fuel pressure SSANGYONG NEW ACTYON SPORTS 2012 Owner's Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2012, Model line: NEW ACTYON SPORTS, Model: SSANGYONG NEW ACTYON SPORTS 2012Pages: 828, PDF Size: 91.28 MB

Page 206 of 828

03-232210-01

Accelerator pedal position

sensor

Detecting driver's intention

for speed up/down

Fuel rail assembly

Relieving the pulsation.

Measuring the fuel pressure.

Distributing the fuel to injectors.

Fuel filter assembly

Supplying clean fuel/fuel

heating/water separation by

priming pump

Plunger type HP pump (1,800 bar)

Vane type LP pump (6 bar)

T-MAP sensor

Measuring booster pressure

and temperature

High pressure pump

Generating high pressurized fuel

and supplying it according to

engine rpm, required volume,

required pressure

Page 207 of 828

03-24

2) Fuel System Flow Diagram

The fuel from the fuel tank is supplied to the fuel heater of fuel filter/priming pump and then low

pressure generated by the low pressure pump (built into HP pump) is transmitted to the HP pump.

The fuel pressure at the HP pump is controlled by the IMV valve, and the maximum allowed

pressure is 1,800 bar. The compressed fuel at the fuel pump is delivered to the rail, and injected by

the injectors according to the injection signals. The injection method is the same with the

conventional method; Fuel return by backleak which operates the needle valve.

The major difference is that the fuel return line is connected to the fuel filter inlet port, not the HP

pump venturi.

The pressure from the high pressure pump is increased to 1,800 bar from 1,600 bar, and the pump

is now installed to the cylinder head (cylinder block for previous model). The fuel pressure is

generated by the operation of intake camshaft and gears. The specifications for the IMV valve and

the fuel temperature sensor are not changed.

Page 209 of 828

03-26

The engine ECU calculates the accelerator pedal based on the input signals from various sensors,

and controls the overall operation of the vehicle.

The ECU receives the signals from various sensor through data line, and performs effective air-fuel

ratio control based on these signals.

The crankshaft speed (position) sensor measures the engine speed, and the camshaft speed

(position) sensor determines the order of injections, and the ECU detects the amount of the

accelerator pedal depressed (driver's will) by receiving the electrical signals from the accelerator

pedal sensor.

The mass air flow sensor detects the volume of intake air and sends the value to the ECU.

The major function of the ECU is controlling air-fuel ratio to reduce the emission level (EGR valve

control) by detecting instantaneous air flow change with the signals from the mass air flow sensor.

Also, the ECU uses the signals from the coolant temperature & air temperature sensors, booster

pressure sensor, atmospheric pressure sensor to: a) determine injection starting point and set

value for pilot injection, and b) deal with various operations and variable conditions.

Page 212 of 828

04-51719-00

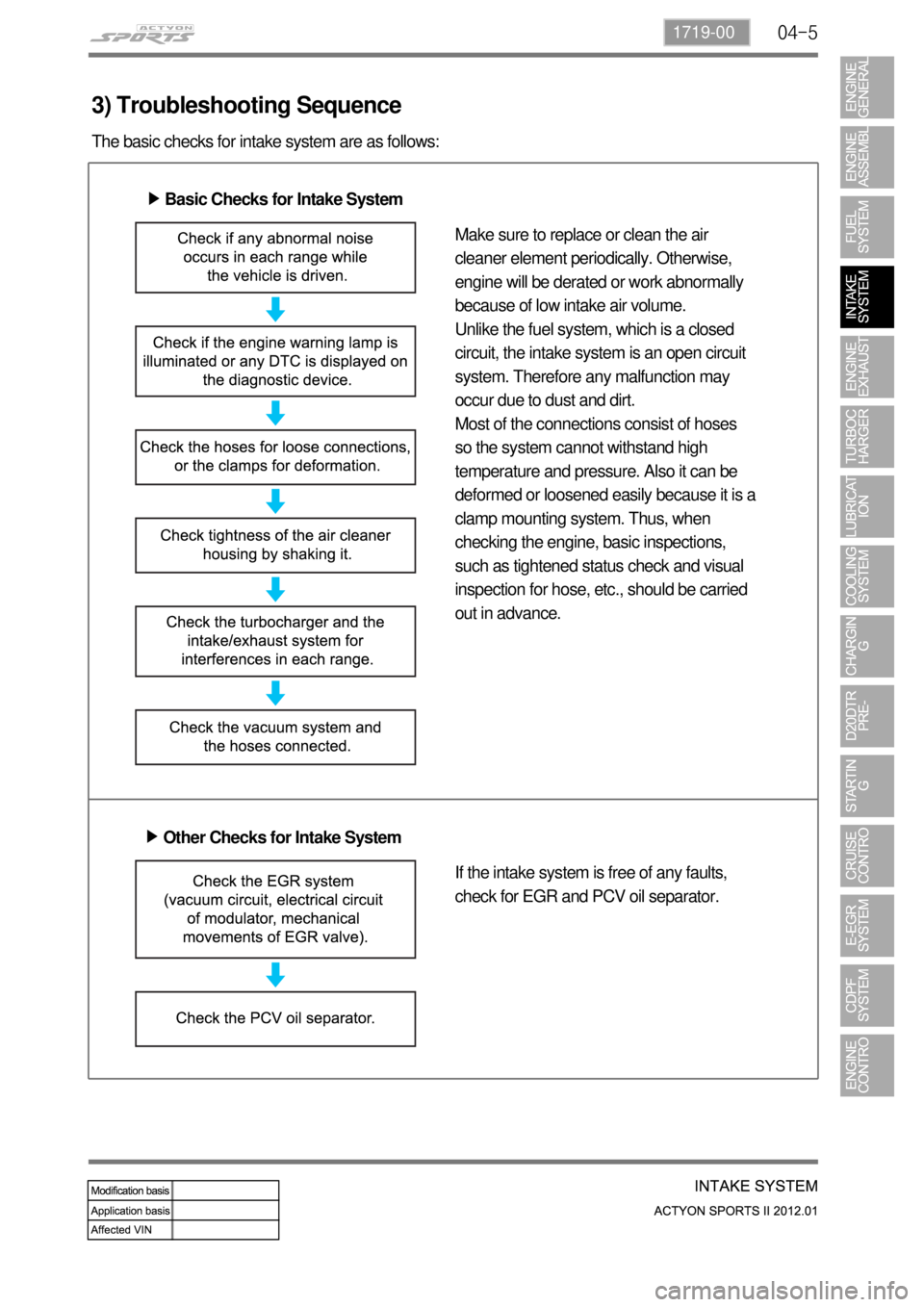

3) Troubleshooting Sequence

The basic checks for intake system are as follows:

Basic Checks for Intake System ▶

Make sure to replace or clean the air

cleaner element periodically. Otherwise,

engine will be derated or work abnormally

because of low intake air volume.

Unlike the fuel system, which is a closed

circuit, the intake system is an open circuit

system. Therefore any malfunction may

occur due to dust and dirt.

Most of the connections consist of hoses

so the system cannot withstand high

temperature and pressure. Also it can be

deformed or loosened easily because it is a

clamp mounting system. Thus, when

checking the engine, basic inspections,

such as tightened status check and visual

inspection for hose, etc., should be carried

out in advance.

Other Checks for Intake System ▶

If the intake system is free of any faults,

check for EGR and PCV oil separator.

Page 218 of 828

04-111719-00

LoadEngine speed Swirl valveAmount of

swirlRemarks

Low speed,

Low loadbelow 3,000

rpmClosed HeavyIncreased EGR ratio, better air-fuel

mixture (reduce exhaust gas)

High speed,

High loadover 3,000 rpm Open LightIncrease charge efficiency, higher

engine power

The variable swirl valve actuator operates

when turning the ignition switch ON/OFF

position to open/close the swirl valve. In this

period, the soot will be removed and the

learning for swirl valve position is performed.

Swirl: This is the twisted (radial) air flow along the cylinder wall during the intake stroke. This

stabilizes the combustion even in lean air-fuel mixture condition.

Swirl valve

3) Features

Swirl and air intake efficiency

To generate the swirl, the intake port should be serpentine design. This makes the resistance

in air flow. The resistance in air flow in engine high speed decreases the intake efficiency.

Eventually, the engine power is also decreased, Thus, the swirl operation is deactivated in high

speed range to increase the intake efficiency.

Relationship between swirl and EGR

To reduce Nox, it is essential to increase EGR ratio. However, if EGR ratio is too high, the PM

also could be very higher. And, the exhaust gas should be evenly mixed with newly aspired air.

Otherwise, PM and CO are dramatically increased in highly concentrated exhaust gas range

and EGR ratio could not be increased beyond a certain limit. If the swirl valve operates in this

moment, the limit of EGR ratio will be higher. -

-

4) Relationship between swirl and fuel injection pressure

The injector for DI engine uses the multi hole design. For this vehicle, there are 8 holes in injector.

If the swirl is too strong, the injection angles might be overlapped and may cause the increased

PM and insufficient engine power. Also, if the injection pressure is too high during strong swirl, the

injection angles might be overlapped. Therefore, the system may decreases the fuel injection

pressure when the swirl is too strong.

Page 296 of 828

14-8

Differential pressure

sensor

Calculates the amount of

PM collected by reading

the pressure difference

between before and after

the CDPF.Engine ECU

DCM 3.7

Post-injectionThrottle

valve

Regulates the rate of air

intake.

CDPF

DOC+DPFFront temperature sensor

Protects the

turbocharger.

Rear temperature sensor

Measures the

temperature of fuel

combustion.

2. COMPONENT

For details, refer to section "Engine Control". *

Page 297 of 828

14-92412-02

3. INPUT/OUTPUT DEVICES

Front temperature sensor: This sensor is installed at the inlet of DOC and detects whether

the DOC can burn (oxidize) the post-injected fuel or not.

Rear temperature sensor: This sensor is installed at the inlet of DPF and monitors that the

temperature of the exhaust gas is kept at 600℃. 1.

2.

<0070008d0047009b008f008c0047009b008c00940097008c00990088009b009c0099008c0047008c009f008a008c008c008b009a0047005d005700570b4500530047009b008f008c004700930090008d008c00470096008d0047006a006b0077006d004700

8a0088009500470089008c00470099008c008b009c008a008c>d. So the amount of fuel

post-injection is decreased.

<0070008d0047009b008f008c0047009b008c00940097008c00990088009b009c0099008c0047008b009900960097009a0047009c0095008b008c00990047005d005700570b4500530047009b008f008c004700990088009b008c00470096008d0047009900

8c008e008c0095008c00990088009b0090009600950047008a>an be decreased. So the

amount of fuel post-injection is increased. -

-

Differential pressure sensor: This sensor checks the amount of PM collected by calculating the

pressure difference between before and after the CDPF.

Electric throttle valve: This valve reduces the intake air flow to raise the temperature of the

exhaust gas when the CDPF is operating during idling. 3.

4.

Page 298 of 828

14-10

4. POST-INJECTION AND AIR MASS CONTROL

A DPS (Differential Pressure Sensor) measures the pressure difference between before and after

the CDPF and detects whether the soot is collected in the CDPF or not. If PM is collected in the

CDPF (In this case the pressure difference between before and after the CDPF exceeds the

specified value. Normally, the system sends the signal when the driving distance becomes

approx. 600 to 1,200 km), the temperature of exhaust gas is increased and the post-injection is

started for regeneration. The amount of fuel post-injection is controlled by the exhaust gas

<009b008c00940097008c00990088009b009c0099008c00470094008c0088009a009c0099008c008b0047008900a00047009b008f008c00470099008c008800990047009b008c00940097008c00990088009b009c0099008c0047009a008c0095009a009600

99005500470070008d0047009b008f008c0047009b008c0094>perature is less than 600℃, the

amount of post-injection is increased to increase the regeneration temperature. Otherwise, the

fuel injection amount is decreased or the fuel is not injected.

When the engine is running with low load, the intake air amount is also controlled as well as fuel

injection amount. This function is used to increaser the combustion temperature by increasing the

amount of fuel post-injection with the lowest air amount within the specified control logic.

Page 299 of 828

14-112412-02

Front temperature sensor

Measures the temperature of

exhaust gas.

This sensor is located at the rear

side of exhaust manifold and

monitors the temperature of

combusted gas to prevent the

exhaust system from overheating.

When the temperature gets

higher, this sensor cuts off the

fuel delivery and controls the EGR

to lower the temperature.Rear temperature sensor

Measure the outlet

temperature of DOC.

This sensor is located at

the rear side of DOC and

monitors the overheating of

CDPF and post injection

volume.

Engine ECU (D20DTR)

Differential pressure sensor

Measures the difference between

inlet and outlet pressures of

CDPF.

If the difference is higher than the

specified value when collecting

the PM, this makes the post

injection for forced recycling of

PM.

T-MAP sensorIntake air

mass

Measures

the

excessive

amount of

PM.

Boost

pressure/

temperature

Injector (C31)

Controls the post injection.

Electric throttle body

Controls the intake air

mass.

HFM sensor

Wide band

oxygen sensor

Page 308 of 828

15-50000-00

Fuel rail pressure

sensorEGR valveFuel temperature

sensor

Electric throttle bodyKnock sensor

(2 ea)

Coolant temperature

sensor

T-MAP sensorD20DTR ECU

E-VGT actuator

Water sensorGCU (Preglow control

unit)

E-EGR bypass valve