drain bolt SSANGYONG MUSSO 2003 Workshop Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2003, Model line: MUSSO, Model: SSANGYONG MUSSO 2003Pages: 1574, PDF Size: 26.41 MB

Page 792 of 1574

3D-12 REAR DRIVE AXLE

Disassembly Procedure

1. Remove the drain plug and drain the oil. Reinstall the drainplug.

2. Remove the axle housing cover. Notice Clean the cover and housing contact surface.

3. Remove the bearing cap bolts and remove the bearing caps. Pull out the differential carrier assembly. Notice Place alignment marks on the bearing cap not to change the caps before removal. When pulling out the differential

carrier assembly, be careful not to damage the axle housing.

4. Disassemble the parts of the differential carrier assembly.

Tightening Torque 28 - 42Nm

Page 991 of 1574

5B-2 MANUAL TRANSMISSIONFASTENER TIGHTENING SPECIFICATIONS

Application

Transmission

Oil Filler Plug

Transmission Mounting Bolt (Housing) Oil Drain PlugFront Propeller Shaft (T/C)Rear Propeller Shaft (T/C)Cross Member Bolt (Center) Cross Member Bolt (Side)

Control Cable Shift Lever Bolt

N�m

25

77 - 87 25

81 - 89 70 - 9021 - 3562 - 93 20 - 30

Page 995 of 1574

5B-6 MANUAL TRANSMISSIONCheck

Loosened transmission or flywheel housing bolts,

improper alignment.Synchronizer damaged or excessively worn. Blocking ring damaged, worn index slots or friction surfaces worn or damaged.

Excessive countershaft end play. Worn or damaged fork due to loosened shaft, rail or shifting fork. TRANSMISSION JUMPS OUT

Action

Tighten bolts to specified value. Realign if necessary. Check or replace synchronizer parts.

Check or replace blocking ring.Check worn or damaged parts. Adjust shim thickness

using roller bearings if necessary.Check for wear or damaged. Replace worn or damaged parts.

Check

Fork or offset lever loose on shaft or rail.

Worn or damaged forks, offset lever, shaft or rail.

Worn or damaged synchronizer. Worn or damaged gears. TRANSMISSION LOCKED IN ONE GEARAction

Replace extension, adapter or case cover. Check or replace loose parts on shaft or rail. Replace roll pin(s).

Remove extension, adapter or case cover. Check forwear or damaged. Replace damaged parts.Check worn or damaged synchronizer parts and

replace if necessary.

Check worn or damaged gears and replace if neces-

sary.

Check

Improper or low transmission oil. Loose bolts or other attaching parts.Improper flywheel housing to engine crankshaftalignment.Noisy transmission bearing. Noisy gears. TRANSMISSION NOISEAction

Add or drain and replace with proper oil.

Tighten as specified.

Realign correctly. Check bearings, bearing rollers and parts for wear or damage.

Replace if necessary.Check for worn or damaged gears(including speedometer gear).

Replace if necessary.

Page 999 of 1574

5B-10 MANUAL TRANSMISSION1 Filler/Drain Plug

2 Shift Mechanism Cover

3 Shift Shaft Lever

4 Outer Select Lever

5 Inner Select Lever

6 Offset Control Lever

7 Bias Spring

8 Bolt

9 Pin

10 Washer

11 Bolt

12 Bolt

13 Extension and Plate Assembly

14 O-Ring & Steel Ring

15 Oiling Funnel

16 Bolt

17 Alignment Bolt

18 Pin

19 Shift Shaft

20 3/4 Shift Fork

21 1/2 Shift Fork

22 Insert

23 Selector Arm Assembly

24 Interlock Plate Assembly

25 Selector Plate

26 O-ring

27 Plug

28 Case Cover

29 Retaining Ring

30 Pivot Pin

31 Back-up Switch

32 5/Reverse Shift Lever

33 Snap Ring

34 5th Synchronizer Retainer

35 5th Synchronizer Assembly

36 Synchronizer Spring

37 Synchronizer Assembly 38 Insert

39 Synchronizer Hub

40 Roll Pin

41 5th Shift Fork

42 Insert

43 Shift Rail Assembly

44 Blocking Ring

45 5th Speed Drive Gear

46 Snap Ring

47 Speed Gear

48 Speed Gear Clip

49 Bolt

50 Input Bearing Retainer

51 Oil Seal

5 2 Shim

53 Bearing Cup

54 Bearing Cone

55 Input Shaft

56 Roller Bearing

57 Spacer

58 Thrust Bearing

59 Thrust Bearing Race

60 5th Speed Driven Gear

61 Bearing Cup

62 Bearing Cone

63 1st Speed Gear

64 Bearing Sleeve Assembly

65 A. Bearing

65 B. Bearing

65 C. Spacer

66 Sleeve

67 Blocking Ring Assembly

68 3/4 synchronizer Assembly

69 Synchronizer Spring

70 Synchronizer Sleeve

71 Insert

72 Synchronizer Sleeve 73 3rd Speed Gear

74 Needle Bearing

75 Spacer

76 Snap Ring

77 Thrust Washer

78 2nd Speed Gear

79 2nd Speed Gear Bearing

80 Spacer

81 Output Shaft Assembly

82 Retaining Ring

83 Thrust Washer

84 Inner Cone

85 Outer Cone Race

86 1/2 Blocking Ring

87 Spring Gear

88 Reverse Sliding Gear

89 Insert Gear

90 Pin

91 Shaft and Hub Assembly

92 Spring

93 Pin Fork and Reverse Roller

Assembly

94 Bolt

95 Rear Bearing Retainer

9 6 Shim

97 Roll Pin

98 Reverse Idler Shaft

99 Reverse Idler Gear Assembly

100 O-ring

101 Bearing Cup

102 Bearing Cup Assembly

103 O-ring

104 Bearing Cup

105 Bearing Cone

106 Counter Shaft Gear

107 Transmission Case Assembly

Page 1003 of 1574

5B-14 MANUAL TRANSMISSION TRANSMISSION Preceding Work : Removal of the shift control cable

1 Clutch Housing

2 Oil Filler Plug............................................ 25 Nm

3 Transmission Assembly

4 Back-up Switch

5 Washer

6 Bolt ...................................................... 77-87 Nm

7 Oil Drain Plug ............................................ 25 Nm

8 Bolt ...................................................... 81-89 Nm

9 Washer

10 Front Propeller Shaft 11 Transfer Case Assembly12 Speedometer Cable

13 Rear Propeller Shaft

14 Washer

15 Bolt ...................................................... 70-80 Nm

16 Cross Member

17 Washer

18 Bolt ...................................................... 21-35 Nm

19 Washer

20 Bolt ...................................................... 62-93 Nm

21 Breather Hose

Page 1006 of 1574

MANUAL TRANSMISSION 5B-17

UNIT REPAIR MAJOR UNIT Preceding Work : Removal of the transmissionRemoval of the transfer case

Disassembly Procedure

1. Install the removed transmission into a fixture.

2. Remove the drain plug and drain the oil. Using a 13 mm wrench, remove the clamp bolt and position the offset lever in the 3-4 position of neutral. NoticeRemoval of the offset lever in a position other than 3-4 of neutral will be difficult.

3. Using a pin punch and a hammer, remove the roll pin to remove the shift lever from the offset lever.

4 . Using a 15 mm wrench, remove the 8 bolts from the extension housing.

5. Separate the extension housing from the case and shift cover. Separate the offset lever from the shift.NoticeDo not remove the offset lever while the extension housing is still assembled to the case.

6. Remove the offset lever from the extension housing with the detent ball and spring.

7. Remove the roll pin from either the offset lever or extension housing.

Page 1007 of 1574

5B-18 MANUAL TRANSMISSION

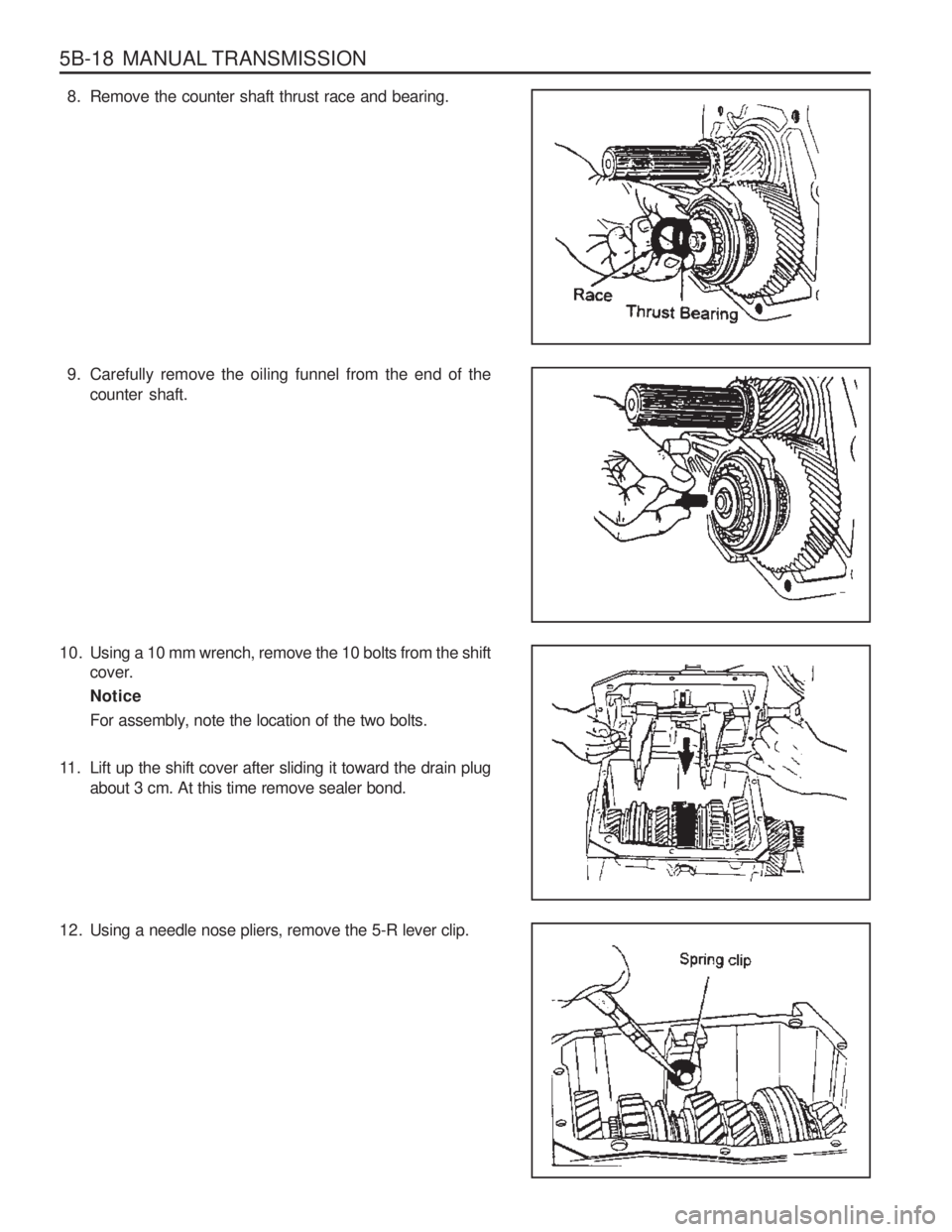

8. Remove the counter shaft thrust race and bearing.

9. Carefully remove the oiling funnel from the end of thecounter shaft.

10. Using a 10 mm wrench, remove the 10 bolts from the shift cover. Notice

For assembly, note the location of the two bolts.

11. Lift up the shift cover after sliding it toward the drain plug about 3 cm. At this time remove sealer bond.

12. Using a needle nose pliers, remove the 5-R lever clip.

Page 1015 of 1574

5B-26 MANUAL TRANSMISSION

21. Completely compress the detent spring.

22. To install the extension housing to the case, apply sealerto the top two bolts and tighten them and tighten the 6 bolts.

23. Apply sealer to the back-up lamp switch and drain plug and tighten them.

24. Using a hammer, install the offset lever-to-shift roll pin.

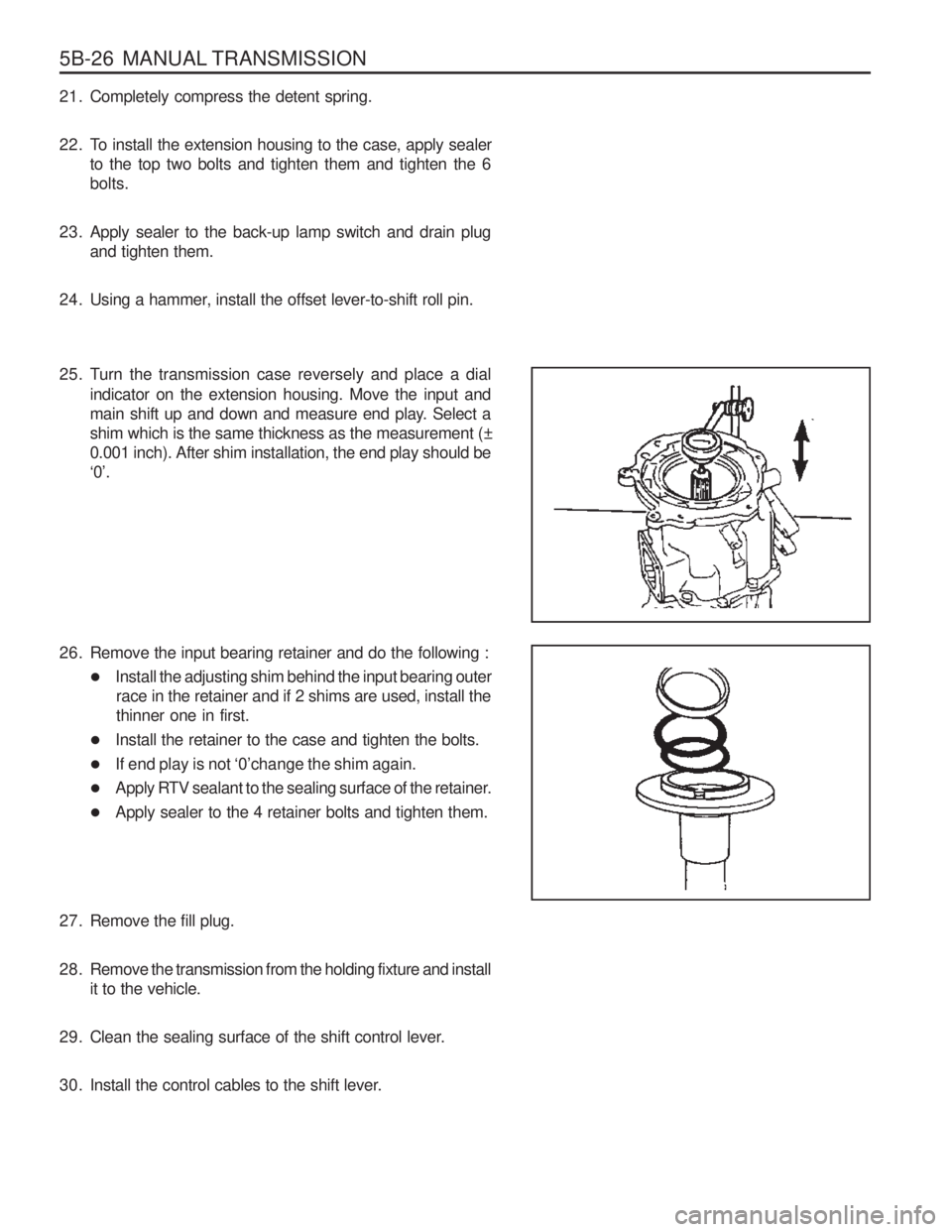

25. Turn the transmission case reversely and place a dial indicator on the extension housing. Move the input and

main shift up and down and measure end play. Select a

shim which is the same thickness as the measurement (±0.001 inch). After shim installation, the end play should be

‘0’.

26. Remove the input bearing retainer and do the following : �Install the adjusting shim behind the input bearing outer

race in the retainer and if 2 shims are used, install thethinner one in first.

� Install the retainer to the case and tighten the bolts.

� If end play is not ‘0’change the shim again.

� Apply RTV sealant to the sealing surface of the retainer.

� Apply sealer to the 4 retainer bolts and tighten them.

27. Remove the fill plug.

28. Remove the transmission from the holding fixture and install it to the vehicle.

29. Clean the sealing surface of the shift control lever.

30. Install the control cables to the shift lever.

Page 1055 of 1574

TRANSFER CASE (PART TIME 4408) 5D1-3

Cannot Front Wheel Drive when Shifted 4H,4LDIAGNOSIS

Electric Shift Problems

Action

Overhaul and check, replace if necessary. Overhaul and check for wear and damage.

Replace if necessary.

Check sliding parts, replace if necessary.

Checks

Faulty or Damaged TCCU, Speed Sensor, Motor, Clutch or Internal Wirings Damaged or Worn Shift Cam, Hub, Fork and Rail Shift Binding Shift Fork, Hub Collar or Gear

Checks

Broken Drive Chain Action

Check sliding parts, replace if necessary.

Noise in 4WD Operation

Checks

Improper or low oil Loosened bolts or mounted partsNoisy T/C bearing Noisy gears Action

Drain and replace with specified oil. Retighten as specified.Disassemble bearings and parts and check for wear or

damage. Replace if necessary. Check for wear and damage including speedometer

gear, replace if necessary.

Noise in 4H or 4L

Checks

Worn or Damaged Sprockets or Drive Chain

Incorrect Tire Pressure Action

Disassemble and check for wear and damage, replace

if necessary. Adjust tire pressure.

Transfer Case Oil Leakage

Action

Replace the case. Clean case and parts and check for leakage.

Remove breather hose and clean, replace if necessary.Use specified oil and adjust oil level.Retighten Use specified sealant and retighten. Replace

Checks

Cracked Transfer CaseLeakage from Other PartsBreather CloggingImproper or too much OilLoosened Sealing Bolts Improperly Applied Sealant Worn or Damaged Oil Seal

Page 1064 of 1574

5D1-12 TRANSFER CASE (PART TIME 4408)

Removal & Installation Procedure

1. Disconnect the negative terminal from the battery.

2. Lift up the vehicle and fix it safely.

3. Remove the drain plug and drain the oil.Reinstall the drain plug.

* If planar damper is installed, unscrew 4 bolts and remove the planar damper.

Installation Notice

Tightening Torque 19 - 30 Nm

4. Remove the breather hose.

5. Disconnect the speedometer cable connector and other cable connectors and wiring harnesses.

6. Support the transfer case with jack and remove the front and rear propeller shafts from the transfer case. Installation Notice

Front

Rear 81 - 89 Nm 70 - 80 NmTightening Torque