service SSANGYONG NEW ACTYON SPORTS 2012 Owner's Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2012, Model line: NEW ACTYON SPORTS, Model: SSANGYONG NEW ACTYON SPORTS 2012Pages: 828, PDF Size: 91.28 MB

Page 361 of 828

01-111113-01

2) Compression Pressure Test

Standard Service Data ▶

A9912 0012B (001 589 76 21 00) Compression Pressure Tester -

Measuring Procedure ▶

Warm the engine up to normal operating temperature.

Remove the spark plugs using the spark plug wrench.

Place the diagram sheet to compression pressure tester A9912 0012B (001 589 76 21 00).

Connect the adaptor to compression pressure tester A9912 0012B (001 589 76 21 00)

and install it into the spark plug hole.

Crank the engine approx. eight revolutions by using the start motor.

Compare the measurements of compression pressure tester A9912 0012B (001 589 76 21

00) with the specifications.

Measure the compression pressure of the other cylinders in the same way.

If measured value is not within the specifications, perform the cylinder pressure leakage

test. -

-

-

-

-

-

-

-

Discharge the combustion residues in the cylinders before testing the compression

pressure.

Apply the parking brake before cranking the engine. -

-

Page 383 of 828

04-72112-01

4) Water Pump

The belt-driven centrifugal water pump consists of an impeller, a drive shaft, and a belt pulley.

The impeller is supported by a completely sealed bearing.

The water pump is serviced as an assembly and, therefore, cannot be disassembled.

5) Thermostat

A wax pellet-type thermostat controls the flow of the engine coolant through the engine cooling

system. The thermostat is mounted in the thermostat housing to the front of the cylinder head.

The thermostat stops the flow of the engine coolant from the engine to the radiator to provide

faster warm-up, and to regulate the coolant temperature. The thermostat remains closed while the

engine coolant is cold, preventing circulation of the engine coolant through the radiator. At this

point, the engine coolant is allowed to circulate only throughout the heater core to warm it quickly

and evenly.

As the engine warms, the thermostat opens. This allows the engine coolant to flow through the

radiator wherethe heat is dissipated. This opening and closing of the thermostat permits enough

engine coolant to enter the radiator to keep the engine within proper engine temperature operating

limits.

The wax pellet in the thermostat is hermetically sealed in a metal case. The wax element of the

thermostat expands when it is heated and contracts when it is cooled.

As the vehicle is driven and the engine warms, the engine coolant temperature increases. When

the engine coolant reaches a specified temperature, the wax pellet element in the thermostat

expands and exerts pressure against the metal case, forcing the valve open. This allows the

engine coolant to flow through the engine cooling system and cool the engine.

As the wax pellet cools, the contraction allows a spring to close the valve.

The thermostat begins to open at 82°C(180 °F) and is fully open at 95°C(203°F). The thermostat

closes at 80°C (176°F).

6) Electric Cooling Fan

Keep hands, tools, and clothing away from the engine cooling fans to help prevent personal

injury.

This fan is electric and can turn on even when the engine is not running. -

If a fan blade is bent or damaged in any way, no attempt should be made to repair or reuse

the damaged part. A bent or damaged fan assembly should always be replaced with a new

one to prevent possible injury. -

Page 393 of 828

05-6

(2) Cold Cranking Amperage

The cold cranking amperage test is expressed at a battery temperature of -18°C(0°F).

The current rating is the minimum amperage, which must be maintained by the battery for 30

seconds at the specified temperature, while meeting a minimum voltage requirement of 7.2 volts.

This rating is a measure of cold cranking capacity.

The battery is not designed to last indefinitely. However, with proper care, the battery will provide

many years of service. If the battery tests well, but fails to perform satisfactorily in service for no

apparent reason, the following factors may point to the cause of the trouble:

Vehicle accessories are left on overnight.

Slow average driving speeds are used for short periods.

The vehicle's electrical load is more than the generator output, particularly with the addition of

aftermarket equipment.

Defects in the charging system, such as electrical shorts, a slipping generator belt, a faulty

generator, or a faulty voltage regulator.

Battery abuse, including failure to keep the battery cable terminals clean and tight or a loose

battery hold-down clamp.

Mechanical problems in the electrical system, such as shorted or pinched wires. ·

·

·

·

·

·

3) Charging Time Required

The time required to charge a battery will vary depending upon the following factors:

Size of Battery - A Completely discharged large heavy-duty battery required more than twice

the recharging time as a completely discharged small passenger car battery. ▶

<007b008c00940097008c00990088009b009c0099008c00470054004700680047009300960095008e008c00990047009b00900094008c0047009e00900093009300470089008c00470095008c008c008b008c008b0047009b00960047008a008f0088009900

8e008c00470088009500a0004700890088009b009b008c0099>y at -18°C(0°F) than at

27°C(80°F).

When a fast charger is connected to a cold battery, the current accepted by the battery will be

very low at first.

The battery will accept a higher current rate as the battery warms. ▶

Charger Capacity - A charger which can supply only 5 amperes will require a much longer

charging period than a charger that can supply 30 amperes or more. ▶

State-of-Charge - A completely discharged battery requires more than twice as much charge

as a onehalf charged battery.

Because the electrolyte is nearly pure water and a poor conductor in a completely discharged

battery, the current accepted by the battery is very low at first. Later, as the charging current

causes the electrolyte acid content to increase, the charging current will likewise increase. ▶

Page 397 of 828

05-10

9) Starting System

The engine electrical system includes the battery, the ignition, the starter, the generator, and all

the related wiring.

Diagnostic tables will aid in troubleshooting system faults. When a fault is traced to a particular

component, refer to that component section of the service manual.

The starting system circuit consists of the battery, the starter motor, the ignition switch, and all the

related electrical wiring.

All of these components are connected electrically.

Page 504 of 828

04-138210-01

3) Fuel Level Gauge

The fuel level gauge displays the resistance value of the float on the fuel sender in the fuel tank

through a pointer. Note that this vehicle doesn't have a service hole for checking the fuel sender

connector in the fuel tank.

The fuel sender and its connector can be checked and replaced only when the fuel tank is

removed. The power supply and resistance value should be measured at the connector in front of

the fuel sender (refer to wiring diagram).

When the power supply and output resistance are normal, the float operation by fuel level may be

defective; if so, replace the fuel sender.

Low fuel warning lamp comes on when:

The fuel level drops to 9 L or less. The lamp goes off if the fuel level reaches 9.5 L or more.This table shows the tolerance and resistance value changes by fuel level in normal

conditions. Therefore, the differences that can be occurred by the road conditions and fuel

fluctuations are ignored.

Page 516 of 828

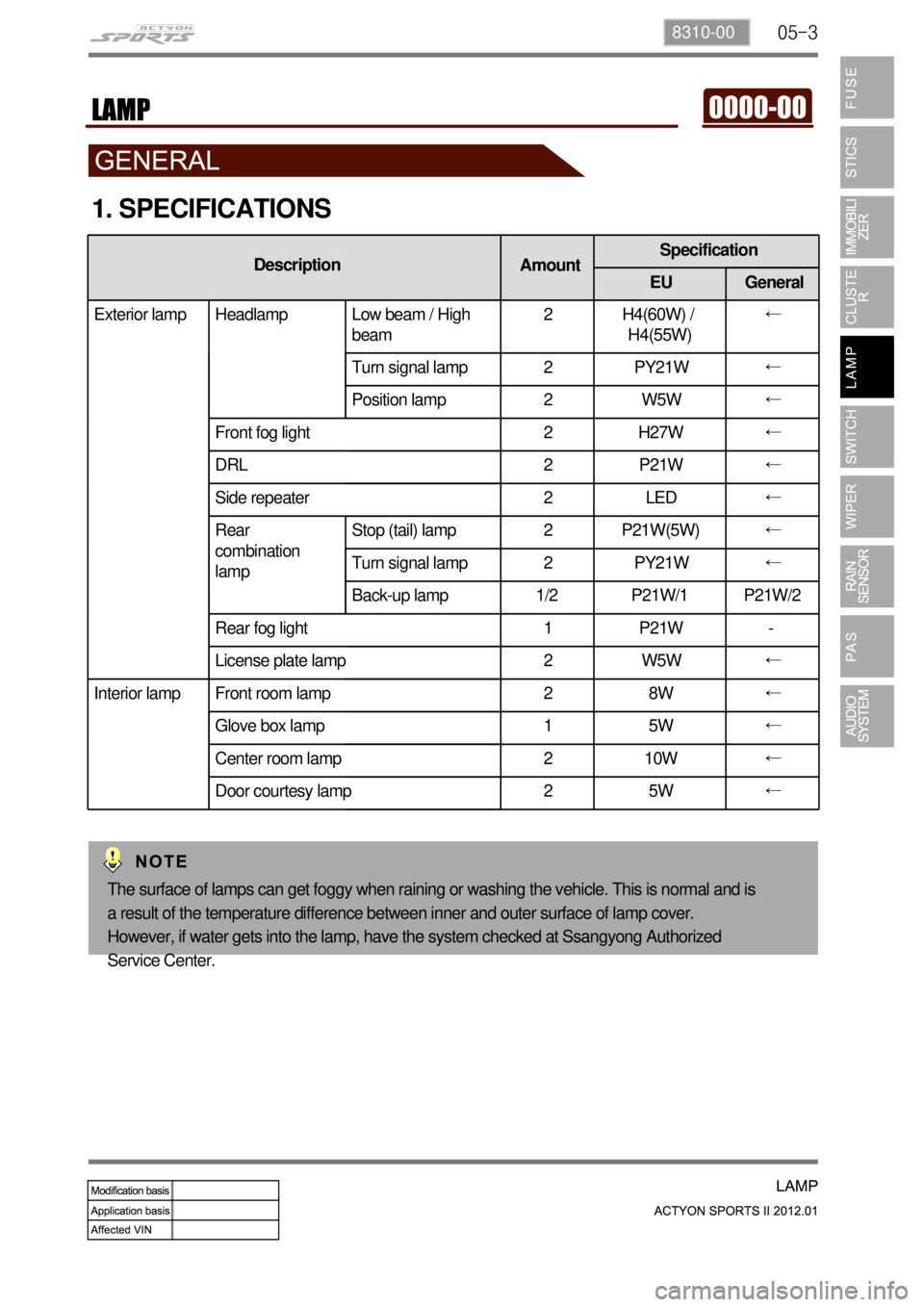

05-38310-00

1. SPECIFICATIONS

AmountSpecification

EU General

Exterior lamp Headlamp Low beam / High

beam2 H4(60W) /

H4(55W)←

Turn signal lamp 2 PY21W←

Position lamp 2 W5W←

Front fog light 2 H27W←

DRL 2 P21W←

Side repeater 2 LED←

Rear

combination

lampStop (tail) lamp 2 P21W(5W)←

Turn signal lamp 2 PY21W←

Back-up lamp 1/2 P21W/1 P21W/2

Rear fog light 1 P21W -

License plate lamp 2 W5W←

Interior lamp Front room lamp 2 8W←

Glove box lamp 1 5W←

Center room lamp 2 10W←

Door courtesy lamp 2 5W←Description

The surface of lamps can get foggy when raining or washing the vehicle. This is normal and is

a result of the temperature difference between inner and outer surface of lamp cover.

However, if water gets into the lamp, have the system checked at Ssangyong Authorized

Service Center.

Page 549 of 828

01-53680-01

2. FEATURES AND SPECIFICATIONS

1) Specifications

Description DSI M78 (6-speed) Remarks

Gear ratio1st 3.53:1

2nd 2.14:1

3rd 1.48:1

4th 1.16:1

5th 0.87:1

6th 0.68:1

Reverse 3.09:1

Transmission flui

dFluid Fuchs FES 209-3292 ATF

Capacity Approx. 9.5 L

Change interval Check the fluid at every

30,000 km or 1 year, and

change it if necessary.Under the severe driving

conditions, change the fluid

at every 60,000 km.

Resistance of oil

temperature

sensor-20 430.7 ~ 533.9 kΩ

0 146.8 ~ 175.7 kΩ

20 56.74 ~ 65.86 kΩ

100 3.201 ~ 3.399 kΩ

Gear position

sensor1 -

2 -

3 -

D 2.686 kΩ ± 8%

N 5.036 kΩ ± 8%

R 8.953 kΩ ± 8%

P 16.786 kΩ ± 8%

Severe driving conditions? *

Towing a trailer or off-road driving (Inspect the

leak of fl uid at any time, occasionlly)

Taxi, patrol service or delivery service

(extended idling and excessive driving with low

speed)

Frequent stop-and-go traffi c, extended idling,

short driving distance -

-

-Driving in a hilly or mountainous terrain,

sandy, or dusty area

Driving frequently at high speed over 170

km/hour

Driving frequently in area where heavy

traffi c under the ambient temperature

above 32°C -

-

-

Page 560 of 828

01-16

4. LIMP HOME MODE

In case of transmission malfunction ▶

If a serious fault occurs in the automatic transmission, the TCU enters the limp home

mode to secure safe driving and protect the automatic transmission.

As power is no longer supplied to the solenoid, the current basic function (P, R, N, D) is

maintained and the 4th gear can be maintained only by the operation of the hydraulic

system without electrical operation.

The ECU communicates with other electric modules with CAN. If a serious fault occurs, the

transmission automatically enters the limp home mode for service.

The TCU monitors all factors which can affect to the performance of the transmission and

diagnose the system according to OBD II regulation. 1.

2.

3.

4.

In case of overheated transmission ▶

The TCU enters the limp home mode when the batter voltage drops below 8 V.

If the transmission is overheated, the shift pattern is changed to the hot mode to cool the

transmission more efficiently.

While the transmission is overheated, the selector lever symbol and engine temperature

warning lamp on the instrument cluster blink until the transmission is cooled down to the

normal operation temperature. If the transmission is excessively overheated, the gear

cannot be shifted but remains in the neutral position. 1.

2.

3.

Towing the vehicle with A/T ▶

The best way to transport the vehicle is to load it to a truck and transport it, especially if the

vehicle is 4WD.

If towing the vehicle with the propeller shaft connected, the transmission or oil pump of

transfer case may malfunction, resulting in internal damage due to poor lubrication. -

Page 593 of 828

02-33170-01

Description Specification

Gear ratio 1st 4.489 : 1

2nd 2.337 : 1

3rd 1.350 : 1

4th 1.000 : 1

5th 0.784 : 1

6th 0.679 : 1

Reverse 4.253 : 1

Synchronizer

ring type1st T: Triple-cone

2nd T: Triple-cone

3rd T: Triple-cone

4th S: Single-cone

5th D: Double-cone

6th S: Single-cone

Reverse T: Triple-cone

Shifting Type Floor change type

Gear selector

lever position

Transmission

fluidType HD MTF 75W/85 (SHELL) or HK MTF 75W/85(SK)

Capacity

Sercive interval Inspect and replenish every 60000 km or 3 years (under

severe driving conditions, change every 120,000 km)

1. SPECIFICATION

Reversing:

High-force type

What’s the severe conditions?

Towing a trailer or off-road driving (Inspect

the leak of fluid at any time, occasionlly)

Taxi, patrol service or delivery service

(extended idling and excessive driving with

low speed)

Frequent stop-and-go traffic, extended

idling, short driving distance -

-

-Driving in a hilly or mountainous terrain,

sandy, or dusty area

Driving frequently at high speed over 170

km/hour

Driving frequently in area where heavy

traffic under the ambient temperature

above 30°C -

-

-

Page 594 of 828

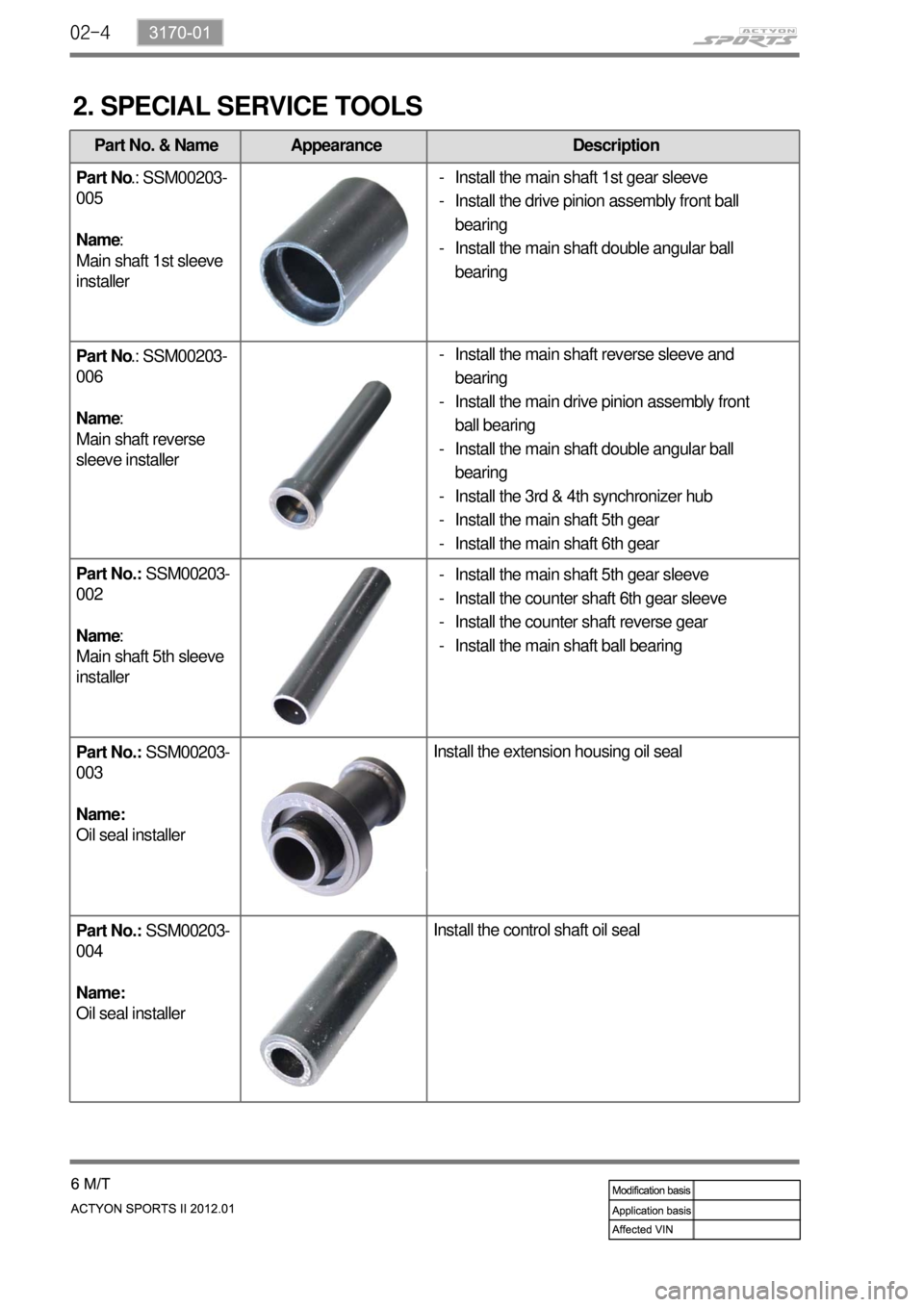

02-4

Part No. & Name Appearance Description

Part No.: SSM00203-

005

Name:

Main shaft 1st sleeve

installer

Part No.: SSM00203-

006

Name:

Main shaft reverse

sleeve installer

Part No.: SSM00203-

002

Name:

Main shaft 5th sleeve

installer

Part No.: SSM00203-

003

Name:

Oil seal installerInstall the extension housing oil seal

Part No.: SSM00203-

004

Name:

Oil seal installerInstall the control shaft oil seal

2. SPECIAL SERVICE TOOLS

Install the main shaft reverse sleeve and

bearing

Install the main drive pinion assembly front

ball bearing

Install the main shaft double angular ball

bearing

Install the 3rd & 4th synchronizer hub

Install the main shaft 5th gear

Install the main shaft 6th gear -

-

-

-

-

-Install the main shaft 1st gear sleeve

Install the drive pinion assembly front ball

bearing

Install the main shaft double angular ball

bearing -

-

-

Install the main shaft 5th gear sleeve

Install the counter shaft 6th gear sleeve

Install the counter shaft reverse gear

Install the main shaft ball bearing -

-

-

-