Brake switch SSANGYONG MUSSO 2003 Service Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2003, Model line: MUSSO, Model: SSANGYONG MUSSO 2003Pages: 1574, PDF Size: 26.41 MB

Page 570 of 1574

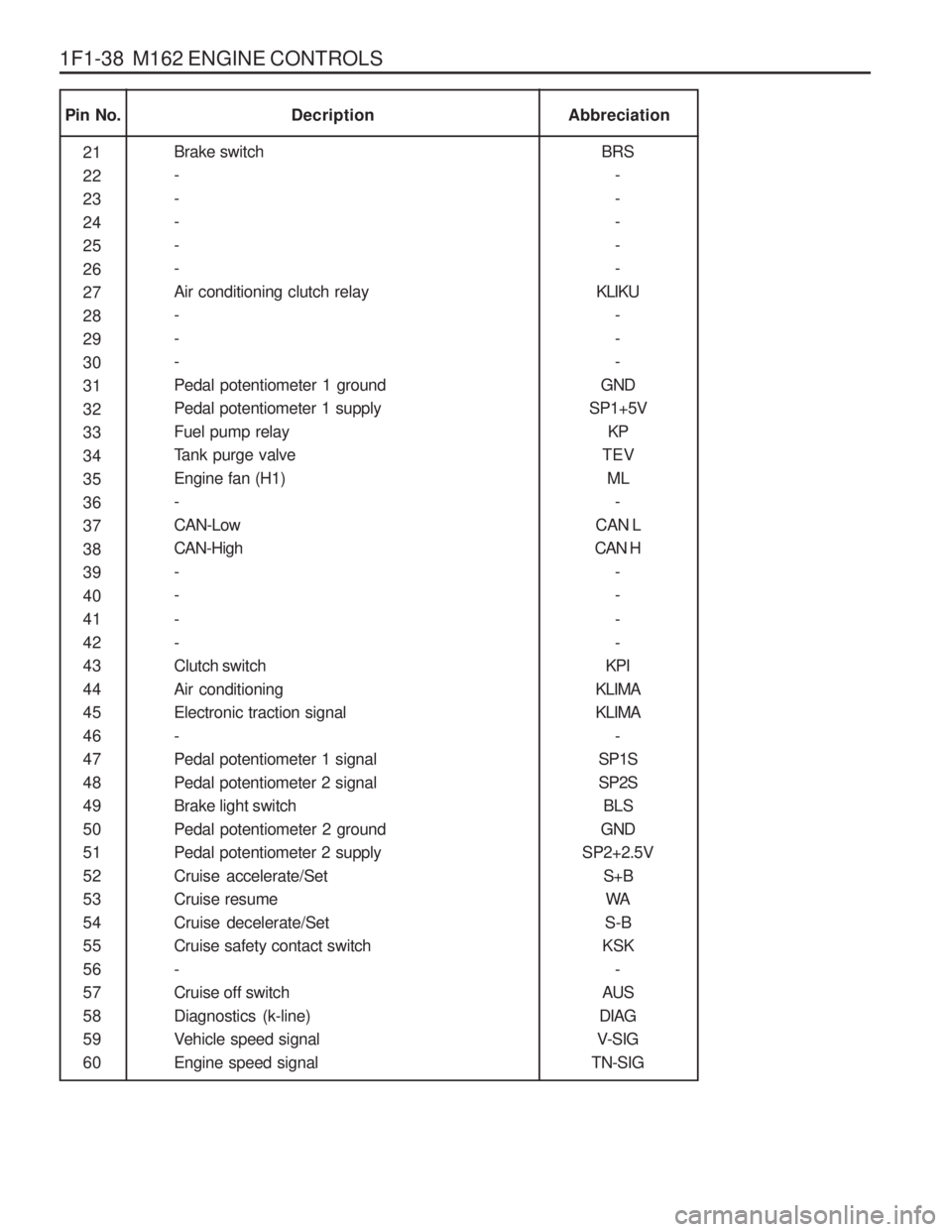

1F1-38 M162 ENGINE CONTROLS

Pin No.Abbreciation

Decription

21 222324252627282930313233343536373839404142434445464748495051525354555657585960 BRS

-----

KLIKU ---

GND

SP1+5V KP

TEV ML -

CAN L

CAN H -- - -

KPI

KLIMAKLIMA -

SP1SSP2S BLS

GND

SP2+2.5V S+BWA

S-B

KSK -

AUS

DIAG

V-SIG

TN-SIG

Brake switch-----Air conditioning clutch relay---Pedal potentiometer 1 groundPedal potentiometer 1 supplyFuel pump relay

Tank purge valveEngine fan (H1)-CAN-LowCAN-High-- - -Clutch switchAir conditioningElectronic traction signal-Pedal potentiometer 1 signalPedal potentiometer 2 signalBrake light switchPedal potentiometer 2 groundPedal potentiometer 2 supplyCruise accelerate/SetCruise resumeCruise decelerate/SetCruise safety contact switch-Cruise off switchDiagnostics (k-line)

Vehicle speed signalEngine speed signal

Page 573 of 1574

M162 ENGINE CONTROLS 1F1-41

Application

Pin No.Description

- Starter motor TM.50- - Electronic ground--- Lambda probe 1 heating Power ground TM.31

V-BATTERY TM.87

V-BATTERY TM.30Immobilizer crypto read Immobilizer crypto write -Lambda probe 1 groundLambda probe 1 signal- - -Brake switch-- - --Air conditioning clutch relay- - -1 23 4 5678 9

10 11

12 13 14 15161718 19 20212223 24 25262728 29 30-

TM.50 - -

GND - --

LSH1

TM.31TM.87TM.30

WFS I/O WFS O

-

GND LS1 - - -

BRS -- - --

KLIKU - - - -

� --

� -- -

�

�

�

�

�

� -

�

� - - -

� -- - --

� - - - -

� - -

� - --

�

�

�

�

�

�

-

�

� - - -

� -- - --

� - - -

� : Standard, �: Option Remarks

Abbreviation E32 ENG,

5speed M/T

E32 ENG,

4speed A/T (BTRA)

Page 574 of 1574

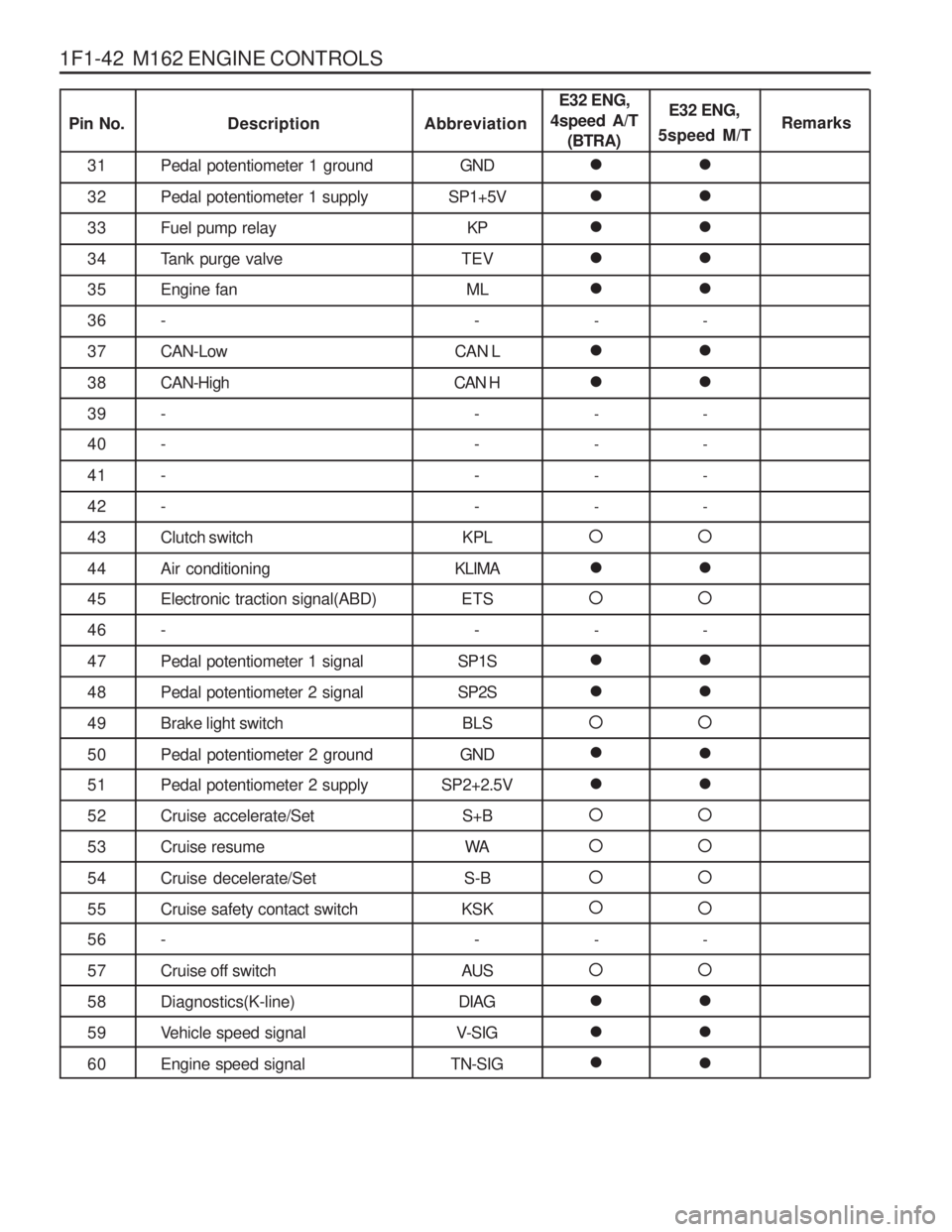

1F1-42 M162 ENGINE CONTROLS

Pin No.Description

Pedal potentiometer 1 ground Pedal potentiometer 1 supplyFuel pump relay

Tank purge valve Engine fan -CAN-LowCAN-High - - --Clutch switchAir conditioning Electronic traction signal(ABD) -Pedal potentiometer 1 signalPedal potentiometer 2 signalBrake light switchPedal potentiometer 2 ground Pedal potentiometer 2 supply Cruise accelerate/SetCruise resumeCruise decelerate/SetCruise safety contact switch - Cruise off switchDiagnostics(K-line)

Vehicle speed signalEngine speed signal31 323334 35 363738 39 40 41424344 45 4647484950 51 52535455 56 57585960GND

SP1+5V KP

TEV ML

-

CAN L

CAN H

- - --

KPL

KLIMA ETS

-

SP1SSP2S BLS

GND

SP2+2.5V

S+BWA

S-B

KSK -

AUS

DIAG

V-SIG

TN-SIG �

�

�

�

�

-

�

� - - --

� �

�

-

�

�

� �

�

�

�

�

� -

� �

�

� �

�

�

�

�

-

�

� - - --

� �

�

-

�

�

� �

�

�

�

�

� -

� �

�

� Remarks

Abbreviation E32 ENG,

5speed M/T

E32 ENG,

4speed A/T (BTRA)

Page 703 of 1574

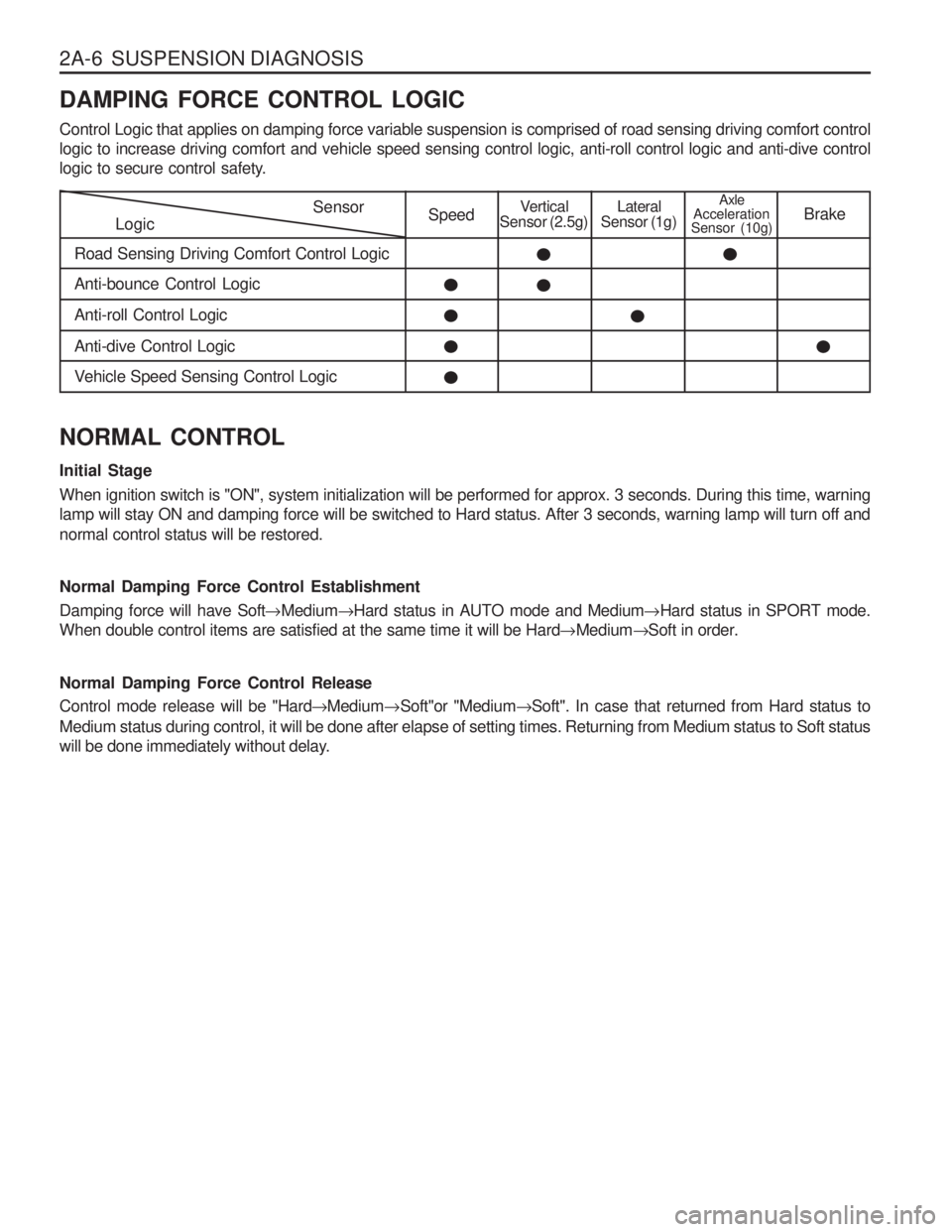

2A-6 SUSPENSION DIAGNOSIS DAMPING FORCE CONTROL LOGIC Control Logic that applies on damping force variable suspension is comprised of road sensing driving comfort control logic to increase driving comfort and vehicle speed sensing control logic, anti-roll control logic and anti-dive control

logic to secure control safety.

LogicSensor

Road Sensing Driving Comfort Control LogicSpeedVertical

Sensor (2.5g)Lateral

Sensor (1g)Axle

Acceleration

Sensor (10g) Brake

Anti-bounce Control Logic Anti-roll Control LogicAnti-dive Control Logic

Vehicle Speed Sensing Control Logic

NORMAL CONTROL Initial Stage When ignition switch is "ON", system initialization will be performed for approx. 3 seconds. During this time, warning lamp will stay ON and damping force will be switched to Hard status. After 3 seconds, warning lamp will turn off and normal control status will be restored. Normal Damping Force Control Establishment Damping force will have Soft �Medium �Hard status in AUTO mode and Medium �Hard status in SPORT mode.

When double control items are satisfied at the same time it will be Hard �Medium �Soft in order.

Normal Damping Force Control Release Control mode release will be "Hard �Medium �Soft"or "Medium �Soft". In case that returned from Hard status to

Medium status during control, it will be done after elapse of setting times. Returning from Medium status to Soft status

will be done immediately without delay.

Page 708 of 1574

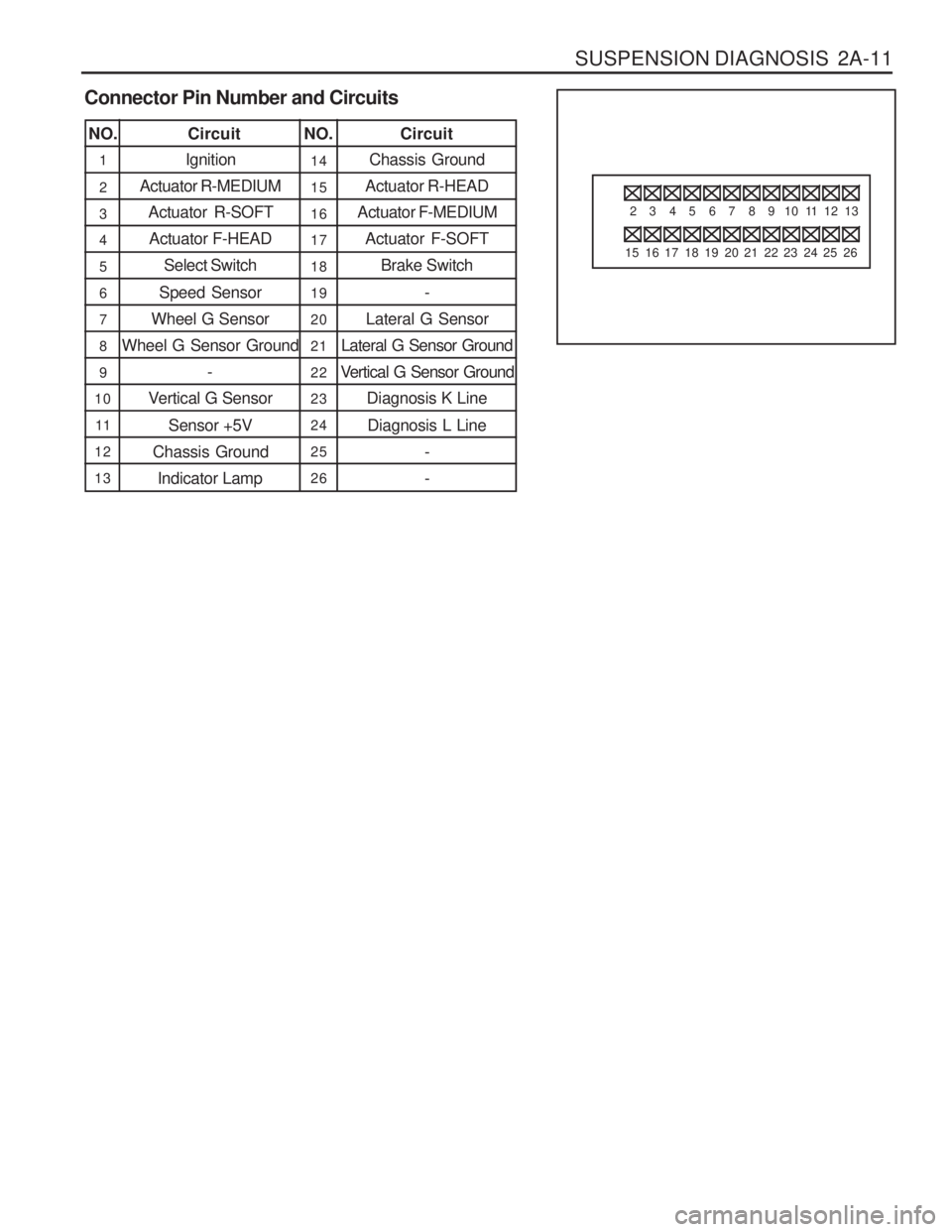

SUSPENSION DIAGNOSIS 2A-11

Connector Pin Number and Circuits

2

15

3

16

4

17

5

18

6

19

7

20

8

21

9

22

10

23

11

24

12

25

13

26

Ignition

Actuator R-MEDIUM Actuator R-SOFT

Actuator F-HEAD Select Switch

Speed Sensor

Wheel G Sensor

Wheel G Sensor Ground

-

Vertical G Sensor

Sensor +5V

Chassis Ground Indicator Lamp

NO. CircuitNO. Circuit

1 14

21 5

316

417

518

619

720

821

922

10 23

11 2 4

12 25

13 26 Chassis Ground

Actuator R-HEAD

Actuator F-MEDIUM

Actuator F-SOFT Brake Switch

-

Lateral G Sensor

Lateral G Sensor Ground

Vertical G Sensor Ground Diagnosis K Line

Diagnosis L Line - -

Page 714 of 1574

2B-4 WHEEL ALIGNMENT1. Perform wheel alignment preliminary inspection.

2. Check the brakes for dragging.

3. Road test the vehicle.Does the vehicle lead/pull?

1. Cross switch the front tire and wheel assemblies. 2. Road test the vehicle. Does the vehicle lead/pull? 1. Check the front wheel alignment. Is the alignment within specifications?

1. Compare the front camber and front caster to specifications.Are they within specifications?

1. Check the vehicle frame. Is the frame bent?

1. Straighten the frame. Is the repair complete?

1. The probable cause is the tires.

2. Switch the left front tire and wheel assembly with

the left rear tire and wheel assembly.

3. Road test the vehicle. Does the vehicle still lead/pull?

1. Switch the left front tire and wheel assembly with the left rear tire and wheel assembly and replace theleft front tire. Does the repair complete?

1. Switch the right front tire and wheel assembly with

the right rear tire and wheel assembly.

2. Road test the vehicle. Does the vehicle still lead/pull?

1. Switch the right front tire and wheel assembly with the right rear tire and wheel assembly and replace the right front tire. Is the repair complete? Action

Radial Tire Lead/Pull Diagnosis Chart

Step

1Values(s)

- Ye s

Go to Step 2

Go to Step 3

Go to Step 4

Go to Step 7

Go to Step 6

Go to Step 3

Go to Step 9

System OK

Go to Step 1

System OK No

System OK System OK Adjust

alignment

Go to Step 5

Go to Step 1

-

Go to Step 8

Go to Step 1

Go to Step 10

Go to Step 1

2 345 6 7 8 9

10 - - - - - - - - -

Page 806 of 1574

HYDRAULIC BRAKES 4A-9

BRAKE PEDAL1 Clevis Pin

2 Brake Pedal

3 Stop Lamp Switch

4 Pad

5 Nut ....................................................... 21-35 Nm

6 Yoke Pin

7 Fulcrum Pin

8 Return Spring

9 Pedal Mounting Bracket

10 Washer 11 Nut ....................................................... 16-32 Nm

12 Bolt ........................................................ 8-18 Nm

13 Stopper Bolt .............................................. Adjust

14 Rubber Pad ........................................... Replace

Page 807 of 1574

4A-10 HYDRAULIC BRAKES

Removal & Installation Procedure

1. Remove the stop lamp switch connector.

2. Remove the clevis pin and disconnect the brake boosterpush rod. Notice

� Install in the upper hole (1), in case of Mando brake and

in the below hole (2), incase of PBR brake.

� Install the snap pin fully in the hole of clevis pin.

� Apply the grease around the hole of clevis pin.

3. Loosen the nut (4EA) and bolt (2EA) and remove the brake pedal.

4. Installation should follow the removal procedure in reverse order.

Tightening Torque 8 - 18 Nm

Page 808 of 1574

HYDRAULIC BRAKES 4A-11

Adjustment Procedure

1. Pedal HeightNotice If pedal height is not in specified value, loosen the stop lamp nut (B) and adjust the pedal height.

2. Pedal Stroke

Height (A) 150 mm (From the carpet)

Notice If pedal stroke is not in specified value, loosen the stop bolt and lock nut (F) and adjust the pedal stroke.

3. Free Play

Stroke (C) Mando : 138 mm

PBR : 132mm

Notice

To adjust, depress the brake pedal several times until there is no more vacuum left in the vacuum line.

To adjust, loosen the lock nut (D) of the push rod and turn the rod.

Free Play (E) 1 - 4 mm

Inspection Procedure

1. Inspect the wear of bushing.

2. Inspect the warp and bend of brake pedal.

3. Inspect the return spring of brake pedal.

4. Inspect the conductivity when connecting the tester to the stop lamp switch connector.

Page 836 of 1574

ANTILOCK BRAKE SYSTEM 4F-7

ABD SYSTEM DESCRIPTION

General: The Automatic Brake Differential Lock (ABD) is a traction system by means of brake intervention only, available in a low speed range (< 60kph). It workes on µ-split roads with sidewise different friction coefficients.

The spinning driven wheel is braked and the drive torque can be transferred to the wheel on the high- µ side.

During ABD active, the ABD information lamp is blinking.The temperature of the brakes is calculated by a mathematical model and ABD is switched passive if the calculated temperature is greater than a threshold value(500 °C).

ABD is permitted again, when the calculated temperature is less than 350 °C.

Control Algorithm: The input signals for the control algorithm are the filteredwheel speed signals from the ABS speed processing. With the speed difference of the driven wheels, the control deviation is calculated. If the control deviation exceeds a certain threshold value,

the wheel with the greater slip is braked actively. The threshold value depends on the vehicle speed:It is reduced with increasing vehicle speed down to a constant value.

Pressure Modulation: Depending on the control deviation and the wheel acceleration of the spinning wheel, pressure increase, hold and decrease are made.

The pressure modulation is done with the conventional control with the valves. ASV, USV, EV and AV according the the following table:

Speed Range: ABD is available in the speed range � 60 kph.

Above 60 kph vehicle speed, ABD is passive. It is possible to initiate ABD operation up to a vehicle speed of 55kph.

Increase Open

Open

Open

ASV Decrease

Hold

Closed

Closed

Closed

Closed

Closed

Open

Open

Closed

Closed

USV

EVAV

Speed difference driven wheels [kph]

18

6 12 60ABD operation

Vehicle speed[kph]