operate the vehicle under normal operating

conditoins.

4. Visually inspect the suspected component. You

should be able to trace the leak path over the white

powder surface to the source.

Black Light and Dye Method

A dye and light kit is available for finding leaks, Refer to

the manufacturer's directions when using the kit.

1. Pour the specified amount of dye into the engine oil

fill tube.2. Operate the vehicle normal operating conditions as

directed in the kit.

3. Direct the light toward the suspected area. The dyed

fluid will appear as a yellow path leading to the

source.

Repairing the Leak

Once the origin of the leak has been pinpointed and

traced back to its source, the cause of the leak must be

determined n order for it to be repaired properly. If a

gasket is replaced, but the sealing flange is bent, the

new gasket will not repair the leak. The bent flange must

be repaired also. Before attempting to repair a leak,

check for the following conditions and correct them as

they may cause a leak.

Gaskets

lThe fluid level/pressure is too high.

lThe crankcase ventilation system is malfunctioning.

lThe fasteners are tightened improperly or the threads

are dirty or damaged.

lThe flanges or the sealing surface is warped.

lThere are scratches, burrs or other damage to the

sealing surface.

lThe gasket is damaged or worn.

lThere is cracking or porosity of the component.

lAn improper seal was used (where applicable).

Seals

lThe fluid level/pressure is too high.

lThe crankcase ventilation system is malfunctioning.

lThe seal bore is damaged (scratched, burred or

nicked).

lThe seal is damaged or worn.

lImproper installation is evident.

lThere are cracks in the components.

lThe shaft surface is scratched, nicked or damaged.

lA loose or worn bearing is causing excess seal wear.

DIAGNOSIS

Page 46 of 1463

1A2-2 GENERAL ENGINE INFORMATION

E20 Engine

¬

¬

¬

¬

¬

¬ Application

Idle Speed (rpm)

Fuel Injection Pressure (kg/cm²)

Oil Capacity (liter)

Lubrication Type

Oil Filter Type

Fuel

ENGINE SPECIFICATIONS (Cont'd)

E23 Engine

750 ± 50

3.2 - 4.2

7.5

Forced by Gear Pump

Full Flow with Paper Filter

Unleaded Gasoline

MSE 3.62S/3.53S (Motorsteuer Elektronik : German)

MSE : Engine Control Electronic

3.62S : 6 cylinder version

3.53S : 4 cylinder version

Page 52 of 1463

1A2-8 GENERAL ENGINE INFORMATION

OIL LEAK DIAGNOSIS

Most fluid oil leaks are easily located and repaired by

visually finding the leak and replacing or repairing the

necessary parts. On some occasions a fluid leak may

be difficult to locate or repair. The following procedures

may help you in locating and repairing most leaks.

Finding the Leak

1. Identify the fluid. Determine whether it is engine oil,

automatic transmission fluid, power steering fluid, etc.

2. Identify where the fluid is leaking from.

2.1 After running the vehicle at normal operating

temperature, park the vehicle over a large sheet

of paper.

2.2 Wait a few minutes.

2.3 You should be able to find the approximate

location of the leak by the drippings on the

paper.

3. Visually check around the suspected component.

Check around all the gasket mating surfaces for

leaks. A mirror is useful for finding leaks in areas that

are hard to reach.

4. If the leak still cannot be found, it may be necessary

to clean the suspected area with a degreaser, steam

or spray solvent.

4.1 Clean the area well.

4.2 Dry the area.

4.3 Operate the vehicle for several miles at normal

operating temperature and varying speeds.

4.4 After operating the vehicle, visually check the

suspected component.

4.5 If you still cannot locate the leak, try using the

powder or black light and dye method.

Powder Method

1. Clean the suspected area.

2. Apply an aerosol-type powder (such as foot powder)

to the suspected area.

3. Operate the vehicle under normal operating

conditoins.

4. Visually inspect the suspected component. You

should be able to trace the leak path over the white

powder surface to the source.

Black Light and Dye Method

A dye and light kit is available for finding leaks, Refer to

the manufacturer's directions when using the kit.

1. Pour the specified amount of dye into the engine oil

fill tube.

2. Operate the vehicle normal operating conditions as

directed in the kit.

3. Direct the light toward the suspected area. The dyed

fluid will appear as a yellow path leading to the

source.

Repairing the Leak

Once the origin of the leak has been pinpointed and

traced back to its source, the cause of the leak must be

determined n order for it to be repaired properly. If a

gasket is replaced, but the sealing flange is bent, the

new gasket will not repair the leak. The bent flange must

be repaired also. Before attempting to repair a leak,

check for the following conditions and correct them as

they may cause a leak.

Gaskets

lThe fluid level/pressure is too high.

lThe crankcase ventilation system is malfunctioning.

lThe fasteners are tightened improperly or the threads

are dirty or damaged.

lThe flanges or the sealing surface is warped.

lThere are scratches, burrs or other damage to the

sealing surface.

lThe gasket is damaged or worn.

lThere is cracking or porosity of the component.

lAn improper seal was used (where applicable).

Seals

lThe fluid level/pressure is too high.

lThe crankcase ventilation system is malfunctioning.

lThe seal bore is damaged (scratched, burred or

nicked).

lThe seal is damaged or worn.

lImproper installation is evident.

lThere are cracks in the components.

lThe shaft surface is scratched, nicked or damaged.

lA loose or worn bearing is causing excess seal wear.

DIAGNOSIS

Page 68 of 1463

1A3-10 GENERAL ENGINE INFORMATION

OIL LEAK DIAGNOSIS

Most fluid oil leaks are easily located and repaired by

visually finding the leak and replacing or repairing the

necessary parts. On some occasions a fluid leak may

be difficult to locate or repair. The following

procedures may help you in locating and repairing

most leaks.

Finding the Leak

1. Identify the fluid. Determine whether it is engine

oil, automatic transmission fluid, power steering

fluid, etc.

2. Identify where the fluid is leaking from.

2.1 After running the vehicle at normal operating

temperature, park the vehicle over a large

sheet of paper.

2.2 Wait a few minutes.

2.3 You should be able to find the approximate

location of the leak by the drippings on the

paper.

3. Visually check around the suspected component.

Check around all the gasket mating surfaces for

leaks. A mirror is useful for finding leaks in areas

that are hard to reach.

4. If the leak still cannot be found, it may be

necessary to clean the suspected area with a

degreaser, steam or spray solvent.

4.1 Clean the area well.

4.2 Dry the area.

4.3 Operate the vehicle for several miles at

normal operating temperature and varying

speeds.

4.4 After operating the vehicle, visually check the

suspected component.

4.5 If you still cannot locate the leak, try using the

powder or black light and dye method.

Powder Method

1. Clean the suspected area.

2. Apply an aerosol-type powder (such as foot

powder) to the suspected area.

3. Operate the vehicle under normal operating

conditions.

4. Visually inspect the suspected component. You

should be able to trace the leak path over the white

powder surface to the source.

Black Light and Dye Method

A dye and light kit is available for finding leaks, Refer

to the manufacturer's directions when using the kit.1. Pour the specified amount of dye into the engine

oil fill tube.

2. Operate the vehicle normal operating conditions

as directed in the kit.

3. Direct the light toward the suspected area. The

dyed fluid will appear as a yellow path leading to

the source.

Repairing the Leak

Once the origin of the leak has been pinpointed and

traced back to its source, the cause of the leak must

be determined n order for it to be repaired properly. If

a gasket is replaced, but the sealing flange is bent,

the new gasket will not repair the leak. The bent flange

must be repaired also. Before attempting to repair a

leak, check for the following conditions and correct

them as they may cause a leak.

Gaskets

lThe fluid level/pressure is too high.

lThe crankcase ventilation system is malfunctioning.

lThe fasteners are tightened improperly or the

threads are dirty or damaged.

lThe flanges or the sealing surface is warped.

lThere are scratches, burrs or other damage to the

sealing surface.

lThe gasket is damaged or worn.

lThere is cracking or porosity of the component.

lAn improper seal was used (where applicable).

Seals

lThe fluid level/pressure is too high.

lThe crankcase ventilation system is malfunctioning.

lThe seal bore is damaged (scratched, burred or

nicked).

lThe seal is damaged or worn.

lImproper installation is evident.

lThere are cracks in the components.

lThe shaft surface is scratched, nicked or damaged.

lA loose or worn bearing is causing excess seal

wear.

DIAGNOSIS