oil filter SSANGYONG MUSSO 2003 Owner's Guide

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2003, Model line: MUSSO, Model: SSANGYONG MUSSO 2003Pages: 1574, PDF Size: 26.41 MB

Page 326 of 1574

OM600 ENGINE MECHANICAL 1B3-61

38. Replace the O-ring of heater feed pipe and install it to thecylinder head. NoticeFor installation, clean the hole.

39. Install the bracket of heater feed pipe to the oil filter.

40. Install the fuel pipe and the accelerator control linkage.

41. Connect the fuel lines to the injection nozzles and to the injection pump. Box Wrench Insert 000 589 77 03 00

Tightening Torque 18 Nm

Page 328 of 1574

OM600 ENGINE MECHANICAL 1B3-63

TIMING CASE COVER

Preceding Work : Removal of the cooling fanRmoval of the V-belt tensioning device Removal of the vibration damper and hub Removal of the alternator

1 Bolt............................................................ 10Nm

2 Cylinder Head Cover

3 Gasket ................................................... Replace

4 Socket Bolt ................................................ 25Nm

5 Fuel Filter

6 Square Nut

7 Oil Pan

8 Socket Bolt ................................................ 10Nm

9 Bolt .................................................... M6 : 10Nm

M8 : 23Nm 10 Power Steering Pump

11 Bolt

12 Belt Pulley 13 Bolt

............................................................ 32Nm

14 Timing Case Cover

15 Bolt ............................................................ 23Nm

16 Alternator Bracket

17 Bolt ............................................................ 45Nm

18 Bolt ............................................................ 25Nm

19 Bolt ............................................................ 10Nm

20 Closing Cover

21 Socket Bolt ................................................ 23Nm

22 Guide Pulley

23 Bolt .............................................................. 9Nm

24 Guide Pulley Bracket

25 Nut ............................................................. 23Nm

Page 357 of 1574

1B3-92 OM600 ENGINE MECHANICAL

28. Remove the connecting rod bearing cap.

29. Install the piston.

30. Rotate the crankshaft by hand and check whether it rotatessmoothly.

31. If the bearings are damaged,

- replace the oil presser relief valve. - clean the oil pump and oil filter housing carefully and

replace the hose if necessary. Notice After assembling the engine, check the camshaft timing, adjust the start of fuel injection and check the TDC sensorbracket setting.

32. Fill oil and run the engine and then check the oil pressure and oil level. Notice Install the original oil filter element and then change the engine oil and oil filter element after 1,000 - 1,500km.

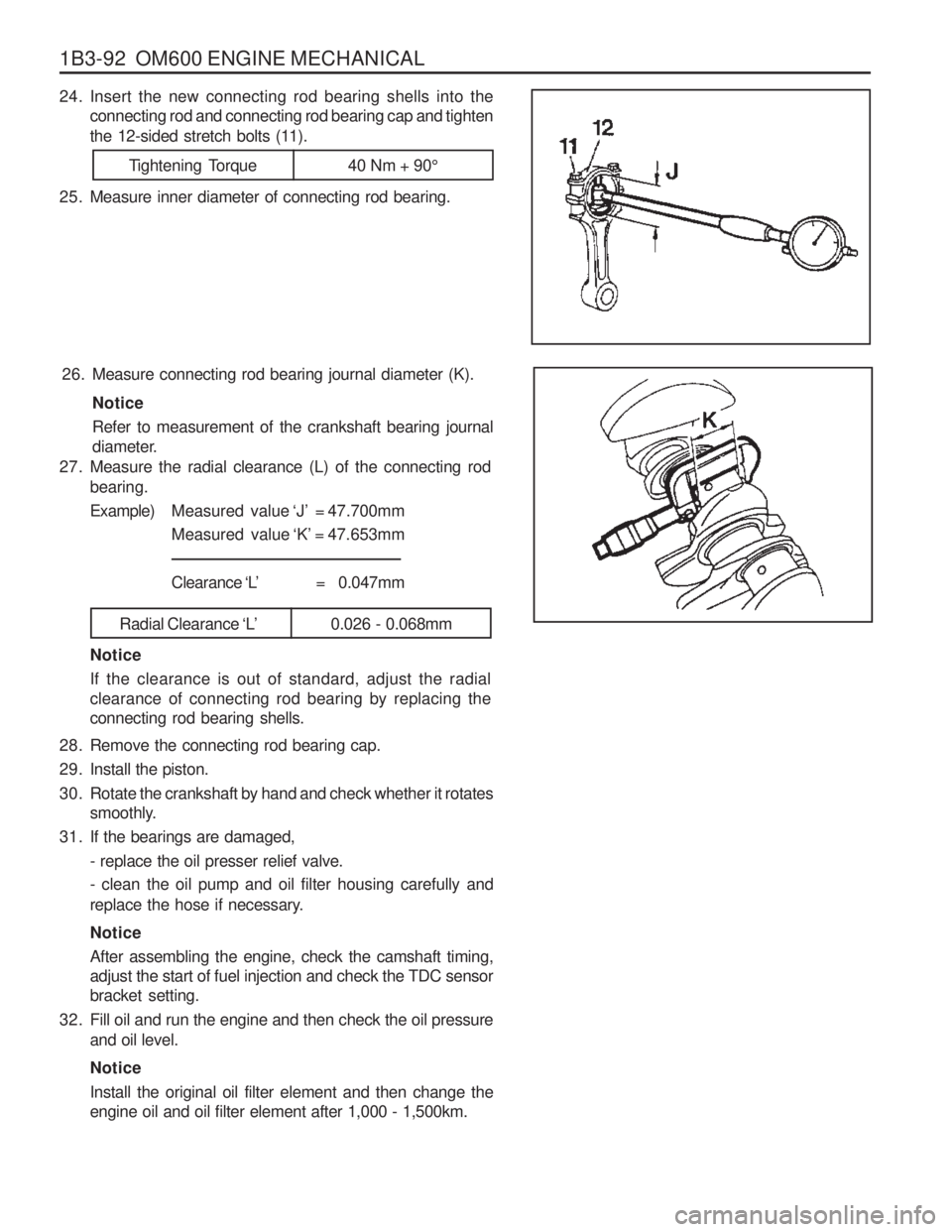

27. Measure the radial clearance (L) of the connecting rod

bearing. Example) Measured value ‘J’ = 47.700mm

Measured value ‘K’ = 47.653mm

Clearance ‘L’ = 0.047mm

Radial Clearance ‘L’0.026 - 0.068mm

Notice If the clearance is out of standard, adjust the radial clearance of connecting rod bearing by replacing theconnecting rod bearing shells.

26. Measure connecting rod bearing journal diameter (K).

Notice Refer to measurement of the crankshaft bearing journal

diameter.

24. Insert the new connecting rod bearing shells into theconnecting rod and connecting rod bearing cap and tighten

the 12-sided stretch bolts (11).

25. Measure inner diameter of connecting rod bearing.

Tightening Torque 40 Nm + 90 °

Page 433 of 1574

OM600 ENGINE MECHANICAL 1B3-169

OIL FILTER1 Nut ............................................................ 25 Nm

2 Oil Filter ..................................................... Cover

3 O-Ring ................................................... Replace

4 Oil Filter ...............Element Replace If necessary

5 Oil Filter Housing 6 Bolt (M8)

.................................................... 10Nm

7 Oil Pressure Switch

8 Gasket

9 Bolt ........................................................... 25 Nm

Page 434 of 1574

1B3-170 OM600 ENGINE MECHANICAL

Removal & Installation Procedure

1. Remove the oil filter cover and then drain the oil.

2. Remove the oil pressure switch line.

3. Remove the oil filter housing.

4. Clean the sealing surface.

5. Installation should follow the removal procedure in thereverse order.

Page 437 of 1574

OM600 ENGINE MECHANICAL 1B3-173

Oil Filter

a From Oil Pump

b To Main Oil Galleryc To Oil Pan

Page 754 of 1574

3A-4 FRONT DRIVE AXLE AUTO-LOCKING HUB

1 Cap

2 Filter

3 Vacuum Diaphragm

4 Diaphragm Retainer

5 Piston

6 Bolt (M10)

7 Lock Washer

8 O-ring

9 Retaining Ring

10 Clutch Ring 11 Body

12 Return Spring

13 Bearing

14 O-ring

15 Retaining Ring

16 Inner Drive Gear

17 Oil Seal

18 Oil Seal Race

19 Axle Retaining Ring

Page 985 of 1574

5A-126 AUTOMATIC TRANSMISSION

Oil Filter and Pan Assembly Notice

1. Replace the filter whenever rebuilding a transmission where a significant amount of mechanical damage hasoccurred.

2. To aid the assembly of the pan gasket, use a small amount of Vaseline at the pan/gasket interface. This ensures that the gasket remains on the pan ridge. Do not over torque pan bolts as this may distort the pan and cause leaks.

3. Ensure that the internal line pressure plus in the valve body is fitted.

To assemble the oil filter and pan assembly (refer to figures 8.63 and 8.64), proceed as follows.

1. Lubricate the oil filter sealing ring with automatic transmission fluid.

2. Carefully assemble the oil filter to the valve body. The spigot must not lean on one side while being fitted. Refer to figure 8.63.

3. Secure the oil falter assembly with the retainer.

4. Check that the magnet is located in the dimple in the comer of the oil pan.

5. Assemble the gasket on the pan lip. The gasket must be free of any distortion when installed.

6. Fit the oil pan assembly to the transmission case and tighten the securing bolts to specification and sequence (refer to figure 8.65). Do not over torque.

Page 1137 of 1574

5D2-48 TRANSFER CASE (TOD)

6. Install the front planet to the sun gear and input shaft.Install the internal snap ring to the planetary carrier.

7. Place the tanged snap ring in the case. Expand snap ring with snap ring pliers and install planetary carrier assembly. Check installation by holding the case and carefully tappingthe face of the input shaft against a wooden block to makesure the snap ring is installed.

8. Remove all traces of gasket sealant from the front case and mounting adapter mating surfaces. Install a bead ofgasket sealant on the surface of the front case.

9. Install the high-low shift fork and high-low collar as an assembly into the front planet. Notice Make sure that the nylon wear pads are installed on the shift fork and snapped securely into place.

12 Rear Output Shaft

13 Oil Strainer

14 Coupling Hose

15 Hose Clamp

16 Pump Body

10. If new pump is used, align the flat of the output shaft and

the flat of the pump. Slide the pump onto the output shaft.

�Do not disassemble oil pump. It is serviced only as an

assembly. Check the pump to make sure the pump

rotates freely.

� Do not remove the plastic insert from the bore of the

new pump. Discard it after it slides out during pumpinstallation to the rear output shaft.

� While turning the output shaft, prime the pump through

the oil filter pickup tube or housing inlet hole with clean

Automatic Transmission Fluid or equivalent.

11. Inspect the outside surfaces and bore of the oil pump. If there is no discoloration in the pump housing, gear or cover,and the pump bore and the lube holes of the output shaft show evidence of oil, the pump is working.

Page 1138 of 1574

TRANSFER CASE (TOD) 5D2-49

12. Install the output shaft and oil pump in the input shaft.Make sure that the internal splines of the ouput shaft

engage the internal splines of the high-low shift collar. Make sure that the oil pump retainer arm and oil filter leg are inthe groove and slot of the front case.

13. Install the magnet in the slot in the front case just above the oil filter leg.

14. Install the front output shaft in the front case.

15. Install the thrust washer on the rear output shaft. Install the chain, drive sprocket and driven sprocket as an assembly over the output shaft. Notice

�The driven sprocket (on the front output shaft) must

be installed with the marking REAR facing toward the rear case, if so marked.

� Drive sprocket has a bushing pressed into it.

16. Install tone wheel onto the front output shaft. Make sure the spline on the tone wheel engages the spline on thefront output shaft.

17. Install clutch pack assembly onto the rear output shaft. Make sure the spline of the clutch pack engages to the spline of the sprocket.

18. Install snap ring onto the rear output shaft. Start the snap

ring over the spline and use the wave spring to seat the snap ring in the snap ring groove. If the snap ring will notinstall, the thrust washer inside the clutch pack may not

be seated properly. 1 2 Rear Output Shaft

1 6 Oil Pump

6 1 Magnet

1 2 Rear Output Shaft

1 3 Oil Strainer

1 6 Oil Pump

1 6 a Pump Retainer