solenoid SSANGYONG MUSSO 2003 Repair Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2003, Model line: MUSSO, Model: SSANGYONG MUSSO 2003Pages: 1574, PDF Size: 26.41 MB

Page 1212 of 1574

9A-10 BODY WIRING SYSTEM94 Seat Belt Switch (Driver)

95 Seat Belt Switch (Dirver)

96 Parking Brake Switch

97 Rear Cigarette Lighter

9 8 OVPR ................................................................. Gasoline E/G

99 LH Side Repeater ............................................... Rear Fog Lamp

100 Engine Wiring Connector

101 Engine Joint Connector

102 Engine Joint Connector ......................................Gasoline E/G

103 ECS Engine Wiring Connector ...........................Diesel E/G & Gasoline E/G with HFM ECU

104 ABD Engine Wiring Connector ...........................ABD 5.0

105 ABD Engine Wiring Connector ...........................ABD 5.0

105-1 ABS Engine Wiring Connector ............................ABS 5.0

106 Canister Purge Solenoid Valve ...........................Gasoline E/G with MSE ECU

106-1 Canister Purge Solenoid Valve ...........................E20 & E23 Gasoline E/G with FHM ECU

107 Econo/Standard Solenoid Valve .........................Gasoline E/G with Automatic Transmission

108 CO Potentio Meter .............................................. Gasoline E/G with HFM ECU & CO Potentio Meter

109 Front Wiper Motor 11 0 O 2 Sensor

........................................................... E20 or E23 Gasoline E/G

111 RH Side Repeater

112 Engine Wiring Connector

113 Vertical Sensor

114 Lateral Sensor

115 Diagnosis

11 6 Joint Box ............................................................. Gasoline E/G (E32)

117 Canister Purge Solenoid Valve ...........................E32 Gasoline E/G with HFM ECU

118 Led Antenna ...................................................... Rolling code type Immobilizer

119 E-key Connector ................................................ Gasoline E/G with Rolling Code Type Immobilizer

120 Receiver Unit ...................................................... Gasoline E/G with Rolling Code Type Immobilizer

121 Receiver Unit ...................................................... Gasoline E/G with Rolling Code Type Immobilizer

122 Receiver Antenna .............................................. Gasoline E/G with Rolling Code Type Immobilizer

123 Receiver Connector ........................................... Gasoline E/G with Rolling Code Type Immobilizer

124 ICU Connector .................................................... Gasoline E/G with Rolling Code Type Immobilizer

125 ICU ..................................................................... Gasoline E/G with TOD (MSE ECU 3.2 Engine Only)

126 CAN Line ............................................................ Gasoline E/G with TOD (MSE ECU 3.2 Engine Only)

127 TOD ................................................................... Gasoline E/G with TOD (MSE ECU 3.2 Engine Only)

128 TOD ................................................................... Gasoline E/G with TOD (MSE ECU 3.2 Engine Only)

129 Transfer Case Speed Sensor .............................Gasoline E/G with TOD (MSE ECU 3.2 Engine Only)

130 Engine Main Wiring Connector ...........................Gasoline E/G with MSE ECU

131 Remote Engine Start .......................................... Diesel E/G with A/T & Black Out Lamp

132 Remote Engine Start .......................................... Diesel E/G with A/T & Black Out Lamp

133 TCU .................................................................... Diesel E/G with BTRE A/T

134 TCU .................................................................... Diesel E/G with BTRE A/T

135 Ground 5 ............................................................ Diesel E/G

136 Start Protection Relay .........................................Diesel E/G with Rolling Code Type Immobilizer

137 EGR control unit ................................................. Diesel E/G

1 3 8 ICU 1 .................................................................. Diesel E/G with Rolling Code Type Immobilizer

1 3 9 ICU 2 .................................................................. Diesel E/G with Rolling Code Type Immobilizer

140 Injection Pump Valve Extension ..........................Diesel E/G with Rolling Code Type Immobilizer

141 Injection Pump Valve Extension ..........................Diesel E/G with Rolling Code Type Immobilizer

142 EGR Solenoid .................................................... Diesel E/G

143 ICU led ................................................................ Diesel E/G with Rolling Code Type Immobilizer

144 Immobilizer Solenoid Valve ..................................Diesel E/G with Crypto Type Immobilizer

147 Immobilizer Unit ................................................... Diesel E/G with Crypto Type Immobilizer

Page 1214 of 1574

9A-12 BODY WIRING SYSTEM

15 LH Damper........................................................... ECS

16 Ground 1

17 Ground 2

18 Locking Hub Solenoid

19 Condenser Fan Relay .........................................Gasoline E/G

20 LH Position Lamp

21 LH Head Lamp

22 LH Head Lamp Leveling Device ...........................Leveling Device

23 Thermo Switch 2 .................................................. Gasoline E/G with HFM

24 Thermo Switch 3 .................................................. Gasoline E/G with HFM & Air Conditioner

25 LH Front Fog Lamp

26 LH Horn ............................................................... Black Out Driving Lamp (Domestic)

27 Condenser Fan Motor .........................................Diesel E/G

28 Black Out Driving Lamp .......................................Black Out Driving Lamp (Domestic)

29 LH Horn ............................................................... Leveling Device

30 LH Condenser Fan Motor ....................................Gasoline E/G with Air Conditioner

31 Thermo Switch 1 .................................................. Diesel E/G or Gasoline E/G with HFM

32 Resistor ............................................................... Gasoline E/G with Air Conditioner

33 Thermo Switch 4 .................................................. Gasoline E/G with HFM & Air Conditioner

34 Ambient Censor ................................................... Air Conditioner

35 RH Condenser Fan Motor ....................................Gasoline E/G

36 RH Horn

37 RH Front Fog Lamp

38 RH Position Lamp

39 RH Head Lamlp

40 RH Head Lamp Leveling Device ..........................Leveling Device

41 Wheeling Sensor ................................................. ECS

42 Wheel Speed Sensor (FR) ..................................ABS 5.0, 5.3 or ABD 5.0, 5.3

43 RH Damper .......................................................... ECS

44 Alternator Extension Connector ...........................Gasoline E/G

45 Alternator ............................................................. Gasoline E/G

46 Alternator Extension Joint box ..............................Diesel E/G

47 Alternator Extension Connector ...........................Diesel E/G

48 Ground 3

49 Fusible Link Box ................................................... Gasoline E/G

49-1 Fusible Link Box ................................................... Diesel E/G

50 Receiver Dryer ..................................................... Gasoline E/G with Air Conditioner

50-1 Receiver Dryer ..................................................... Diesel E/G with Air Conditioner

51 Hood Switch ......................................................... Diesel E/G with Black Out Driving Lamp

52 Front Washer Motor ............................................. Gasoline E/G

53 Main Wiring Connector

Page 1225 of 1574

BODY WIRING SYSTEM 9A-23

MANUAL TRANSMISSION1 Main Wiring Connector ......................Diesel E/G

2 Main Wiring Connector ..................Gasoline E/G

3 Main Wiring Connector .........................Gasoline

(E32, E23) E/G

4 Back Up Switch 5 Oil Pressure Switch

6 Start Motor Solenoid

7 Micro Switch

8 Speed Sensor (Turbo Diesel Engine Only)

Page 1226 of 1574

9A-24 BODY WIRING SYSTEM

AUTOMATIC TRANSMISSION (BENZ)1 Main Wiring Connector

2 Start Lock Switch

3 Automatic Transmission Change Over Valve

4 Transmission Overload Protection Switch ...........................Gasoline E/G 5 Oil Pressure Switch

6 Start Solenoid

7 Micro Switch

....................................... Diesel E/G

8 Speed Sensor .......................... T urbo Diesel E/G

Page 1227 of 1574

BODY WIRING SYSTEM 9A-25

AUTOMATIC TRANSMISSION (BTRA)1 Main Wiring Connector

2 Main Wiring Connector

3 Transmission

4 Transmission Lever

5 Oil Pressure Switch ............................Diesel E/G6 Start Motor Solenoid

7 Throttle Position Sensor

....................Diesel E/G

8 Speed Sensor .......................... T urbo Diesel E/G

9 Inhibitor Switch

Page 1315 of 1574

MUSSO-SPORTS 1A-3

SUPPLEMENT

HUBER EGR

SYSTEM DESCRIPTION The following chart shows the relationship between the input and the output in Huber EGR control unit. Compared to traditional system that only operates theEGR valve with RPM sensor and Micro switch, the HuberEGR control unit bring big differences that of traditionalsystem on the functions.

Input Signal

RPM sensor (CPS)

EGR valve lift sensor

Throttle position sensor (TPS) - M/T

Shift lever position

Throttle position sensor (TPS)

Vehicle speed sensor(VSS) Basic input signal for EGR operation Engine cold or hot signal

Position signal of EGR valve that is triggered by vacuum modulator 1 Transfer the engine load signal to the control unit directly (manual transmission)

TCU (A/T)

EGR

Control

Unit

Coolant temperature sensor (CTS)

Solenoid valve (Control forvacuum modulator 2)

If the control unit determines it is in no-load sharp accel- eration mode after analyzing the input signals, this conver- sion type switch reduces the fuel consumption by cutting off the intake air pressure from

fuel injection ALDA and gen- erating the vacuum pressure. In no-load sharp acceleration

mode, Duty Control ( continu- ous precise control) is acti- vated according to the varia- tions of the input signals when the solenoid valve generates the vacuum pressure in ALDA.

Vacuum modulator 2

The opening value of the modulator is precisely con- trolled by input signals and programmed MAP, and the opening value of EGR valve is also changed by the varia- tions of vacuum pressure to EGR valve. The changed opening value is transferred to the control unit as input signal.

Vacuum modulator 1

TCU in automatic transmission equipped vehicle transfers the information such as driving conditions and speeds into the EGR control unit. EGR control unit uses the shift lever position and vehicle speed as important information for operating the solenoid valve during no-load sharp acceleration mode. In manual transmission, the signal of vehicle speed is transferred into the EGR control unit directly.

Clutch switch

In manual transmission, the clutch switch is the one of core elements to determine driving condition. Output Signal

EGR Control Unit

Page 1316 of 1574

1A-4 MUSSO-SPORTS

SUPPLEMENT

from vacuum pump

EGR valve

EGR control unit

KAA5A020

KAA5A020

KAA5A020

KAA5A020 EGR COMPONENTS EGR Unit

1. Location: behind passenger's side panel

2. Arrangement: 81-pin connector

3. Integrated self-diagnostic function (Scan-100: not

fixed)

4. Part number For automatic transmission: 28800-07100 For manual transmission: 28800-07000

Vacuum Modulator

1. Location: in front of intake manifold

2. Continuous precise control with the signals from EGR unit (PWM-Pulse With Modulation Control)

3. Rated voltage: 12 V

4. Operating voltage: 8 ~ 16 V

5. Resistance (at 20 °C): 15.4 ± 0.7 �

6. Operating range of vacuum (Duty control)

Vacuum modulator 1: 0 ~ 600 mbar

Vacuum modulator 2: 300 ~ 600 mbar

7. Modulator control

Vacuum modulator 1: for controlling EGR valve

Vacuum modulator 2: for controlling no-load sharp

acceleration (ALDA control)

not used connector

Vacuum modulator 1

(for controlling EGR valve)Vacuum modulator 2

(for controlling ALDA)

from vacuum pump

Vacuum modulator 1

Vacuum modulator 2

Solenoid valve

ALDAIntake

manifold

EGR control unit

Page 1318 of 1574

1A-6 MUSSO-SPORTS

SUPPLEMENT

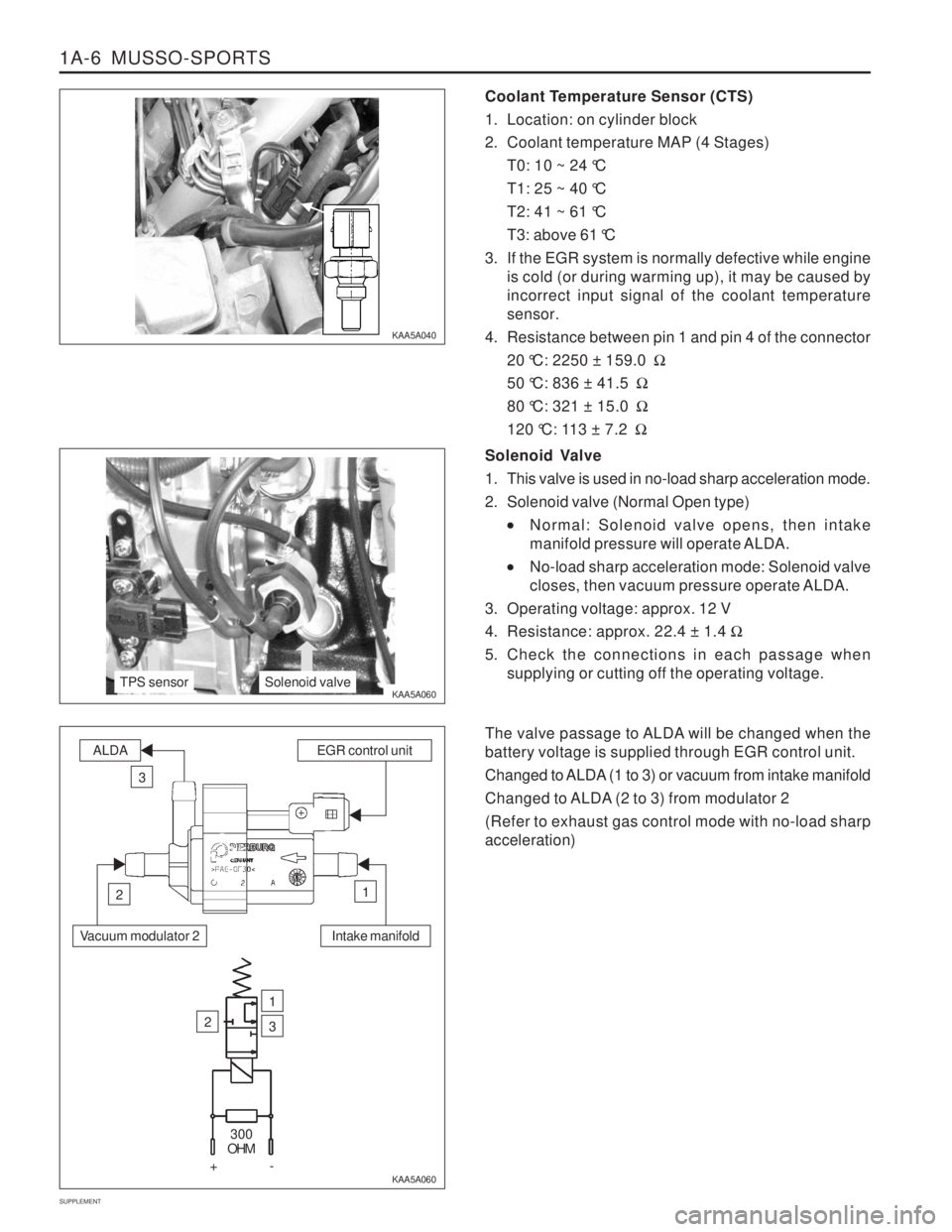

Coolant Temperature Sensor (CTS)

1. Location: on cylinder block

2. Coolant temperature MAP (4 Stages) T0: 10 ~ 24 °C

T1: 25 ~ 40 °C

T2: 41 ~ 61 °C

T3: above 61 °C

3. If the EGR system is normally defective while engine is cold (or during warming up), it may be caused by incorrect input signal of the coolant temperaturesensor.

4. Resistance between pin 1 and pin 4 of the connector 20 °C: 2250 ± 159.0 �

50 °C: 836 ± 41.5 �

80 °C: 321 ± 15.0 �

120 °C: 113 ± 7.2 �

KAA5A040 KAA5A060

KAA5A060Solenoid Valve

1. This valve is used in no-load sharp acceleration mode.

2. Solenoid valve (Normal Open type)

Normal: Solenoid valve opens, then intake

manifold pressure will operate ALDA.

No-load sharp acceleration mode: Solenoid valve

closes, then vacuum pressure operate ALDA.

3. Operating voltage: approx. 12 V

4. Resistance: approx. 22.4 ± 1.4 �

5. Check the connections in each passage when supplying or cutting off the operating voltage.

The valve passage to ALDA will be changed when the battery voltage is supplied through EGR control unit.

Changed to ALDA (1 to 3) or vacuum from intake manifold

Changed to ALDA (2 to 3) from modulator 2 (Refer to exhaust gas control mode with no-load sharp acceleration)

TPS sensorSolenoid valve

Intake manifold

ALDAEGR control unit

3

12

Vacuum modulator 2

2

1

3

300

OHM

+-

Page 1322 of 1574

1A-10 MUSSO-SPORTS

SUPPLEMENT

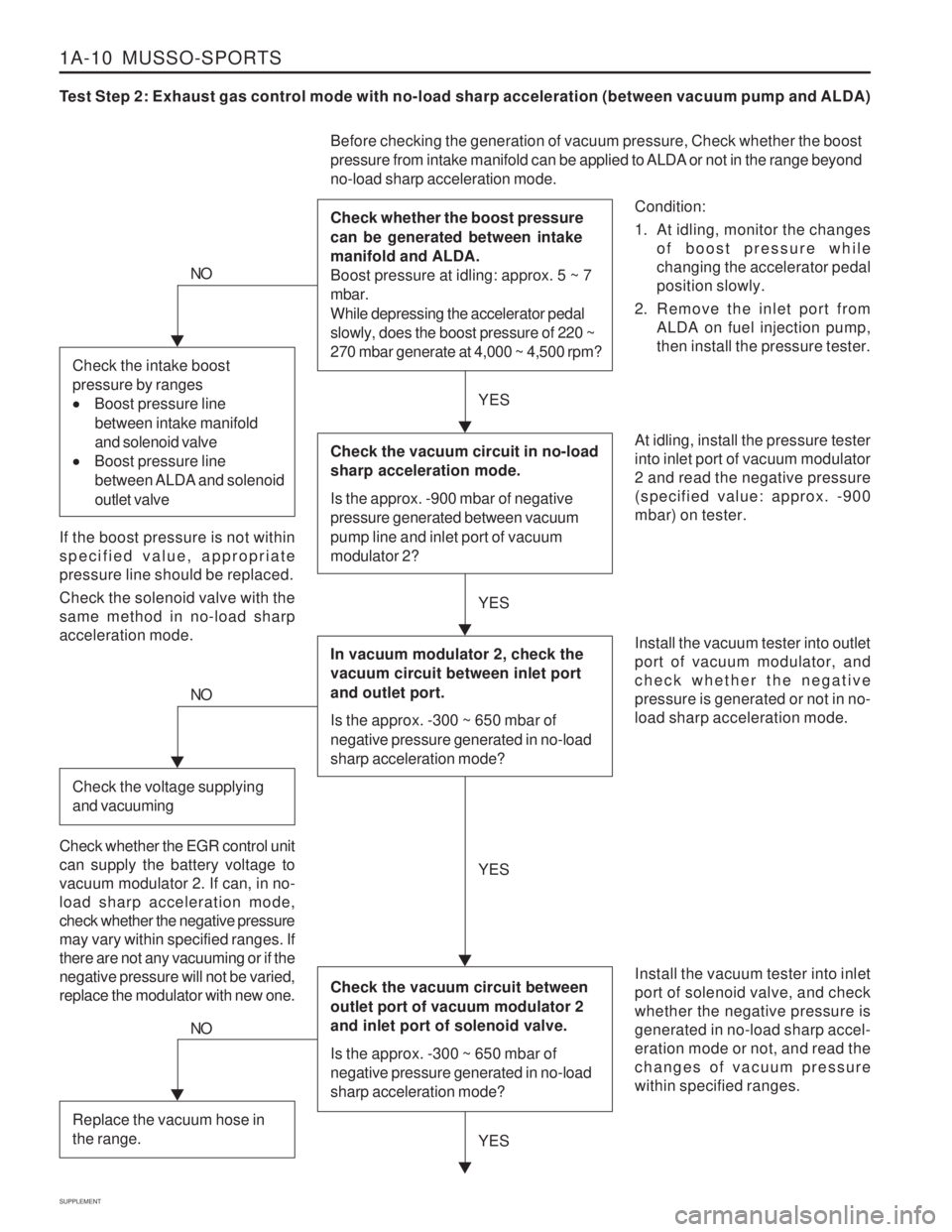

Test Step 2: Exhaust gas control mode with no-load sharp acceleration (between vacuum pump and ALDA)

Condition:

1. At idling, monitor the changesof boost pressure while changing the accelerator pedalposition slowly.

2. Remove the inlet port from ALDA on fuel injection pump,then install the pressure tester.

Before checking the generation of vacuum pressure, Check whether the boost

pressure from intake manifold can be applied to ALDA or not in the range beyond no-load sharp acceleration mode. Check whether the boost pressure can be generated between intake manifold and ALDA. Boost pressure at idling: approx. 5 ~ 7 mbar. While depressing the accelerator pedal slowly, does the boost pressure of 220 ~ 270 mbar generate at 4,000 ~ 4,500 rpm?

At idling, install the pressure tester into inlet port of vacuum modulator2 and read the negative pressure(specified value: approx. -900mbar) on tester. Install the vacuum tester into inlet port of solenoid valve, and checkwhether the negative pressure isgenerated in no-load sharp accel-eration mode or not, and read thechanges of vacuum pressurewithin specified ranges.

NO

If the boost pressure is not within specified value, appropriatepressure line should be replaced. Check the solenoid valve with the same method in no-load sharpacceleration mode.

YES

YES

Check the vacuum circuit in no-load sharp acceleration mode. Is the approx. -900 mbar of negative pressure generated between vacuum pump line and inlet port of vacuum modulator 2?

In vacuum modulator 2, check the vacuum circuit between inlet port and outlet port. Is the approx. -300 ~ 650 mbar of negative pressure generated in no-load sharp acceleration mode?

Check the vacuum circuit between outlet port of vacuum modulator 2 and inlet port of solenoid valve. Is the approx. -300 ~ 650 mbar of negative pressure generated in no-load sharp acceleration mode?

Install the vacuum tester into outlet port of vacuum modulator, andcheck whether the negativepressure is generated or not in no-load sharp acceleration mode.

Check the intake boost pressure by ranges

Boost pressure line

between intake manifold and solenoid valve

Boost pressure line

between ALDA and solenoid outlet valve

NO

Check the voltage supplying and vacuuming

Check whether the EGR control unit can supply the battery voltage tovacuum modulator 2. If can, in no-load sharp acceleration mode,check whether the negative pressuremay vary within specified ranges. Ifthere are not any vacuuming or if thenegative pressure will not be varied,replace the modulator with new one. YES

YES

NO

Replace the vacuum hose in the range.

Page 1323 of 1574

MUSSO-SPORTS 1A-11

SUPPLEMENT

Install the vacuum tester into out- let port of solenoid valve, andcheck whether the negative pres-sure is generated in no-load sharpacceleration mode or not, and readthe changes of vacuum pressurewithin specified ranges.

YES

In solenoid valve, check whether the vacuum pressure is generated between inlet port and outlet port. When the power is supplied, does the solenoid valve close and the intake boost pressure cut off to complete the vacuum circuit?

NO

Replace the vacuum hose in the range.

Install the vacuum tester into out- let port of solenoid valve, andcheck whether the negative pres-sure is generated in no-load sharpacceleration mode or not, and readthe changes of vacuum pressurewithin specified ranges.

YES

Check whether the vacuum pressure is generated between outlet port of solenoid valve and inlet port of ALDA. Is the approx. -300 ~ 650 mbar of negative pressure generated in no-load

sharp acceleration mode?

NO

Replace the vacuum hose in the range.