water pump SSANGYONG MUSSO 1998 Workshop Repair Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1998, Model line: MUSSO, Model: SSANGYONG MUSSO 1998Pages: 1463, PDF Size: 19.88 MB

Page 16 of 1463

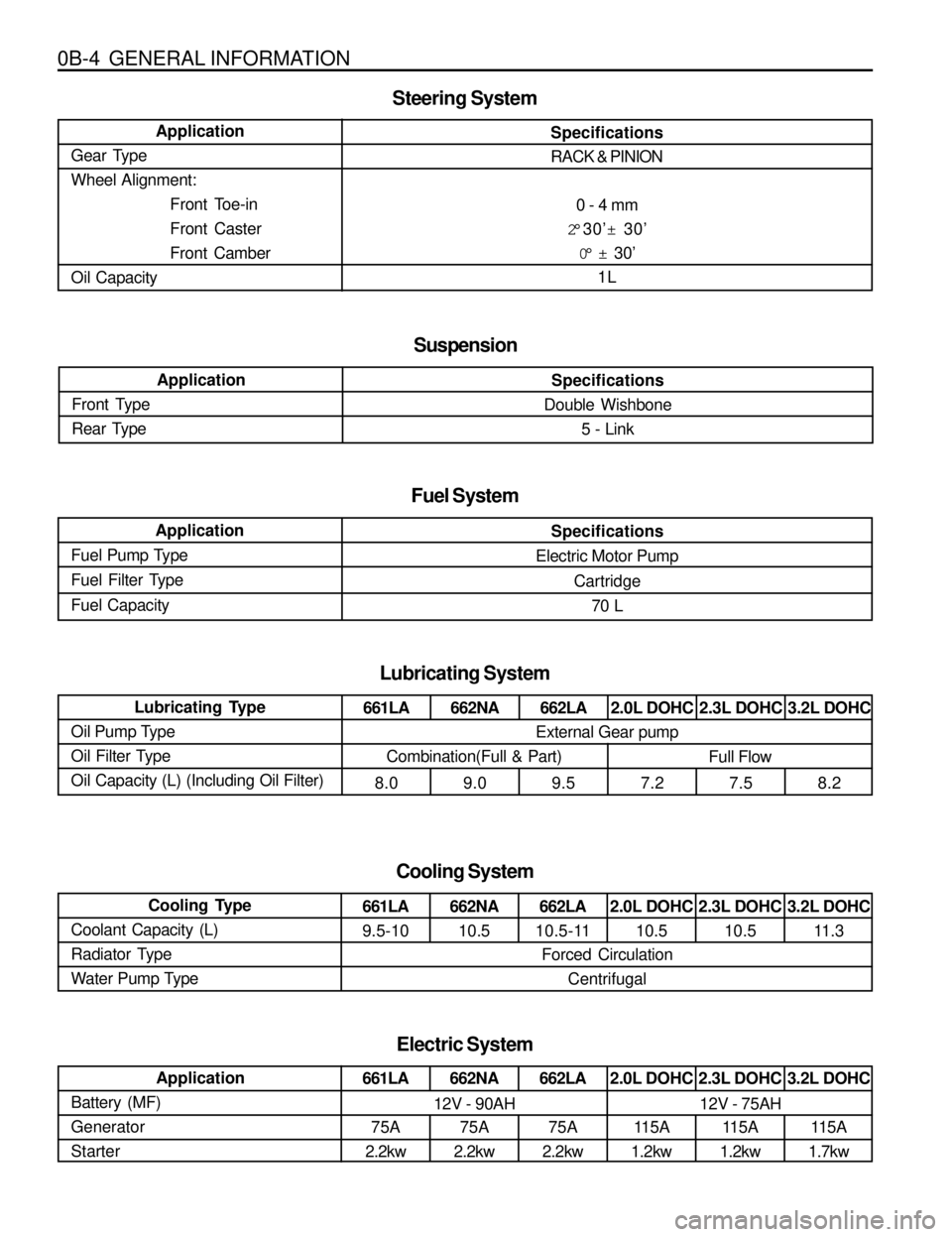

0B-4 GENERAL INFORMATION

Specifications

RACK & PINION

0 - 4 mm

2°30’± 30’

0° ± 30’

1L Application

Gear Type

Wheel Alignment:

Front Toe-in

Front Caster

Front Camber

Oil Capacity

Steering System

Application

Front Type

Rear Type

Suspension

Specifications

Double Wishbone

5 - Link

Application

Fuel Pump Type

Fuel Filter Type

Fuel Capacity

Specifications

Electric Motor Pump

Cartridge

70 L

Fuel System

Lubricating Type

Oil Pump Type

Oil Filter Type

Oil Capacity (L) (Including Oil Filter)

Lubricating System

661LA

8.0662NA

9.0662LA

9.52.0L DOHC

7.22.3L DOHC

7.53.2L DOHC

8.2

External Gear pump

Combination(Full & Part)

Full Flow

Cooling Type

Coolant Capacity (L)

Radiator Type

Water Pump Type

Cooling System

661LA

9.5-10662NA

10.5662LA

10.5-112.0L DOHC

10.52.3L DOHC

10.53.2L DOHC

11.3

Forced Circulation

Centrifugal

Application

Battery (MF)

Generator

Starter

Electric System

661LA

75A

2.2kw662NA

75A

2.2kw662LA

75A

2.2kw2.0L DOHC

115A

1.2kw2.3L DOHC

115A

1.2kw3.2L DOHC

115A

1.7kw

12V - 90AH12V - 75AH

Page 76 of 1463

M162 ENGINE MECHANICAL 1B1-3

N

· ·· ·

·m

20 / +90°

40

72 - 88

20 / +90°

25 - 35

22.5 - 27.5

22.5 - 27.5

22.5 - 27.5

22.5 - 27.5

30

26 - 34

30

8 - 10

25

25

22.5 - 27.5

29 - 35

22.5 - 27.5

9 - 11

50

9 - 11

15Application

Exhaust Camshaft Sproket Bolt

Chain Tensioner Screw Plug

Chain Tensioner Assembly

Exhaust Camshaft Sprocket to Camshaft

Oil Pump Sprocket Bolt

Tensioning Device Bolt

Water Pump Pulley

Upper Intake Manifold Bolt

Lower Intake Mainfold Bolt

Flange Bolt to Exhaust Mainfold

Exhaust Mainfold Nut to Stud Bolt

Rivet Nut in Exhuast Mainfold Hole

Pre-silencer Bolt

Oil Drain Plug

Oil Filter Cover

Oil Filter Bolt

Oil Pump Drive Sprocket Bolt

Oil Pump Mounting Bolt

Oil Strainer Bracket Bolt

Oil Pressure Relief Valve Screw Plug

Oil Dipstick Guide Tube Bolt

Oil Gallery Screw Plug

FASTENER TIGHTENING SPECIFICATIONS (Cont’d)

Page 99 of 1463

1B1-26 M162 ENGINE MECHANICAL

Poly V-Belt Arrangement

1 Belt Tensioning Pulley

2 Crankshaft Belt Pulley

3 A/C Compressor Pulley

4 Cooling Fan Pulley5 Alternator Pulley

6 Idler

7 Power Steering Pump Pulley

8 Cooling Fan and Water Pump Pulley

Page 100 of 1463

M162 ENGINE MECHANICAL 1B1-27

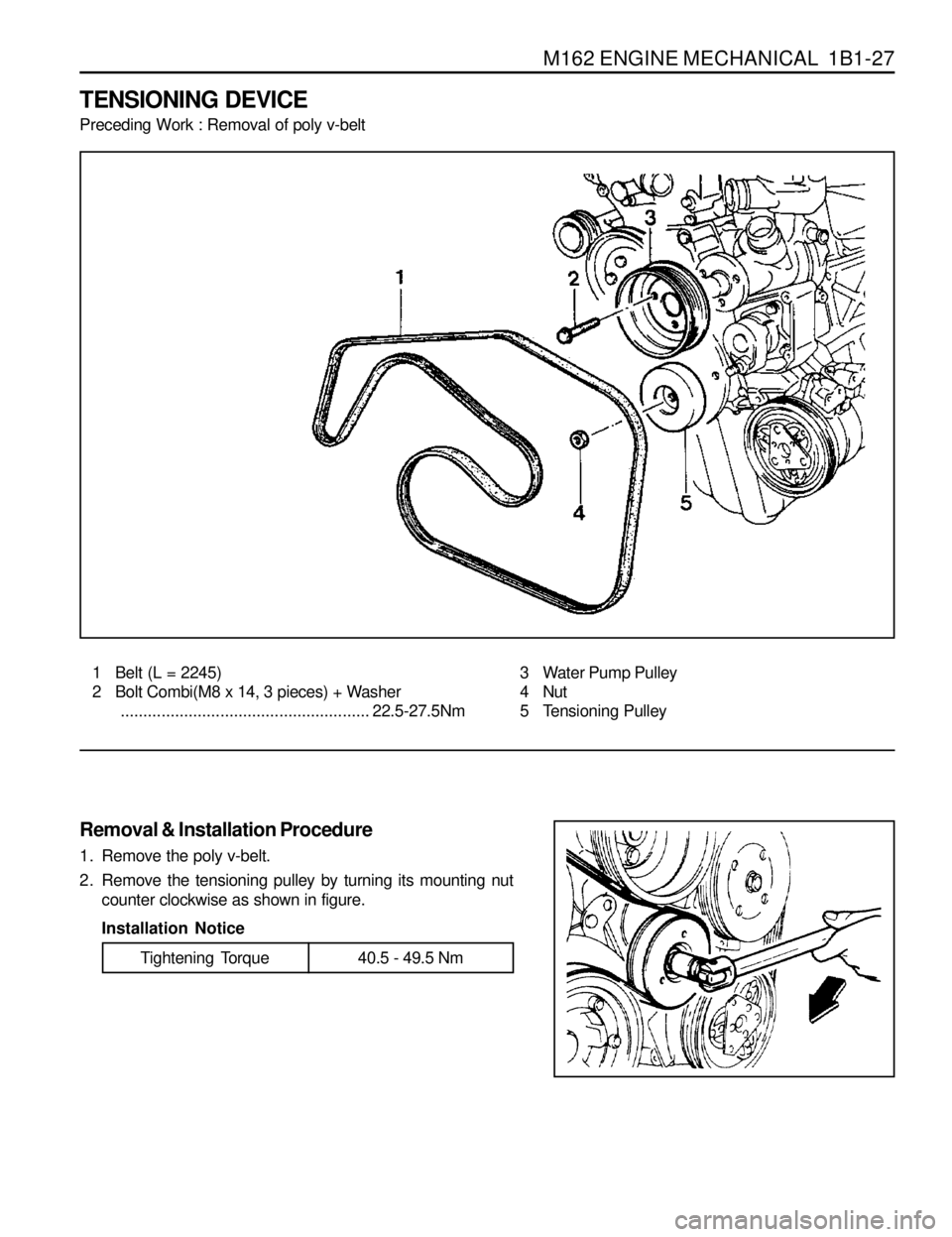

TENSIONING DEVICE

Preceding Work : Removal of poly v-belt

1 Belt (L = 2245)

2 Bolt Combi(M8 x 14, 3 pieces) + Washer

.......................................................22.5-27.5Nm

Removal & Installation Procedure

1. Remove the poly v-belt.

2. Remove the tensioning pulley by turning its mounting nut

counter clockwise as shown in figure.

Installation Notice3 Water Pump Pulley

4 Nut

5 Tensioning Pulley

Tightening Torque 40.5 - 49.5 Nm

Page 101 of 1463

1B1-28 M162 ENGINE MECHANICAL

4. Remove the mounting bolts(M8 x 30, 3 pieces) at the

tensioning device, and remove the tensioning device (arrow).

Installation Notice 3. Remove the 3 bolts (2) and remove the water pump pulley

(arrow).

Installation Notice

5. Installation should follow the removal procedure in the

reverse order.

Tightening Torque 22.5 - 27.5 Nm

Tightening Torque 26 - 32 Nm

Page 192 of 1463

M161 ENGINE MECHANICAL 1B2-3

N

· ·· ·

·m

20 / + 90°

40

72 - 88

20 / + 90°

25 - 35

22.5 - 27.5

22.5 - 27.5

22.5 - 27.5

22.5 - 27.5

30

26 - 34

30

8 - 10

25

25

22.5 - 27.5

29 - 35

22.5 - 27.5

9 - 11

50

9 - 11

15Application

Exhaust Camshaft Sproket Bolt

Chain Tensioner Screw Plug

Chain Tensioner Assembly

Exhaust Camshaft Sprocket to Camshaft

Oil Pump Sprocket Bolt

Tensioning Device Bolt

Water Pump Pulley

Upper Intake Manifold Bolt

Lower Intake Mainfold Bolt

Flange Bolt to Exhaust Mainfold

Exhaust Mainfold Nut to Stud Bolt

Rivet Nut in Exhuast Mainfold Hole

Pre-Silencer Bolt

Oil Drain Plug

Oil Filter Cover

Oil Filter Bolt

Oil Pump Drive Sprocket Bolt

Oil Pump Mounting Bolt

Oil Strainer Bracket Bolt

Oil Pressure Relief Valve Screw Plug

Oil Dipstick Guide tube Bolt

Oil Gallery Screw Plug

FASTENER TIGHTENING SPECIFICATIONS (Cont’d)

Page 218 of 1463

M161 ENGINE MECHANICAL 1B2-29

Poly V-belt Arrangement

1 Belt Tensioning Pulley

2 Crankshaft Belt Pulley

3 A/C Compressor Pulley5 Alternator Pulley

7 Power Steering Pump Pulley

8 Water Pump Pulley

Page 233 of 1463

1B2-44 M161 ENGINE MECHANICAL

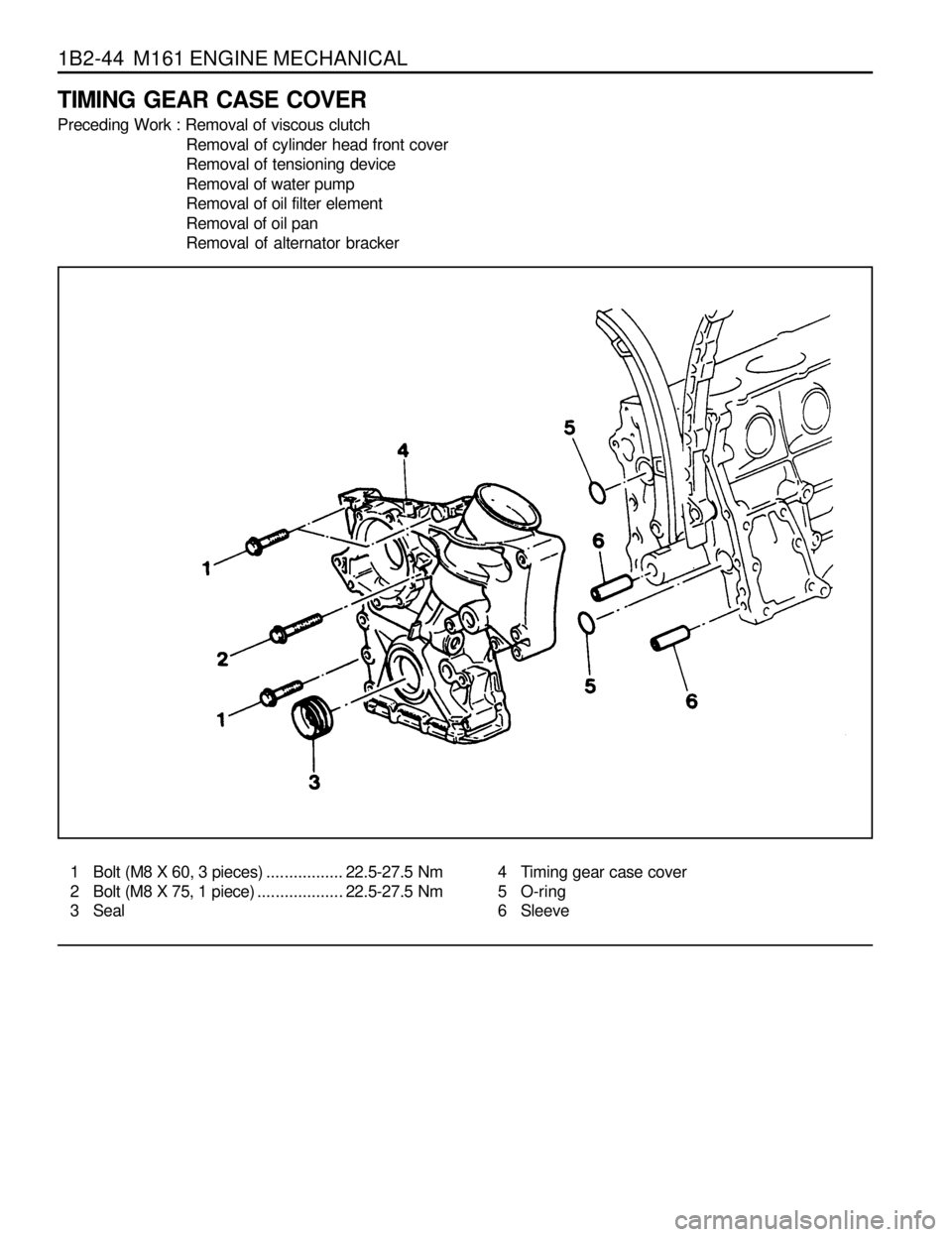

TIMING GEAR CASE COVER

Preceding Work : Removal of viscous clutch

Removal of cylinder head front cover

Removal of tensioning device

Removal of water pump

Removal of oil filter element

Removal of oil pan

Removal of alternator bracker

1 Bolt (M8 X 60, 3 pieces).................22.5-27.5 Nm

2 Bolt (M8 X 75, 1 piece)...................22.5-27.5 Nm

3 Seal4 Timing gear case cover

5 O-ring

6 Sleeve

Page 490 of 1463

SECTION 1D1

M162 ENGINE COOLING

Specifications . . . . . . . . . . . . . . . . . . . . . . . 1D1-1

General Specifications . . . . . . . . . . . . . . . . . 1D1-1

Fastener Tightening Specifications . . . . . . . . 1D1-2

Special Tools . . . . . . . . . . . . . . . . . . . . . . . 1D1-3

Special Tools Table . . . . . . . . . . . . . . . . . . . . 1D1-3

Diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . 1D1-4

System Leakage Test . . . . . . . . . . . . . . . . . . 1D1-4

Maintenance and Repair . . . . . . . . . . . . . . 1D1-5

On-Vehicle Service . . . . . . . . . . . . . . . . . . . . . 1D1-5Coolant Drain and Fill Up . . . . . . . . . . . . . . . 1D1-5

Coolant Connection Fitting . . . . . . . . . . . . . . 1D1-7

Water Pump . . . . . . . . . . . . . . . . . . . . . . . . . 1D1-8

Thermostat . . . . . . . . . . . . . . . . . . . . . . . . . 1D1-10

Oil Cooler Pipe Line . . . . . . . . . . . . . . . . . . 1D1-11

Cooling Fan and Viscous Clutch . . . . . . . . . 1D1-12

Cooling Fan Shroud . . . . . . . . . . . . . . . . . . 1D1-14

Radiator . . . . . . . . . . . . . . . . . . . . . . . . . . . 1D1-15

SPECIFICATIONS

GENERAL SPECIFICATIONS

CAUTION: Disconnect the negative battery cable before removing or installing any electrical unit or when a

tool or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable

will help prevent personal injury and damage to the vehicle. The ignition must also be in LOCK unless otherwise

noted.

TABLE OF CONTENTS

Description

Water Cooling Forced Circulation

Double Cross Flow

70,000 kcal/h

580 x 482 x 45 mm

f 460, Six Blades

ALUTEC - P78

50 : 50

11.3 L

3.4 L

1.4 bar Application

Cooling Type

Radiator

Dimension(Width´Height´Thickeness)

Cooling Fan

Anti-Freeze Agent

Mixing Ratio of Anti-Freeze Agen with Water (Anti-Freeze Agent : Water)

Coolant Capacity

Reservoir Capacity

Cap Operating Pressure (Reservoir Tank Pressure Cap)

Circulation Type

Radiation Capability

Page 495 of 1463

1D1-6 M162 ENGINE COOLING

6. Remove the de-aeration hose clamp in the coolant pump

and remove the de-aeration hose.

7. Fill up the coolant through the coolant reservoir tank.

Notice

lMatch the anti-freeze and the water ratio to 50 : 50.

lSupplement the coolant until the coolant overflows to

the deaeration hose.

8. Insert the de-aeration hose and completely tighten the

clamp.

9. Check the coolant level in the coolant reservoir tank.

10. Warm up(until thermostat is opened) the engine and

recheck the coolant level in the reservoir tank and fill up

the coolant if necessary.