EGR SSANGYONG MUSSO 2003 Owner's Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2003, Model line: MUSSO, Model: SSANGYONG MUSSO 2003Pages: 1574, PDF Size: 26.41 MB

Page 1322 of 1574

1A-10 MUSSO-SPORTS

SUPPLEMENT

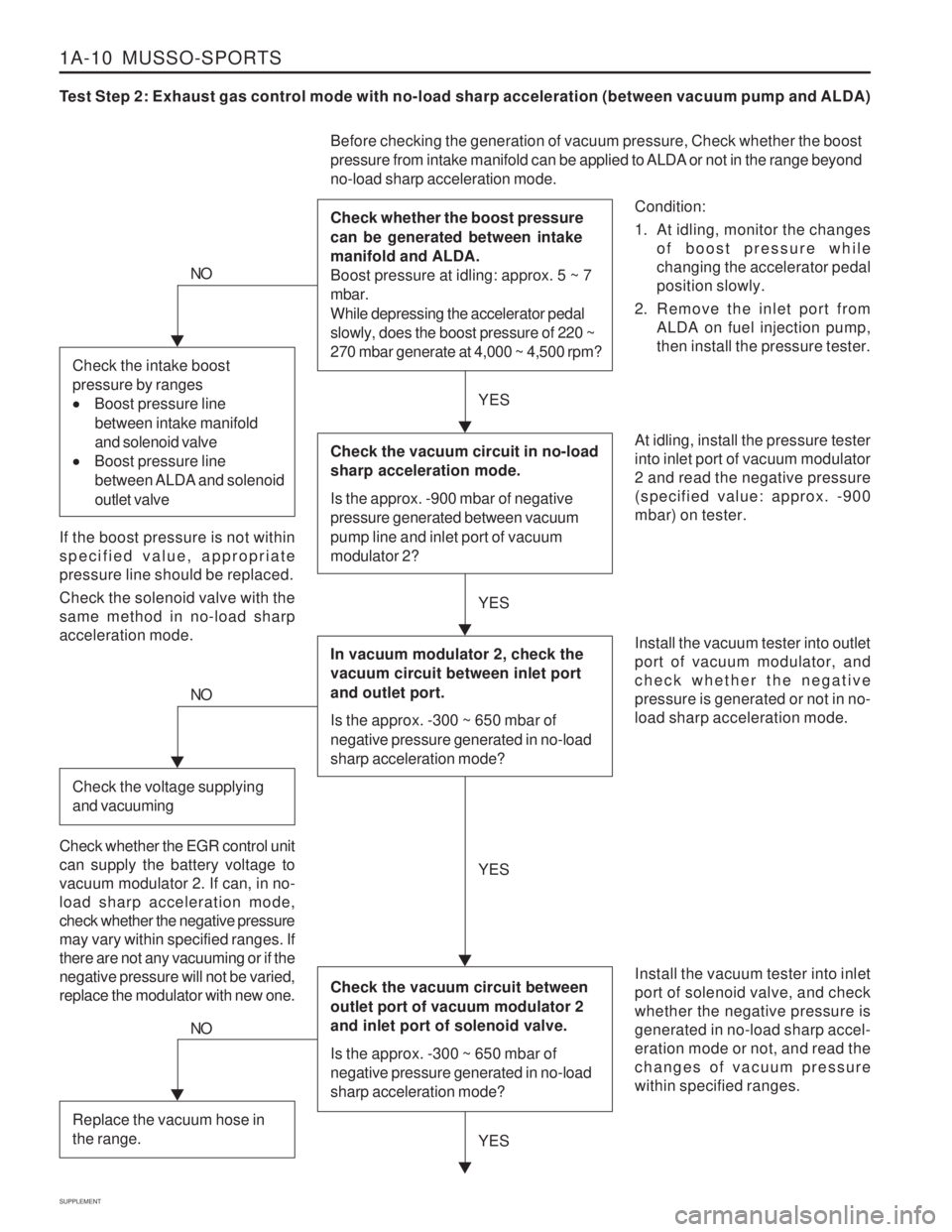

Test Step 2: Exhaust gas control mode with no-load sharp acceleration (between vacuum pump and ALDA)

Condition:

1. At idling, monitor the changesof boost pressure while changing the accelerator pedalposition slowly.

2. Remove the inlet port from ALDA on fuel injection pump,then install the pressure tester.

Before checking the generation of vacuum pressure, Check whether the boost

pressure from intake manifold can be applied to ALDA or not in the range beyond no-load sharp acceleration mode. Check whether the boost pressure can be generated between intake manifold and ALDA. Boost pressure at idling: approx. 5 ~ 7 mbar. While depressing the accelerator pedal slowly, does the boost pressure of 220 ~ 270 mbar generate at 4,000 ~ 4,500 rpm?

At idling, install the pressure tester into inlet port of vacuum modulator2 and read the negative pressure(specified value: approx. -900mbar) on tester. Install the vacuum tester into inlet port of solenoid valve, and checkwhether the negative pressure isgenerated in no-load sharp accel-eration mode or not, and read thechanges of vacuum pressurewithin specified ranges.

NO

If the boost pressure is not within specified value, appropriatepressure line should be replaced. Check the solenoid valve with the same method in no-load sharpacceleration mode.

YES

YES

Check the vacuum circuit in no-load sharp acceleration mode. Is the approx. -900 mbar of negative pressure generated between vacuum pump line and inlet port of vacuum modulator 2?

In vacuum modulator 2, check the vacuum circuit between inlet port and outlet port. Is the approx. -300 ~ 650 mbar of negative pressure generated in no-load sharp acceleration mode?

Check the vacuum circuit between outlet port of vacuum modulator 2 and inlet port of solenoid valve. Is the approx. -300 ~ 650 mbar of negative pressure generated in no-load sharp acceleration mode?

Install the vacuum tester into outlet port of vacuum modulator, andcheck whether the negativepressure is generated or not in no-load sharp acceleration mode.

Check the intake boost pressure by ranges

Boost pressure line

between intake manifold and solenoid valve

Boost pressure line

between ALDA and solenoid outlet valve

NO

Check the voltage supplying and vacuuming

Check whether the EGR control unit can supply the battery voltage tovacuum modulator 2. If can, in no-load sharp acceleration mode,check whether the negative pressuremay vary within specified ranges. Ifthere are not any vacuuming or if thenegative pressure will not be varied,replace the modulator with new one. YES

YES

NO

Replace the vacuum hose in the range.

Page 1324 of 1574

1A-12 MUSSO-SPORTS

SUPPLEMENT

KAA5A020

KAA5A020

KAA5A020 EXHAUST GAS RECIRCULATION MODULE Removal and Installation Procedure

1. After releasing fixing screw of door scuff to the

passenger seat , remove the door scuff.

KAA5A020 2. After releasing fixing bolt of cowl side trim, remove

cowl side trim.

3. Remove pin of connector from the EGR module.

4. After releasing the fixing nut(3ea) of EGR module, remove the the EGR module.

5. Installation should follow the removal procedure in the reverse order.

THROTTLE POSITION SENSOR Removal Procedure 1. Disconnect the TPS connector from the TPS.

2. After releasing the fixing bolt, remove the TPS. Installation Procedure

1. Install temporary fixing bolt of TPS.

2. Install connector of TPS on the TPS.

3. Check the voltage of TPS by using SCAN-100.

4. Install completely fixing bolt of TPS.

Page 1325 of 1574

MUSSO-SPORTS 1A-13

SUPPLEMENT

KAA5A020

KAA5A020

KAA5A020VACUUM MODULATOR 1, 2 Removal and Installation Procedure

1. Disconnect vacuum hose and connector from vacuum

module.

2. After releasing fixing bolt from bracket of intake manifold, and then remove vacuum modulator.

3. Installation should follow the removal procedures in the reverse order.

KAA5A020 EGR VALVE AND LIFT SENSOR Removal and Installation Procedure

1. Disconnect vacuum hose and connector from the

EGR valve.

2. After releasing the clamping bolt/nut of EGR Valve pipe and then remove the clamp.

3. After releasing fixing bolt of EGR Valve of Intake Manifold, remove the EGR Valve assembly.

4. Installation should follow the removal procedure in the reverse order.

COOLANT TEMPERATURE SENSOR Removal and Installation Procedure

1. Disconnect the coolant temperature sensor from the coolant temperature sensor.

2. After releasing the coolant temperature sensor from cylinder block and then remove the coolant tempera- ture sensor.

3. Installation should follow the removal procedure in the reverse order.

SOLENOID VALVE Removal and Installation Procedure

1. Disconnect vacuum hose(3ea) and connector from the solenoid valve.

2. Remove the solenoid valve from the fixing bracket of injection pump.

3. Installation should follow the removal procedure in the reverse order.

Page 1346 of 1574

1A-34 MUSSO-SPORTS

SUPPLEMENT

15 IGN1

31

* ( ) : A/T

* A/T TPS, RPM Signal : TCU A5

30

GND

F24

LW A/T

TCU A5 Clutch SW

"1" TPSM/T

41 2

2 RPM Sensor

S201

1 3

LW GrW HUBER EGR ECU (K2004) BG

C R G BrB BrWLRG

10A

BAT+

F17

RY RY 3 9 28 62 61 81 10 29

1

4 6 0798 05 675 4 324 3 332 3 736

WR W WB BrW GR

WR W WB BrW GR BG BrG GL LG YL LB

WR Lift Sensor

EGR Valve Water Sensor

Temp EGR Modulator Exhanst Gas

RecirculationModulator Sol Valve

W WB BrW GR BG BrG GL LG YL LB

S201

8

12 10A

213 7 8

B

13(11) 14(12) 11(9) 12(10) 9(7) (10)8

C901 (C902)

C901

C108

C105

C104

G204

Ef 2 Ef 8

80A60A

C103

2

56 7 2 1

16 15 1411 10

4. HUBER EGR CIRCUIT(MUSSO SPORT)

Page 1347 of 1574

MUSSO-SPORTS 1A-35

SUPPLEMENT

Main - Engine Engine - Engine Genertor - EngineMain - T/M Main - T/M MainMain

C103 (2Pin, White) C105 (8Pin, Black) C108 (16Pin, Black)C901 (16Pin, Black) C902 (12Pin, Black) S201 (Black)G204

b. CONNECTOR IDENTIFICATION SYMBOL & PIN NUMBER POSITION

a. CONNECTOR INFORMATION

C902

W/H T/M

C101

W/H MAIN C102

W/H MAIN C108

W/H ENGINE

CONNECTOR(NUMBER) CONNECTING. WIRING HARNESSCONNECTOR POSITION

Inside The Engine Room Fuse Block

Beside Pre-Heating Unit (DSL):MUSSO SPORT

Under The Air Cleaner Housing (DSL, N/Turbo) Upper The T/C(M/T)Upper The T/C(A/T) Behind The Cluster Upper The Huber EGR

1

2

1234

5678

1234 5678

9 101112

13 14 15 16

1234 5678

9 101112

13 14 15 16

C901

W/H T/M

1234

5678

9101112

HUBER EGR

CONTROL UNIT

24

43

23

42

22

41

21

40

20

39

19

38

18

37

17

36

16

35

15

34

14

33

13

32

12

31

11

30

10

29

9

28

8

27

7

26

6

25

62

81

61

80

60

79

59

78

58

77

57

76

56

75

55

74

54

73

53

72

52

71

51

70

50

69

49

68

48

67

47

66

46

65

45

64

12 45 3

44

63

Page 1358 of 1574

POSITION OF CONNECTORS AND GROUNDS 2-9

S204 (DSL/GSL)

S101 (DSL/GSL)

11) SPLICE PACK S202 (DSL/GSL)

S201 (DSL/GSL)

S205 (DSL/GSL)

3 2 1Ef2

80A Ef6

40A

Ef14

15A

WFusible Link Box

Head Lamp Relay (Low) '30' Fog Lamp Relay '30'

Tail Lamp Relay '30'GL

GL

GL GL

GL

1 2 3 4

5 6 7 8

5C204

LW

LW

DLC '2' Stics '29'

EGR Control unit '3' (DLC) Clock '3'VSS '3' F24 (10A)

Seat Warmer Control unit '9'

Stop Lamp Switch '3' (GSL)

LW LW LW LW LW

1 2 3 4

5 6 7 8RY RY RY RY

RYRY RY RYStics '1'

F17 (10A)

Seat belt Switch '3'

Chime Bell '2', Buzzer '3' DLC '14'

Key Reminder Switch '3' Clock '1'

C212 '10' Audio '5'

S203 (DSL/GSL)

1 2 3 4

5 6 7 8

16

Thermo AMP '3'(DSL)

Thermo AMP '4'(GSL)

Rear Wiper/WasherSwitch '8'LW

LW LW

C212

LWF19 (10A)

Blower Relay 'S1'A/C Switch '3'

S401 (DSL/GSL)

1 2 3 4

5 6 7 84

7

Ef10

10A

C212 C101ECS Switch '4'

Rear Wiper/Washer Switch '6'

A/C Control Panel '11' Tail Lamp Relay '87'

Door unlock Switch '4' Defroster Switch '4'

Audio '3', 4WD Switch '7'

Front Cigar Lighter '2'

Seat Warmer Switch '6' Fog Lamp Switch '4'

Hazard Switch '2'Clock '4'GW GW

GW

GW GW

GW

GW GW

1 2 3 4

5 6 7 8BrW BrW BrB YW

BrBBrB BrW LYECM '38'

'37' ECM

TCM 'A23' 'A24' TCM

TOD 'A10' 'A11' TOD

RESISTOR (M/T)

1 2 3 4

8 9

10 11B B

BRear RH Combi Lamp '4' Rear LH Combi Lamp '4'

5 6 7

12 13 14

2

Door lock Actuator '2'

G302B

B B

C402 BRear Wiper Motor '3' High Maunted Stop Lamp '2'

BLicense Lamp '2'

License Lamp '2'

Page 1369 of 1574

CONTENTS

1. STARTING & CHARGING CIRCUIT ........................................................................................... 5-8

1) GSL E23 MB A/T ............................................................................................................... ...................................... 5-8

2) GSL BTRE A/T, GSL E32 MB A/T ................................................................................................. ........................5-10

3) DSL NA BTRE A/T, M/T ......................................................................................................... .................................5-12

4) DSL LA BTRE A/T, M/T ......................................................................................................... .................................5-14

2. PREHEAT'G UNIT CIRCUIT ...................................................................................................... 5-16

3. EGR CONTROL CIRCUIT.......................................................................................................... 5-18

4. ECM (E23, MSE) ............................................................................................................... .......... 5-20

1) OVPR, FUEL PUMP, CCP SOLENOID CIRCUIT ........................................................................................ ....... 5-20

(1) W/O EURO III ............................................................................................................... ..................................................................... 5-20

(2) W/ EURO III ................................................................................................................ ....................................................................... 5-22

2) IGNITION COIL, SENSOR (CAM SHAFT, MAP, CKP), CAM SHAFT ACTUATOR, CPS CIRCUIT .............. 5-24 (1) W/O EURO III ............................................................................................................... ..................................................................... 5-24

(2) W/ EURO III ................................................................................................................ ....................................................................... 5-26

SECTION 5

ELECTRICAL WIRING DIAGRAMS

Page 1385 of 1574

5-18 ELECTRICAL WIRING DIAGRAMS

3. EGR CONTROL UNITMain - Engine Main - T/M Main - T/M MainEngine Main Main

C109 (16Pin, Black)C208 (12Pin, Black) C209 (8Pin, Black) S201 (Black) G103 G203G205

b. CONNECTOR IDENTIFICATION SYMBOL & PIN NUMBER POSITION

a. CONNECTOR INFORMATION

ENGINE RPMSENSOR

C208

W/H MAIN C209

W/H MAIN EGR CONTROL

UNIT

C109

W/H ENGINE

MICRO SWITCH

CONNECTOR(NUMBER) CONNECTING. WIRING HARNESSCONNECTOR POSITION

Inside The Engine Room Fuse Block Upper The T/C (DSL) Upper The T/C (DSL)Behind The Cluster Behind The Right Head Lamp Upper The ECM Beside The TCCU

1234

567812 3

4567812

1234 5678

9 101112

13 14 15 16

1234 5678

9 101112

13 5

24 6

EGR SOLENOID

12

31

15

GND

G103

G203 G205 G205

F24

LWS201

1 8 3

45 7 6 8

LW

EGR Control Unit

R>R5IN

A>15

10A IGN 1

C109

11

C208

1

2 BrW

BrW BrW

6

TCM "A7" TCM

"A21"

R>R4 IN

R>R3

IN

A>10

C209

Engine RPM

Sensor

8

C208

C209 BrB

BrB (M/T)

B (A/T)

RY RY

4 2 31RL RL B

B

B B

B MS1 MS2

BrB EGR Sol.V/V

MicroSwitch 1 2

C209

3

C208

2

75 C208

8 C209

1 LY LYC208

1 C209

2

: M/T

Page 1386 of 1574

ELECTRICAL WIRING DIAGRAMS 5-19

W/H T/M

c. POSITION OF CONNECTORS AND GROUNDS

W/H MAIN (I/P)

S201C201C351

C301~C303

G201

S202

C212

G204

C203

C110C361C213

S204

S203

S205G202

C204

G205TCCU

C305

EBCM

G209

C206B, C206,

C207, C208,

C208B, C209,C210G207

C304G203

TCM

G208

d. SPLICE PACK S201 (BLACK)

1 2 3 4

5 6 7 8

5C204

LW

LW

DLC '2' Stics '29'

EGR Control unit '3' (DLC) Clock '3'VSS '3' F24 (10A)

Seat Warmer Control unit '9'

Stop Lamp Switch '3' (GSL)

LW LW LW LW LW

Page 1400 of 1574

ELECTRICAL WIRING DIAGRAMS 5-33

W/H MAIN (I/P)

c. POSITION OF CONNECTORS AND GROUNDS

d.SPLICE PACK

S201 (BLACK)

1 2 3 4

5 6 7 8

5C204

LW

LW

DLC '2' Stics '29'

EGR Control unit '3' (DLC) Clock '3'VSS '3' F24 (10A)

Seat Warmer Control unit '9'

Stop Lamp Switch '3' (GSL)

LW LW LW LW LW

S205 (COLORLESS)

1 2 3 4

5 6 7 8BrW BrW BrB YW

BrBBrB BrW LYECM '38'

'37' ECM

TCM 'A23' 'A24' TCM

TOD 'A10' 'A11' TOD

RESISTOR (M/T)