SSANGYONG MUSSO 1998 Workshop Repair Manual

MUSSO 1998

SSANGYONG

SSANGYONG

https://www.carmanualsonline.info/img/67/57510/w960_57510-0.png

SSANGYONG MUSSO 1998 Workshop Repair Manual

Page 22 of 1463

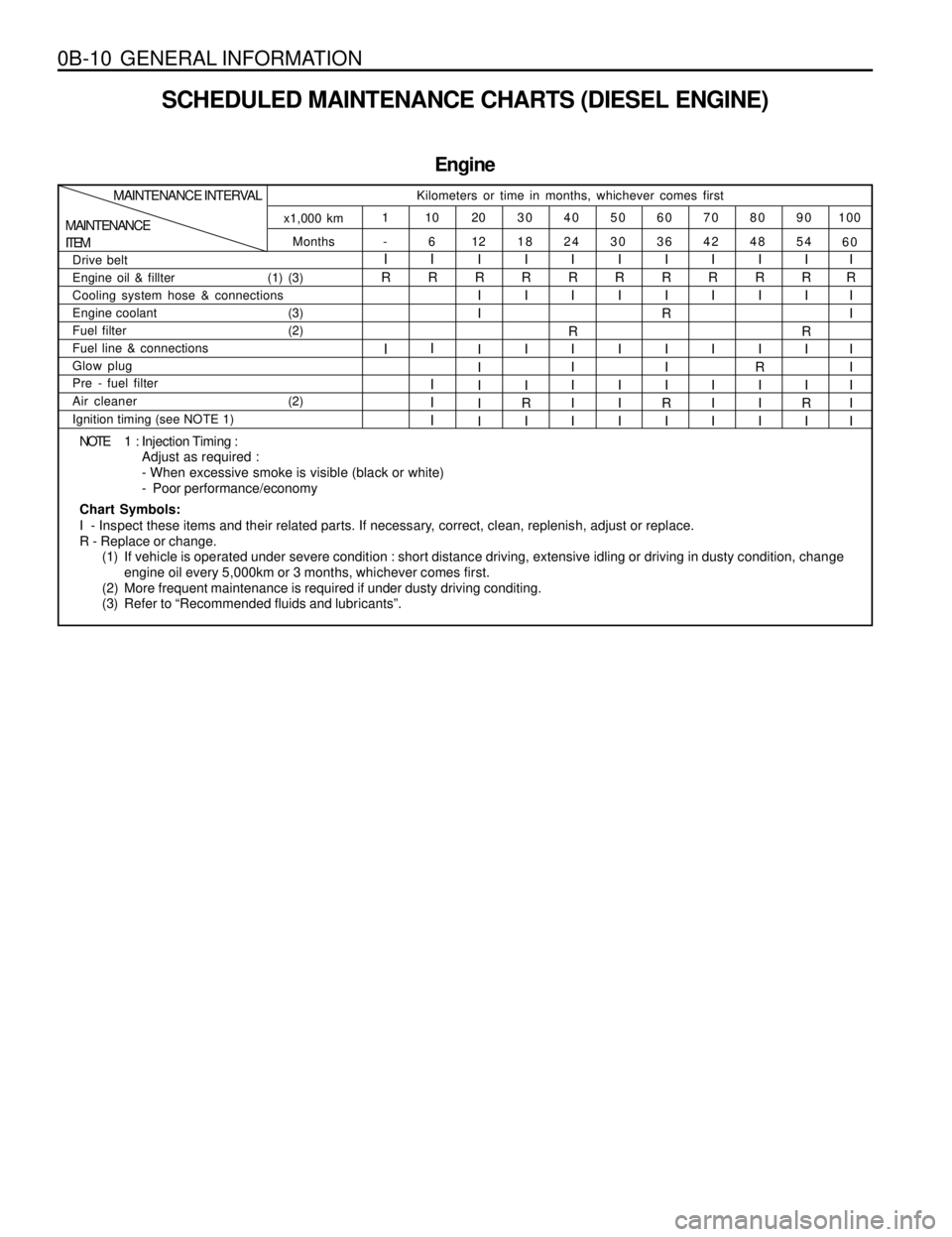

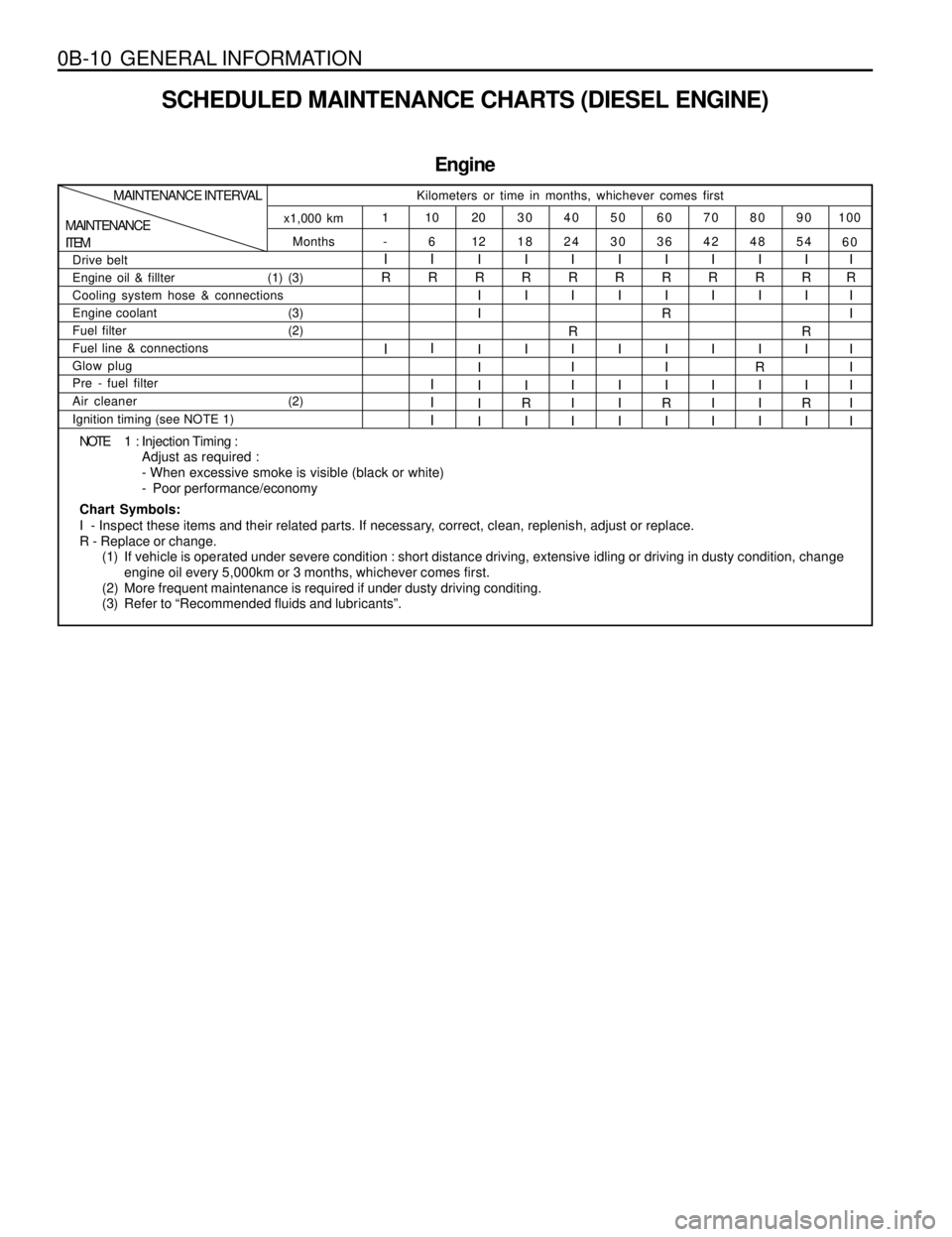

0B-10 GENERAL INFORMATION

SCHEDULED MAINTENANCE CHARTS (DIESEL ENGINE)

Engine

Months

-

MAINTENANCE

ITEMMAINTENANCE INTERVAL

Kilometers or time in months, whichever comes first

100 90 80 70 60 50 40 30 20 10 1

60 54 48 42 36 30 24 18 12 6 x1,000 km

NOTE 1 :Injection Timing :

Adjust as required :

- When excessive smoke is visible (black or white)

- Poor performance/economy

Chart Symbols:

I - Inspect these items and their related parts. If necessary, correct, clean, replenish, adjust or replace.

R - Replace or change.

(1) If vehicle is operated under severe condition : short distance driving, extensive idling or driving in dusty condition, change

engine oil every 5,000km or 3 months, whichever comes first.

(2) More frequent maintenance is required if under dusty driving conditing.

(3) Refer to “Recommended fluids and lubricants”.

Drive belt

Engine oil & fillter (1) (3)

Cooling system hose & connections

Engine coolant (3)

Fuel filter (2)

Fuel line & connections

Glow plug

Pre - fuel filter

Air cleaner (2)

Ignition timing (see NOTE 1)I

R

II

R

I

I

I

I

I

R

I

I

I

I

I

I

II

R

I

I

I

R

II

R

I

R

I

I

I

I

II

R

I

I

I

I

II

R

I

R

I

I

I

R

II

R

I

I

I

I

II

R

I

I

R

I

I

II

R

I

R

I

I

R

II

R

I

I

I

I

I

I

I

Page 331 of 1463

OM600 ENGINE MECHANICAL 1B3-29

1 Threaded Ring........................................130 Nm

2 Prechamber

PRECHAMBER

Preceding Work : Removal of glow plug

Removal of fuel injection nozzle

3 Cylinder Head

Page 345 of 1463

OM600 ENGINE MECHANICAL 1B3-43

18. Disconnect the booster hose connected to intake manifold.

19. Remove the intake manifold and gasket.

20. Remove the cylinder head cover and gasket with the blow-

by gas hose.

21. Disconnect the glow plug cables.

Page 346 of 1463

1B3-44 OM600 ENGINE MECHANICAL

22. Remove the cable channel.

23. Disconnect the cables from the glow plug sensor and

coolant temperature sensor.

24. Remove the heater pipe bracket from the oil filter.

25. Pry off the clamp and push the heater feed pipe forward

and then pull out the pipe.

Page 361 of 1463

OM600 ENGINE MECHANICAL 1B3-59

27. Replace the seal and then install the chain tensioner.

Tightening Torque 80 Nm

28. Remove the engine lock.

29. Insert the nozzle washer into the hole to face round part

downward.

30. Install the fuel injection nozzle.

Tightening Torque 40 Nm

31. Connect the fuel hose.

32. Install the cable channel and connect the cables to glow

plugs.

Page 362 of 1463

1B3-60 OM600 ENGINE MECHANICAL

35. Connect the wires to the coolant temperature sensor and

the glow plug sensor.

36. Replace the intake manifold gasket.

37. Install the intake manifold.

Tightening Torque 25 Nm

33. Replace the gasket and install the cylinder head cover.

Tightening Torque 10 Nm

34. Install the blow-by hose.

Page 439 of 1463

OM600 ENGINE MECHANICAL 1B3-137

CAMSHAFT TIMING TEST

Preceding Work : Removal of glow plug

1 Cylinder Head Cover

2 Bolt............................................................10Nm

3 Gasket ................................................... Replace4 Valve Tappet

5 Cylinder Head

Timing

Condition of camshaft

New

After approx. 20,000kmIntake valve

Open

ATDC 11.33°

ATDC 12°Close

ABDC 17°

ABDC 18°Exhaust valve

Open

BBDC 28°

BBDC 27°Close

BTDC 15.25°

BTDC 14°

«At 2mm of valve lifting stroke.

Page 449 of 1463

OM600 ENGINE MECHANICAL 1B3-147

TIMING CHAIN

Preceding Work : Removal of glow plug

Removal of chain tensioner

Removal of cooling fan

Removal of cylinder head cover

1 Chain Link

2 Timing Chain

3 Camshaft Sprocket

4 Outer Plate

Page 563 of 1463

SECTION 1E3

OM600 ENGINE ELECTRICAL

Specifications . . . . . . . . . . . . . . . . . . . . . . . 1E3-1

General Specifications . . . . . . . . . . . . . . . . . 1E3-1

Maintenance and Repair . . . . . . . . . . . . . . 1E3-2

On-Vehicle Service . . . . . . . . . . . . . . . . . . . . . 1E3-2

TABLE OF CONTENTS

Caution: Disconnect the negative battery cable before removing or installing any electrical unit or when a

tool or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable

will help prevent personal injury and damage to the vehicle. The ignition must also be in LOCK unless otherwise

noted.

Application

Alternator

Starter

Glow PlugDescription

12V - 75A

12V - 2.2kW

11.5V

SPECIFICATIONS

GENERAL SPECIFICATIONS

Glow Plug . . . . . . . . . . . . . . . . . . . . . . . . . . . 1E3-2

Alternator . . . . . . . . . . . . . . . . . . . . . . . . . . . 1E3-6

Starter Motor . . . . . . . . . . . . . . . . . . . . . . . . . 1E3-8

Page 564 of 1463

1E3-2 OM600 ENGINE ELECTRICAL

Preheating System

General information

The preheating system consists of control, coolant temperature

sensor and glow plugs.

lControl relay - preheating time.

lCoolant temperature sensor.

lGlow plug.

GLOW PLUG

1 Wiring Harness

2 Nut .............................................................. 4 Nm3 Wire Terminal

4 Glow Plug

MAINTENANCE AND REPAIR

ON-VEHICLE SERVICE