4WD SSANGYONG MUSSO 2003 Service Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2003, Model line: MUSSO, Model: SSANGYONG MUSSO 2003Pages: 1574, PDF Size: 26.41 MB

Page 3 of 1574

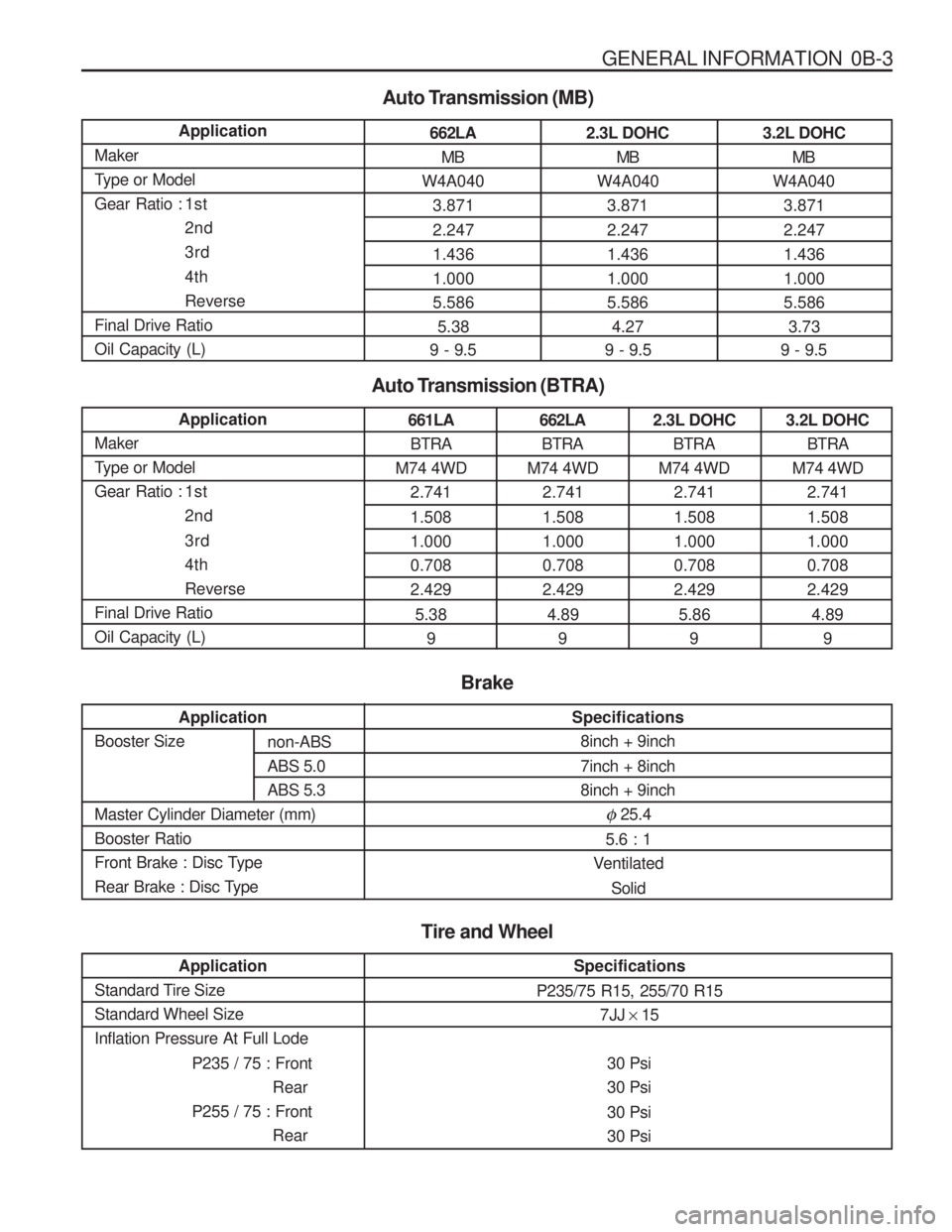

GENERAL INFORMATION 0B-3

662LA MB

W4A040 3.871 2.247 1.4361.0005.5865.38

9 - 9.5

Auto Transmission (MB)

Application

Maker

Type or Model

Gear Ratio : 1st 2nd3rd 4th Reverse

Final Drive RatioOil Capacity (L)

2.3L DOHC MB

W4A040 3.871 2.247 1.4361.0005.5864.27

9 - 9.5 3.2L DOHC

MB

W4A040 3.871 2.247 1.4361.0005.5863.73

9 - 9.5

661LA

BTRA

M74 4WD

2.741 1.508 1.0000.7082.429

5.38 9

Auto Transmission (BTRA)

Application

Maker

Type or Model

Gear Ratio : 1st 2nd 3rd 4thReverse

Final Drive RatioOil Capacity (L)662LA BTRA

M74 4WD

2.741 1.508 1.0000.7082.429

4.89 9 2.3L DOHC

BTRA

M74 4WD

2.741 1.508 1.0000.7082.429

5.86 9 3.2L DOHC

BTRA

M74 4WD

2.741 1.508 1.0000.7082.429

4.89 9

Tire and Wheel

Specifications

P235/75 R15, 255/70 R15 7JJ × 15

30 Psi 30 Psi 30 Psi 30 Psi

Application

Standard Tire SizeStandard Wheel SizeInflation Pressure At Full Lode

P235 / 75 : FrontRear

P255 / 75 : Front Rear

Application

Booster Size Master Cylinder Diameter (mm) Booster Ratio

Front Brake : Disc Type

Rear Brake : Disc Type

Specifications 8inch + 9inch 7inch + 8inch 8inch + 9inch

� 25.4

5.6 : 1

Ventilated

Solid

Brake

non-ABS ABS 5.0ABS 5.3

Page 864 of 1574

AUTOMATIC TRANSMISSION 5A-5

SCHEMATIC AND ROUTING DIAGRAMS

TCU CIRCUIT (4WD-DIESEL)

Page 865 of 1574

5A-6 AUTOMATIC TRANSMISSION

TCU CIRCUIT (4WD-GASOLINE)

Page 877 of 1574

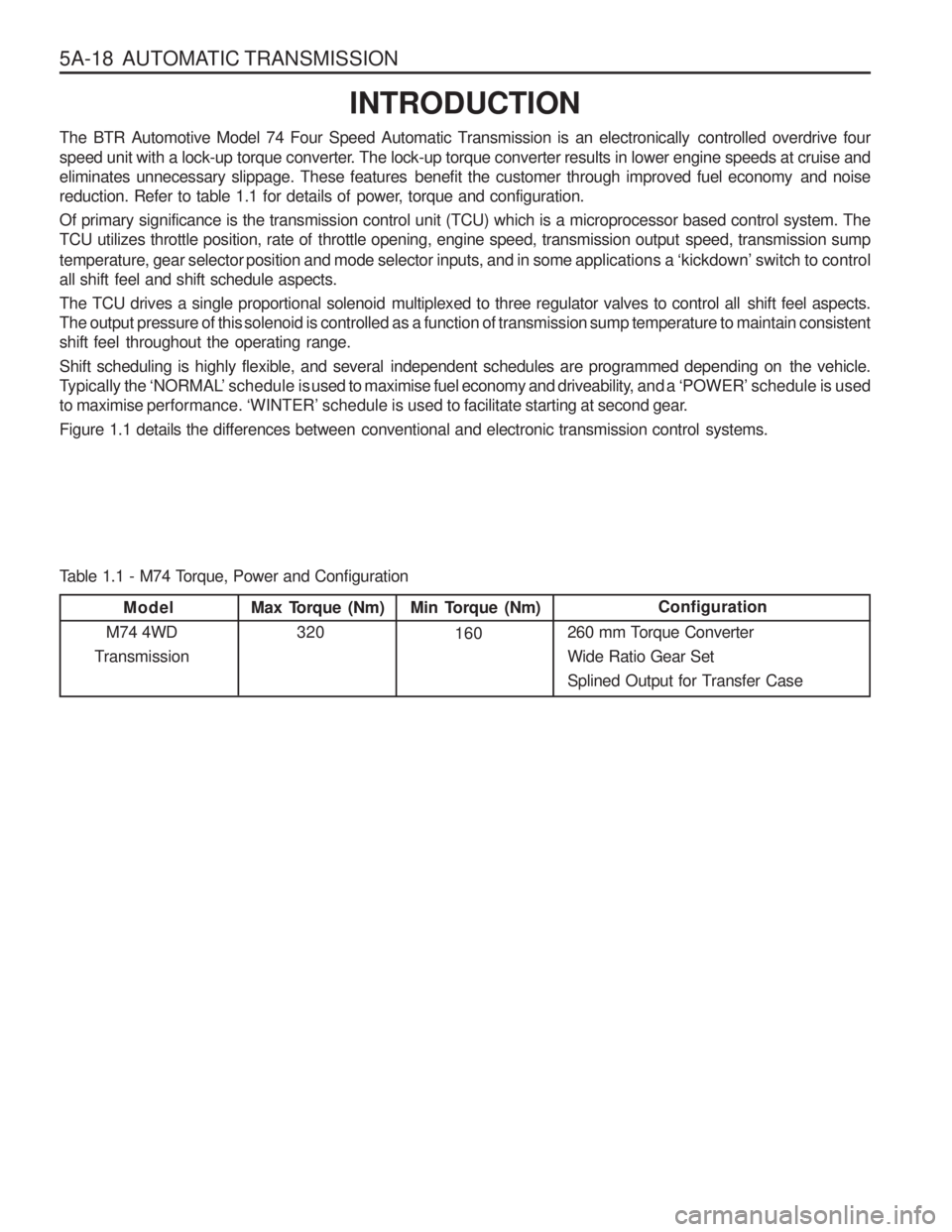

5A-18 AUTOMATIC TRANSMISSIONINTRODUCTION

The BTR Automotive Model 74 Four Speed Automatic Transmission is an electronically controlled overdrive four

speed unit with a lock-up torque converter. The lock-up torque converter results in lower engine speeds at cruise and

eliminates unnecessary slippage. These features benefit the customer through improved fuel economy and noise

reduction. Refer to table 1.1 for details of power, torque and configuration.

Of primary significance is the transmission control unit (TCU) which is a microprocessor based control system. The

TCU utilizes throttle position, rate of throttle opening, engine speed, transmission output speed, transmission sump

temperature, gear selector position and mode selector inputs, and in some applications a ‘kickdown’ switch to control

all shift feel and shift schedule aspects.

The TCU drives a single proportional solenoid multiplexed to three regulator valves to control all shift feel aspects.

The output pressure of this solenoid is controlled as a function of transmission sump temperature to maintain consistent

shift feel throughout the operating range.

Shift scheduling is highly flexible, and several independent schedules are programmed depending on the vehicle.

Typically the ‘NORMAL’ schedule is used to maximise fuel economy and driveability, and a ‘POWER’ schedule is used

to maximise performance. ‘WINTER’ schedule is used to facilitate starting at second gear.

Figure 1.1 details the differences between conventional and electronic transmission control systems.

Max Torque (Nm)

320 Configuration

260 mm Torque Converter Wide Ratio Gear Set

Splined Output for Transfer CaseMin Torque (Nm) 160

Model

M74 4WD

Transmission

Table 1.1 - M74 Torque, Power and Configuration

Page 883 of 1574

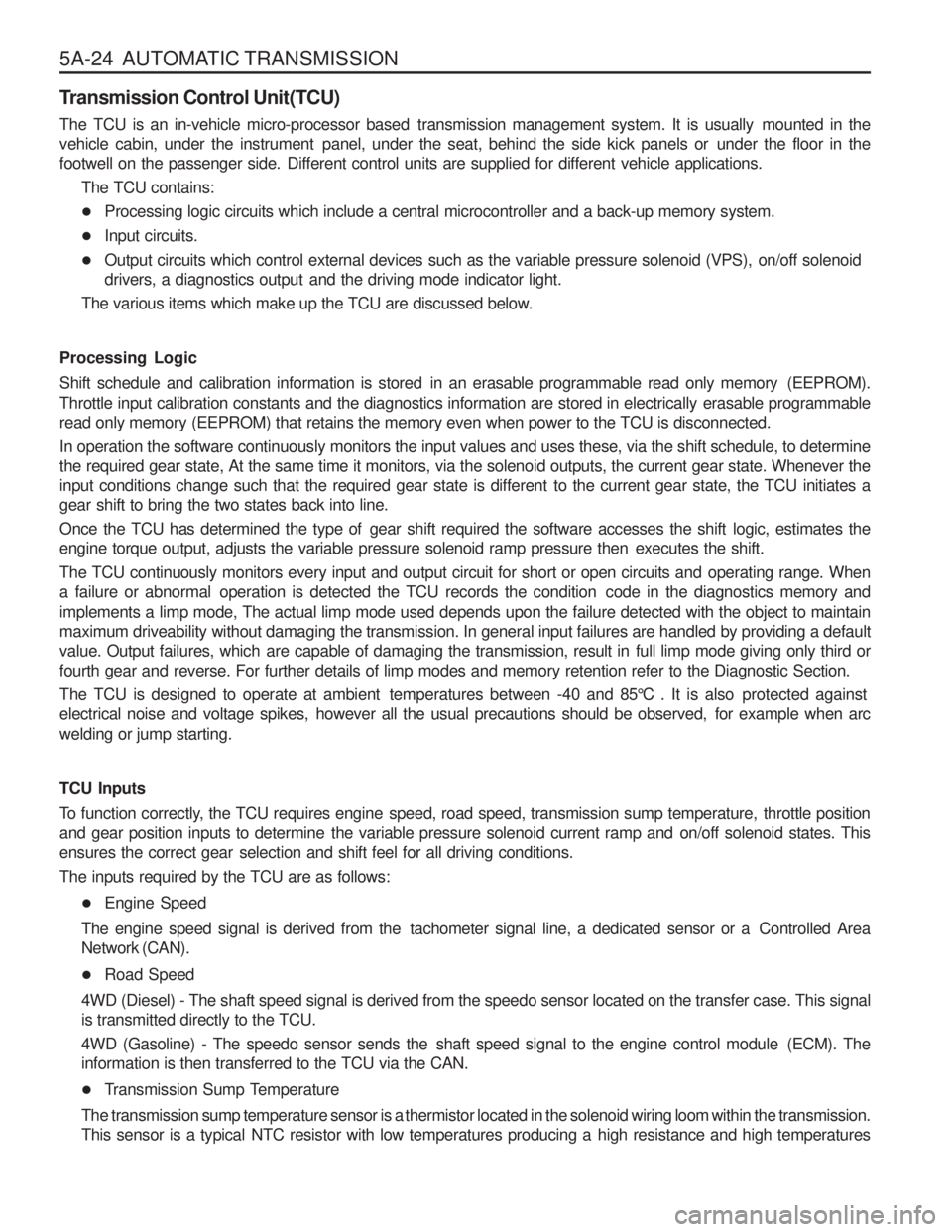

5A-24 AUTOMATIC TRANSMISSION

Transmission Control Unit(TCU)

The TCU is an in-vehicle micro-processor based transmission management system. It is usually mounted in the

vehicle cabin, under the instrument panel, under the seat, behind the side kick panels or under the floor in the

footwell on the passenger side. Different control units are supplied for different vehicle applications.The TCU contains:

� Processing logic circuits which include a central microcontroller and a back-up memory system.

� Input circuits.

� Output circuits which control external devices such as the variable pressure solenoid (VPS), on/off solenoid

drivers, a diagnostics output and the driving mode indicator light.

The various items which make up the TCU are discussed below.

Processing Logic

Shift schedule and calibration information is stored in an erasable programmable read only memory (EEPROM).

Throttle input calibration constants and the diagnostics information are stored in electrically erasable programmable

read only memory (EEPROM) that retains the memory even when power to the TCU is disconnected. In operation the software continuously monitors the input values and uses these, via the shift schedule, to determine the required gear state, At the same time it monitors, via the solenoid outputs, the current gear state. Whenever the

input conditions change such that the required gear state is different to the current gear state, the TCU initiates a

gear shift to bring the two states back into line.

Once the TCU has determined the type of gear shift required the software accesses the shift logic, estimates the

engine torque output, adjusts the variable pressure solenoid ramp pressure then executes the shift.

The TCU continuously monitors every input and output circuit for short or open circuits and operating range. When

a failure or abnormal operation is detected the TCU records the condition code in the diagnostics memory and

implements a limp mode, The actual limp mode used depends upon the failure detected with the object to maintain

maximum driveability without damaging the transmission. In general input failures are handled by providing a default

value. Output failures, which are capable of damaging the transmission, result in full limp mode giving only third or

fourth gear and reverse. For further details of limp modes and memory retention refer to the Diagnostic Section.

The TCU is designed to operate at ambient temperatures between -40 and 85°C . It is also protected against

electrical noise and voltage spikes, however all the usual precautions should be observed, for example when arc welding or jump starting. TCU Inputs

To function correctly, the TCU requires engine speed, road speed, transmission sump temperature, throttle position

and gear position inputs to determine the variable pressure solenoid current ramp and on/off solenoid states. This

ensures the correct gear selection and shift feel for all driving conditions. The inputs required by the TCU are as follows: � Engine Speed

The engine speed signal is derived from the tachometer signal line, a dedicated sensor or a Controlled Area Network (CAN).

� Road Speed

4WD (Diesel) - The shaft speed signal is derived from the speedo sensor located on the transfer case. This signal is transmitted directly to the TCU.

4WD (Gasoline) - The speedo sensor sends the shaft speed signal to the engine control module (ECM). The

information is then transferred to the TCU via the CAN.

� Transmission Sump Temperature

The transmission sump temperature sensor is a thermistor located in the solenoid wiring loom within the transmission.

This sensor is a typical NTC resistor with low temperatures producing a high resistance and high temperatures

Page 907 of 1574

5A-48 AUTOMATIC TRANSMISSION POWER FLOW - PARK AND NEUTRAL

In Park and Neutral, there is no drive to the planetary gear set. The rear band is applied to eliminate ‘clunk’ on

engagement of the reverse gear, and to improve the low range engagement for 4WD applications. No other clutches

or bands are applied.

In Park the transmission is mechanically locked by engaging a case mounted pawl with teeth on the output shaft ring

gear. Control

To maintain this arrangement in the steady state solenoids and valves are activated as follows:

� Solenoids S1 and S2 are switched off.

� Line (pump) pressure is applied to the primary regulator valve (PRV) and to the solenoid supply valve.

� The converter, oil cooler, and lubrication circuits are charged from the primary regulator valve.

� The line 500 circuit is charged by the solenoid supply valve.

� The S5 circuit is charged by the variable pressure solenoid (S5).

� Line pressure is prevented from entering the drive circuit by the manual valve.

� The B1 circuit and all clutch circuits are open to exhaust.

Refer to figure 5.1 and table 5.2.

Table 5.2 - Engaged Elements - Park arid Neutral

Gear State

Park and Neutral C1

- C2

- C3

- C4

- B1

- B2

X 1-2

OWC - 3-4

OWC - LU

CLUTCH -

ELEMENTS ENGAGED

Page 919 of 1574

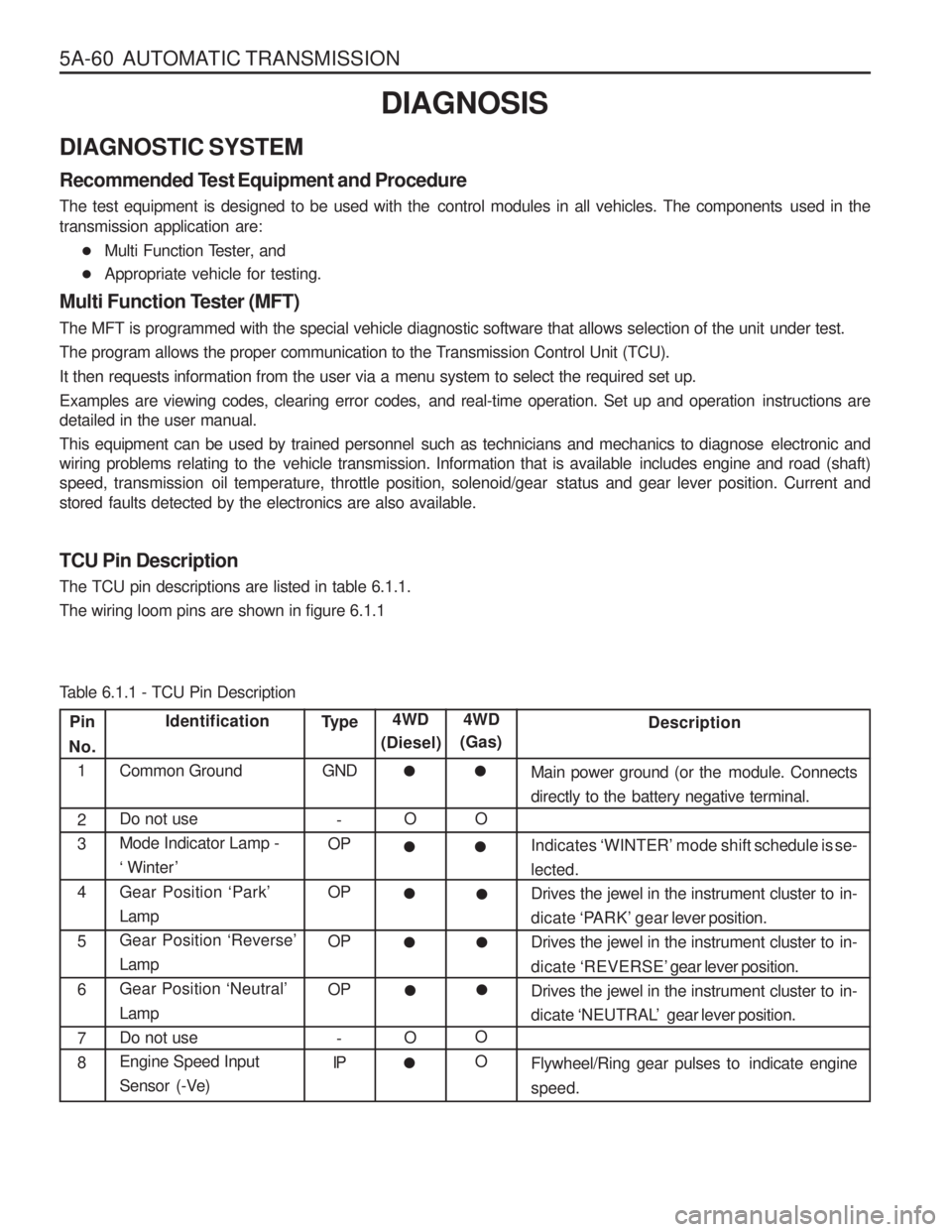

5A-60 AUTOMATIC TRANSMISSIONDIAGNOSIS

DIAGNOSTIC SYSTEM Recommended T est Equipment and Procedure

The test equipment is designed to be used with the control modules in all vehicles. The components used in the transmission application are: � Multi Function Tester, and

� Appropriate vehicle for testing.

Multi Function Tester (MFT)

The MFT is programmed with the special vehicle diagnostic software that allows selection of the unit under test.

The program allows the proper communication to the Transmission Control Unit (TCU).

It then requests information from the user via a menu system to select the required set up.

Examples are viewing codes, clearing error codes, and real-time operation. Set up and operation instructions are detailed in the user manual.

This equipment can be used by trained personnel such as technicians and mechanics to diagnose electronic and

wiring problems relating to the vehicle transmission. Information that is available includes engine and road (shaft)

speed, transmission oil temperature, throttle position, solenoid/gear status and gear lever position. Current andstored faults detected by the electronics are also available.

TCU Pin Description The TCU pin descriptions are listed in table 6.1.1. The wiring loom pins are shown in figure 6.1.1

Pin

No. 1 2 3 4 5 6 7 8Identification

Common Ground Do not use Mode Indicator Lamp -‘ Winter ’

Gear Position ‘Park ’

LampGear Position ‘Reverse ’

LampGear Position ‘Neutral ’

LampDo not useEngine Speed Input

Sensor (-Ve) Type

GND -

OP OP OP OP

-

IP Description

Main power ground (or the module. Connects

directly to the battery negative terminal. Indicates ‘WINTER ’ mode shift schedule is se-

lected.

Drives the jewel in the instrument cluster to in-dicate ‘PARK ’ gear lever position.

Drives the jewel in the instrument cluster to in- dicate ‘REVERSE ’ gear lever position.

Drives the jewel in the instrument cluster to in- dicate ‘NEUTRAL ’ gear lever position.

Flywheel/Ring gear pulses to indicate engine speed.

4WD

(Diesel)

O O

�

�

�

�

� 4WD

(Gas)

O O O

�

�

�

�

�

�

Table 6.1.1 - TCU Pin Description

Page 920 of 1574

AUTOMATIC TRANSMISSION 5A-61

Pin

No. 9 10

11

12 13 14 1516 17 1819 20 21 22 2324 25 26 27 28 29 30Identification

Mode Indicator Lamp - ‘ Power ’

Throttle Position Sensor Output as Pulse Width Modulation for TODAir Conditioner Input SignalKickdown Switch Mode Switch

Transfer Case Input (High) -4WD Lamp High Ignition Switch Do not use Gear Position ‘1’ Lamp/

Gear Position Code 1

*Gear Position ‘2’ Lamp/

Gear Position Code 2* Gear Position ‘3’ Lamp/

Gear Position Code 3* Gear Position ‘Drive ’

Lamp/ Gear Position Code 4*CAN (-ve)CAN (+ve) K-line Communication Link Engine Speed InputSensor (+ve)Road Speed Pulses Shaft Speed Sensor SignalThrottle Position Sensor -GroundThrottle Position Sensor - Reference Throttle Position Sensor -Input Signal

Transfer(or Case Input

(Low) - 4WD Lamp Low Type

OP OP

-

IP IP IP IP

-

OPOPOP OP

I/O

I/O

I/O IP

OP

IP

GND

REF IP IP Description

Indicates ‘POWER ’ mode shift schedule is se-

lected.

Provides an analogue signal of the throttle po- sition for the T orque on Demand (T OD) Con-

trol Module. Input

Switch to indicate when a kickdown is required

at high throttle position. Switch to select ‘NORMAL ’, ‘POWER ’ or ‘WIN-

TER ’ shift schedule.

Voltage varies from OV to 12V. Switch to indicate 4WD ’HIGH RANGE ’ is se-

lected.

Ignition power is used as the main power source

to drive the unit and the solenoids.

Drives jewel in the instrument cluster to indi- cate gear leverposition ’1'. Drives jewel in the instru-

ment cluster to indicate gear lever position ’2'. Drives jewel in the instru-

ment cluster to indicate gear lever position’3'.

Drives jewel in the instrument cluster to indi- cate ‘ DRIVE ’. gear lever position.

CAN low side bus communication (CANL).

CAN high side bus communication (CANH).

Diagnostic information and vehicle coding.

Flywheel/Ring gear pulses to indicate engine speed.

Road speed signals derived from shaft speedsensors.

This sensor transmit shaft speed signal to the TCU. Throttle position sensor ground. This is the 5V reference voltage supply gener-

ated by the unit for the throttle position sensor.

This sensor is a resistance potentiometer indi-

cating throttle position.

Voltage varies 0V to 5V.Switch to indicate 4WD ’LOW RANGE ’ is se-

lected.

4WD

(Diesel)

O O O O

�

�

�

4WD

(Gas)

O O O O O O OO

�

�

�

��

��

��

��

��

��

��

��

�

��

�

�

�

�

��

�

Page 921 of 1574

5A-62 AUTOMATIC TRANSMISSION

Identification

Gear Lever Position

Transmission Oil

Temperature Solenoid 4 Solenoid 1 Do not use Solenoid 5Return (-ve) Gear Lever Position - Ground

Transmission Oil

Temperature - Ground Solenoid 6 Solenoid 2 Solenoid 3 Solenoid 7 Do not use Solenoid 5 (+ve) Type

IP IP

OPOP -

IP

GND GND OPOP OP OP -

OP Description

This switch has discreet values indicating the

positions selected by the gear shift lever

(PRNDL). Voltage varies 0V to 5V.

Resistive sensor indicates transmission tem-perature .High R = low temp Low R = high temp

Voltage varies 0V to 5V.

On/Off solenoid normally open, combines with

other On/off solenoid 3 for shift quality and se-quencing.

On/off solenoid normally open, combines with

other On/off solenoid to set the selected gear.

This ensures the earth path for the VPS and

the current in this line is monitored to give feed-

back control of the VPS. PRNDL switch ground. Ground reference for temperature sensor in-

put.

On/Off solenoid normally open, sets low/high line pressure.

On/off solenoid normally open, combines with

other On/off solenoid to set the selected gear.

On/off solenoid normally open, combines with

On/off solenoid 4 for shift quality and sequenc- ing.

On/off solenoid normally open, locks up the

torque converter to Increase cruising efficiency. This is the variable force solenoid which ramps the pressure during gear changes and solenoid

switching, to enhance transmission shift quality.

4WD

(Diesel)

O O

�

� 4WD

(Gas)

O O

�

�

��

��

��

��

Pin

No. 31 32 33 34 35 36 37 38 39 40 41 42 43 44

��

��

��

��

��

��

� = circuit connected

O = circuit not connected

* = unique

OP = Output

IP = Input

I/O = Input/output

GND = Ground

REF = Reference

Notice :

Page 939 of 1574

5A-80 AUTOMATIC TRANSMISSION6. Switch off the engine and raise the vehicle on the hoist, if applicable, ensuring that the vehicle is level.

7. Three minutes after the engine has stopped, but no longer than one hour, remove the filler pump, The correct level is reached when ATF is aligned with the bottom of the filler hole. If the correct level is not reached, then add

a small quantity of ATF to the correct level.

8. Replace the transmission filler plug and clean all remnants of ATF on the transmission and vehicle.

9. Tighten the transmission filler plug to specification.

Checking, Adding Fluid and Filling - Drained or Dry Transmission

To set the correct fluid level proceed as follows. 1. Set the transmission selector to Park and switch the engine off.

2. Raise the vehicle on a hoist (or leave over a service pit).

3. Clean all dirt from around the service fill plug prior to removing the plug, Remove the oil service fill plug. Clean the fill plug and check that there is no damage to the ‘O’ ring. Install the filler pump into the filler hole.

4. Lower the vehicle with the filler pump still connected and partially fill the transmission. This typically requires approximately :

a. If the transmission torque converter is empty:

9.0 litres - 4WD9.0 litres - RWD

b. If the transmission torque converter is full: 4.5 litres - 4WD4.5 litres - RWD

5. Start the vehicle in Park with the Parking brake and foot brake applied with the engine idling, cycle the transmission gear selector through all positions, adding ATF until gear application is felt.

6. Then add an additional 0.5 litres of ATF.

7. Switch off the engine and raise the vehicle on the hoist. Remove the filler pump and replace the filler plug. The plug shall be tightened to specification.

8. The vehicle is then to be driven between 3.5 and 4.5 kilometers at light throttle so that the engine does not exceed 2500 rpm. This should result in the transmission temperature being in the range 50 to 60 °C.

9. With the engine idling, cycle the transmission selector through all gear positions with the brake applied.

10. Stop the engine. Raise the vehicle on the hoist, if applicable ensuring the vehicle is level.

11. Three minutes after the engine has stopped, but no longer than one hour, remove the filler plug. The correct level is reached when ATF is aligned with the bottom of the filler hole. If the correct level is not reached, then add

a small quantity of ATP to the correct level.

12. Replace the transmission filler plug and clean all remnants of ATF on the transmission and vehicle. Tighten the transmission Filler plug to specification.

ELECTRONIC ADJUSTMENTS Idle Speed Adjustment

Carry out the adjustments to the idle speed as detailed in the workshop manual.

Throttle Position Calibration

Should the throttle position data stored in the TCU be lost or be out of specification, as indicated by a diagnostic

trouble message, it may be re-established by the following procedure. � Check that the hot engine idle speed is within specification.

� Allow the engine to idle in ‘Drive ’ for 60 seconds with the air conditioner (if fitted) turned off. The closed throttle

reference point in the TCU has now been set.

Switch the engine off but leave the ignition on. Hold the accelerator pedal on the floor for 60 seconds. The wide open

throttle reference point in the TCU has now been set.