instrument panel SSANGYONG MUSSO 2003 Service Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2003, Model line: MUSSO, Model: SSANGYONG MUSSO 2003Pages: 1574, PDF Size: 26.41 MB

Page 568 of 1574

1F1-36 M162 ENGINE CONTROLS

Location Engine ECU is located at the inside of cowl side trim in right bottom of instrument panel of passenger side. Removal & Installation Procedure

1. Turn the ignition switch to "OFF" position.

2. Disconnect the battery negative cable

3. Remove the cowl side trim form passenger side.

4. Unscrew four securing nuts for ECU from mounting bracket.Installation Notice

5. Pulling out the ECU from bracket.

6. Disconnect the vehicle side coupling(B).

7. Installation should follow the removal procedure in the reverse order.

Tightening Torque 9 - 11 Nm

Page 883 of 1574

5A-24 AUTOMATIC TRANSMISSION

Transmission Control Unit(TCU)

The TCU is an in-vehicle micro-processor based transmission management system. It is usually mounted in the

vehicle cabin, under the instrument panel, under the seat, behind the side kick panels or under the floor in the

footwell on the passenger side. Different control units are supplied for different vehicle applications.The TCU contains:

� Processing logic circuits which include a central microcontroller and a back-up memory system.

� Input circuits.

� Output circuits which control external devices such as the variable pressure solenoid (VPS), on/off solenoid

drivers, a diagnostics output and the driving mode indicator light.

The various items which make up the TCU are discussed below.

Processing Logic

Shift schedule and calibration information is stored in an erasable programmable read only memory (EEPROM).

Throttle input calibration constants and the diagnostics information are stored in electrically erasable programmable

read only memory (EEPROM) that retains the memory even when power to the TCU is disconnected. In operation the software continuously monitors the input values and uses these, via the shift schedule, to determine the required gear state, At the same time it monitors, via the solenoid outputs, the current gear state. Whenever the

input conditions change such that the required gear state is different to the current gear state, the TCU initiates a

gear shift to bring the two states back into line.

Once the TCU has determined the type of gear shift required the software accesses the shift logic, estimates the

engine torque output, adjusts the variable pressure solenoid ramp pressure then executes the shift.

The TCU continuously monitors every input and output circuit for short or open circuits and operating range. When

a failure or abnormal operation is detected the TCU records the condition code in the diagnostics memory and

implements a limp mode, The actual limp mode used depends upon the failure detected with the object to maintain

maximum driveability without damaging the transmission. In general input failures are handled by providing a default

value. Output failures, which are capable of damaging the transmission, result in full limp mode giving only third or

fourth gear and reverse. For further details of limp modes and memory retention refer to the Diagnostic Section.

The TCU is designed to operate at ambient temperatures between -40 and 85°C . It is also protected against

electrical noise and voltage spikes, however all the usual precautions should be observed, for example when arc welding or jump starting. TCU Inputs

To function correctly, the TCU requires engine speed, road speed, transmission sump temperature, throttle position

and gear position inputs to determine the variable pressure solenoid current ramp and on/off solenoid states. This

ensures the correct gear selection and shift feel for all driving conditions. The inputs required by the TCU are as follows: � Engine Speed

The engine speed signal is derived from the tachometer signal line, a dedicated sensor or a Controlled Area Network (CAN).

� Road Speed

4WD (Diesel) - The shaft speed signal is derived from the speedo sensor located on the transfer case. This signal is transmitted directly to the TCU.

4WD (Gasoline) - The speedo sensor sends the shaft speed signal to the engine control module (ECM). The

information is then transferred to the TCU via the CAN.

� Transmission Sump Temperature

The transmission sump temperature sensor is a thermistor located in the solenoid wiring loom within the transmission.

This sensor is a typical NTC resistor with low temperatures producing a high resistance and high temperatures

Page 1097 of 1574

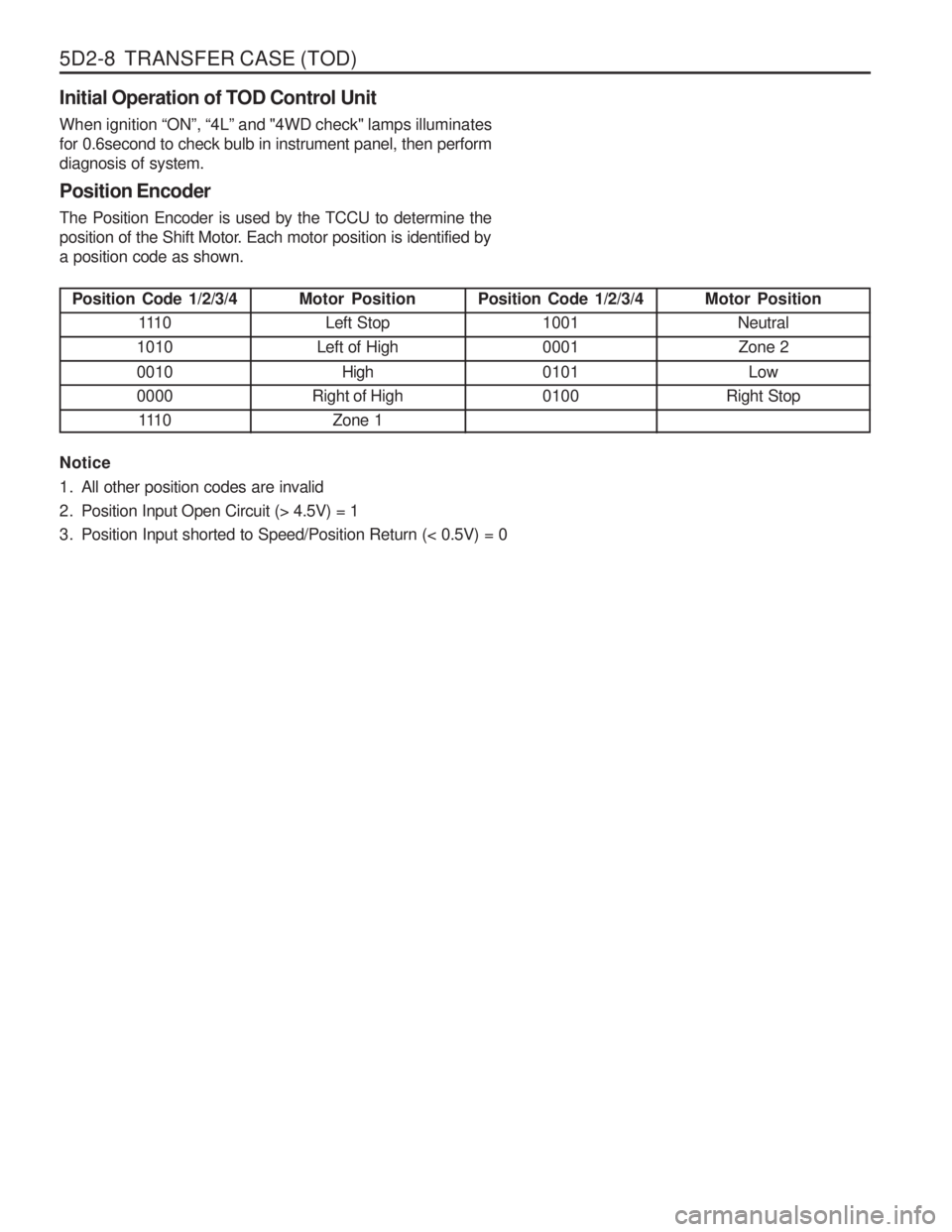

5D2-8 TRANSFER CASE (TOD)Position Code 1/2/3/4 111 0

1010 0010 0000 111 0

Initial Operation of TOD Control Unit When ignition

“ON ”, “4L ” and "4WD check" lamps illuminates

for 0.6second to check bulb in instrument panel, then perform diagnosis of system. Position Encoder The Position Encoder is used by the TCCU to determine the

position of the Shift Motor. Each motor position is identified bya position code as shown. Notice

1. All other position codes are invalid

2. Position Input Open Circuit (> 4.5V) = 1

3. Position Input shorted to Speed/Position Return (< 0.5V) = 0

Motor Position

Left Stop

Left of High

High

Right of High Zone 1 Position Code 1/2/3/4

1001 0001 0101 0100 Motor Position

NeutralZone 2

Low

Right Stop

Page 1171 of 1574

FATC-HAVC 7D-15

TROUBLESHOOTING Check and Service Incar sensor is a sensor that detects interior air temperature and a thermistor that decreases its resistance when temperature up and increases when temperature down.

1. Check that there are incar sensor fault code (11,12) by using self-diagnosis function.

2. Disconnect incar sensor 2-pin connector that installed on

inner lower instrument panel cover of driver ’s side and

remove the sensor.

3. Check that measured resistance value among incar sensor terminals is as shown in the right side graph. Notice Measure resistance value by soaking the sensor in the ice water and check changes in resistance values after soaking

it in the very hot water.

4. If resistance value is out of specification, replace the incar sensor.

5. Install the sensor and turn the ignition switch to ON position and check that voltage between No. 12A terminal of incar

sensor and body (-) is 5V.

6. Check current between the No. 12B and 12A connector terminals of the incar sensor and the No. 1 and 5 connector terminals of the airconditioner control unit and repair the wire if defective.

Page 1173 of 1574

FATC-HAVC 7D-17

7b7a

Water sensor connector

3

�

0.5RB

Airconditioner control unit connector

V

5

�

0.5BL

Water Sensor

Water sensor is a thermistor that detects engine coolant temperature to operate the blower speed to LO when water temperature is less than 50.

1. Check that there are water sensor fault code (15,16) by

using self-diagnosis function.

3. Check that measured resistance value among water sensor terminals is as shown in the right side graph. Notice Measure resistance value by soaking the sensor in the ice water and check changes in resistance values after soaking

it in the very hot water.

4. If resistance value is out of specification, replace the water sensor.

5. Install the sensor and turn the ignition switch to ON position and check that voltage between No. 7a terminal of the water

sensor and body (-) is 5V.

6. Check current between the No. 7a and 7b connector terminals of the water sensor and the No. 3 and 5 connector terminals of the airconditioner control unit and repair the wire if defective.

2. Disconnect water sensor 2-pin connector that installed on

the heater unit of inner instrument panel and remove the

water sensor.

Page 1176 of 1574

7D-20 FATC-HAVC Fault : air flow does not change toward panel side.

8H

Remove the center panel of the instrument panel.

Measure voltage between 8I terminal positive pole (+) and body (-).

Measured voltage is 12V.Check No. 24 fuse (15A) in the fuse box.

Turn the ignition switch OFF and disconnect harness of

the mode actuator.

Ye sNo

Disconnect 8-pin connector of the mode actuator and turn the ignition switch to ON position.

Check that it operates toward each directions when

ground is connected to terminal (8J, 8H, 8F, 8D, 8B) of

the mode actuator alternatively.

Mode actuator

connector

Mode actuator is normal.

Ye s

Repair and replace the mode actuator.

No

Check the intake actuator linkage and door

for proper operation and repair if necessary.Disconnect 20-pin connector from the airconditioner control unit.

Check current between the mode actuator (8J, 8H, 8F,

8D, 8B) and the airconditioner control unit (11, 12, 13,14, 15).

Is there current?

Ye s

Repair open wire between the mode actuator and the control unit.

No

Replace the good control unit and re-check. If no fault, replace the control panel.

14 15

+

-

8

IWiring side connector

8I

8J 8H 8F 8D 8B 8A

Mode actuator connector Control unit connector

12 13

11

8B 8D 8F 8J