trailer SSANGYONG MUSSO 2003 Service Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2003, Model line: MUSSO, Model: SSANGYONG MUSSO 2003Pages: 1574, PDF Size: 26.41 MB

Page 9 of 1574

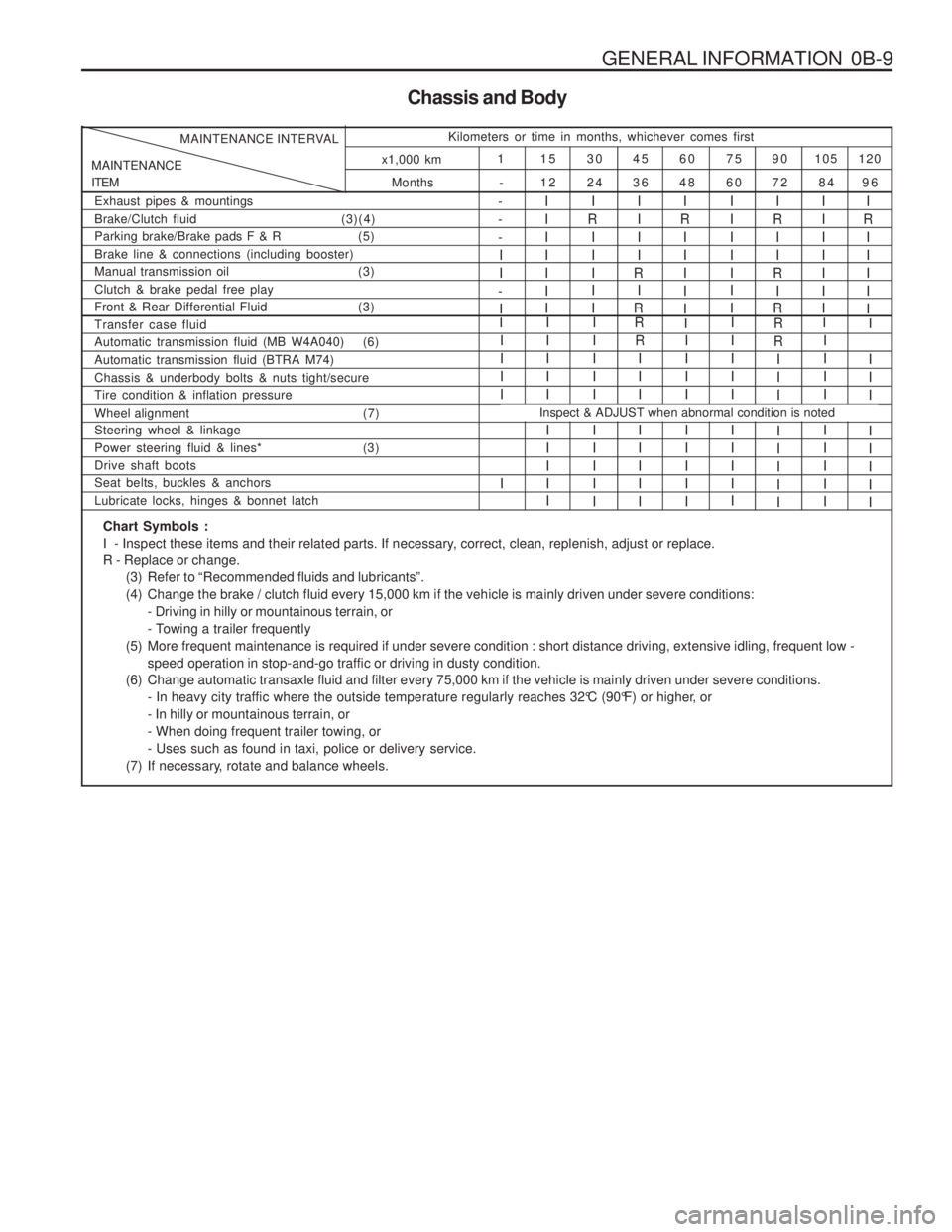

GENERAL INFORMATION 0B-9

Chassis and Body

Months

MAINTENANCE ITEM MAINTENANCE INTERVAL

Kilometers or time in months, whichever comes first

120

105

90

75

60

45

30

15

1

96

84

72

60

48

36

24

12

-

x1,000 km

Exhaust pipes & mountings Brake/Clutch fluid

(3)(4)

Parking brake/Brake pads F & R (5)Brake line & connections (including booster)

Manual transmission oil (3) Clutch & brake pedal free play

Front & Rear Differential Fluid (3)I

R

IIIII- --II

-

I IIIIII I

I

R I II I I IIII

R I

R IIIII I II

R

II

R I

R IIIIII II

R I IIII

Automatic transmission fluid (MB W4A040) (6) Automatic transmission fluid (BTRA M74)Chassis & underbody bolts & nuts tight/secure Tire condition & inflation pressure

Wheel alignment (7) Steering wheel & linkage

Power steering fluid & lines* (3)Drive shaft boots Seat belts, buckles & anchors Lubricate locks, hinges & bonnet latchIIII I I IIII I III I I IIII I IIII

R

III I IIII IIII I IIIIIIIII I III I

R R

III I IIII IIII I IIII

Transfer case fluidRII

I

Inspect & ADJUST when abnormal condition is noted

I

I II I IIII

Chart Symbols :

I - Inspect these items and their related parts. If necessary, correct, clean, replenish, adjust or replace.R - Replace or change.

(3) Refer to “Recommended fluids and lubricants”.

(4) Change the brake / clutch fluid every 15,000 km if the vehicle is mainly driven under severe conditions:- Driving in hilly or mountainous terrain, or

- Towing a trailer frequently

(5) More frequent maintenance is required if under severe condition : short distance driving, extensive idling, frequent low - speed operation in stop-and-go traffic or driving in dusty condition.

(6) Change automatic transaxle fluid and filter every 75,000 km if the vehicle is mainly driven under severe conditions. - In heavy city traffic where the outside temperature regularly reaches 32°C (90°F) or higher, or- In hilly or mountainous terrain, or- When doing frequent trailer towing, or- Uses such as found in taxi, police or delivery service.

(7) If necessary, rotate and balance wheels.

Page 11 of 1574

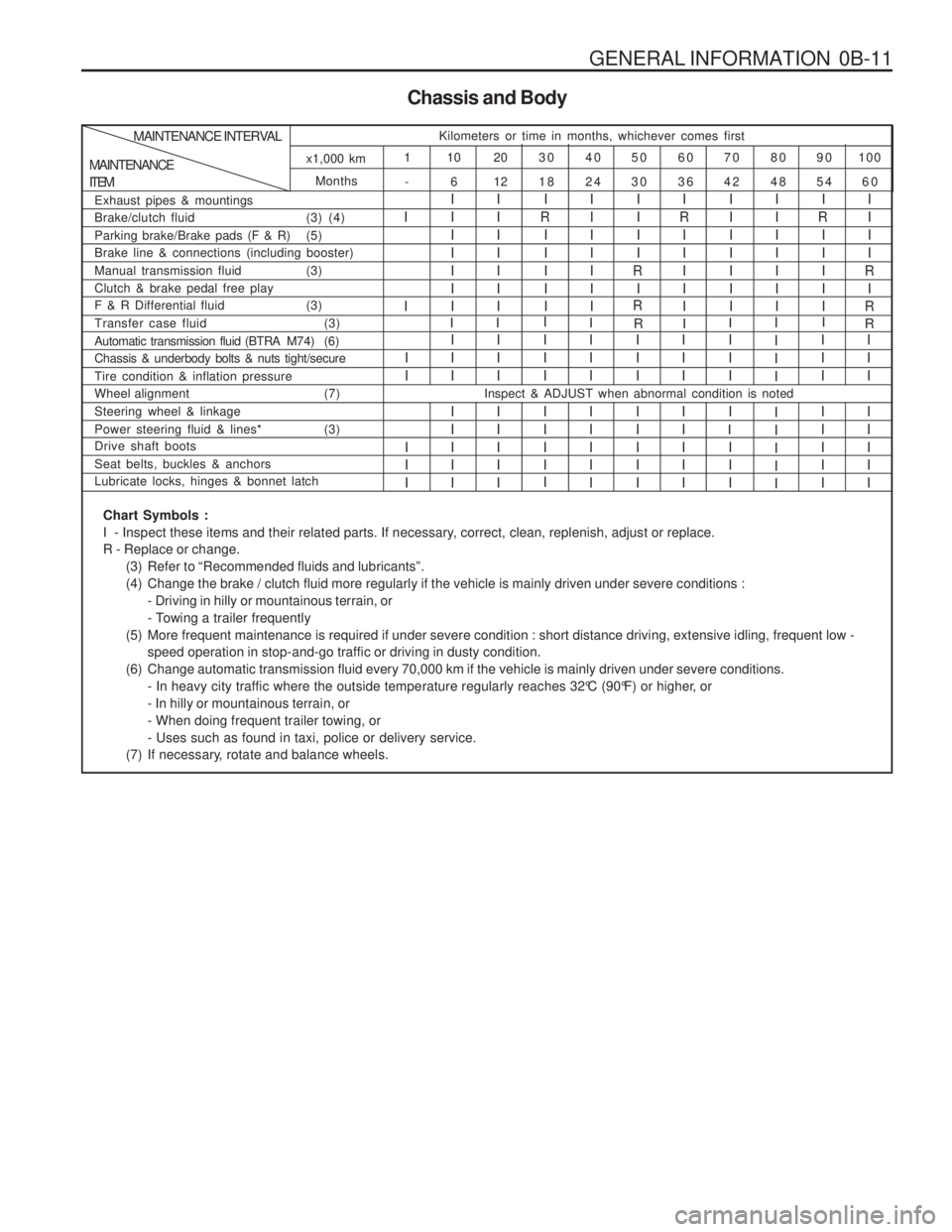

GENERAL INFORMATION 0B-11

Chassis and Body

Months -

MAINTENANCE ITEMMAINTENANCE INTERVAL

Kilometers or time in months, whichever comes first

100

90

80

70

60

50

40

30

20

10

1

60

54

48

42

36

30

24

18

12

6

x1,000 km

Exhaust pipes & mountings

Brake/clutch fluid (3) (4)

Parking brake/Brake pads (F & R) (5) Brake line & connections (including booster)

Manual transmission fluid (3)Clutch & brake pedal free play

F & R Differential fluid (3)

I I I IIIIIIIIIIIII I

R

IIIII IIIIIII IIII

R I

R I

R

IIIII IIIIIIIIIIIIII I

R

IIIII IIII

R I

R

Automatic transmission fluid (BTRA M74) (6) Chassis & underbody bolts & nuts tight/secure Tire condition & inflation pressure

Wheel alignment (7) Steering wheel & linkage

Power steering fluid & lines* (3) Drive shaft boots Seat belts, buckles & anchors Lubricate locks, hinges & bonnet latchI II I IIII III I IIII IIII I III I

I II I IIII III I IIIIIII I IIII III II II III I IIIIIII I IIII

Transfer case fluid (3)

RI R

I

I

I

I I I II IIII I IIII

Inspect & ADJUST when abnormal condition is noted

II I

Chart Symbols :

I - Inspect these items and their related parts. If necessary, correct, clean, replenish, adjust or replace.R - Replace or change.

(3) Refer to “Recommended fluids and lubricants”.

(4) Change the brake / clutch fluid more regularly if the vehicle is mainly driven under severe conditions :- Driving in hilly or mountainous terrain, or

- Towing a trailer frequently

(5) More frequent maintenance is required if under severe condition : short distance driving, extensive idling, frequent low - speed operation in stop-and-go traffic or driving in dusty condition.

(6) Change automatic transmission fluid every 70,000 km if the vehicle is mainly driven under severe conditions. - In heavy city traffic where the outside temperature regularly reaches 32°C (90°F) or higher, or- In hilly or mountainous terrain, or- When doing frequent trailer towing, or- Uses such as found in taxi, police or delivery service.

(7) If necessary, rotate and balance wheels.

Page 1215 of 1574

BODY WIRING SYSTEM 9A-13

FLOOR1 ECS Main Wiring Connector ........................ ECS

2 Main Wiring Connector

3 Main Wiring Connector

4 Main Wiring Connector

5 ABD Main Wiring Connector ........................ ABD

6 LH Front Door Switch

7 LH Tension Reducer

8 Ground 1

9 LH Rear Door Wiring Connector

10 Wheel Speed Sensor (RL) ..................ABD, ABS

11 Damper (RL) ................................................ ECS

12 LH Rear Door Switch

13 LH Rear Speaker

14 Ground 2

15 Power Socket

16 Power Antenna

17 Diode

18 LH Rear Combination Lamp

19 Tail Gate Wiring Connector

20 Tail Gate Wiring Connector 21 Tail Gate Wiring Connector

22 Rear Heated

23 Luggage Lamp

2 4 ABD ECU

..................................................... ABD

25 Ground 4 ..................................................... ABD

26 ECS ............................................................. ECS

27 Wheel Speed Sensor (RR) .................ABD, ABS

28 Damper (RR) ............................................... ECS

29 RH Rear Door Switch

30 RH Rear Speaker

31 Ground 3

32 RH Rear Combination Lamp

33 Trailer Connector

34 Rear Washer Motor

35 RH Tension Reducer

36 RH Front Door Switch

37 RH Rear Door Wiring Connector

38 RH Front Door Wiring Connector

39 Wheel Speed Sensor (RR) .................ABD, ABS

40 Acceleration Sensor ..................................... ABD

Page 1374 of 1574

5-6 ELECTRICAL WIRING DIAGRAMS

39. SEAT WARMER CIRCUIT ........................................................................................................ 5-182

40. AUDIO CIRCUIT ............................................................................................................... ........ 5-184

41. ABS 5.3 CIRCUIT ............................................................................................................. ........ 5-186

42. ABD 5.3 CIRCUIT ............................................................................................................. ........ 5-188

1) POWER SUPPLY, GROUND, WHEEL SPEED SENSOR CIRCUIT ................................................................. 5-188

2) MODULATOR CIRCUIT ......................................................................................................................................... 5-190

43. AIR BAG CIRCUIT ............................................................................................................. ...... 5-192

44. IMMOBILIZER(DIESEL-CRYPTO TYPE) CIRCUIT.................................................................. 5-194

45. IMMOBILIZER(GASOLINE HFM-ROLLING CODE TYPE) CIRCUIT ..................................... 5-196

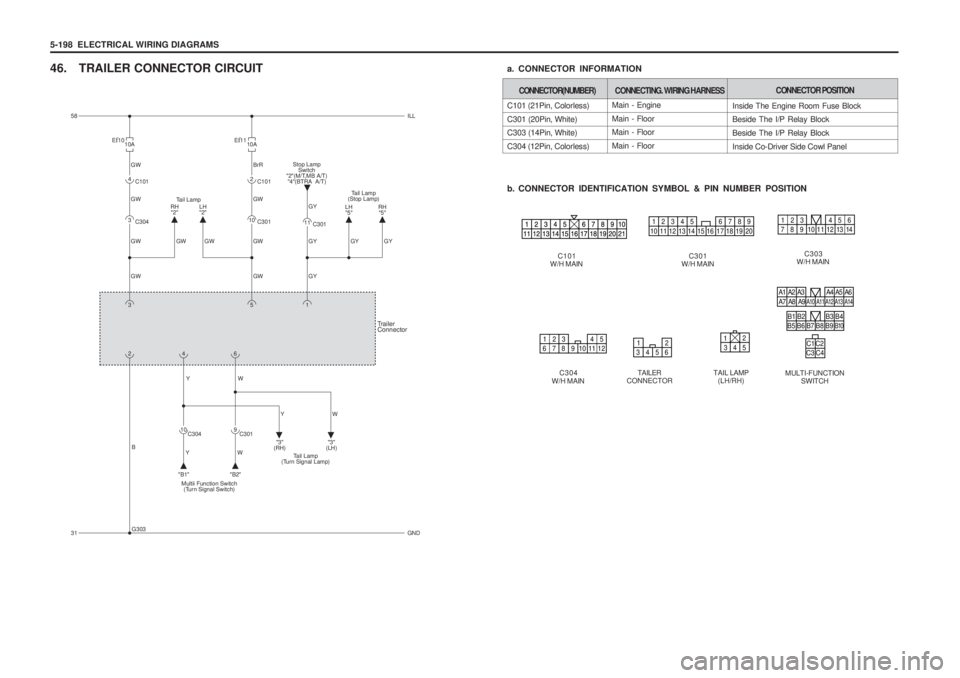

46.TRAILER CONNECTOR CIRCUIT ........................................................................................... 5-198

Page 1573 of 1574

5-198 ELECTRICAL WIRING DIAGRAMS

46. TRAILER CONNECTOR CIRCUITb. CONNECTOR IDENTIFICATION SYMBOL & PIN NUMBER POSITION

a. CONNECTOR INFORMATION

C101

W/H MAIN C301

W/H MAIN C303

W/H MAIN

C304

W/H MAIN TAILER

CONNECTOR TAIL LAMP

(LH/RH)

MULTI-FUNCTION SWITCH

12345 6789

10 11 12 13 14 15 16 17 18 19 2012 45

78 3

9 101112 13 6

14

23 4

7

1

6891011 5

1212

34561

345 2C1

C2

C3 C4

B1 B2 B3 B4

B5 B6 B7 B8 B9B10

A1 A2 A3 A4 A5 A6

A7 A8 A9A10 A11 A12 A13 A14

Main - Engine Main - Floor Main - Floor Main - Floor

C101 (21Pin, Colorless)C301 (20Pin, White) C303 (14Pin, White) C304 (12Pin, Colorless)

CONNECTOR(NUMBER)

CONNECTING. WIRING HARNESSCONNECTOR POSITION

Inside The Engine Room Fuse Block Beside The I/P Relay Block Beside The I/P Relay BlockInside Co-Driver Side Cowl Panel58 ILL

31 GND

G303

B

Y

Y

E

f10

Trailer Connector

10A

C101

GW GW GW

GW GW GW

4

24

10

C304

C304

3

3

RH"2" Tail LampGY GY

GY GY

C301

11

1

RH

"5"

GY

LH"5" Tail Lamp

(Stop Lamp)

Stop Lamp

Switch

"2"(M/T,MB A/T) "4"(BTRA A/T)

Ef11 10A

C101

BrR GW GW

GW

2

C301

10

5

LH"2"

"B1"

Multii Function Switch(Turn Signal Switch) Tail Lamp

(Turn Signal Lamp)

"3"

(RH)

W YW

W

6

9

C301

"B2" "3"

(LH)