fuel filter SSANGYONG MUSSO 2003 User Guide

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2003, Model line: MUSSO, Model: SSANGYONG MUSSO 2003Pages: 1574, PDF Size: 26.41 MB

Page 281 of 1574

1B3-16 OM600 ENGINE MECHANICAL

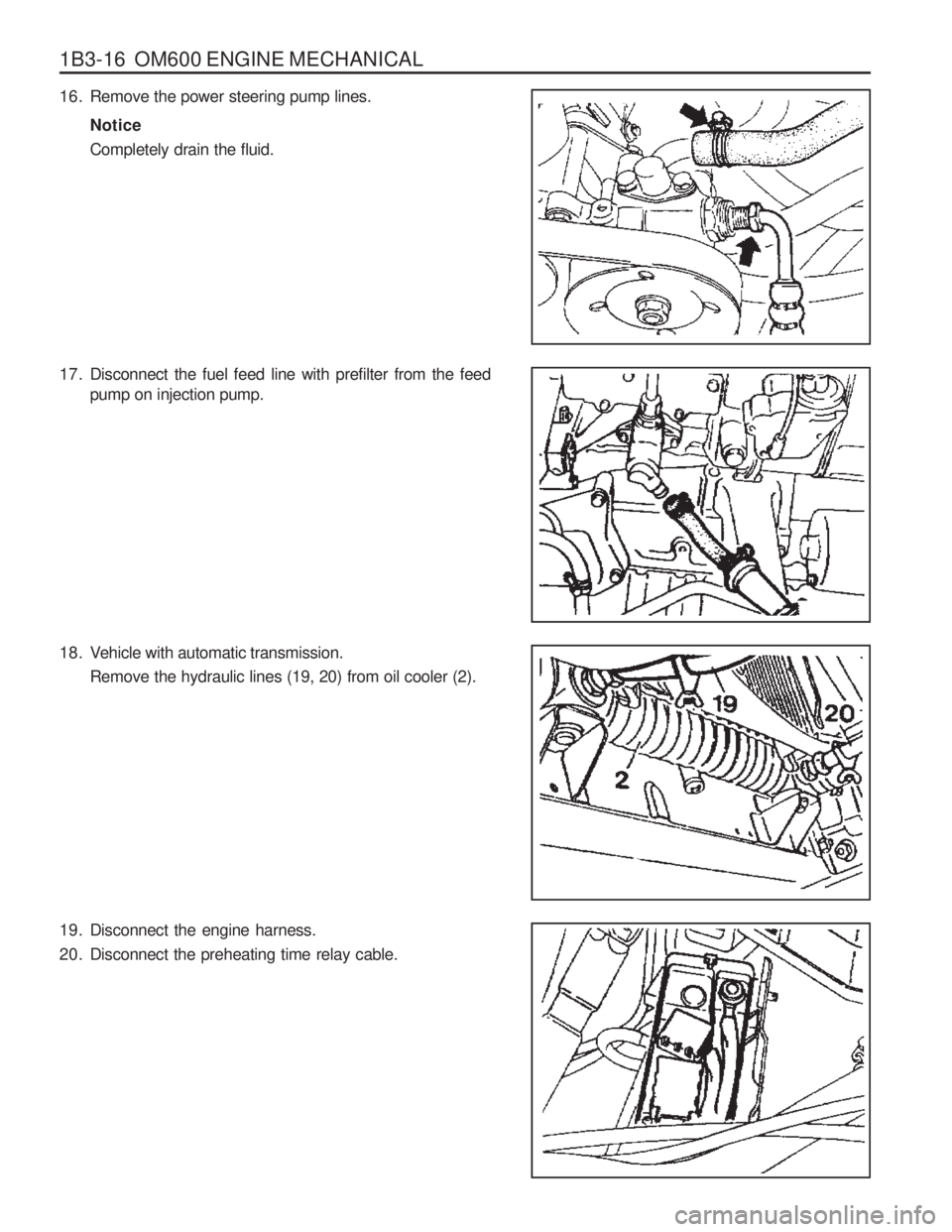

16. Remove the power steering pump lines.Notice Completely drain the fluid.

17. Disconnect the fuel feed line with prefilter from the feed pump on injection pump.

18. Vehicle with automatic transmission. Remove the hydraulic lines (19, 20) from oil cooler (2).

19. Disconnect the engine harness.

20. Disconnect the preheating time relay cable.

Page 282 of 1574

OM600 ENGINE MECHANICAL 1B3-17

26. Disconnect the starter motor wires and remove the startermotor.

21. Remove the fuel lines from the fuel filter and cover thefilter with plug.

22. Disconnect the brake booster hose from vacuum pump.

23. Disconnect the other vacuum lines.

24. Disconnect the ground cable.

25. Disconnect the alternator wires.

Page 302 of 1574

OM600 ENGINE MECHANICAL 1B3-37

CYLINDER HEAD1 Fuel Injection Pipe ..................................... 18Nm

2 Cylinder Head

3 Gasket ................................................... Replace

4 Bolt ............................................................ 25Nm

5 Washer

6 Clamp

7 Heater Feed Pipe

8 Bolt

9 Washer

10 Bolt 11 Nozzle Washer ....................................... Replace

12 Fuel Injection Nozzle ............................ 35-40 Nm

13 Hexagon Socket Bolt ................................. 25 Nm

14 Washer

15 Bolt ........................................................... 25 Nm

16 Cylinder Head Bolt ..............................See Table

17 Cylinder Head Cover

18 Bolt ........................................................... 10 Nm

19 Gasket

2 0 Camshaft 21 Camshaft Drive Sprocket

....................... Replace

22 Washer

23 Bolt(12-Sided) .................................. 25Nm + 90 °

24 Sliding Rail

25 Sliding Rail Pin

26 Sliding Rail Pin

27 Chain Tensioner ....................................... 80 Nm

28 Gasket ................................................... Replace

29 Cooling Fan .............................................. Check

30 Hexagon Socket Bolt ................................. 45 Nm

31 Tensioning Lever

32 Bolt ........................................................... 25 Nm

33 Bolt

34 Nut ............................................................ 23 Nm

35 Fuel Filter

36 Turbo Charger

37 Intake Duct

38 Gasket ................................................... Replace

39 Intake Manifold

Page 310 of 1574

OM600 ENGINE MECHANICAL 1B3-45

26. Disconnect the fuel lines from the fuel filter.

27. Disconnect the fuel lines from the injection pump.

28. Remove the fuel filter(35).

29. Remove the fuel injection nozzle(12) and nozzlewasher(11).

Socket Wrench Insert 001 589 65 09 00

Page 319 of 1574

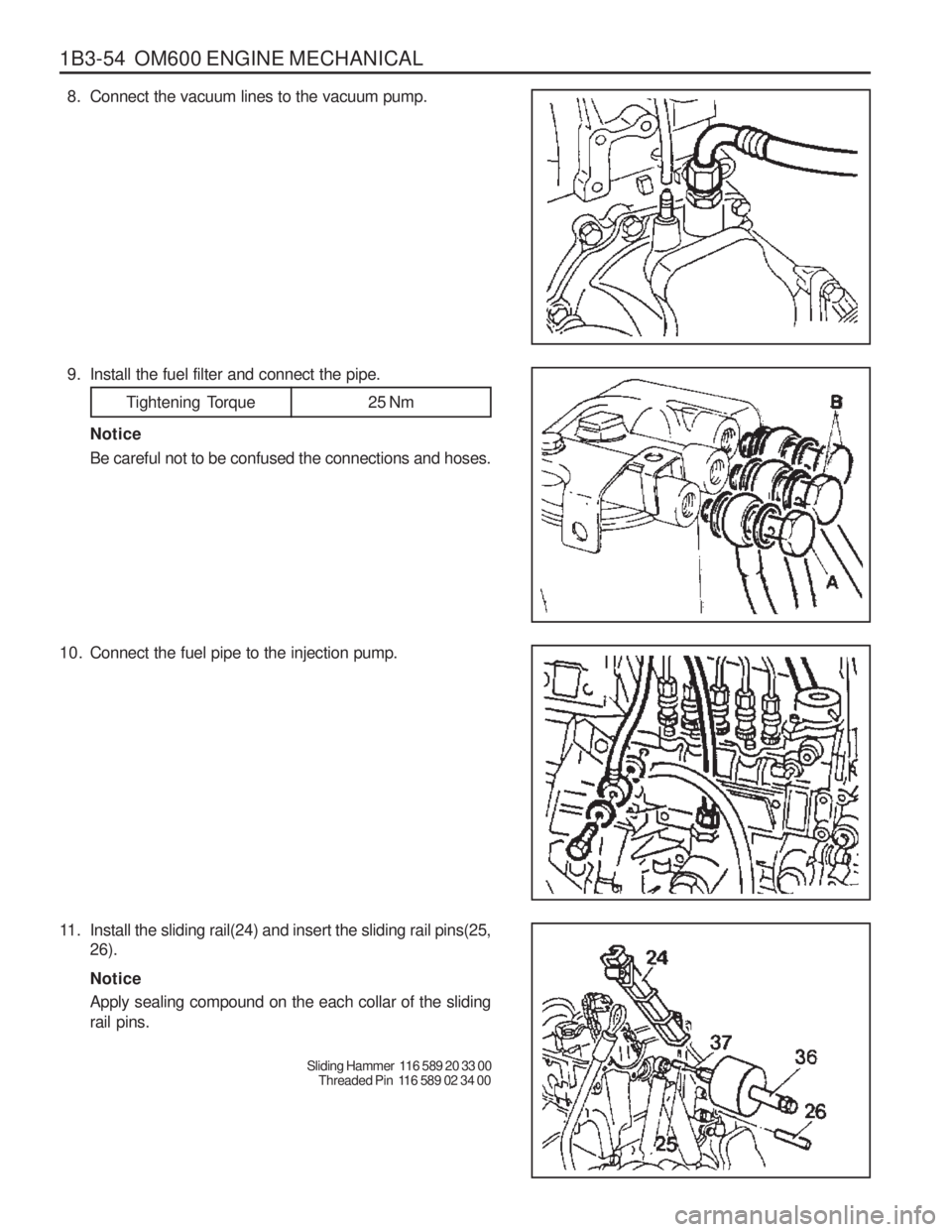

1B3-54 OM600 ENGINE MECHANICAL8. Connect the vacuum lines to the vacuum pump.

9. Install the fuel filter and connect the pipe.

Tightening Torque 25 Nm

Notice Be careful not to be confused the connections and hoses.

10. Connect the fuel pipe to the injection pump.

11. Install the sliding rail(24) and insert the sliding rail pins(25, 26). Notice Apply sealing compound on the each collar of the sliding rail pins.

Sliding Hammer 116 589 20 33 00Threaded Pin 116 589 02 34 00

Page 326 of 1574

OM600 ENGINE MECHANICAL 1B3-61

38. Replace the O-ring of heater feed pipe and install it to thecylinder head. NoticeFor installation, clean the hole.

39. Install the bracket of heater feed pipe to the oil filter.

40. Install the fuel pipe and the accelerator control linkage.

41. Connect the fuel lines to the injection nozzles and to the injection pump. Box Wrench Insert 000 589 77 03 00

Tightening Torque 18 Nm

Page 328 of 1574

OM600 ENGINE MECHANICAL 1B3-63

TIMING CASE COVER

Preceding Work : Removal of the cooling fanRmoval of the V-belt tensioning device Removal of the vibration damper and hub Removal of the alternator

1 Bolt............................................................ 10Nm

2 Cylinder Head Cover

3 Gasket ................................................... Replace

4 Socket Bolt ................................................ 25Nm

5 Fuel Filter

6 Square Nut

7 Oil Pan

8 Socket Bolt ................................................ 10Nm

9 Bolt .................................................... M6 : 10Nm

M8 : 23Nm 10 Power Steering Pump

11 Bolt

12 Belt Pulley 13 Bolt

............................................................ 32Nm

14 Timing Case Cover

15 Bolt ............................................................ 23Nm

16 Alternator Bracket

17 Bolt ............................................................ 45Nm

18 Bolt ............................................................ 25Nm

19 Bolt ............................................................ 10Nm

20 Closing Cover

21 Socket Bolt ................................................ 23Nm

22 Guide Pulley

23 Bolt .............................................................. 9Nm

24 Guide Pulley Bracket

25 Nut ............................................................. 23Nm

Page 330 of 1574

OM600 ENGINE MECHANICAL 1B3-65

11. Remove the alternator bracket (16).

9. Disconnect the pipes of power steering pump and removethe belt pulley. Notice

Be careful not to lose the key.

10. Remove the nut and pull out the bolt and then remove the power steering pump.

12. Remove the fuel filter.

Page 334 of 1574

OM600 ENGINE MECHANICAL 1B3-69

10. Install the fuel filter.

11. Install the vacuum pump.

12. Install the power steering pump.

13. Install the power steering pump pulley.

Tightening Torque 25 Nm

Tightening Torque 10 Nm

Tightening Torque 23 Nm

Tightening Torque 32 Nm

14. Install the guide pulley bracket.

Tightening Torque 9 Nm

Page 357 of 1574

1B3-92 OM600 ENGINE MECHANICAL

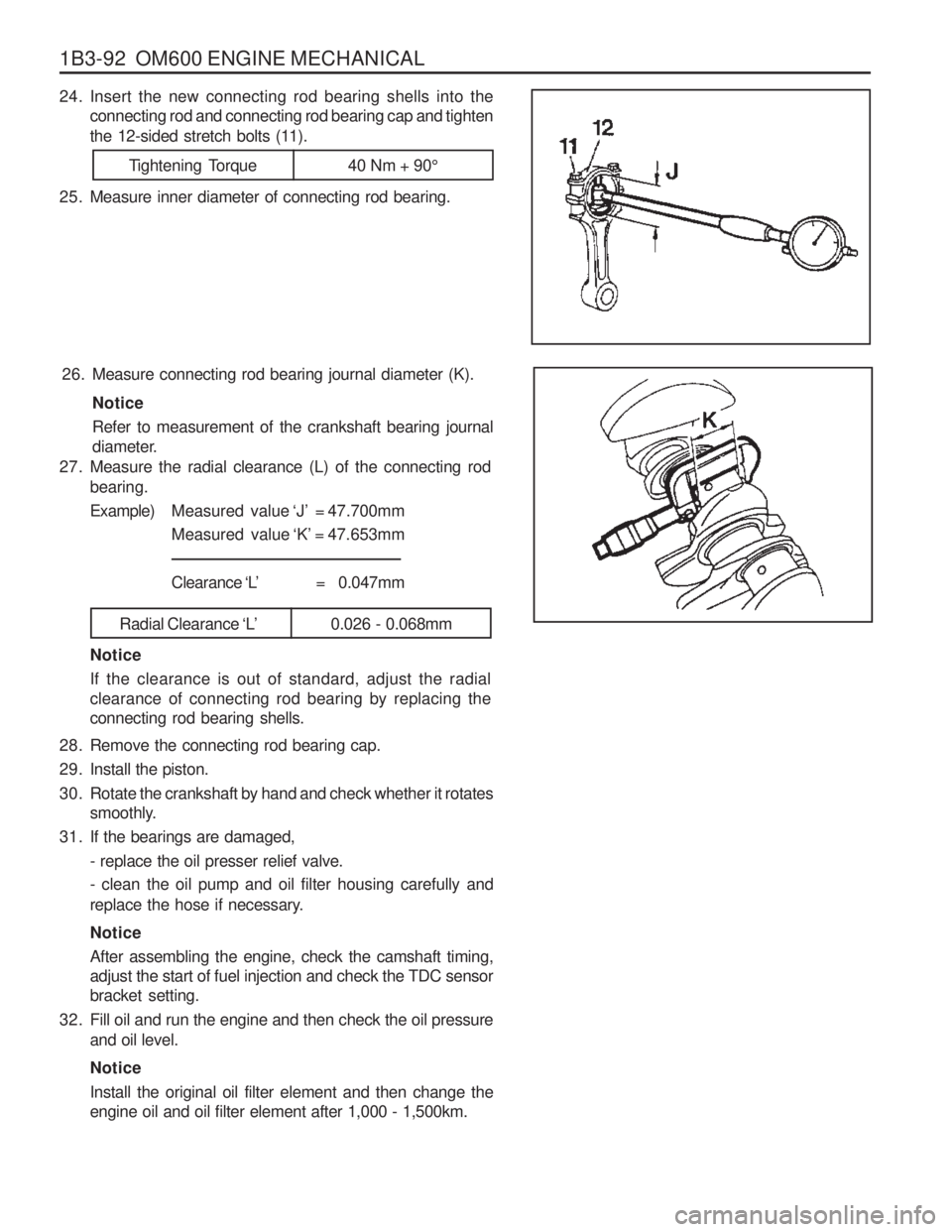

28. Remove the connecting rod bearing cap.

29. Install the piston.

30. Rotate the crankshaft by hand and check whether it rotatessmoothly.

31. If the bearings are damaged,

- replace the oil presser relief valve. - clean the oil pump and oil filter housing carefully and

replace the hose if necessary. Notice After assembling the engine, check the camshaft timing, adjust the start of fuel injection and check the TDC sensorbracket setting.

32. Fill oil and run the engine and then check the oil pressure and oil level. Notice Install the original oil filter element and then change the engine oil and oil filter element after 1,000 - 1,500km.

27. Measure the radial clearance (L) of the connecting rod

bearing. Example) Measured value ‘J’ = 47.700mm

Measured value ‘K’ = 47.653mm

Clearance ‘L’ = 0.047mm

Radial Clearance ‘L’0.026 - 0.068mm

Notice If the clearance is out of standard, adjust the radial clearance of connecting rod bearing by replacing theconnecting rod bearing shells.

26. Measure connecting rod bearing journal diameter (K).

Notice Refer to measurement of the crankshaft bearing journal

diameter.

24. Insert the new connecting rod bearing shells into theconnecting rod and connecting rod bearing cap and tighten

the 12-sided stretch bolts (11).

25. Measure inner diameter of connecting rod bearing.

Tightening Torque 40 Nm + 90 °