weight SSANGYONG MUSSO 1998 Workshop Repair Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1998, Model line: MUSSO, Model: SSANGYONG MUSSO 1998Pages: 1463, PDF Size: 19.88 MB

Page 13 of 1463

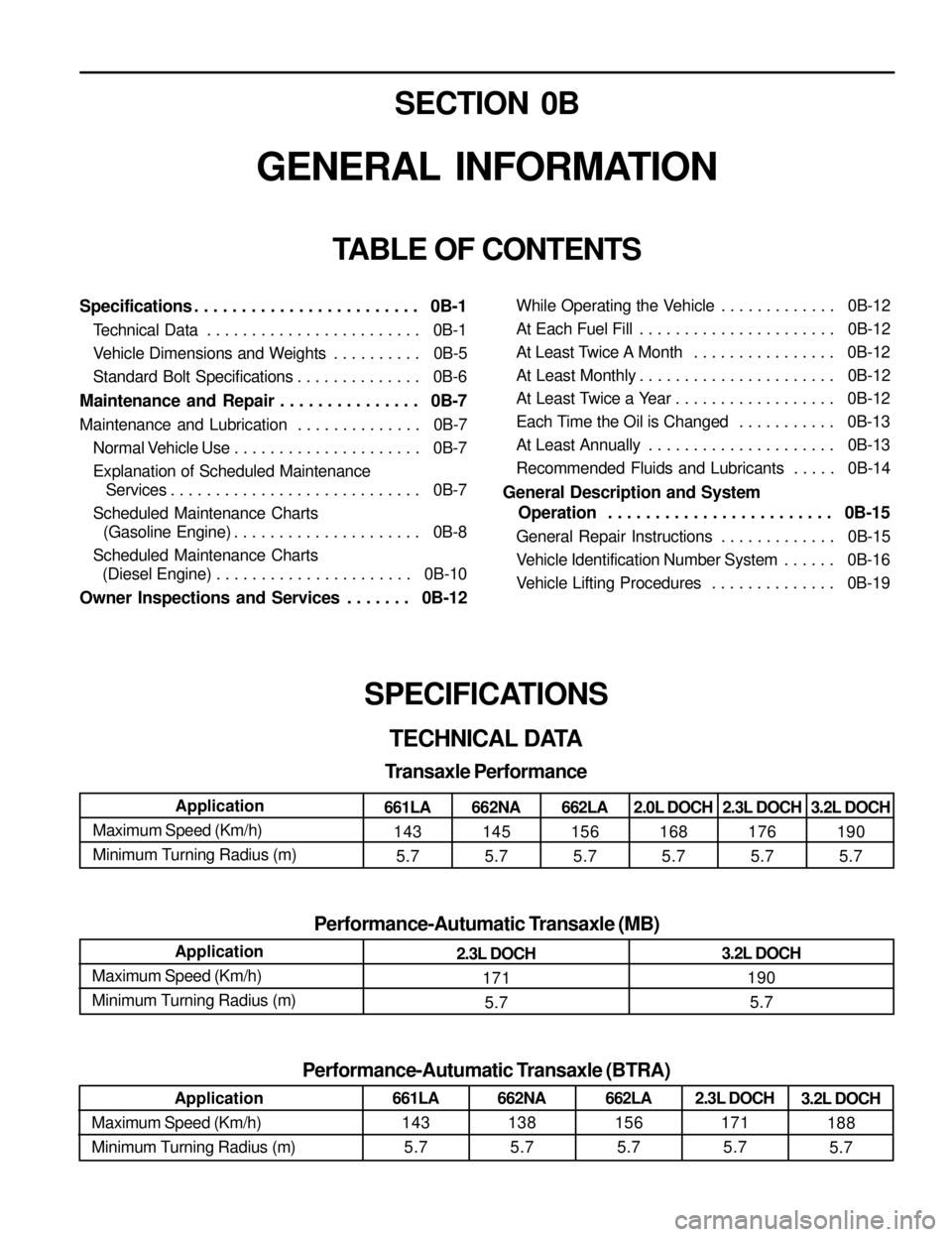

SECTION 0B

GENERAL INFORMATION

Specifications . . . . . . . . . . . . . . . . . . . . . . . . 0B-1

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . 0B-1

Vehicle Dimensions and Weights . . . . . . . . . . 0B-5

Standard Bolt Specifications . . . . . . . . . . . . . . 0B-6

Maintenance and Repair . . . . . . . . . . . . . . . 0B-7

Maintenance and Lubrication . . . . . . . . . . . . . . 0B-7

Normal Vehicle Use . . . . . . . . . . . . . . . . . . . . . 0B-7

Explanation of Scheduled Maintenance

Services . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0B-7

Scheduled Maintenance Charts

(Gasoline Engine) . . . . . . . . . . . . . . . . . . . . . 0B-8

Scheduled Maintenance Charts

(Diesel Engine) . . . . . . . . . . . . . . . . . . . . . . 0B-10

Owner Inspections and Services . . . . . . . 0B-12

TABLE OF CONTENTS

While Operating the Vehicle . . . . . . . . . . . . . 0B-12

At Each Fuel Fill . . . . . . . . . . . . . . . . . . . . . . 0B-12

At Least Twice A Month . . . . . . . . . . . . . . . . 0B-12

At Least Monthly . . . . . . . . . . . . . . . . . . . . . . 0B-12

At Least Twice a Year . . . . . . . . . . . . . . . . . . 0B-12

Each Time the Oil is Changed . . . . . . . . . . . 0B-13

At Least Annually . . . . . . . . . . . . . . . . . . . . . 0B-13

Recommended Fluids and Lubricants . . . . . 0B-14

General Description and System

Operation . . . . . . . . . . . . . . . . . . . . . . . . 0B-15

General Repair Instructions . . . . . . . . . . . . . 0B-15

Vehicle Identification Number System . . . . . . 0B-16

Vehicle Lifting Procedures . . . . . . . . . . . . . . 0B-19

SPECIFICATIONS

TECHNICAL DATA

Transaxle Performance

Application

Maximum Speed (Km/h)

Minimum Turning Radius (m)661LA

143

5.7662NA

145

5.7662LA

156

5.72.0L DOCH

168

5.72.3L DOCH

176

5.73.2L DOCH

190

5.7

Application

Maximum Speed (Km/h)

Minimum Turning Radius (m)

Performance-Autumatic Transaxle (MB)

2.3L DOCH

171

5.73.2L DOCH

190

5.7

Application

Maximum Speed (Km/h)

Minimum Turning Radius (m)

Performance-Autumatic Transaxle (BTRA)

661LA

143

5.7662NA

138

5.7662LA

156

5.72.3L DOCH

171

5.73.2L DOCH

188

5.7

Page 17 of 1463

GENERAL INFORMATION 0B-5

Application

Overall Length (mm)

Overall Width (mm)

Overall Height (mm)

Wheel Base (mm)

Tread :Front (mm)

Rear (mm)

VEHICLE DIMENSIONS AND WEIGHTS

Vehicle Dimensions

Application

Manual : Curb Weight (kg)

Gross Vehicle Weight (kg)

Automatic : Curb Weight (kg)

Gross Vehicle Weight (kg)

Passenger Capacity

Vehicle Weights

Application

4656

1864

1735

2630

1510

1520

661LA

1860

2520

1916

2520

5662NA

1968

2520

1989

2520

5662LA

1890

2520

2005

2520

52.0L DOHC

1937

2520

-

-

52.3L DOHC

1850

2520

1942

2520

53.2L DOHC

1930

2520

2025

2520

5

Page 121 of 1463

1B1-48 M162 ENGINE MECHANICAL

Arrangement of the Thrust Bearing and the Main Bearing

1 - 12 Weight Balance/Color Marking Point

j1 - j7 Journal Main Bearing #1 - #7

lColor Dot Marking

The color dot marking are put on the

1 , 2 , 4 , 6 , 8

,

10 ,12 and it indicates the diameter of crankshaft journal

by color as below.A Crankcase Side

B Bearing Cap Side (Oil Pan Side)

C Axial Fit Bearing (Number 5 Bearing Point)

D Radial Bearing

1 Upper Main Bearing

2 Upper Thrust Bearing

3 Crankshaft

4 Lower Main Bearing

5 Lower Thrust Bearing

Page 161 of 1463

1B1-88 M162 ENGINE MECHANICAL

CONNECTING ROD

Preceding Work : Removal of piston

1 Connecting Rod Bushing

2 Oil Gallery

3 Balance Weight

4 Connecting Rod Bolt

(M9 x 52, 12 m pieces) .. 1st step 40+5 Nm

2nd step 90°+10°

5 Fit Sleeve

6 Upper Connecting Rod Bearing

7 Lower Connecting Rod Bearing

8 BearingShell Lug

9 Marking [Indication(//) or Numbers]

Service Data Standard

Distance (L) from The Connecting Rod Bearing Bore Center to The Bushing Bore Center

Width of The Connecting Rod (B) at Bearing Bore

Width of The Connecting Rod (b) at Bushing Bore

Basic Bore at The Bearing Shell (D1)

Basic Bore at The Bushing (d1)

Bushing Inner Diameter (d)

Clearance Between The Piston Pin and The Bushing

Peak-to-valley Height of Connecting Rod Bushing on Inside

Permissible Wwist of Connecting Rod Bearing Bore to Connecting Rod Bushing Bore

Permissible Deviation of Axial Paralleism of Connecting Rod Bearing Bore to Connecting

Rod Bushing Core

Permissible Deviation of Connecting Rod Bearing Bore from Concentricity

Permissible Difference of Each Connecting Rod in Weight145 ± 0.05 mm

21.940 - 22.000 mm

21.940 - 22.000 mm

51.600 - 51.614 mm

24.500 - 24.571 mm

22.007 - 22.013 mm

0.007 - 0.018 mm

0.005 mm

0.15 mm

0.07 mm

0.01 mm

0.4 g

Page 244 of 1463

M161 ENGINE MECHANICAL 1B2-55

Arrangement of the Thrust Bearing and the Main Bearing

1 - 8 Weight Balance/Color Marking Point

j1 - j5 Journal Main Bearing #1 - #5

lColor Dot Marking

The color dot marking are put on the 1 , 2 , 4 , 6

, 8 , and it indicates the diameter of crankshaft journal

by color as below.A Crankcase Side

B Bearing Cap Side (Oil Pan Side)

1 Upper Main Bearing

2 Upper Thrust Bearing

3 Crankshaft

4 Lower Main Bearing

5 Lower Thrust Bearing

Page 282 of 1463

M161 ENGINE MECHANICAL 1B2-93

CONNECTING ROD

Preceding Work : Removal of piston

1 Connecting Rod Bushing

2 Oil Gallery

3 Balance Weight

4 Connecting Rod Bolt

(M9 x 52, 8 pieces)............1st step 40 Nm

2nd step 90°

5 Fit Sleeve

6 Upper Connecting Rod Bearing

7 Lower Connecting Rod Bearing

8 BearingShell Lug

9 Marking [Indication(//) or Numbers]

Service Data Standard

Distance (L) from The Connecting Rod Bearing to Bushing Bore Center

Width of The Connecting Rod (B) at Bearing Bore

Width of The Connecting Rod (b) at Bushing Bore

Basic Bore at The Bearing Shell (D1)

Basic Bore at The Bushing (d1)

Bushing Inner Diameter (d)

Clearance Between The Piston Pin and The Bushing

Peak-to-valley Height of Connecting Rod Bushing on Inside

Permissible Wwist of Connecting Rod Bearing Bore to

Connecting Rod Bushing Bore

Permissible Deviation of Axial Paralleism of Connecting Rod

Bearing Bore to Connecting Rod Bushing Bore

Permissible Deviation of Axial Paralleism of Connecting Rod Bearing Bore from

Concentricity

Permissible Difference of Each Connecting Rod in WeightE20 : 154 mm

E23 : 149 ± 0.05 mm

21.940 - 22.000 mm

21.940 - 22.000 mm

51.600 - 51.614 mm

24.500 - 24.571 mm

22.007 - 22.013 mm

0.007 - 0.018 mm

0.005 mm

0.1/100 mm

0.045/100 mm

0.01 mm

0.4 g

Page 465 of 1463

OM600 ENGINE MECHANICAL 1B3-163

PISTON

Preceding Work : Removal of the cylinder head

Removal of the oil pump

1 Oil Ring

2 2nd Ring

3 Top Ring

4 Snap Ring.............................................. Replace

5 Piston Pin

6 Piston

7 Connecting Rod Bushing.......................... Check8 Connecting Rod

9 Connecting Rod Upper Bearing Shell

10 Connecting Rod Lower Bearing Shell

11 Connecting Rod Bearing Cap

12 Connecting Rod Bolt.........................35Nm + 90°

13 Crankcase

14 Cylinder Bore

Notice

There are two kinds of connecting rods (for machining) and they are different in weight approx. 15g. When replacing

the connecting rod, measure its weight and ensure that a engine has the same weight of connecting rods. If not, there

would be a unbalancing of engine.

Page 757 of 1463

1F3-28 OM600 ENGINE CONTROLS

Tools Required

001 589 65 09 00 Socket Wrench Insert

000 589 00 68 00 Cleaning Set

Repair Procedure

1. Clamp the nozzle holder (1) in a vice and remove the nozzle

tensioning nut (8).

Notice

Use protective jaws for clamping.

2. Disassemble the fuel injection nozzle.

Socket Wrench Insert 001 589 65 09 00

3. Clean the nozzle needle (6) and nozzle body (7) with an

abradant.

4. Clean the nozzle seat with cleaning cutter.

Cleaning Set 000 589 00 68 00

5. Immerse nozzle needle (6) and nozzle body (7) in filtered

diesel fuel. When the nozzle body is held vertical, the weight

of the nozzle needle must cause it to slide down toward the

nozzle needle seat.

6. Assemble the injection nozzle so that the tip of the thrust

(4) pin is facing toward the nozzle holder.

Tightening Torque 80 Nm

Notice

Nozzle needle (6) and nozzle body (7) should always be

replaced as a pair.

Page 764 of 1463

OM600 ENGINE CONTROLS 1F3-35

INJECTION TIMING DEVICE

Preceding Work : Removal of injection timing device

1 Cam Sprocket........................................... Check

2 Bushing .................................................... Check

3 Governor Weights4 Segment Flange and Drive Hub

5 Compression Springs

Page 765 of 1463

1F3-36 OM600 ENGINE CONTROLS

Disassembly & Assembly

1. Remove the governor weights (3).

2. Pull out the compression springs (5) and cam sprocket (1)

from the segment flange (4).

3. Knock out the bushing with a proper drift.

4. Installation should follow the removal procedure in the

reverse order.