belt SSANGYONG NEW ACTYON SPORTS 2012 Owner's Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2012, Model line: NEW ACTYON SPORTS, Model: SSANGYONG NEW ACTYON SPORTS 2012Pages: 828, PDF Size: 91.28 MB

Page 511 of 828

04-20

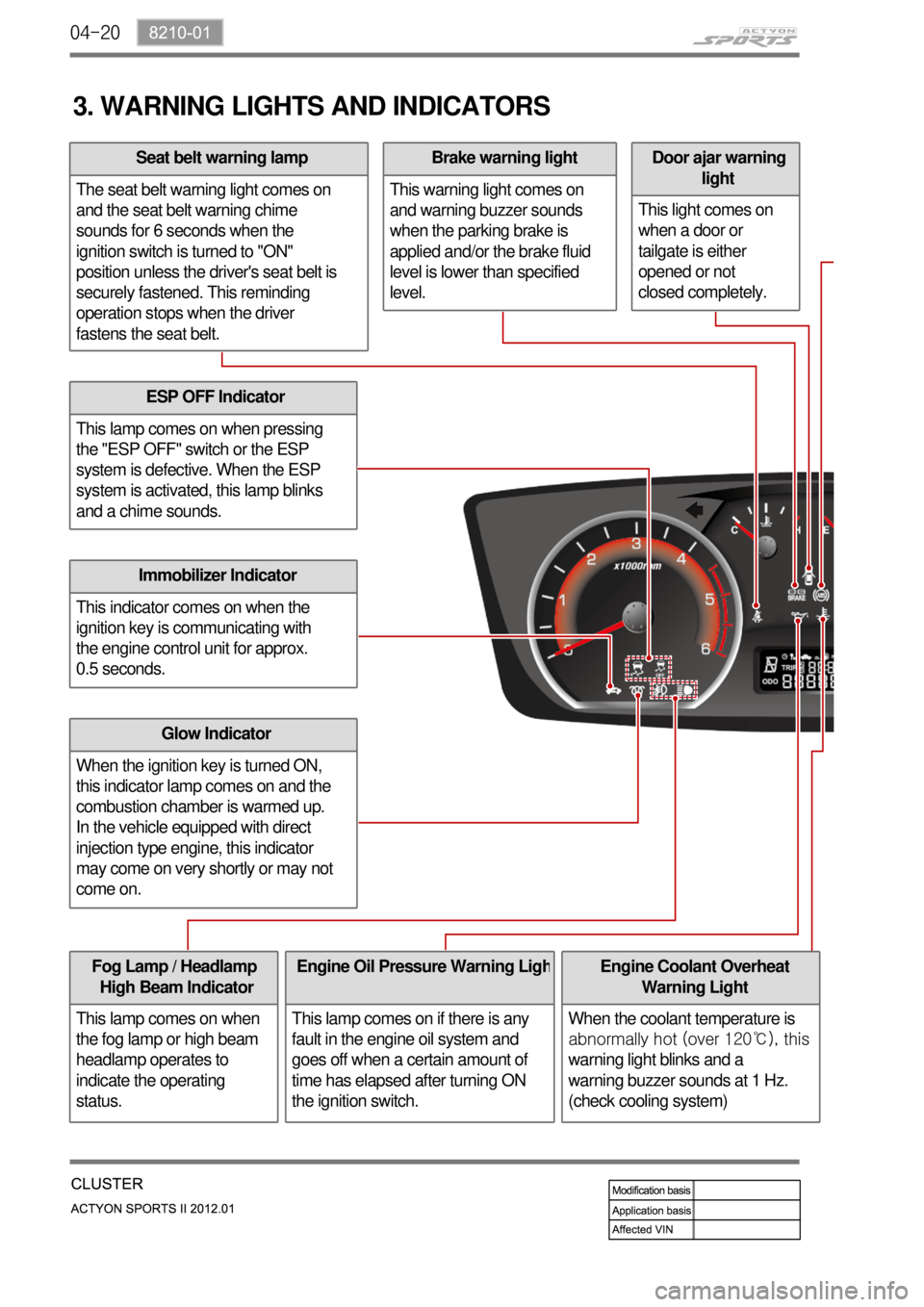

3. WARNING LIGHTS AND INDICATORS

ESP OFF Indicator

This lamp comes on when pressing

the "ESP OFF" switch or the ESP

system is defective. When the ESP

system is activated, this lamp blinks

and a chime sounds.

Immobilizer Indicator

This indicator comes on when the

ignition key is communicating with

the engine control unit for approx.

0.5 seconds.

Glow Indicator

When the ignition key is turned ON,

this indicator lamp comes on and the

combustion chamber is warmed up.

In the vehicle equipped with direct

injection type engine, this indicator

may come on very shortly or may not

come on.

Fog Lamp / Headlamp

High Beam Indicator

This lamp comes on when

the fog lamp or high beam

headlamp operates to

indicate the operating

status.Engine Oil Pressure Warning Ligh

This lamp comes on if there is any

fault in the engine oil system and

goes off when a certain amount of

time has elapsed after turning ON

the ignition switch.

Door ajar warning

light

This light comes on

when a door or

tailgate is either

opened or not

closed completely.Brake warning light

This warning light comes on

and warning buzzer sounds

when the parking brake is

applied and/or the brake fluid

level is lower than specified

level.Seat belt warning lamp

The seat belt warning light comes on

and the seat belt warning chime

sounds for 6 seconds when the

ignition switch is turned to "ON"

position unless the driver's seat belt is

securely fastened. This reminding

operation stops when the driver

fastens the seat belt.

Engine Coolant Overheat

Warning Light

When the coolant temperature is

abnormally hot (over 120℃), this

warning light blinks and a

warning buzzer sounds at 1 Hz.

(check cooling system)

Page 733 of 828

12-74610-01

3. TROUBLESHOOTING

Problem Possible Cause Action

Movements of steering

feels heavyUnregular wear or binding of steering ball joint

due to lack of lubrication or foreign material

insertionLubricate or replace

Damaged or defective steering gear Replace the steering

gear assembly

Incorrect steering pinion preload Adjust

Defective steering shaft joint Replace

leakage of steering fluid Repair or replace

Insuffcient steering fluid or air insertion Fill up fluid or bleed air

Defective steering oil pump Replace

Damaged or loosened pump drive belt Adjust or replace

Clogging of fluid line Repair or replace

Damaged wheel or tire Repair or replace

Defective suspension Repair or replace

Steering wheel pulls to

one sideDamaged steering linkage Replace

Damaged wheel or tire Repair or replace

Defective suspension Repair or replace

Defective brake system Repair or replace

Excessive free play of

steering wheelWorn steering gear Replace the steering

gear assembly

Worn or damaged steering ball joint Replace

Looseness of steering gear box Retighten

Poor returning of

steering wheelBroken or binding of steering ball joint Replace

Improper correct steering pinion preload Replace the steering

gear assembly

Damaged wheel or tire Repair or replace

Defective suspension Repair or replace

Page 734 of 828

12-8

Problem Possible Cause Action

Excessive vibration of

steering wheel

(shimming)Broken steering linkage Replace

Looseness of steering gear box Retighten

Broken or binding of steering ball joint Replace

Worn or damaged front wheel bearing Replace

Damaged wheel or tire Repair or replace

Defective suspension Repair or replace

Abnormal noise from

steering systemLooseness of steering gear box Retighten

Defective steering gear Replace the gear

assembly

Interference between steering column and

partsRepair

Looseness of steering linkage Retighten

Loosened or damaged oil pump drive belt Adjust or replace

Looseness of oil pump bracket Replace

Looseness of oil pump Replace

Air insertion into system Bleed air

Defective oil pump Replace

Abnormal noise when

turning steering wheelLooseness of steering column Retighten

Worn or damaged steering shaft bearing Replace the steering

column

Looseness of intermediate shaft Retighten

Too heavy steering wheel Worn or damaged steering shaft bearing Replace the steering

column

Page 739 of 828

12-134610-01

Oil Pump Pressure Check ▶

Unscrew the pressure line fitting in power

steering pump.

Install the pressure gauge between the

power steering pump and the power

steering oil pressure line.

Place the shift lever to neutral position.

Apply the parking brake.

Open the valve in pressure gauge. Start

the engine and let it run at idle speed.

Turn the steering wheel several times so

that the oil temperature reaches to normal

operating level. 1.

2.

3.

4.

5.

Before checking the pressure, check the oil

level and belt tension. Prepare the empty

container to collect the spilled oil during the

service. Check the oil pump pressure to locate any

defect in oil pump.

Fully close the valve in pressure gauge and

measure the oil pressure. 6.

Relief pressure

90 ± 3 bar

Oil pump

Steering gear box

To prevent internal damage, do not close

the gauge valve over 10 seconds.

Keep the oil temperature at proper range. -

-

Page 742 of 828

12-16

2. SYSTEM LAYOUT

The steering pump is driven by the engine power through a belt. This pump circulates the power

steering oil from the reservoir -> steering pump -> oil supply pipe -> steering gear box -> oil

return pipe -> reservoir to perform steering operations

Steering pump Steering return pipe Steering cylinder

Return line

High pressure line

Return hose & tube

Steering pump &

reservoir

High pressure hose

Linkage gear box Steering wheel

Lower shaft Column & shaft

Page 752 of 828

13-114170-09

1. OVERVIEW

A radial tire uses a cord angle of 90 degrees. That is, the cord material runs in a radial or direct

line from one bead to the other across the tread. In addition, a radial tire has a belt overwrap

under the tread surface to provide greater structural stability. The belt overwrap of a radial tire

distortion while the radial structure enables high speed driving.

Tire supports the weight of the vehicle, reduces the impact from the road and at the same time,

transmits the power to propel, brake and steer on the road. It also functions to maintain a

<009d008c008f0090008a0093008c02c5009a004700940096009d008c0094008c0095009b0055004700700095004700960099008b008c00990047009b00960047008a0096009400970093008c009b008c0047009a009c008a008f0047009b0088009a009200

9a0053004700880047009b00900099008c00470094009c009a>t be structured to be a resilient

vessel of air.

There is wear limit mark on the tire, which protrudes as a strip shape located approximately 1.6

mm from the groove bottom. This wear limit mark is not seen from the outside so there is

additional "▲" mark on the shoulder to let the driver find the wear mark easily. To measure the tire

groove depth, measure at any point other than the point which has a wear limit mark.

The tire is worn unevenly according to the driver's driving habit, improper servicing, low tire

inflation pressure, changed tire location, etc.

Page 754 of 828

13-134170-09

Structure of Tire ▶

Tread

This thick layer of rubber provides the interface between the tire and the road. Wear-resistant

rubber is used to protect the carcass and belt against fractures and impacts and to deliver a long

driving life.

Shoulder

Located between the tread and sidewall, the shoulder rubber is the thickest so that the design

must allow for the easy diffusion of heat generated within the tire while driving.

Sidewall

The part between the shoulder and bead, the flexible sidewall protects the carcass and enhances

the ride. A tire’s ty

pe, size, structure, pattern, manufacturing company, product name and various

characters are indicated here.

Bead

The bead attaches the tire to the rim and wraps the end of the cord fabric. Comprised of the

bead wire, core, flipper and other parts, the bead is generally designed to be slightly tight around

the rim so that in the case of a sudden drop in inflation pressure, the tire will not fall off the rim.

Carcass

As the most important framework of a tire, the entire inner layer of cord fabric is called the

carcass. The carcass acts to support air pressure, vertical load and absorb shocks.

Page 785 of 828

02-38810-01

1. CAUTIONS FOR AIR BAG OPERATION

When there is any deployed air bag (including seat belt pretensioner), the air bag unit should

be replaced. Any DTC (Diagnostic Trouble Code) in the air bag unit should not be cleared

since the unit has data for status when the air bag was deployed as well as information

related to the air bag deployment.

Note that the used components related to the air bag, especially the air bag unit, should be

packaged in an air tight container to prevent any damage.

Do not connect a tester to any connector or component to check supply voltage or

resistance of air bag related components. The detonator may explode due to a sudden extra

power supplied by the tester.

Before removing or installing any air bag related components, disconnect the negative battery

cable. 1.

2.

3.

4.

Collision sensors, a kind of impact G (acceleration) sensor, detect the lateral and longitudinal

collisions and determine whether or not to deploy air bags. The roles of each collision sensor are

as follows:

Front G sensors (inside the air bag unit)

Send signals to the front air bags (driver and passenger air bags) and the driver's and front

passenger's seat belt pretensioners. When the front collision G sensor sends out only the air

bag deployment signal, the signal deploys the two front air bags and activates their seat belt

pretensioners.

Once an air bag deploys, its repair parts vary according to the deployment situation and damage

to the vehicle from collision. Needed repairs also slightly vary between the front air bags and the

curtain air bags. The following are the differences:

Replacement parts when the front air bags deploy:

Air bag unit and its wiring (including connector), seat belt pretensioner and its wiring

(including connector), whole front air bags, instrument panel (IP)

Page 786 of 828

02-4

2. OPERATING RANGE

In the event of the collision, the air bag will be deployed when the G value detected by the G

sensor in the SDM is beyond the impact limit. ▶

Seat Belt Status Air Bag OperationSeat Belt Pretensioner Operation

Fastened Over reference speed Below reference speed

Unfastened Below reference speed Inoperative

Failure, during initial

diagnosisBelow reference speed Below reference speed

No sensor Below reference speed Below reference speed

This is based on frontal collision and reference speed is between approx. 4 and 24 km/h. *

The air bag is deployed in the event of frontal collisions while drving.

But, there are exceptional cases as follows: ▶

Situation Condition

May operate or not

Never operate

Seldom oeprate

Underbody impact from the road surface, impact against the

curb at a very high speed, or dropping impact onto the road

surface with a large angle occurs.

The vehicle rolls over or tips over sideward by severe impact. -

-

A collision with oblique impact to the front seat direction or a front

collision to the diagonal direction occurs.

A front/rear collision occurs.

The vehicle rolls over or tips over sideward with minor impact.

The air bag warning lamp is on. -

-

-

-The vehicle is stationary or a front collision occurs with low speed.

A rear collision occurs.

A minor collision occurs. -

-

-

Page 787 of 828

02-58810-01

3. GENERAL WARNINGS

Do not diagnose the circuit with a circuit tester or attempt to modify any air bag components

including the steering wheel, air bag mounting area and harness.

Incorrect inspection could cause a problem with an air bag and seat belt pretensioner, and

they cannot protect occupants properly. Inspection and repair service should be done only by

a qualified technician.

An infant or a child should not be seated on the front seat alone or on an adult's lap. An infant

or a child could be severely injured by air bag deployed.

A child restraint system should be placed on the rear seat which has the 3-point type seat belt.

Never install a child restraint system on the front seat. Impact by the air bag inflation might

cause severe injury or even death.

When an occupant fastens the seat belt with unstable or inclined posture, the air bag cannot

protect the occupant properly. Moreover, the occupant may be injured by the air bag.

Do not incline toward the steering wheel while driving. If you hit the air bag before it is fully

inflated, brain or neck injury, or even death can occur.

Be careful not to strike the steering wheel, air bag mounting area, any air bag related

component (including wiring) and seat belt pretensioner. You might get severely injured by

sudden deployment of the air bag.

The air bag contains explosive materials, so handle it carefully when disposing or replacing it.

The air bag components will be very hot immediately after deployment. Do not touch them until

they cool down.

Once the air bag/seat belt pretentioner is triggered, it will not deploy again even if an additional

impact is applied to it. Once triggered air bag/seat belt pretensioner related components

cannot be reused, so they should be removed from the vehicle and the whole system should

be replaced with a new one.

Do not place any object or sticker on the air bag mounting area for correct and safe activation

of the air bag.

Do not bang the door. Otherwise, an air bag might operate erroneously.

Hold the outer rim of the steering so that the air bag can inflate without any hindrance.

Do not incline toward the steering wheel or hold the steering wheel with your hands crossed. It

will cause a problem with the air bag activation or severe injury when the air bag inflates.

Never put your hands or feet on the dash board. You can severely injured when the air bag

inflates.

It is normal that a loud noise, dust and smoke occur when the air bag and seat belt

pretensioner operate.

The gas come out of air bag/seat belt pretensioner activation is non-toxic nitrogen gas.

However, if this gas occurs irritation to your skin, eyes, nose, and so on, wash it out with clean

water. Seek medical help if symptoms develop. -

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-