horn SSANGYONG MUSSO 2003 Service Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2003, Model line: MUSSO, Model: SSANGYONG MUSSO 2003Pages: 1574, PDF Size: 26.41 MB

Page 12 of 1574

0B-12 GENERAL INFORMATIONOWNER INSPECTIONS AND SERVICES

WHILE OPERATING THE VEHICLE Horn Operation Blow the horn occasionally to make sure it works. Check all the button locations. Brake System Operation Be alert for abnormal sounds, increased brake pedal travel or repeated puling to one side when braking. Also, if the brake warning light goes on, or flashes, something may be wrong with part of the brake system. Exhaust System Operation Be alert to any changes in the sound of the system or the smell of the fumes. These are signs that the system may be leaking or overheating. Have the system

inspected and repaired immediately. Tires, Wheels and Alignment Operation Be alert to any vibration of the steering wheel or the seats at normal highway speeds. This may mean a wheelneeds to be balanced. Also, a pull right or left on a straight, level road may show the need for a tire pressure adjustment or a wheel alignment. Steering System Operation Be alert to changes in the steering action. An inspection is needed when the steering wheel is hard to turn or

has too much free play, or is unusual sounds are noticedwhen turning or parking. Headlight Aim

Take note of the light pattern occasionally. Adjust the headlights if the beams seem improperly aimed.

AT EACH FUEL FILL A fluid loss in any (except windshield washer) system may indicate a problem. Have the system inspected and

repaired immediately. Engine Oil Level

Check the oil level and add oil if necessary. The best time to check the engine oil level is when the oil is warm.

1. After stopping the engine, wait a few minutes for the oil to drain back to the oil pan.

2. Pull out the oil level indicator (dip stick).

3. Wipe it clean, and push the oil level indicator back down all the way.

4. Pull out the oil level indicator and look at the oil level on it. 5. Add oil, if needed, to keep the oil level above the

lower mark. Avoid overfilling the engine, since this may cause engine damage.

6. Push the indicator all the way back down into the engine after taking the reading.

If you check the oil level when the oil is cold, do not runthe engine first. The cold oil will not drain back to the pan fast enough to give a true oil level reading. Engine Coolant Level and Condition Check the coolant level in the coolant reservoir tank

and add coolant if necessary. Inspect the coolant. Replace dirty or rusty coolant.

Windshield Washer Fluid Level

Check the washer fluid level in the reservoir. Add fluid if

necessary.

AT LEAST TWICE A MONTH Tire And Wheel Inspection and Pressure Check Check the tire for abnormal wear or damage. Also check for damaged wheels. Check the tire pressure when the tires are cold ( check the spare also, unless it is astowaway). Maintain the recommended pressures. Refer

to “Tire and Wheel” is in section 0B.

AT LEAST MONTHLY Light Operation Check the operation of the license plate light, the headlights (including the high beams), the parking lights,the fog lights, the taillight, the brake lights, the turn

signals, the backup lights and the hazard warning flasher. Fluid Leak Check Periodically inspect the surface beneath the vehicle for

water, oil, fuel or other fluids, after the vehicle has been

parked for a while. Water dripping from the air conditioning system after use is normal. If you notice fuel leaks or fumes, find the cause and correct it at once.

AT LEAST TWICE A YEAR Power Steering System Reservoir Level Check the power steering fluid level. Keep the power steering fluid at the proper level. Refer to Section 6A,

Power Steering System. Brake Master Cylinder Reservoir Level Check the fluid and keep it at the proper level. A low fluid level can indicate worn disc brake pads which mayneed to be serviced. Check the breather hole in the reservoir cover to be free from dirt and check for an open passage.

Page 1153 of 1574

6E-2 STEERING WHEEL AND COLUMNMAINTENANCE AND REPAIR

ON-VEHICLE SERVICE

STEERING COLUMN

1 Horn Pad

2 Nut ....................................................... 50-80 Nm

3 Washer

4 Steering Wheel

5 Combination Switch Assembly

6 Combination Switch Lower Cover

7 Combination Switch Upper Cover

8 Bolt

9 Bolt

10 Bolt

11 Crash Pad Panel

12 Bolt ...................................................... 30-40 Nm

13 Spring Washer

14 Steering Column Shaft

15 Bolt ........................................................ 9-14 Nm

16 Bolt ...................................................... 13-40 Nm

17 Column & Shaft Assembly

Page 1154 of 1574

STEERING WHEEL AND COLUMN 6E-3

Removal & Installation Procedure

1. Remove the horn pad from the steering wheel anddisconnect the connectors .

2. Place an alignment marks on the column shaft end and fixing nut and then remove the fixing nut. Installation Notice

3. Remove the steering wheel.

4. Remove the combination switch upper cover .

Tightening Torque 50 - 80 Nm

5. Release the crash pad panel. Notice Remove the hood release wire and the other switch connectors.

Page 1186 of 1574

8B-6 SUPPLEMENTAL RESTRAINT SYSTEM(SRS) AIR BAG MODULE

Air bag module is installed in the pad of steering wheel center and inflator is consisted of igniter, explosives, gas generating material and bag. When crashed, the air bag control unit sends current to the air bag module through squib line and this current ignites as ignition energy (6mJ) momentarily igniting explosives and bag will be inflated by nitrogen gas protecting driver at the same and then deflates.1 Air bag Module

2 Module Housing

3 Bag

4 Module Bracket

5 Retainer Ring

6 Inflator

7 Horn Switch

8 Backing Plate

Page 1199 of 1574

SUPPLEMENTAL RESTRAINT SYSTEM(SRS) 8B-19

Air Bag Horn (Relay) Remote Control (Electronic Circuit)

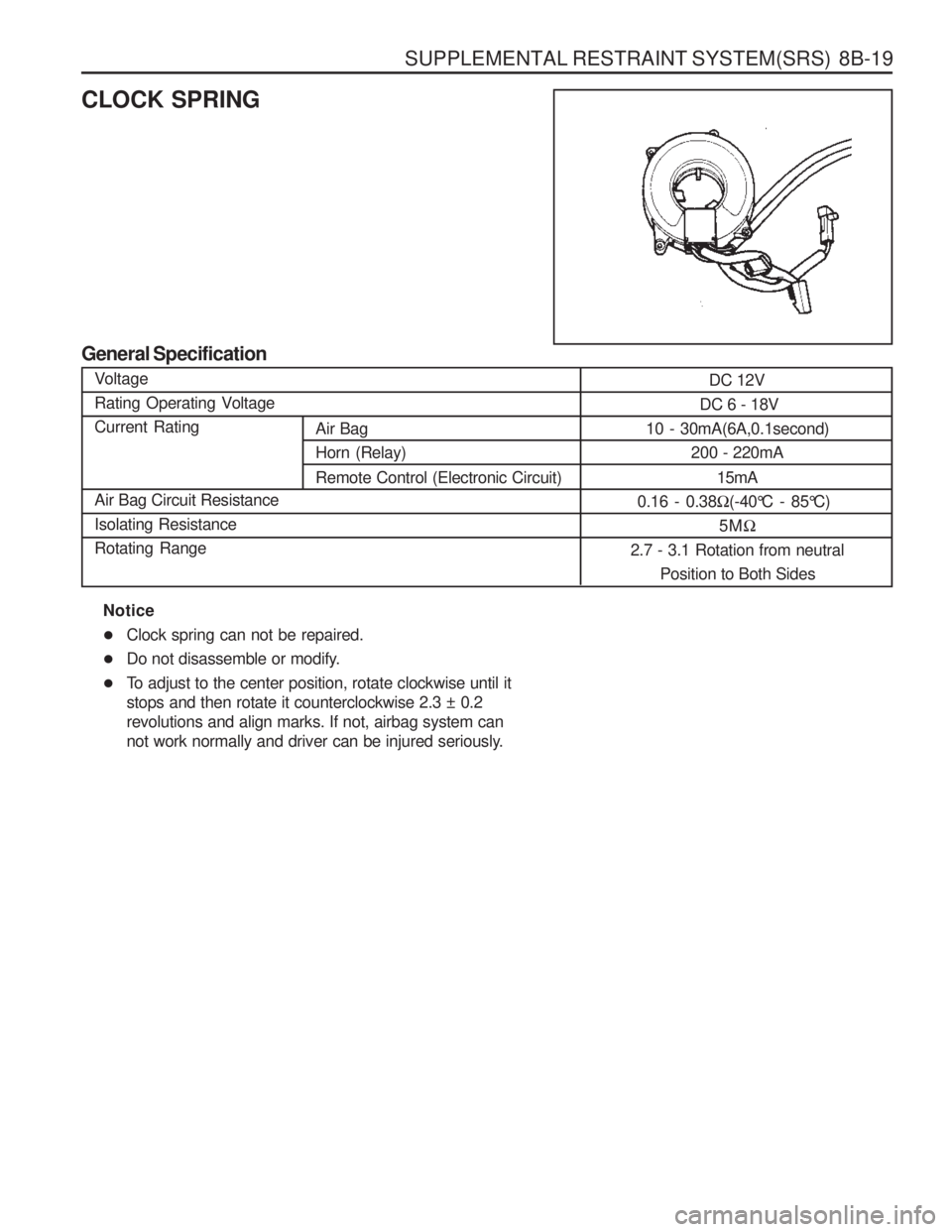

CLOCK SPRING

General SpecificationVoltage

Rating Operating VoltageCurrent Rating Air Bag Circuit Resistance Isolating ResistanceRotating Range DC 12V

DC 6 - 18V

10 - 30mA(6A,0.1second)

200 - 220mA

15mA

0.16 - 0.38 �(-40°C - 85°C)

5M �

2.7 - 3.1 Rotation from neutral Position to Both Sides

Notice

�Clock spring can not be repaired.

� Do not disassemble or modify.

� To adjust to the center position, rotate clockwise until it stops and then rotate it counterclockwise 2.3 ± 0.2revolutions and align marks. If not, airbag system can

not work normally and driver can be injured seriously.

Page 1208 of 1574

9A-6 BODY WIRING SYSTEM Engine Room Fuse (EF) and Relay Box1 Fuse (15A) : ABS, ABD

2 Fuse (20A) : Sun Roof

3 Fuse (10A) : Air Bag

4 Fuse (15A) : Audio, Clock, Out Side Mirror

5 Fuse (30A) : Cigarette lighter, Power Socket

6 Fuse (30A) : Heater

7 Fuse (15A) : Door Lock

8 Fuse (30A) : Rear Heated

9 Fuse (10A) : Audio, Buzzer, Chime, Clock

10 Fuse (30A) : Power Window

11 Fuse (10A) : Immobilizer

12 Fuse (20A) : T/C

13 Fuse (15A) : Interior Lamp

14 Fuse (15A) : Hazard Lamp

15 Fuse (15A) : Stop Lamp

16 Fuse (15A) : Turn signal Lamp, Head Lamp

17 Fuse (10A) : Back up Lamp

18 Fuse (15A) : Cluster, STICS

19 Fuse (15A) : A/T, Diagnosis

20 Fuse (15A) : Over Voltage Protection Relay (Gasolin Only)

21 Fuse (15A) : Seat Heater

22 Fuse (15A) : ECS

23 Fuse (15A) : Front Wiper & Washer

24 Fuse (10A) : Rear Wiper & Washer, A/C

25 Relay : Front Wiper 26 Relay : ABS Warning Lamp

27 Relay : Flasher Unit

28 Relay : Fuel Pump (Gasoline Only)

29 Relay : Shift Lock (A/T)

30 Relay : Clutch Interlock & Neutral

31 Relay : Sun Roof

32 Relay : A/T ‘B’ Interlock (MB A/T)

33 Relay : Power Window

34 Relay : Rear Fog Lamp

35 Relay : ECS

36 Relay : Compressor (Diesel E/G)

Condenser Fan (Gasoline E/G)

37 Relay : Condenser Fan

38 Relay : Air Conditioner

39 Fuse (10A) : Tail Lamp

40 Fuse (15A) : Head Lamp(LH)

41 Fuse (15A) : Head Lamp(RH)

42 Fuse (15A) : Front Fog Lamp

43 Fuse (10A) : Horn

44 Fuse (10A) : Compressor

45 Relay : Resistor with Diode (Gasoline E/G)

46 Relay : Front fog Lamp

47 Relay : Condenser Fan

48 Relay : Tail Lamp

49 Relay : Horn

Page 1213 of 1574

BODY WIRING SYSTEM 9A-11

ENGINE ROOM1 Engine Room Relay Box

1.1 Main Wiring Connector

1.2 Main Wiring Connector

1.3 Main Wiring Connector ........................................Gasoline E/G

1.4 Joint

1.5 Compressor, Condenser Fan Relay .....................Diesel E/G

1.6 Condenser Fan Relay 2

1.7 Air Conditioner Relay

1.8 Resistor with Diode .............................................. Gasoline E/G

1.9 Front Fog Lamp Relay

1.10 Condenser Fan Relay 1

1.11 Tail Lamp Relay

1.12 Horn Relay

2 Octane Selector ................................................... Gasoline E/G with HFM

3 Preheating Unit .................................................... Diesel E/G

4 Preheating Timer Unit .......................................... Diesel E/G

5 ECS Main Wiring Connector ................................ ECS

6 Brake Leveling Fluid Sensor

7 ABD Main Wiring Connector ................................ABD 5.0

7 - 1 ABS Main Wiring Connector ................................ABD 5.0

8 ABD main Wiring Connector ................................ABD 5.0

9 Engine Temperature Sensor ................................Diesel E/G

10 ABS 5.0 ECU ....................................................... ABS 5.0

10-1 ABD 5.0 Modulator ............................................... ABD 5.0

11 Front Washer Motor ............................................. Diesel E/G

12 Head Lamp Relay

13 Compressor ......................................................... Air Conditioner

14 Wheel Speed Sensor ........................................... ABS 5.0 or ABD 5.0

Page 1214 of 1574

9A-12 BODY WIRING SYSTEM

15 LH Damper........................................................... ECS

16 Ground 1

17 Ground 2

18 Locking Hub Solenoid

19 Condenser Fan Relay .........................................Gasoline E/G

20 LH Position Lamp

21 LH Head Lamp

22 LH Head Lamp Leveling Device ...........................Leveling Device

23 Thermo Switch 2 .................................................. Gasoline E/G with HFM

24 Thermo Switch 3 .................................................. Gasoline E/G with HFM & Air Conditioner

25 LH Front Fog Lamp

26 LH Horn ............................................................... Black Out Driving Lamp (Domestic)

27 Condenser Fan Motor .........................................Diesel E/G

28 Black Out Driving Lamp .......................................Black Out Driving Lamp (Domestic)

29 LH Horn ............................................................... Leveling Device

30 LH Condenser Fan Motor ....................................Gasoline E/G with Air Conditioner

31 Thermo Switch 1 .................................................. Diesel E/G or Gasoline E/G with HFM

32 Resistor ............................................................... Gasoline E/G with Air Conditioner

33 Thermo Switch 4 .................................................. Gasoline E/G with HFM & Air Conditioner

34 Ambient Censor ................................................... Air Conditioner

35 RH Condenser Fan Motor ....................................Gasoline E/G

36 RH Horn

37 RH Front Fog Lamp

38 RH Position Lamp

39 RH Head Lamlp

40 RH Head Lamp Leveling Device ..........................Leveling Device

41 Wheeling Sensor ................................................. ECS

42 Wheel Speed Sensor (FR) ..................................ABS 5.0, 5.3 or ABD 5.0, 5.3

43 RH Damper .......................................................... ECS

44 Alternator Extension Connector ...........................Gasoline E/G

45 Alternator ............................................................. Gasoline E/G

46 Alternator Extension Joint box ..............................Diesel E/G

47 Alternator Extension Connector ...........................Diesel E/G

48 Ground 3

49 Fusible Link Box ................................................... Gasoline E/G

49-1 Fusible Link Box ................................................... Diesel E/G

50 Receiver Dryer ..................................................... Gasoline E/G with Air Conditioner

50-1 Receiver Dryer ..................................................... Diesel E/G with Air Conditioner

51 Hood Switch ......................................................... Diesel E/G with Black Out Driving Lamp

52 Front Washer Motor ............................................. Gasoline E/G

53 Main Wiring Connector

Page 1241 of 1574

SECTION 9C

HORNS

Caution: Disconnect the negative battery cable before removing or installing any electrical unit or when a tool or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable will help prevent personal injury and damage to the vehicle. The ignition must also be in LOCK unless otherwisenoted.TABLE OF CONTENTS

Schematic and Routing Diagrams . . . . . . . . 9C-2 Horn . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9C-2

Page 1242 of 1574

9C-2 HORN

HORN

SCHEMATIC AND ROUTING DIAGRAMS