filler SSANGYONG MUSSO 2003 User Guide

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2003, Model line: MUSSO, Model: SSANGYONG MUSSO 2003Pages: 1574, PDF Size: 26.41 MB

Page 230 of 1574

1B2-78 M161 ENGINE MECHANICAL Installation Procedure

1. Connect the thrust pin (6) and the snap ring (5) to the chaintensioner housing (7). Notice When connecting the thrust pin, push in the thrust pin far enough so that it doesn ’t protrude at the chain tensioner

housing.

4. Carefully unscrew the screw plug (1), and remove the seal

(2). Notice

�For the removal of screw plug, be careful that it can be jumped out due to the force of compression spring.

� Remove the screw plug only when the seal andcompression spring are damaged.

5. Carefully remove the filler pin (3), compression spring (4), snap ring (5), and the thrust pin (6).

6. Remove the chain tensioner housing (7) and the seal (8).

3. Insert the compression spring (4) with the filler pin (3) into chain tensioner housing.

2. Install the chain tensioner housing (7), Thrust pin (6), snap

ring (5), and the seal (8). Installation Notice

Tightening Torque 72 - 88 Nm

Page 231 of 1574

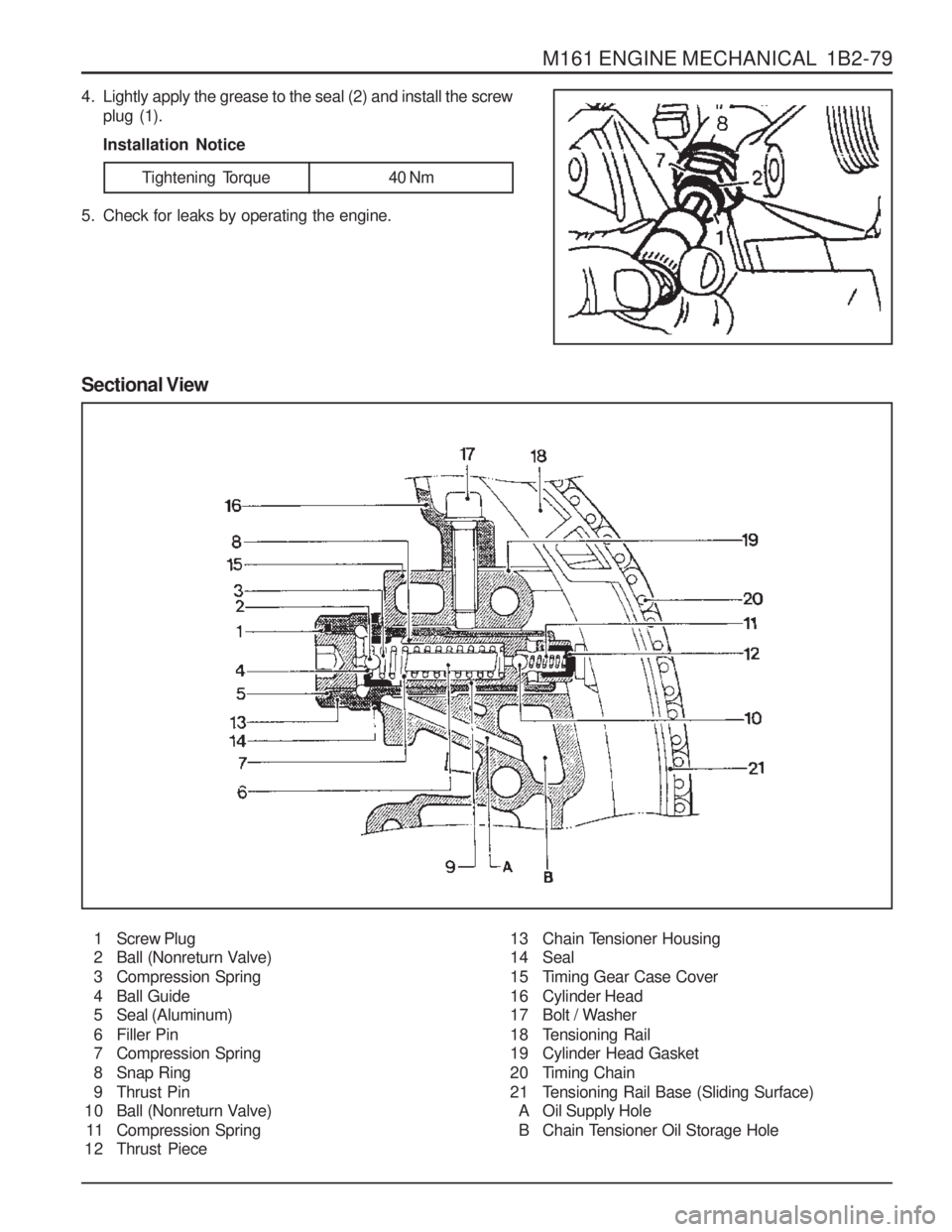

M161 ENGINE MECHANICAL 1B2-79

4. Lightly apply the grease to the seal (2) and install the screwplug (1). Installation Notice

Sectional View

1 Screw Plug

2 Ball (Nonreturn Valve)

3 Compression Spring

4 Ball Guide

5 Seal (Aluminum)

6 Filler Pin

7 Compression Spring

8 Snap Ring

9 Thrust Pin

10 Ball (Nonreturn Valve)

11 Compression Spring

12 Thrust Piece 13 Chain Tensioner Housing

14 Seal

15 Timing Gear Case Cover

16 Cylinder Head

17 Bolt / Washer

18 Tensioning Rail

19 Cylinder Head Gasket

20 Timing Chain

21 Tensioning Rail Base (Sliding Surface)

A Oil Supply Hole

B Chain Tensioner Oil Storage Hole

5. Check for leaks by operating the engine.

Tightening Torque 40 Nm

Page 252 of 1574

1B2-100 M161 ENGINE MECHANICAL9. Fill up engine oil through the engine oil filler opening.

10. Check for oil leaks at normal engine temperature after starting the engine.

11. Stop the engine and wait 5 minutes. Check the oil level and fill up as specified if necessary.

4. Remove the drain plug (1) and drain the engine oil.

Notice Leave the oil filler cap (3) open to ease the engine oil discharge.

5. Tighten the engine oil drain plug after cleaning it. Installation Notice

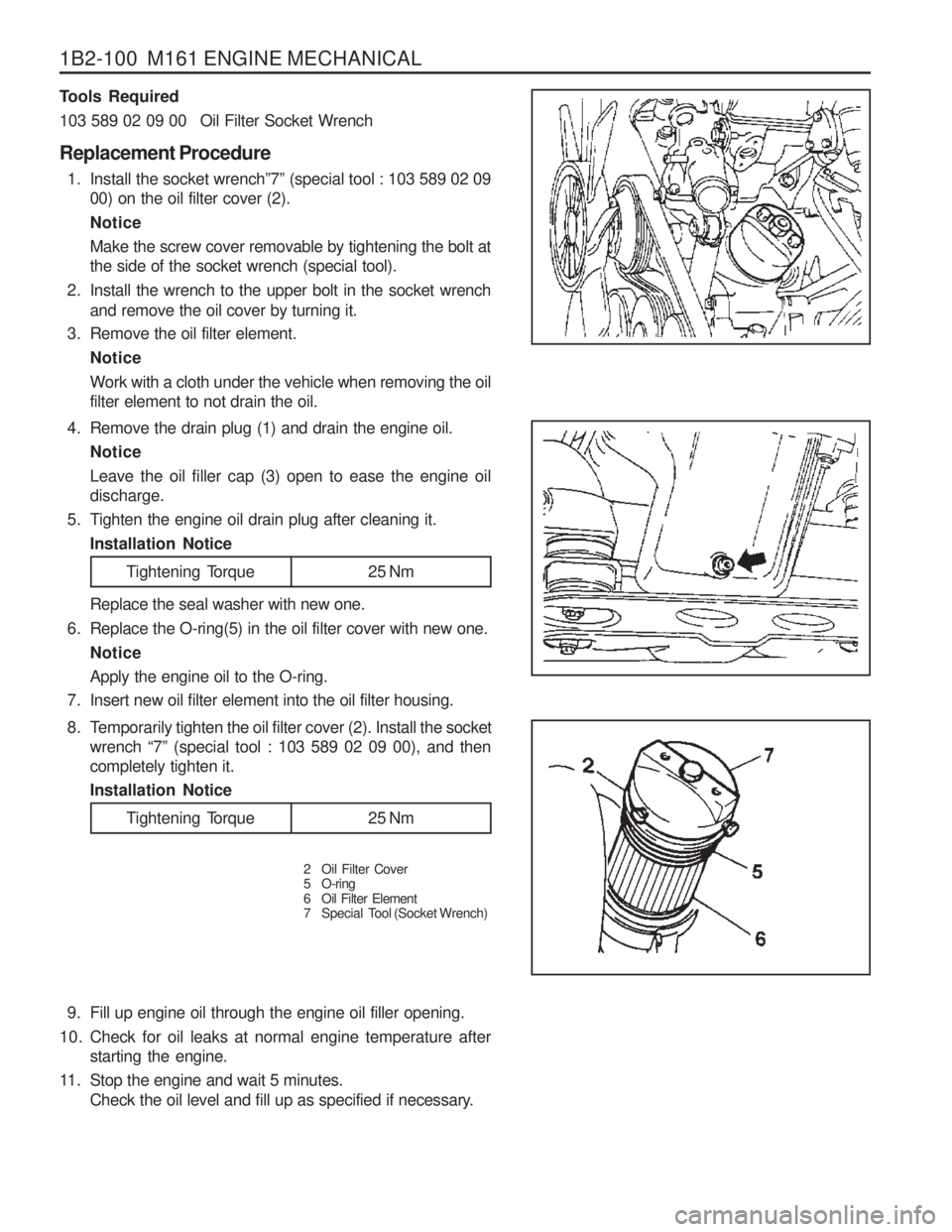

Tools Required

103 589 02 09 00 Oil Filter Socket Wrench Replacement Procedure

1. Install the socket wrench ”7” (special tool : 103 589 02 09

00) on the oil filter cover (2). NoticeMake the screw cover removable by tightening the bolt at the side of the socket wrench (special tool).

2. Install the wrench to the upper bolt in the socket wrench and remove the oil cover by turning it.

3. Remove the oil filter element.

Notice Work with a cloth under the vehicle when removing the oil filter element to not drain the oil. Replace the seal washer with new one.

6. Replace the O-ring(5) in the oil filter cover with new one.

Notice Apply the engine oil to the O-ring.

7. Insert new oil filter element into the oil filter housing.

Tightening Torque 25 Nm

8. Temporarily tighten the oil filter cover (2). Install the socket wrench “7” (special tool : 103 589 02 09 00), and then

completely tighten it. Installation Notice

2 Oil Filter Cover

5 O-ring

6 Oil Filter Element

7 Special Tool (Socket Wrench)

Tightening Torque 25 Nm

Page 411 of 1574

1B3-146 OM600 ENGINE MECHANICAL

Notice Always install the chain tensioner to be filled with oil. Place the chain tensioner in engine oil up to over the collar on the hexagon head with the thrust pin facing up. Slowly push down the thrust pin as far as the stop 7~10 times with the aid of a press or a column drill

Faulty chain tensioners should be replaced completely.

3 Screw Plug

4 Aluminum Gasket

5 Ball

6 Ball Guide

7 Compression Spring

8 Compression Spring

9 Housing

10 Thrust Pin 11 Valve Disc

12 O-Ring

13 Snap Ring

14 Compression Spring

15 Filler

A Feed Bore from Cylinder Head

B To Oil Pan

Page 455 of 1574

1D1-4 M162 ENGINE COOLINGDIAGNOSIS

3. Connect the special tool to the reservoir filler cap and apply 1.4 bar of pressure.

SYSTEM LEAKAGE TEST

Tools Required

124 589 15 21 00 Tester Test Procedure

1. Loosen the cap a little and release pressure and removethe cap. NoticeFor the risk of scalding, cap must not be opened unless the coolant temperature is below 90 °C.

2. Fill coolant up to upper edge (arrow) of reservoir.

Tester 124 589 15 21 00

4. If the pressure on the tester drops, check leakage at the all coolant hoses and pipes and each connections. Replace or retighten if necessary.

Page 471 of 1574

1D2-4 M161 ENGINE COOLINGDIAGNOSIS

3. Connect the special tool to the reservoir filler cap and apply 1.4 bar of pressure.

SYSTEM LEAKAGE TEST

Tools Required

124 589 15 21 00 Tester

Test Procedure

1. Loosen the cap a little and release pressure and remove

the cap. Notice For the risk of scalding, cap must not be opened unless the coolant temperature is below 90 °C.

2. Fill coolant up to upper edge (arrow) of reservoir.

Tester 124 589 15 21 00

4. If the pressure on the tester drops, check leakage at the all coolant hoses and pipes and each connections. Replace

or retighten if necessary.

Page 615 of 1574

1F3-4 OM600 ENGINE CONTROLS

FUEL TANK

1 Fuel Tank

2 The Sender of Fuel Tank

3 2-way Check Valve

4 Pre Filter

5 Front Fuel Filler Neck

6 Rear Fuel Filler Neck

7 Fuel Supply Tube 8 Fuel Return Tube

9 Filter Hose

10 Fuel Tank Hose

11 Fuel Filler Cap

12 Clip

13 Clip

Page 767 of 1574

FRONT DRIVE AXLE 3A-17

1 Front Axle Housing Mounting Bracket

2 Inner Shaft (Left)

3 Bolt...................................................... 55-65 Nm

4 Oil Seal .................................................. Replace

Apply Grease to the Sealing Rib

5 Snap Ring

6 Bearing

7 Snap Ring

8 Oil Drain Plug ....................................... 28-41 Nm

9 Front Axle Housing

10 Breather Nipple 11 Inner Shaft (Right)

12 Pinion Lock Nut ................................ 240-310 Nm

13 Washer

14 Companion Flange

15 Oil Seal .................................................. Replace

Apply Grease to the Sealing Rib

16 Bearing

1 7 Shim

18 Bearing Baffle

1 9 Shim20 Bearing

21 Oil Slinger

22 Drive Pinion

23 Oil Filler Plug ....................................... 28-41 Nm

24 Bolt ...................................................... 39-46 Nm

25 Axle Housing Cover ..............Apply Liquid Gasket

to the Contact Surface

26 Ring Gear

27 Bearing

2 8 Shim

29 Shaft Lock Pin

30 Differential Case

31 Bolt ...................................................... 75-90 Nm

32 Bolt ...................................................... 48-69 Nm

33 Washer

34 Bearing Cap

35 Thrust Washer

36 Side Gear

37 Differential Shaft

38 Differential Pinion

39 Thrust Washer

Page 782 of 1574

3D-2 REAR DRIVE AXLEFASTENER TIGHTENING SPECIFICATIONS

Application

Inner Bracket Mounting Nut Propeller Shaft to Rear Axle Input ShaftLower Arm Mounting Nut Lower Shock Absorber to Axle Housing Upper Arm Mounting NutStabilizer Bar Mounting BoltLateral Rod Mounting NutDrive Pinion Lock Nut Oil Drain Plug Ring Gear Mounting BoltOil Filler Plug

N

m

50 - 65 70 - 80

150 - 180 50 - 65

150 - 180 30 - 45

150 - 180240 - 310 28 - 4275 - 9028 - 42

4.55 4.554.55 4.27 5.863.733.734.89

1.9 L

SEA 80W/90, API GL - 5

M/TA/T (MB) M/T A/T (MB)A/T (BTRA)M/TA/T (MB) A/T (BTRA)

Oil Capacity Oil Specification

Application Description

GENERAL SPECIFICATIONS(CONT'D)

E20 E23 E32

Reduction Ratio

Page 791 of 1574

REAR DRIVE AXLE 3D-11

UNIT REPAIR

AXLE HOUSING Preceding Work : Removal of the axle shaft Removal of the axle housing

1 Drive Pinion Lock Nut ......................240-310 Nm

2 Washer

3 Companion Flange

4 Pinion Oil Seal

5 Bearing Slinger

6 Bearing

7 Shim

8 Shim

9 Bearing Cup

10 Breather Nipple

11 Rear Axle Housing

12 Oil Drain Plug ....................................... 28-42 Nm

1 3 Shim

14 Bearing

15 Drive Pinion

16 Bearing Cap 17 Bolt

.................................................... 87-124 Nm

18 Bearing

1 9 Shim

20 Ring Gear

21 Shaft Lock Pin

22 Differential Case

23 Ring Gear Mounting Bolt ......................75-90 Nm

24 Thrust Washer

25 Differential Pinion

26 Thrust Washer

27 Side Gear

28 Differential Shaft

29 Housing Cover

30 Bolt ...................................................... 38-46 Nm

31 Oil Filler Plug ....................................... 28-42 Nm